Patents

Literature

60results about How to "Rapid Cooling Forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

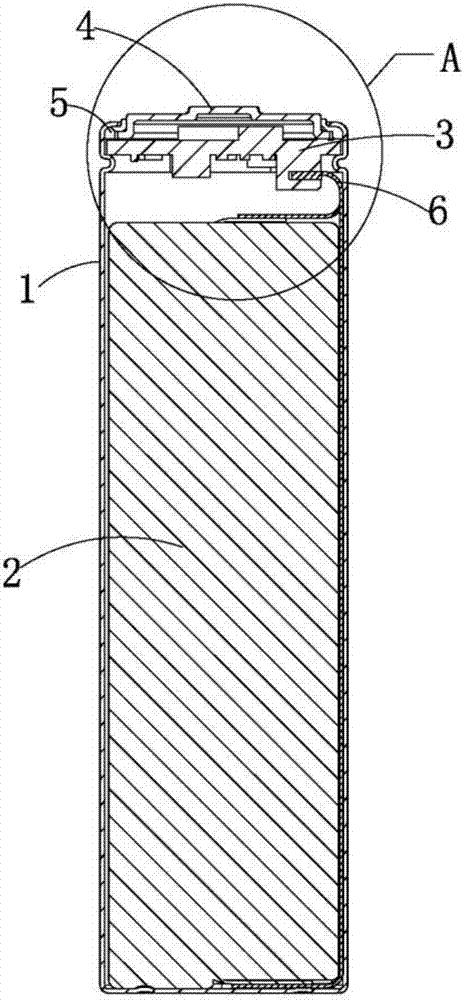

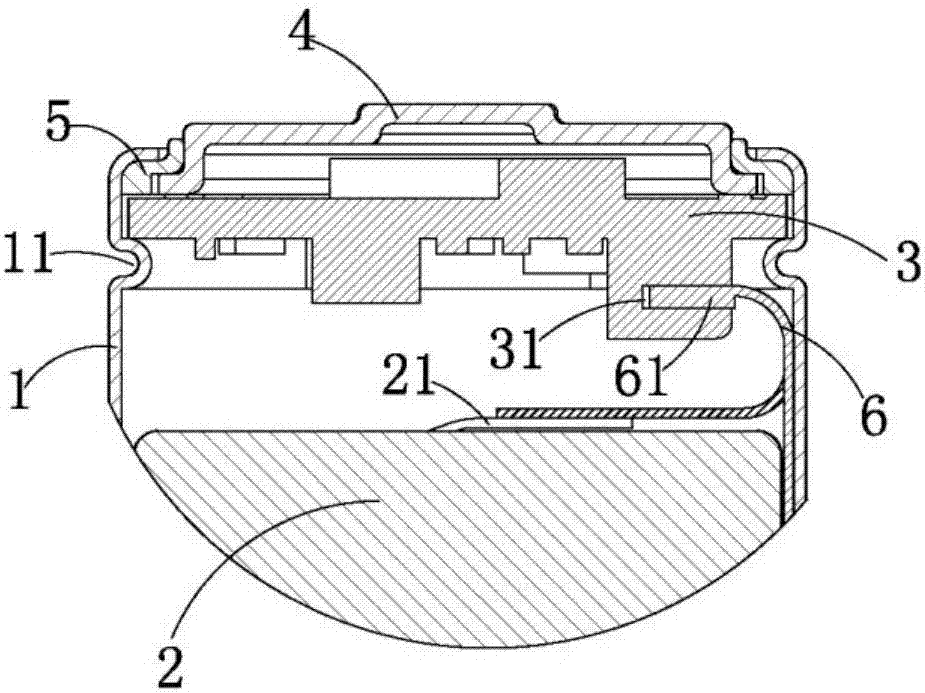

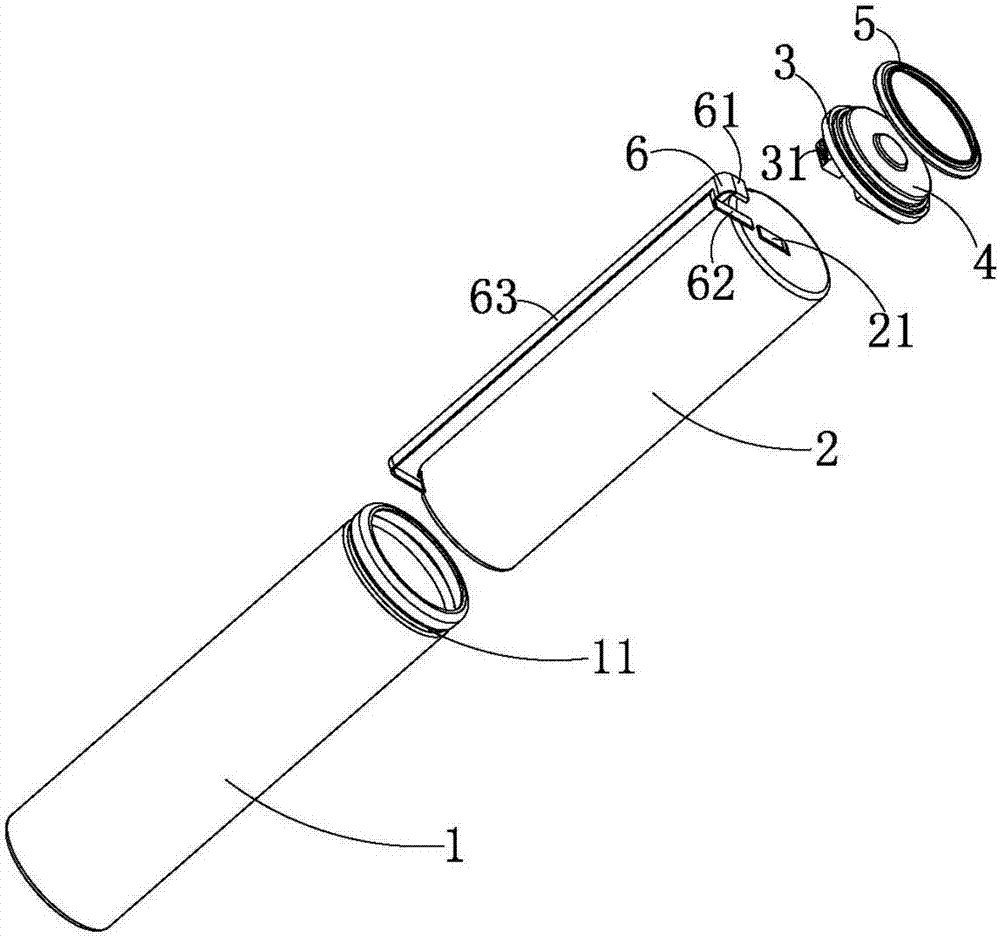

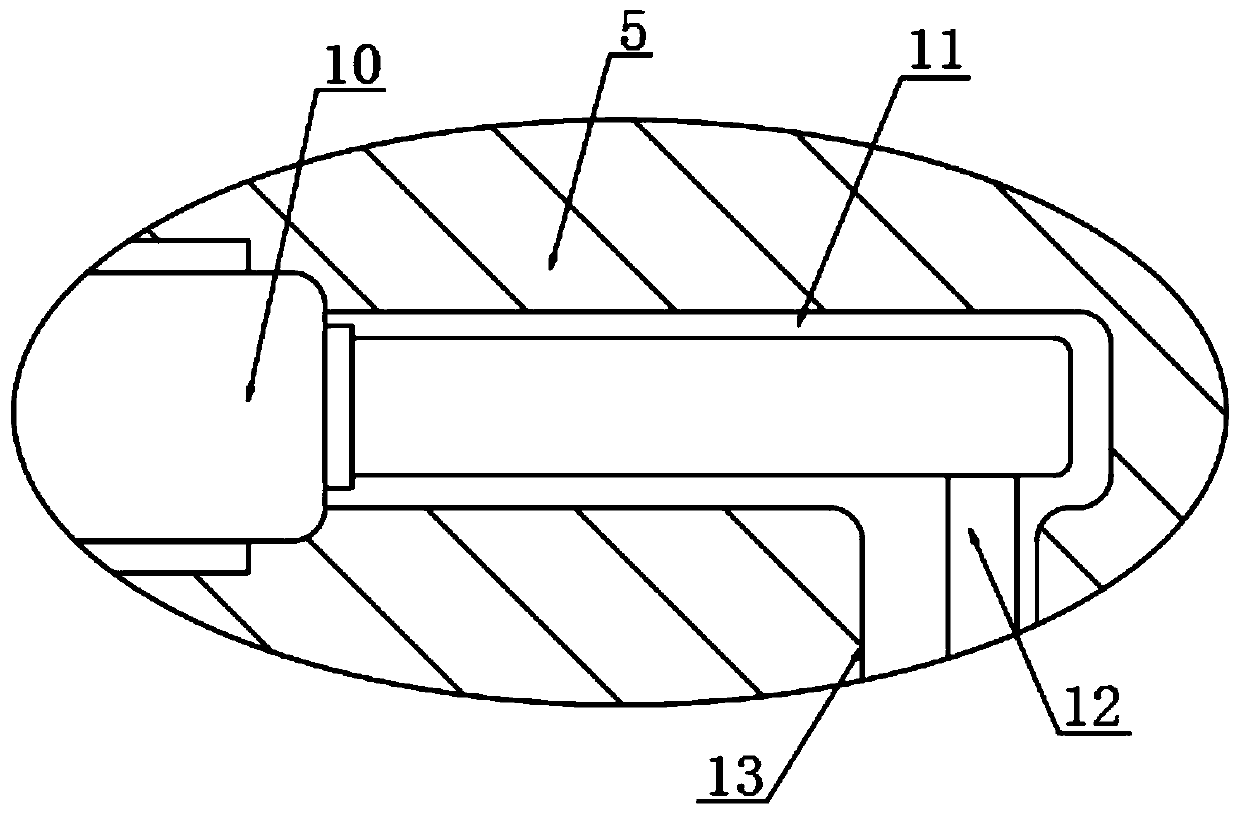

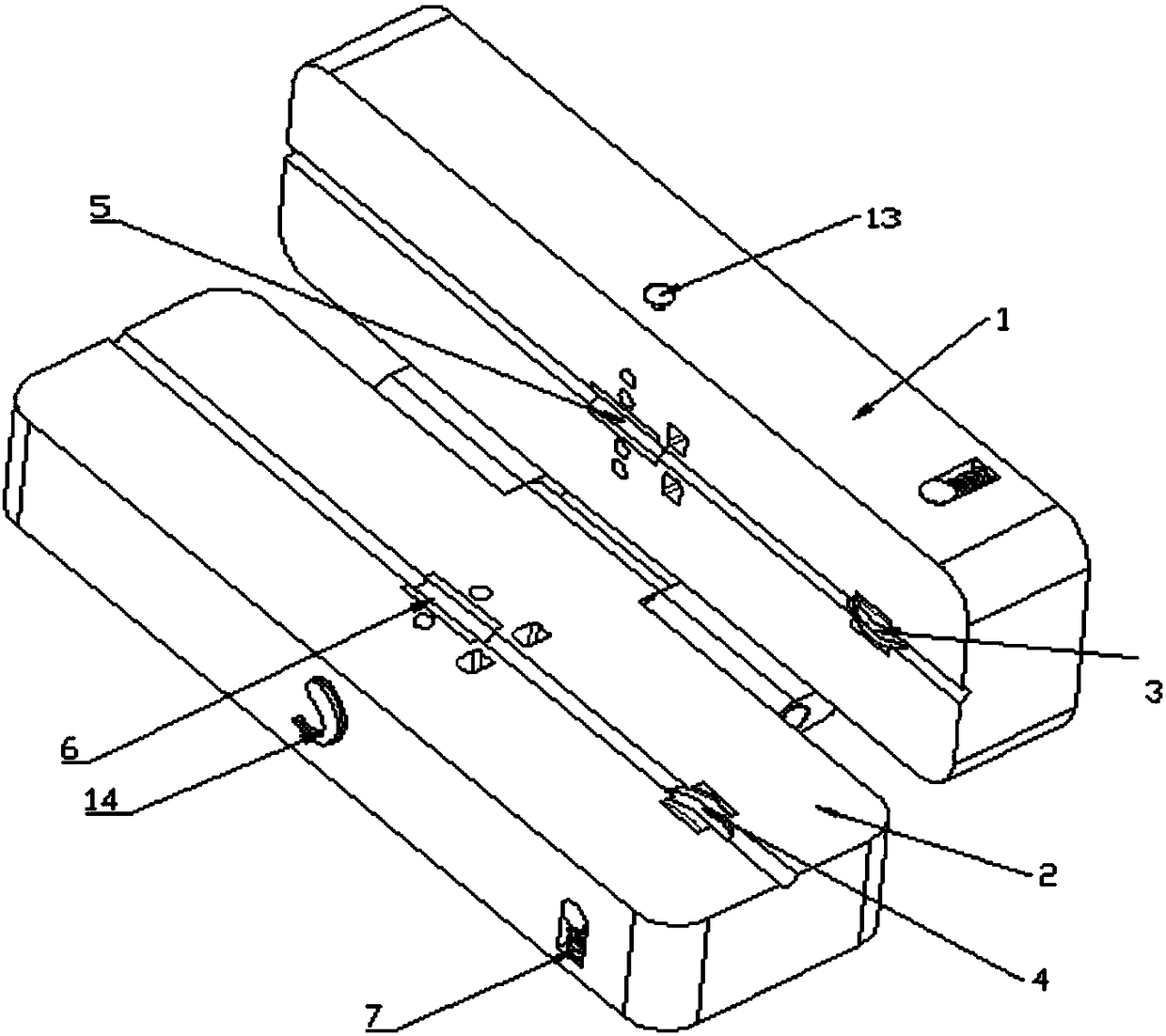

Universal rechargeable battery composed of lithium ion battery cell, and assembling method thereof

PendingCN107275557AEasy to operateLow costFinal product manufactureCurrent conducting connectionsFlexible circuitsElectrical battery

The invention belongs to the technical field of secondary cell, and especially relates to a universal rechargeable battery composed of a lithium ion battery cell, and an assembling method thereof. The universal rechargeable battery comprises a battery shell, the lithium ion battery cell, a circuit board module, a cathode end cap, and an insulating sealing ring; the lithium ion battery cell, the circuit board module, the cathode end cap, and the insulating sealing ring are assembled in the battery shell via laminating successively; the universal rechargeable battery also comprises a flexible circuit board; a cathode tab and an anode tab of the lithium ion battery cell are connected with the flexible circuit board respectively; the flexible circuit board is connected with the circuit board module via electrical connection via inserting. Compared with the prior art, the universal rechargeable battery possesses following advantages: the lithium ion battery cell is provided with the flexible circuit board which is connected with the cathode tab and the anode tab of the lithium ion battery cell via electrical connection, and rapid connection of the flexible circuit board with the circuit board module is realized via inserting, operation is simple, connection is stable and reliable, automatic production can be realized, production efficiency is increased, cost is reduced, product consistency is ensured to be excellent, and reliability is high.

