Method for preparing natural bamboo fibers in pectin removal manner by aid of compound microorganism bactericide

A technology of microbial bacterial agent and composite bacterial agent, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of destroying bamboo fiber bundles, environmental pollution, long cycle, etc., and achieve stable and optimized fiber quality Process conditions, the effect of high fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 composite bacterial agent

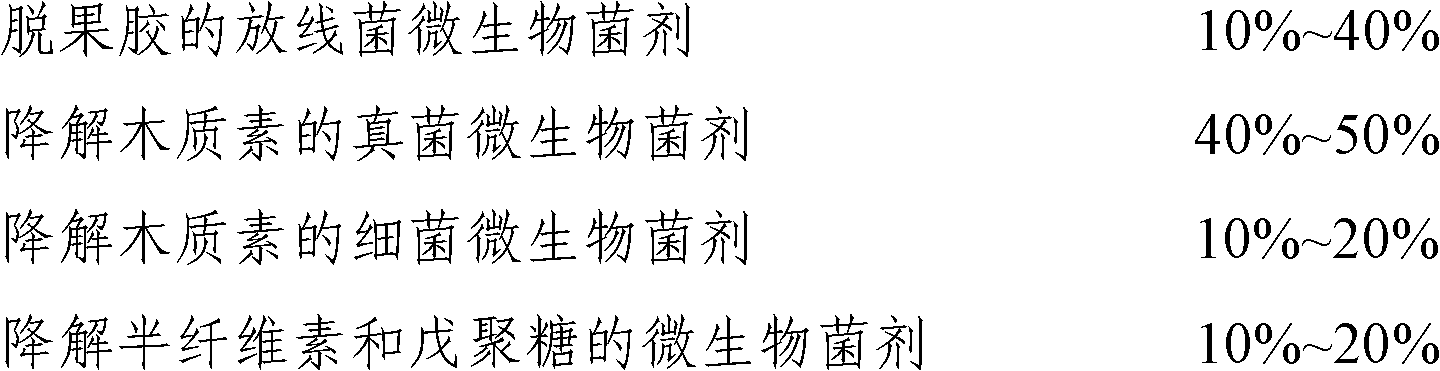

[0040] Special microorganisms with high efficiency in degrading pectin, lignin, hemicellulose and pentosan in rough bamboo fibrils are prepared into composite bacterial agents according to the following volume percentages:

[0041] Compound Bacteria Formula I:

[0042]

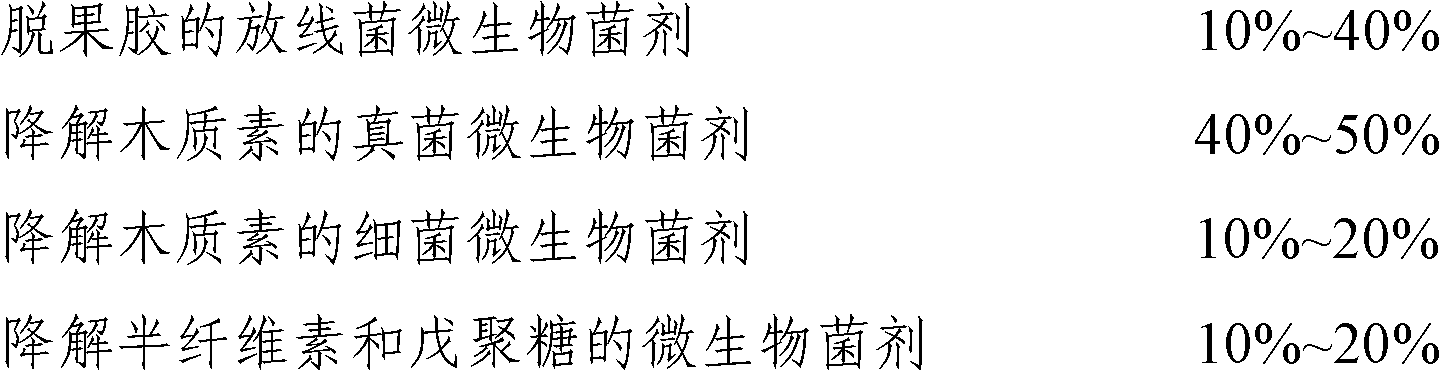

[0043] Compound Bacteria Formula II:

[0044]

