Temporary adhesive for solar energy crystal support and glass and preparation method thereof

A temporary bonding and solar energy technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of environmental pollution, high toxicity of gas, and serious energy consumption, etc., to achieve improved degumming Effects of performance, ease of debonding, and fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

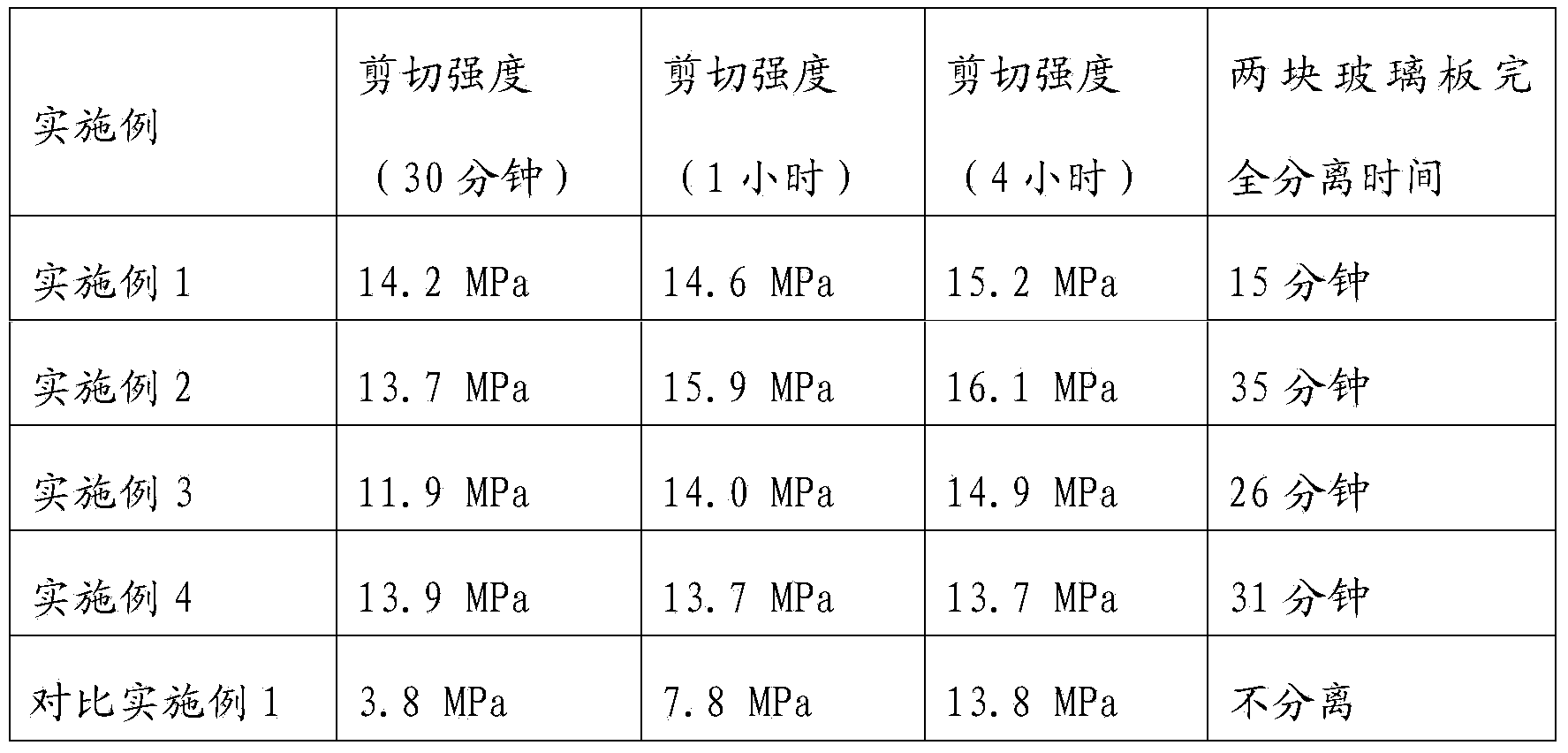

Examples

Embodiment 1

[0025] Accurately weigh component A in the following parts by weight: 52.5 parts of methyl methacrylate (MMA), 22.5 parts of hydroxyethyl methacrylate (HEMA), 4.0 parts of methacrylic acid (MAA), thermal expansion micrometers commercially available in Matsumoto 25.0 parts of ball F-36D, 8.0 parts of tetramethylthiourea, and 4.0 parts of gas-phase silicon A300. Put the above-mentioned raw materials into the double planetary power mixer in turn, vacuumize to -0.1MPa, and rotate at 800 rpm minute, under the condition that the revolution speed is 8 revs / min, mechanically stirred for 2 hours, and mixed uniformly to obtain the A component of the solar crystal tray-glass temporary bonding adhesive of the present invention, which is packaged and placed for use;

[0026] Accurately weigh the following component B by weight: 42.0 parts of methyl methacrylate (MMA), 18.0 parts of hydroxyethyl methacrylate (HEMA), 6.0 parts of methacrylic acid (MAA), ethylene dimethacrylate 15.0 parts of ...

Embodiment 2

[0028] Accurately weigh the following components of A by weight: 32.0 parts of methyl methacrylate (MMA), 10.0 parts of hydroxyethyl methacrylate (HEMA), 31.0 parts of ethylene glycol dimethacrylate. 10.0 parts of heat-expandable microspheres MP-12 sold, 8.0 parts of diisopropyl-p-toluidine, and 2.0 parts of fumed silicon A300 were added to the double-planetary power mixing mixer in turn, vacuumed to -0.09MPa, and Under the condition that the rotation speed is 500 rpm and the revolution speed is 7 rpm, mechanically stir for 2 hours and mix evenly to obtain component A of the solar crystal tray-glass temporary adhesive of the present invention, which is packaged and placed for use;

[0029] Accurately weigh the following component B by weight: 30.0 parts of methyl methacrylate (MMA), 15.0 parts of hydroxyethyl methacrylate (HEMA), 20.0 parts of isobornyl methacrylate, and 10.0 parts of azodicarbonamide , 6.0 parts of benzoyl peroxide, 0.01 parts of p-benzoquinone, 2.0 parts of ...

Embodiment 3

[0031] Accurately weigh the following component A by weight: 30.0 parts of methyl methacrylate (MMA), 15.0 parts of methacrylic acid (MAA), 10.0 parts of isobornyl methacrylate, thermally expandable microsphere MP 20.0 parts of -12, 6.0 parts of N,N-dimethylaniline, and 9.0 parts of fumed silicon A380, add the above-mentioned raw materials into the double planetary power mixer in turn, vacuumize to -0.08MPa, and rotate at 700 rpm / minute, under the condition that the revolution speed is 6 revs / min, mechanically stirred for 2 hours, mixed uniformly, obtained the A component of the solar crystal tray-glass temporary bonding adhesive of the present invention, packaged and placed for use;

[0032] Accurately weigh the following component B by weight: 45.0 parts of methyl methacrylate (MMA), 10.0 parts of ethylene glycol dimethacrylate, 25.0 parts of methacrylic acid (MAA), diisopropyl azodicarboxylate 15.0 parts of ester, 2.0 parts of cumene hydroperoxide, 0.3 part of 264 antioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com