Ironing equipment for synthetic leather processing

A synthetic leather and equipment technology, applied in textiles and papermaking, spray/jet textile material treatment, fabric surface trimming, etc., can solve the problems of increased pulling power, uneven wrinkling, increased energy consumption, etc., and achieve space saving and reasonable structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

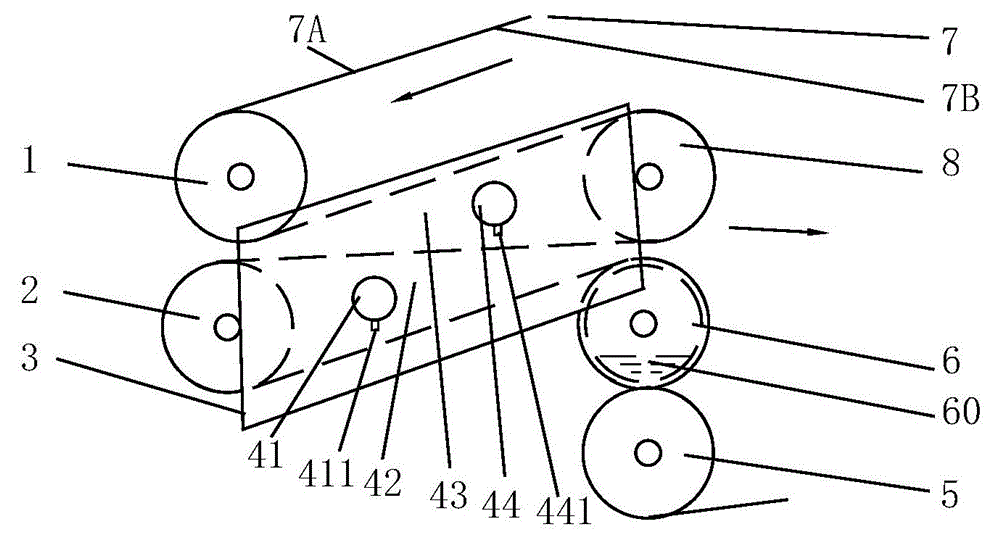

[0028] Embodiment 2, on the basis of Embodiment 1, also includes the first driving roller 2, the second driving roller 8, and the cloth 7 passes through the second driving roller 8, the first driving roller 2, the heating roller 6 and the pressure roller in sequence 5 is transported to the coating machine, the second driving roller 8, the first driving roller 2, the heating roller 6 and the cloth 7 form a first cavity 42, and the two sides of the first cavity 42 are respectively sealed by the steam trap 3, and the first The steam pipe 41 passes through one of the steam traps 3 , and the water mist ejected from the first steam pipe 41 can humidify a surface 7B of the cloth 7 .

Embodiment 3

[0029] Embodiment three, on the basis of embodiment two, also includes a third transmission roller 1, cloth 7 is transmitted to the second transmission roller 8 through the third transmission roller 1, the third transmission roller 1, the second transmission roller 8, the third transmission roller A transmission roller 2 and cloth 7 form a second cavity 43, the two sides of the second cavity 43 are respectively sealed by the steam barrier 3, the second cavity 43 is provided with a second steam pipe 44, and the second steam pipe 44 passes through The steam trap 3 communicates with the ultrasonic water atomization generator, and the second steam pipe 44 is provided with a plurality of second nozzles 441 , and the water mist sprayed out by the second nozzles 441 can humidify the other surface 7A of the cloth 7 .

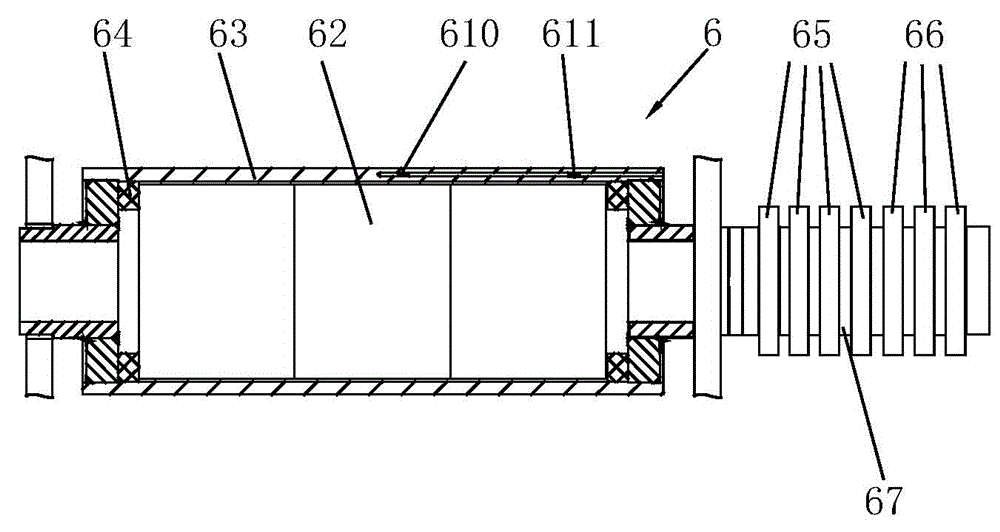

[0030] The ultrasonic water atomization generator includes a high-frequency generator, a drive circuit, an ultrasonic transmitter and a power supply connected in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com