Continuous drying equipment for particle or powder plastics

A technology for drying equipment and powder, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of low efficiency, high power consumption, complex equipment structure, etc., and achieve high efficiency, low energy consumption, The effect of continuous drying treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

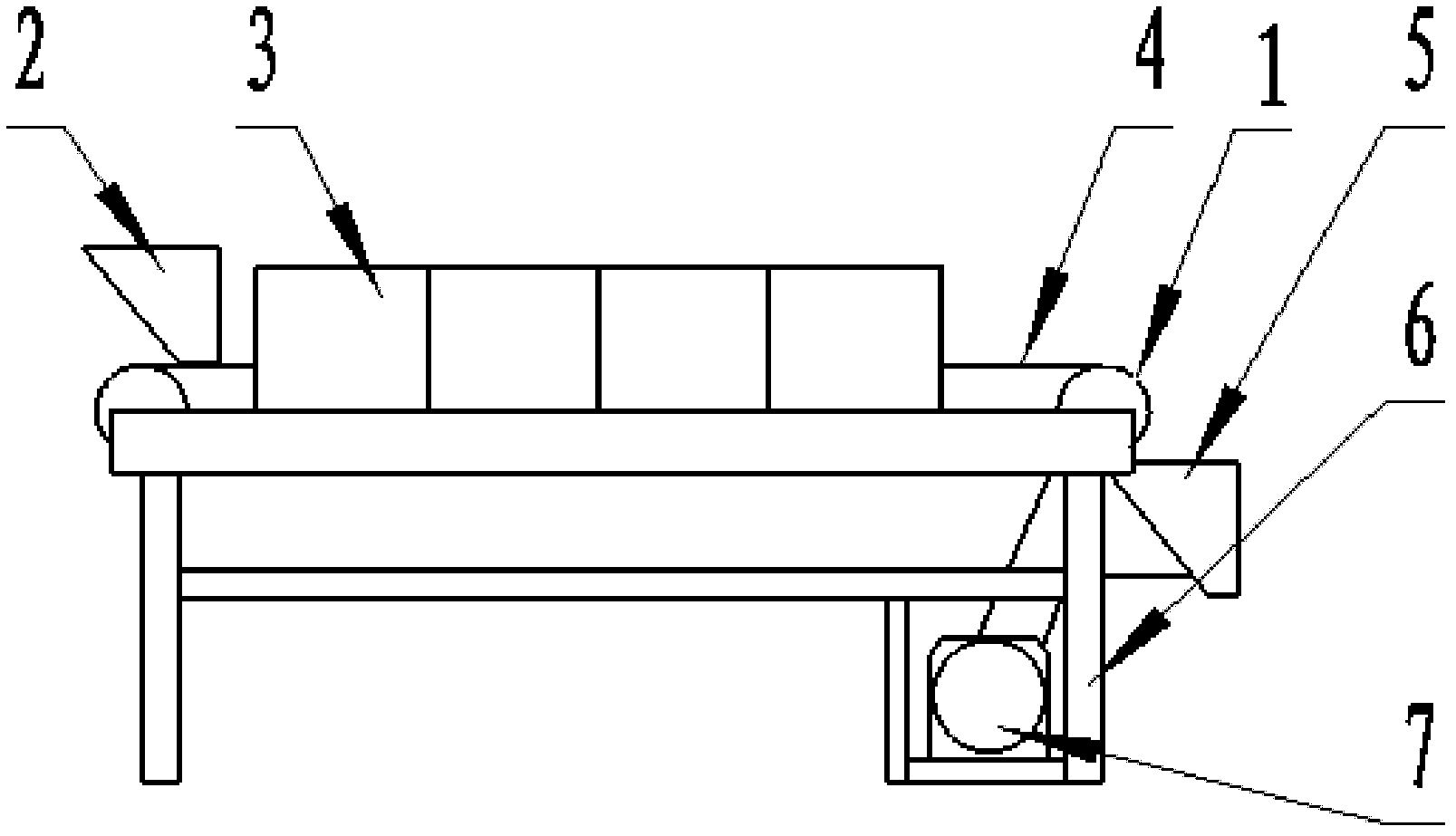

[0018] Example 1: In figure 1 Among them, the conveyor belt driving roller 1 runs under the drive of the reducer and the speed regulating motor 7, and drives the conveyor belt 4 to move continuously, and the PE particles or powder materials are evenly distributed on the conveyor belt 4 according to a certain thickness through the feeding hopper 2, Pass through the area covered by the tunnel 3 with the microwave generator smoothly at a certain running speed. During this period, the water molecules in the PE particles or powder materials undergo high-frequency resonance under the action of microwaves, resulting in intermolecular friction and rapid heat generation. And evaporate to achieve the purpose of drying. The dried PE granules or powder materials are bagged and packaged through the discharge hopper 5 . The specific structure of the frame 6 can be designed and determined according to actual use needs.

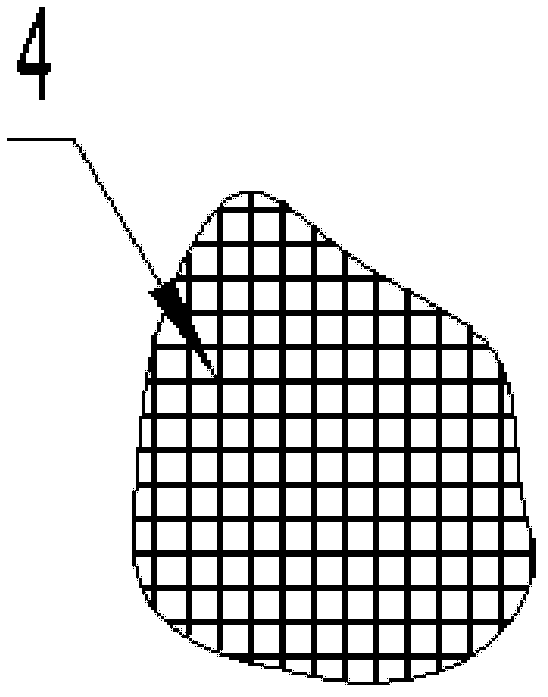

[0019] figure 2 It is schematically illustrated that the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com