Photoresist removing method

A photoresist and hard shell technology, which is applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as polymer impurity defects, photoresist bubbling rupture, etc., to improve deglue ability, The effect of speeding up the degumming rate and improving product yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

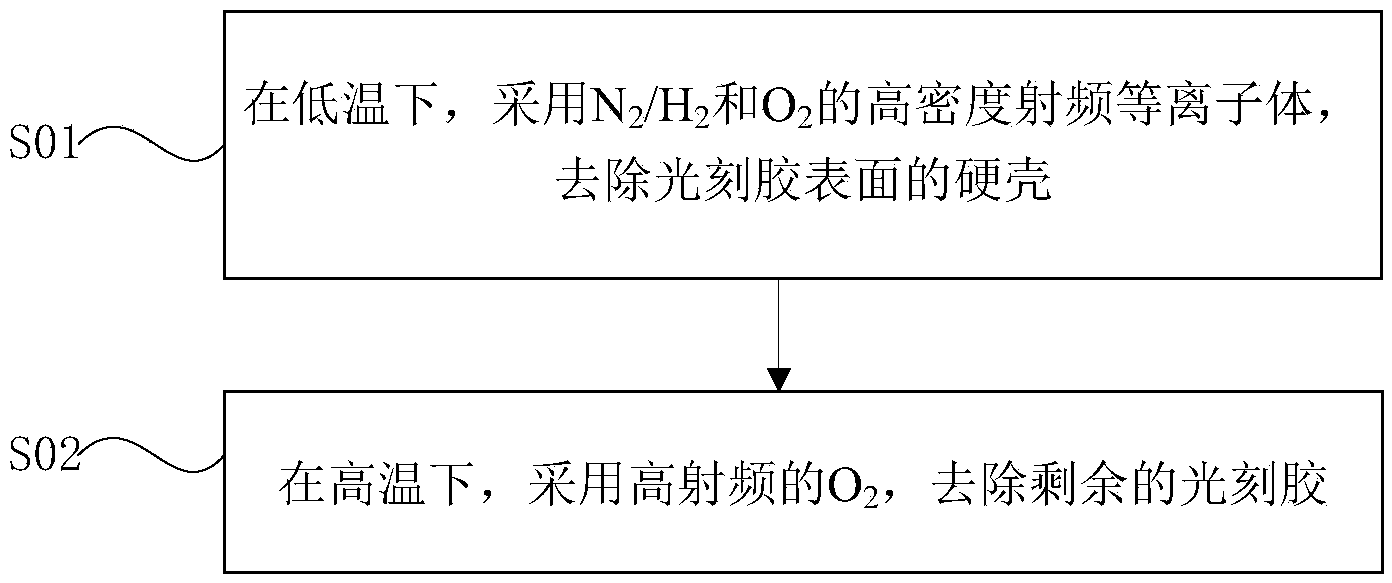

[0027] see figure 2 , the photoresist removal method in this embodiment, the photoresist surface has a hard shell after ion implantation, which includes the following two steps:

[0028] Step S01, at low temperature, using N 2 / H 2 and O 2 The high-density radio frequency plasma removes the hard shell on the surface of the photoresist.

[0029] The "low temperature" described in this step is much lower than the crust removal temperature in the prior art. Generally, the crust removal reaction temperature in the prior art is 200-300°C, as long as it is much lower than the reaction temperature, and it is not easy to make the The temperature at which the volatile solvent in the glue emits is within the protection scope of the present invention, preferably 50-80° C., which can not only ensure the reaction rate, but also prevent the volatile solvent from excessively dispersing.

[0030] Since this step adopts a low temperature reaction temperature, in order to ensure the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com