Integrated inductor production line

A production line, integrated technology, applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve the problems of excessive work content, inability to improve production speed, and low degree of automation, avoiding manual handling, The effect of compact production cycle and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

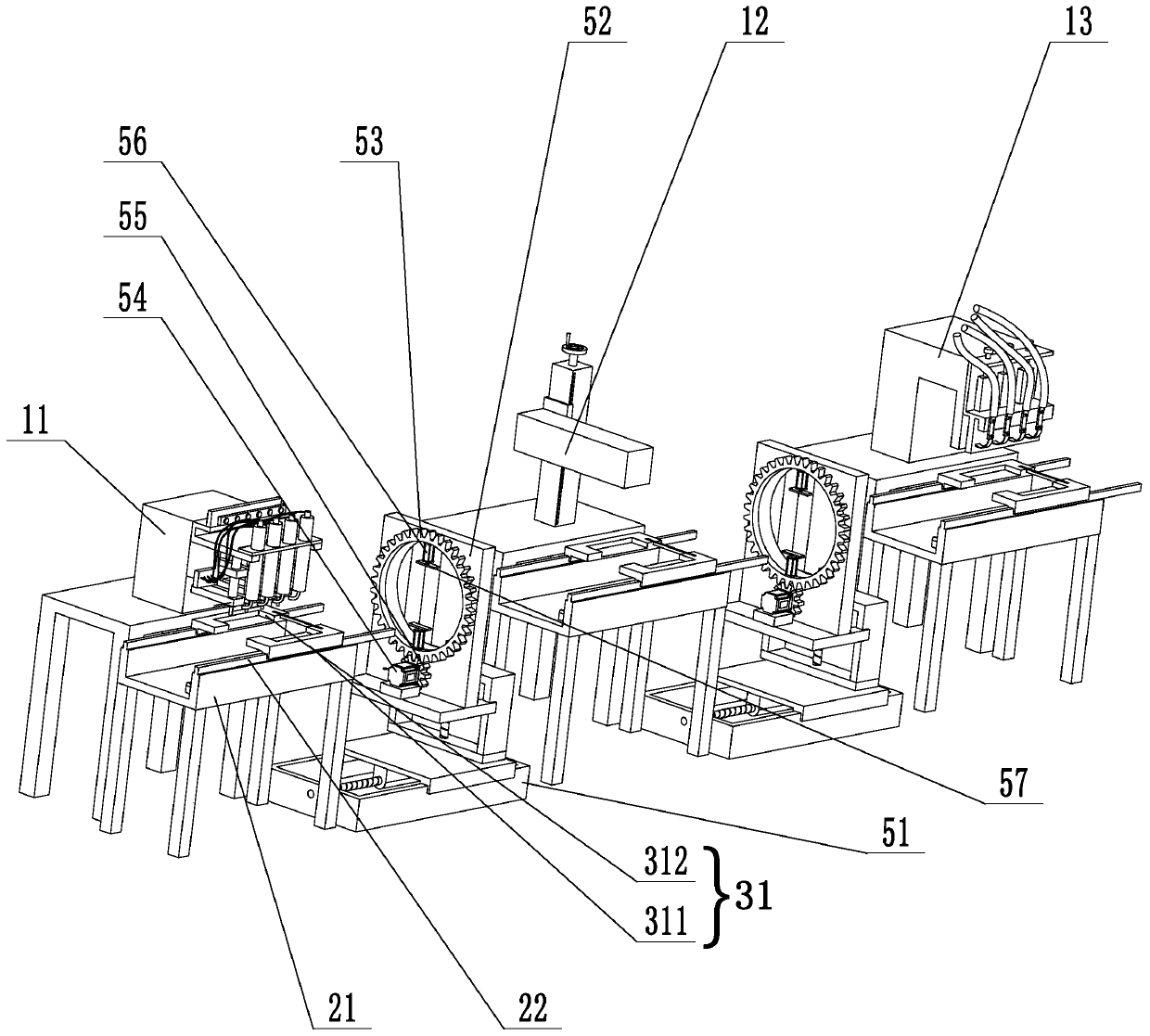

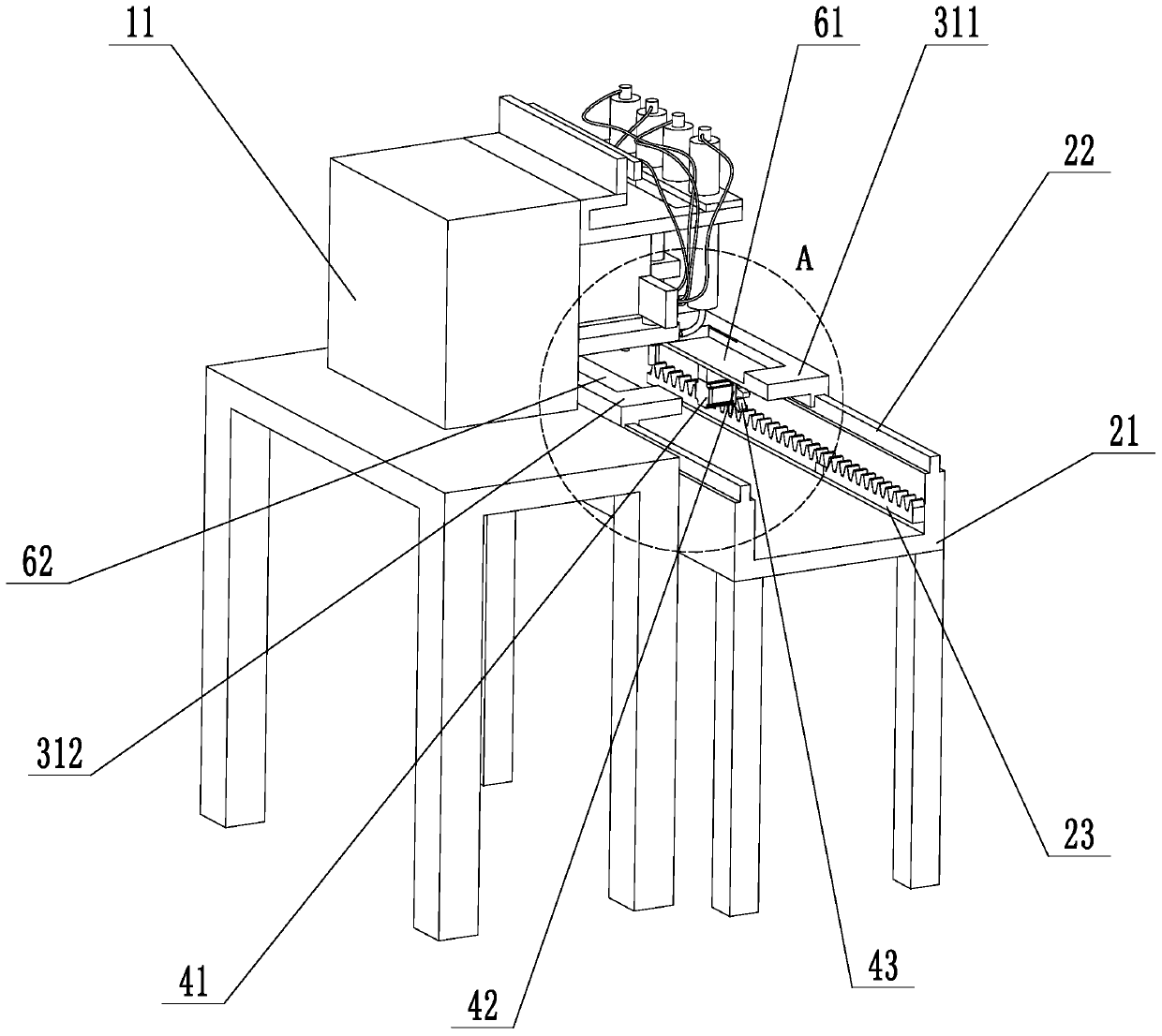