Owner:SHENZHEN MODERN SKY TECH CO LTD

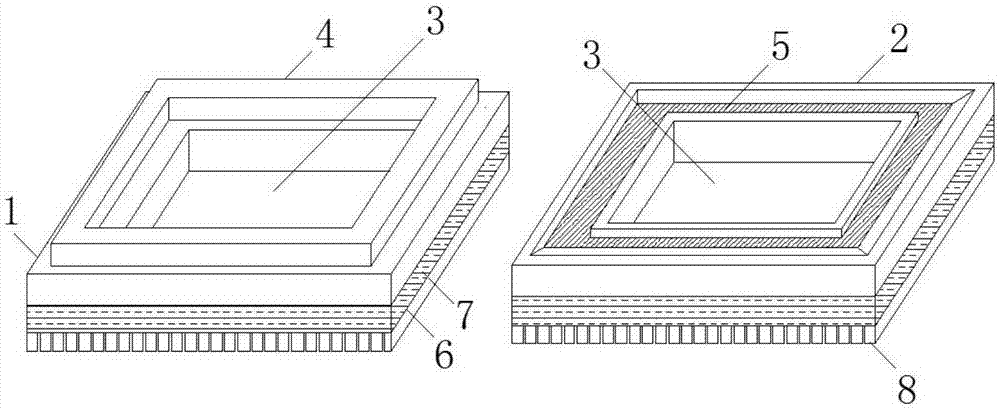

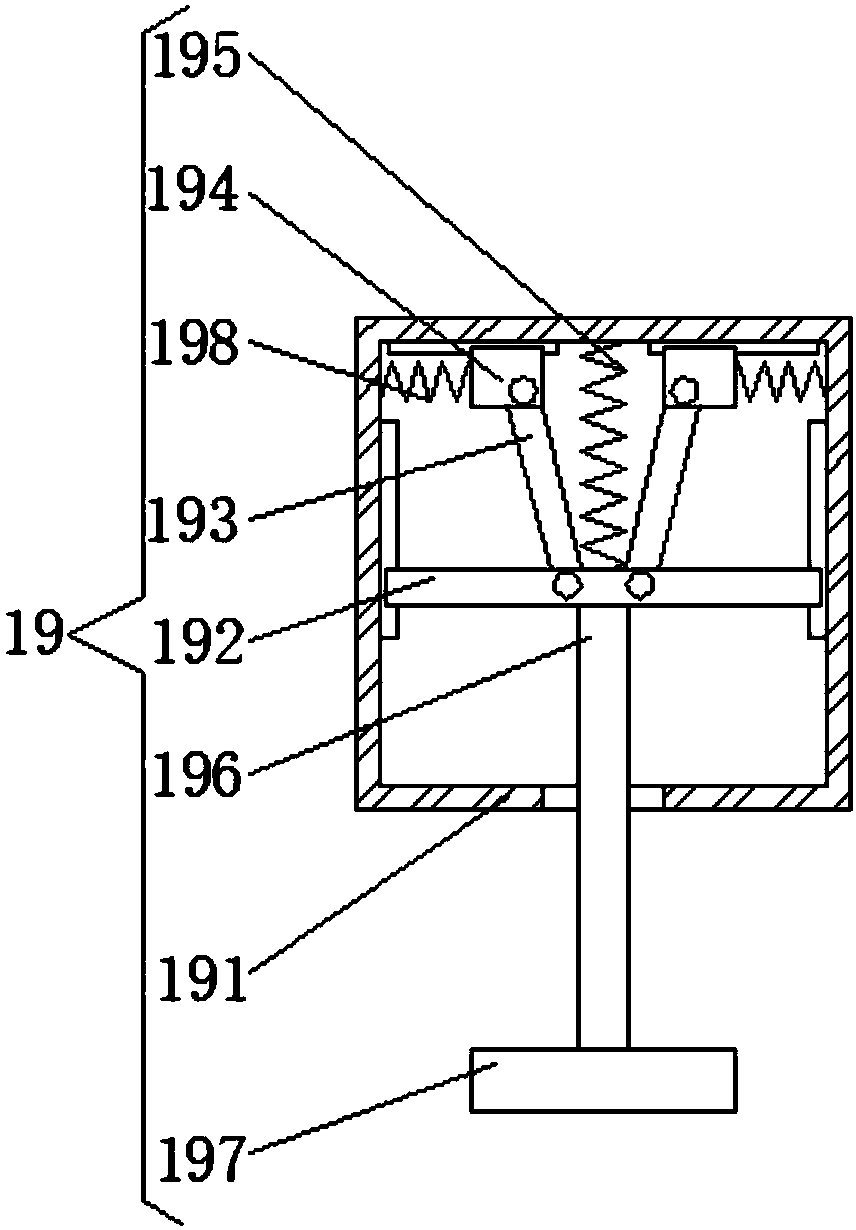

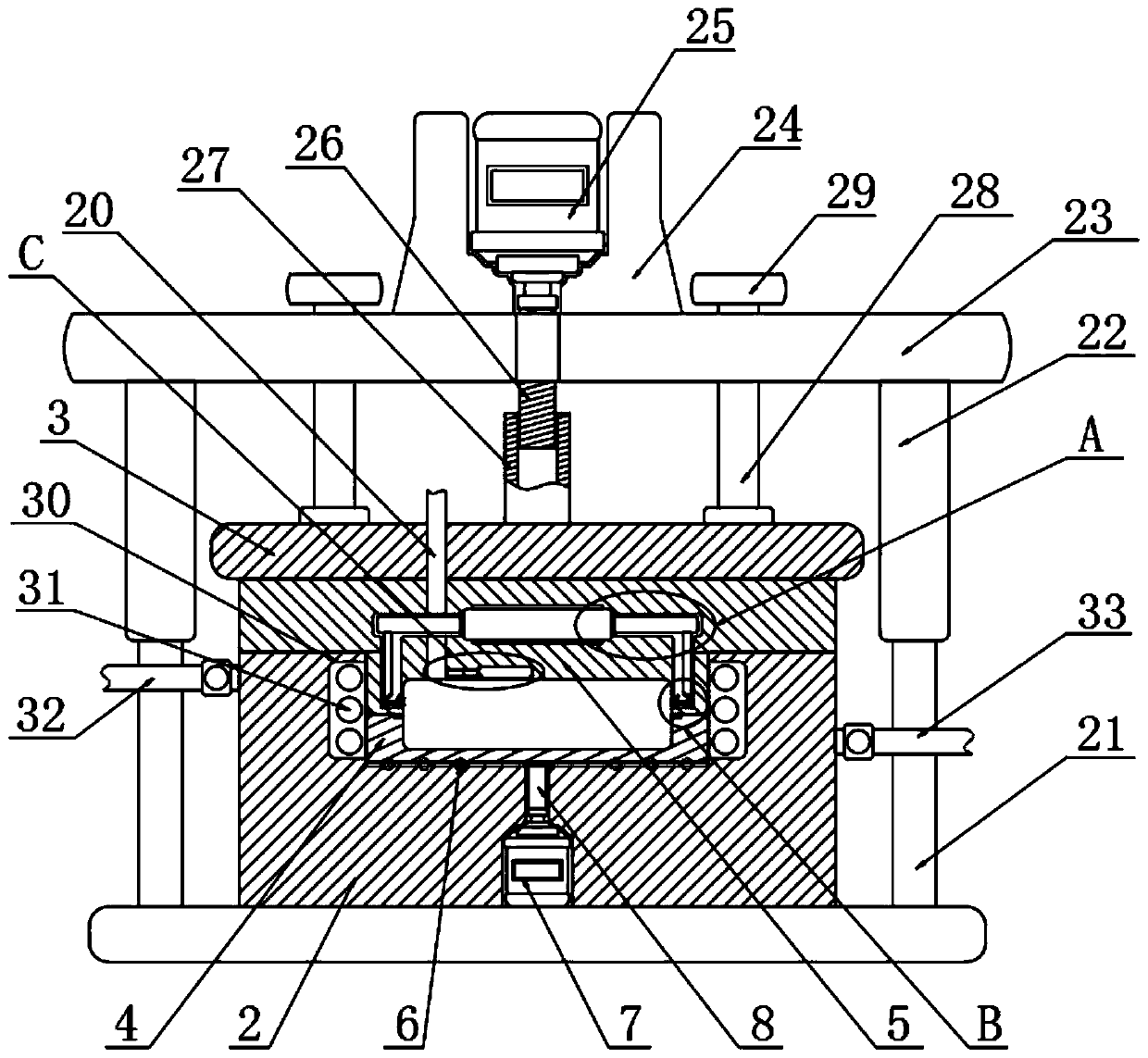

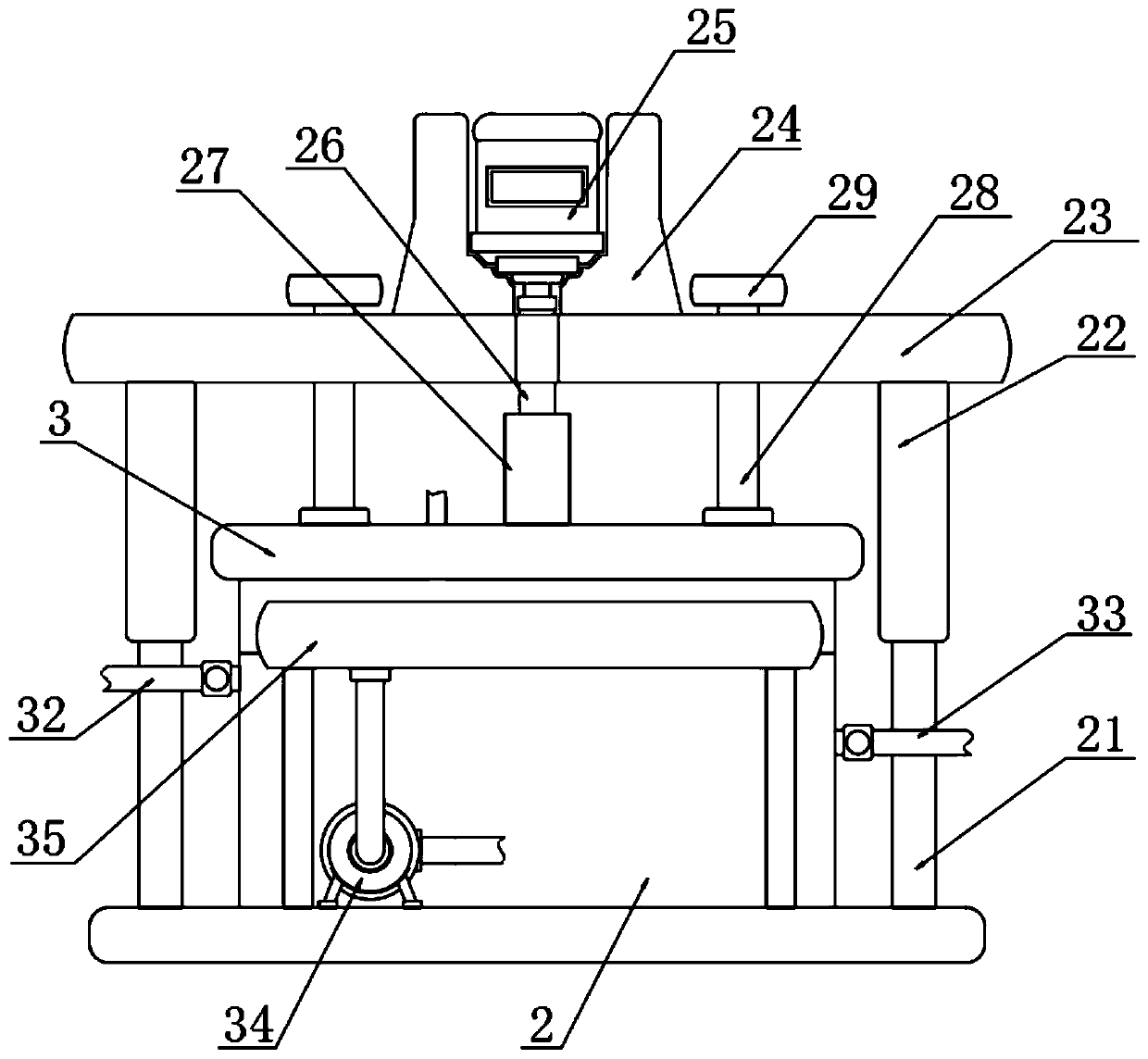

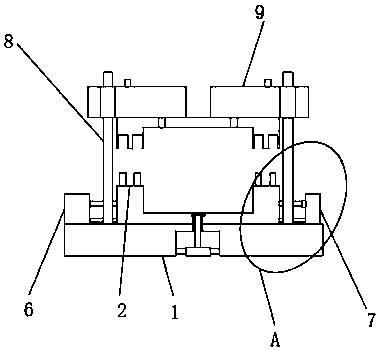

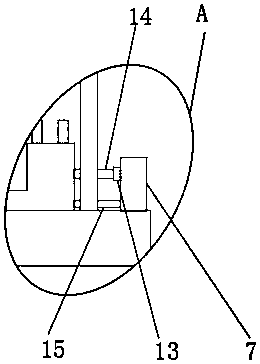

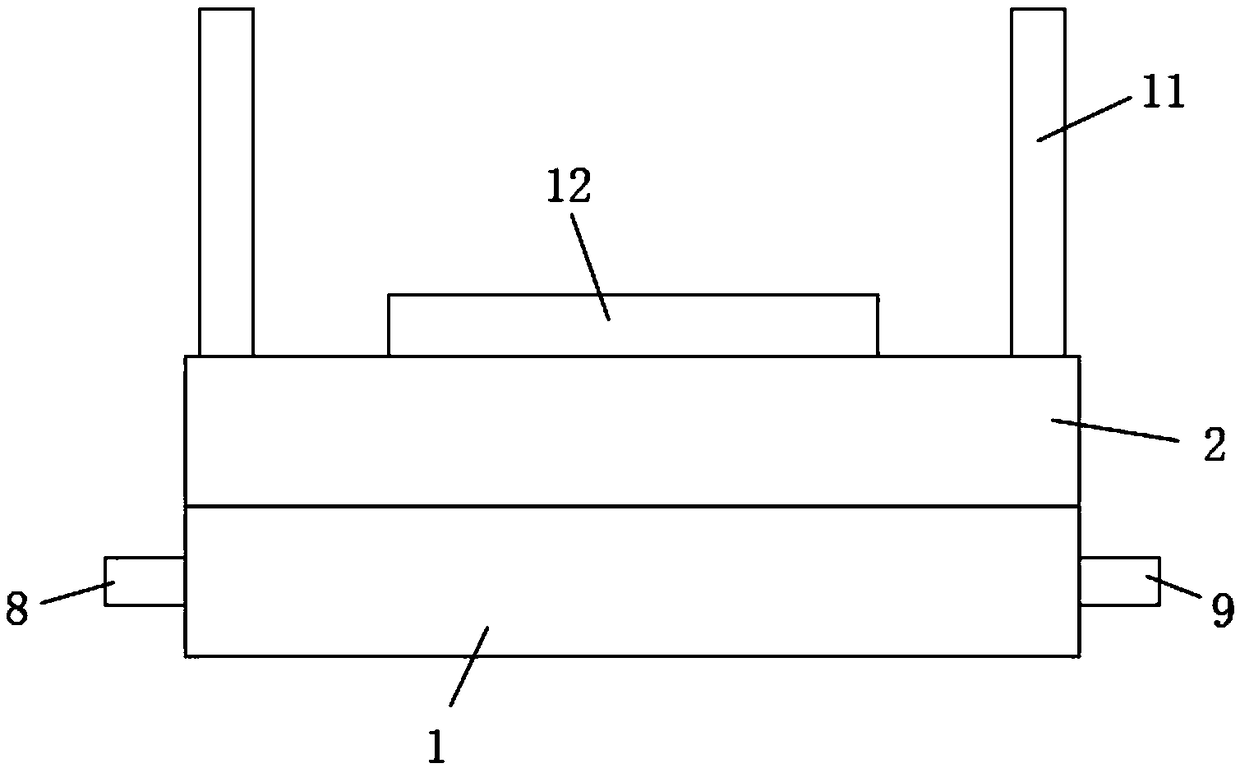

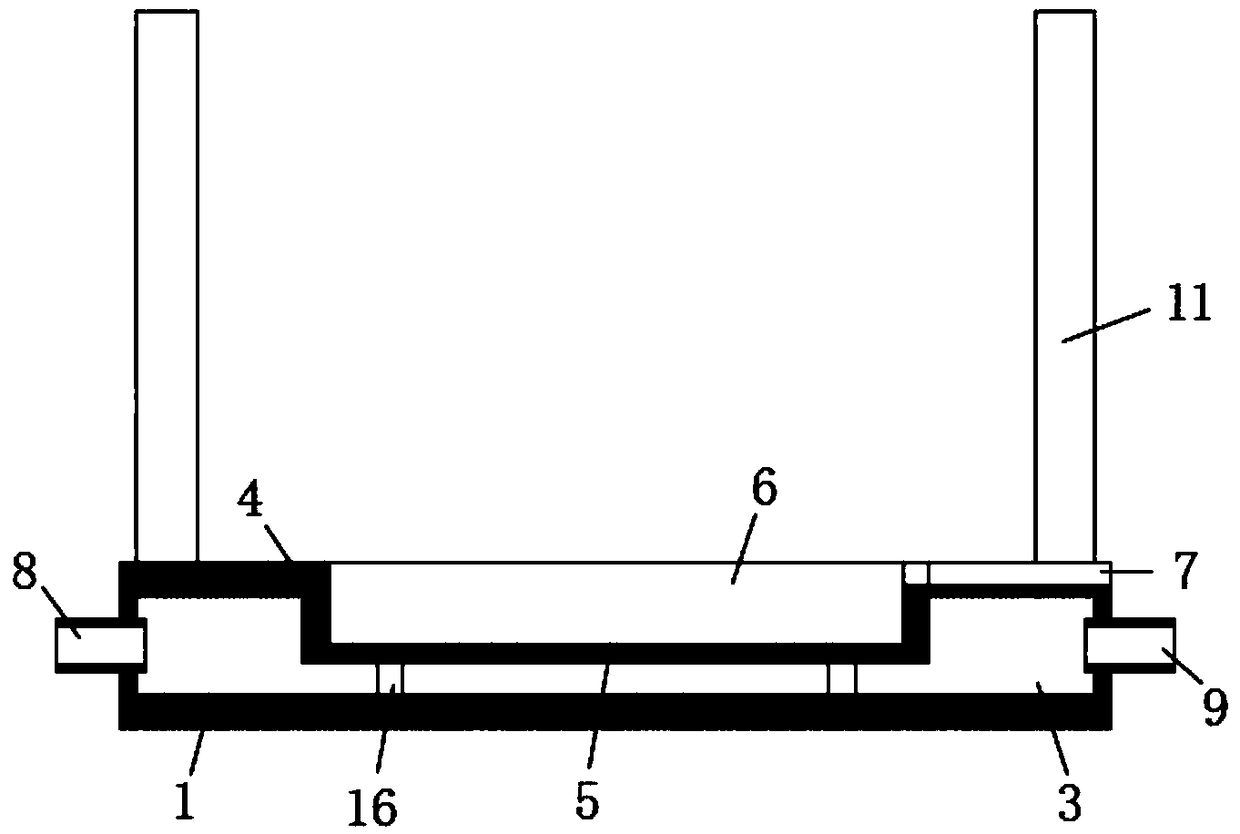

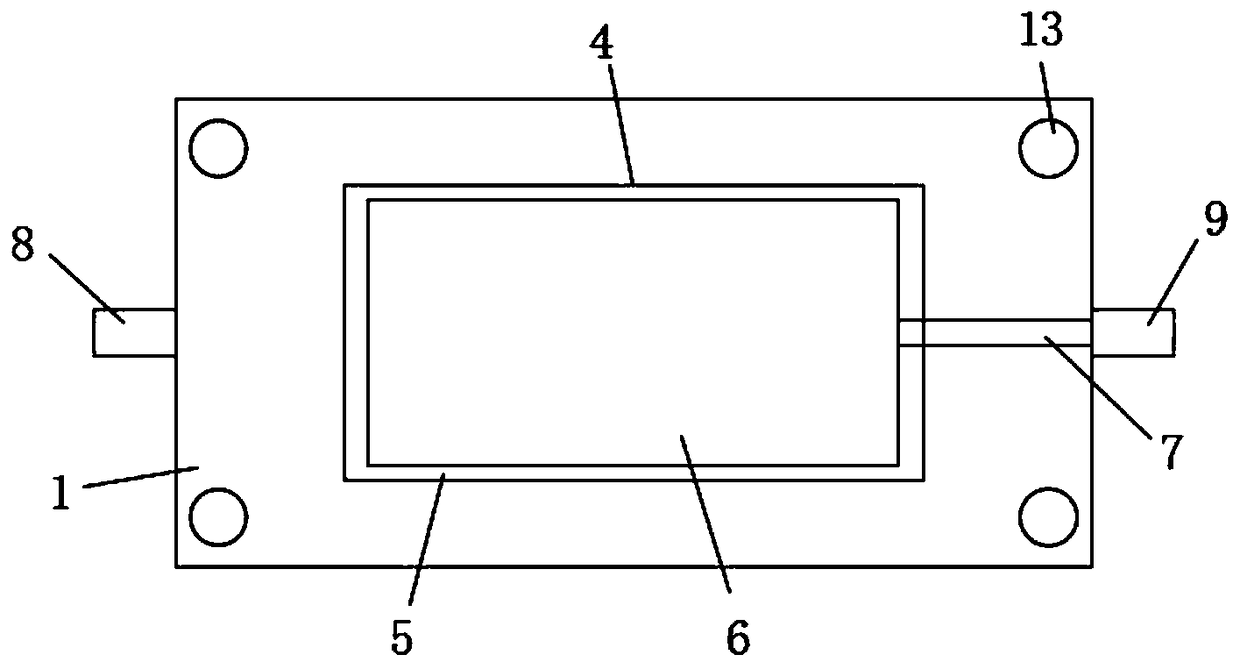