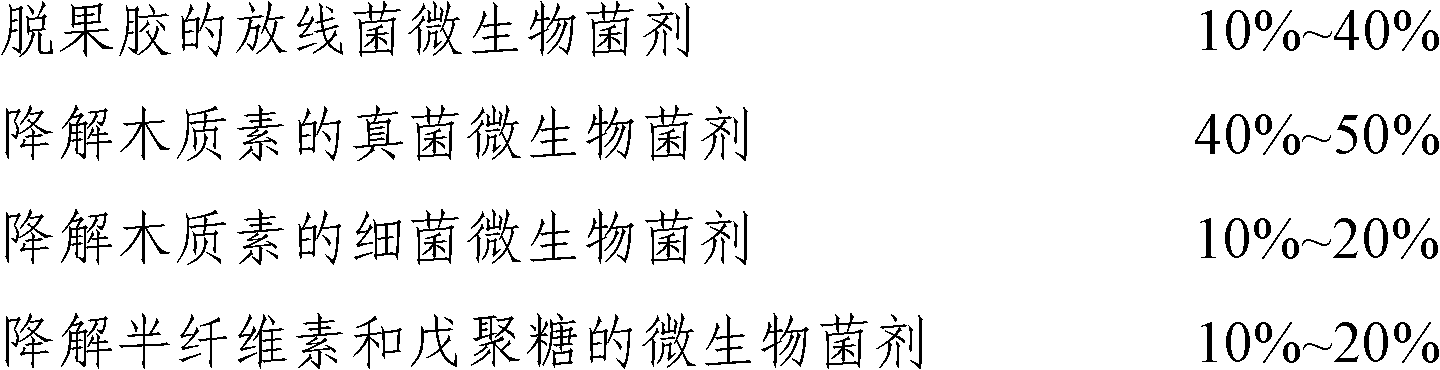

[0045] Compound Bacteria Formula III:

[0046]

[0047]

[0048] Compound Bacteria Formula IV:

[0049]

[0050] Compound Bacteria Formula V:

[0051]

[0052] Among the above-mentioned composite bacterial agent formulas I~V, the microbial bacterial agent of depectin contains 4×10 7 Actinomycetes spores / ml; the microbial agent for degrading lignin contains 5×10 8 fungal spores / ml; the microbial agent for degrading lignin contains 2×10 bacteria 7 CFU / ml; the microbial agent for degrading hemicellulose and pentosan contains 2×10 8 fungal spores / ml.

[0053] Wherein, the act...

Embodiment 2

[0054] The degradation of embodiment 2 crude bamboo fiber pectin

[0055] Micromonospora bronze (Micromonosporachalcea) in the genus Micromonospora (Micromonospora), which is a special strain for producing pectinase, was activated, then transferred to the fermentation medium, and cultivated at 25 ° C for 20 h, as the second One-time degumming bacterial classification, degumming fermented broth bacterial classification can be recycled repeatedly, adds in the above-mentioned fermented liquor after thick bamboo fiber is weighed (mass volume ratio g of thick bamboo fibril and fermented liquor: ml is 1: 25, normal pressure After degumming the pectinase-producing bacteria for 48 hours, rinse and dry with water to observe the degumming effect, compare the residual glue before and after degumming, the residual glue rate is 11.4%, and the color of the bamboo fiber after degumming is lighter than that before degumming The formula of pectin degradation fermentation medium is as follows: ...

Embodiment 3

[0057] Degradation of embodiment 3 thick bamboo raw fiber lignin

[0058] Degradation of lignin: the special bacterial species (fungus being the basidiomycetes (Baidimycetes) in the brown rot fungus (Monilia laxa) ) of the lignin degrading enzyme produced after optimization, the bacterium being the aeruginosa (Pseudomonas) in the genus (Pseudomonas) Pseudomonas (P.Aeruginosa)) were respectively activated by liquid medium, in which the fungi were cultured at 32°C for 2 days, and the bacteria were cultured at 37°C for 24 hours, so that the concentrations of the fungi and bacteria reached 1×10 8 Fungal spores / ml, 1×10 6 ~1×10 7 CFU / ml. Then add fungi and bacteria to the fungi and bacteria fermentation medium according to the inoculum amount of 5-15%, adjust the pH value to 7.0, and finally weigh the bamboo fiber after depectin and add it to the fungi and bacteria to produce lignin degradation The enzyme was degummed in the fermentation medium for 48 hours (the mass volume rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com