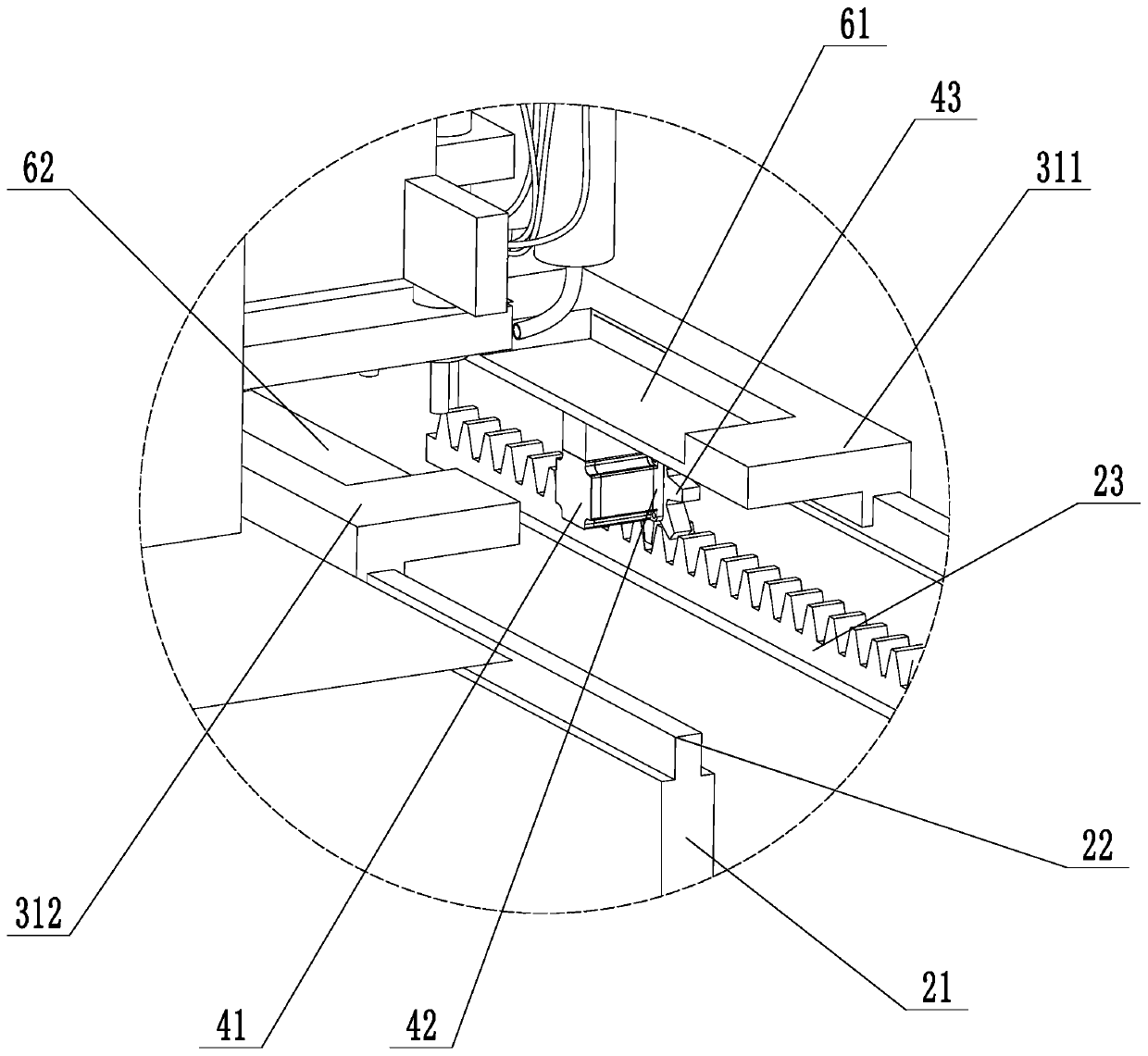

[0046] refer to figure 1, is an integrated inductance production line disclosed by the present invention, including a winding machine 11, a laser stripping machine 12, a welding machine 13, a transport platform 21, a transport device, a turning device, and the like. The quantity of transport platform 21 is three joints, and is arranged at interval along the straight line, and there is gap between adjacent transport platform 21, supply turning device uses, and a set of restaurant device is arranged on every section transport platform 21. The winding machine 11, the laser stripping machine 12 and the welding machine 13 are sequentially placed on one side of the three sets of transport devices. The quantity of turning devices is two sets, which are respectively placed in two gaps between the three sets of transporting devices.

[0047] The winding machine 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com