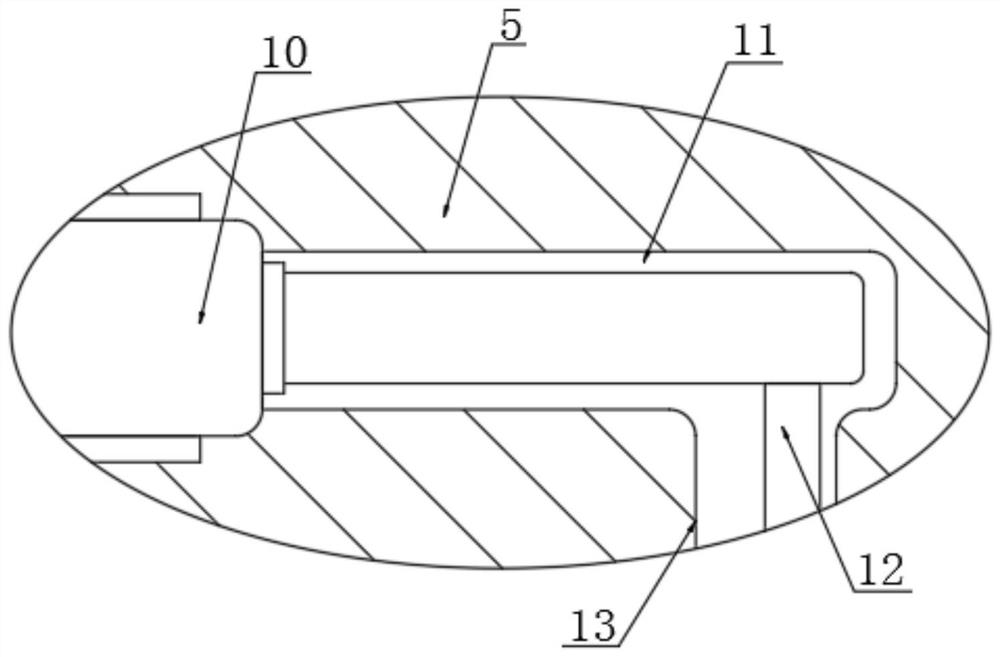

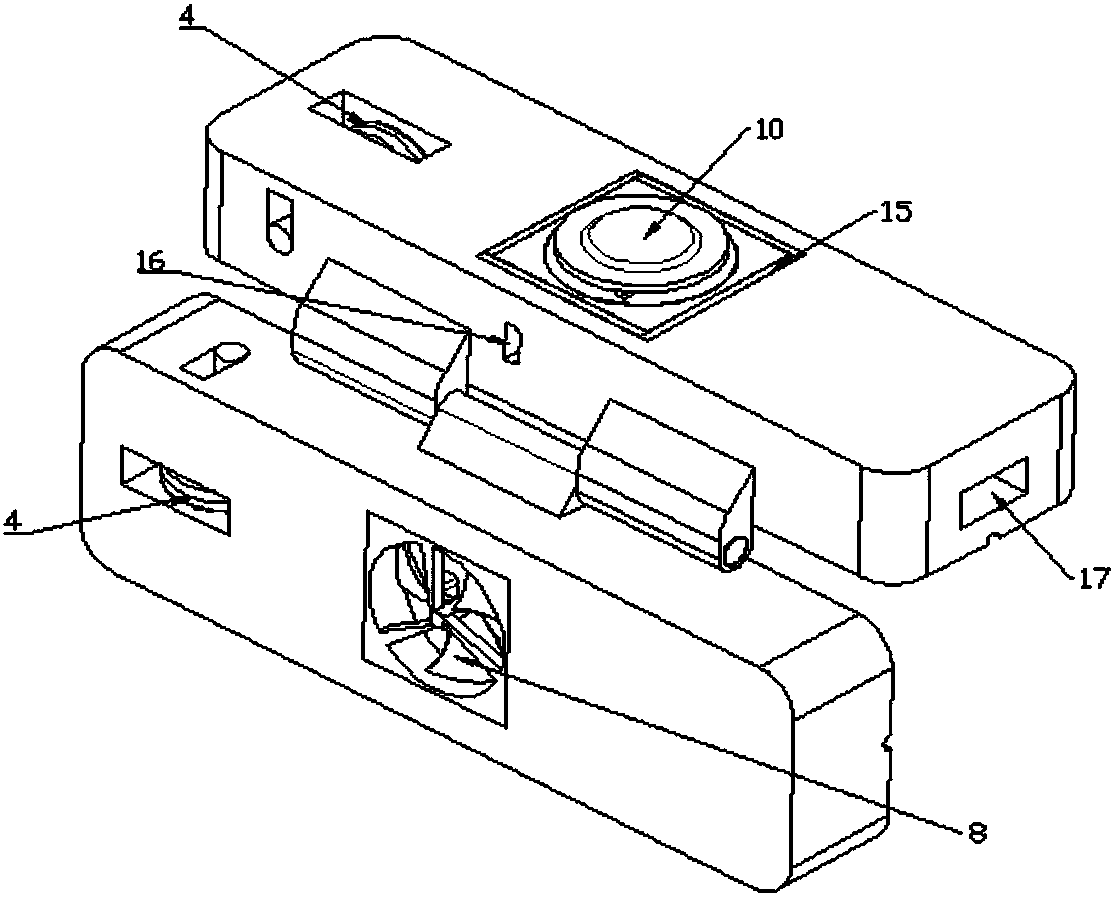

Mold accurate in locating

The invention discloses a mold accurate in locating. The mold comprises an upper mold body and a lower mold body. The upper mold body and the lower mold body are each provided with a mold cavity. A buckle strip is arranged on the lower surface of the upper mold body. A