Stainless steel wire rope, production technology and application thereof

A production process, stainless steel technology, applied in coatings, textile cables, textiles and papermaking, etc., can solve the problems of shortened service life of steel wire ropes, poor corrosion resistance and high temperature oxidation resistance of steel wire ropes, complicated production process of steel wire ropes, etc. Large, good acid resistance, uniform crystal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

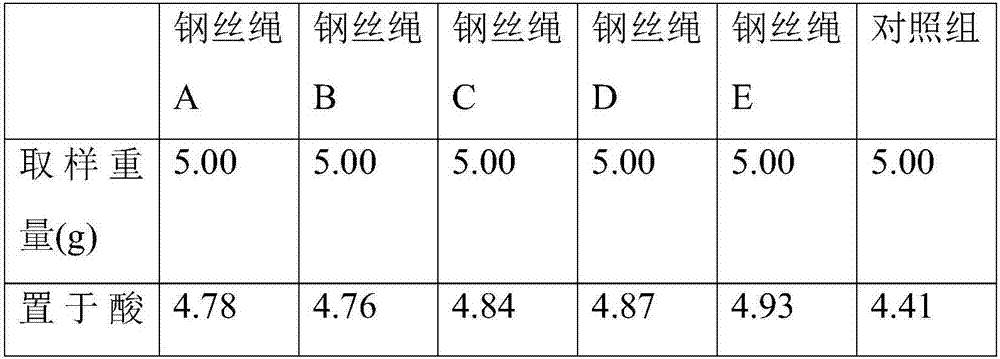

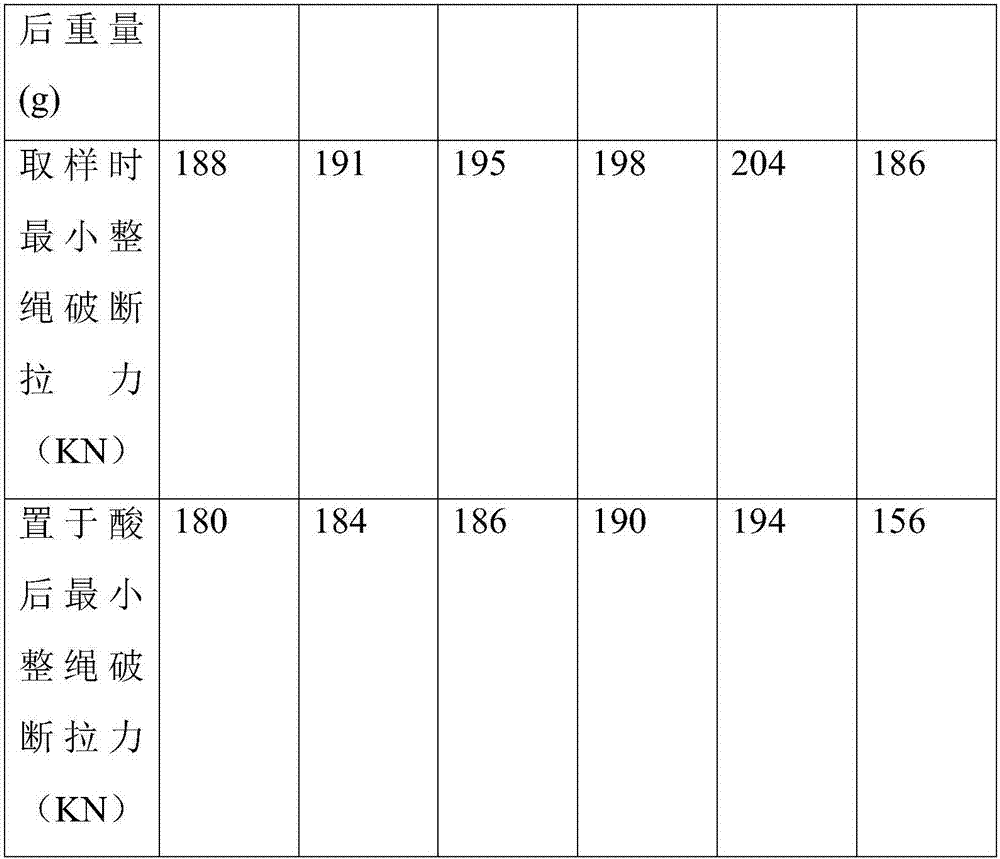

Embodiment 1

[0029] A stainless steel wire rope, the chemical composition of the stainless steel wire includes: C0.012, Si0.06, Cr10.0, Ni21.0, Mn2.50 according to the mass percentage, and the balance is Fe and unavoidable impurities. The above preparation method is carried out to prepare the steel wire rope A.

Embodiment 2

[0031] Same as Example 1, the difference is that the chemical composition of the stainless steel wire rope includes: C0.02, Si0.07, P0.02, Cr12.0, Ni23.0, Mn4.00, S0.015, Cu0 .075, N0.008, Ti0.015, the balance being Fe and unavoidable impurities, steel wire rope B was obtained by the above preparation method.

Embodiment 3

[0033] Same as Example 1, the difference is that the chemical composition of the stainless steel wire rope includes: C0.017, Si0.068, P0.013, Cr11.3, Ni22.3, Mn3.70, S0.008, Cu0.04, N0.004, Ti0.011, the balance is Fe and unavoidable impurities, and the steel wire rope C is obtained through the above preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com