groove is formed in the corresponding position of the upper surface of the lower mold body. The upper surface of the upper mold body and the lower surface of the lower mold body are each provided with a cooling cavity. Cooling liquid is injected into each cooling cavity. Heat radiation structures are evenly distributed on the surface of each cooling cavity. During use, the upper mold body presses the buckle strip of the upper mold body into the groove in the lower mold body so that accurate locating of the upper mold body and the lower mold body can be achieved, no deviation is generated, and the yield of produced products is high; and heat of products in the mold can be absorbed through the cooling liquid in the cooling cavities, the heat absorbed by the cooling liquid is radiated through the heat radiation structures, and therefore the products can be fast cooled and formed, the production efficiency is improved, meanwhile, cooling can be achieved without the help of external equipment, and use is convenient.

Owner:CHONGQING KUANTIAN AGRI DEV CO LTD

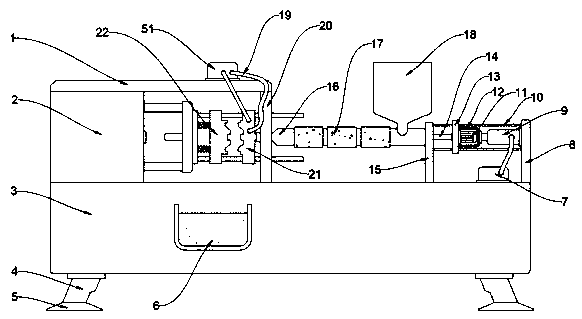

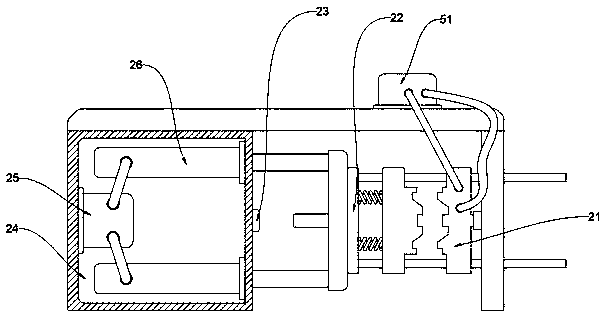

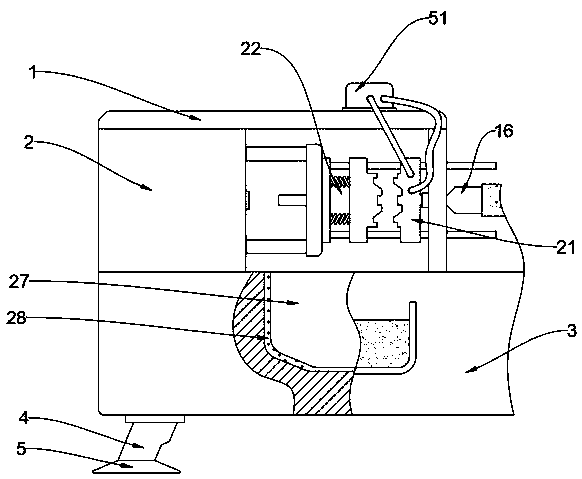

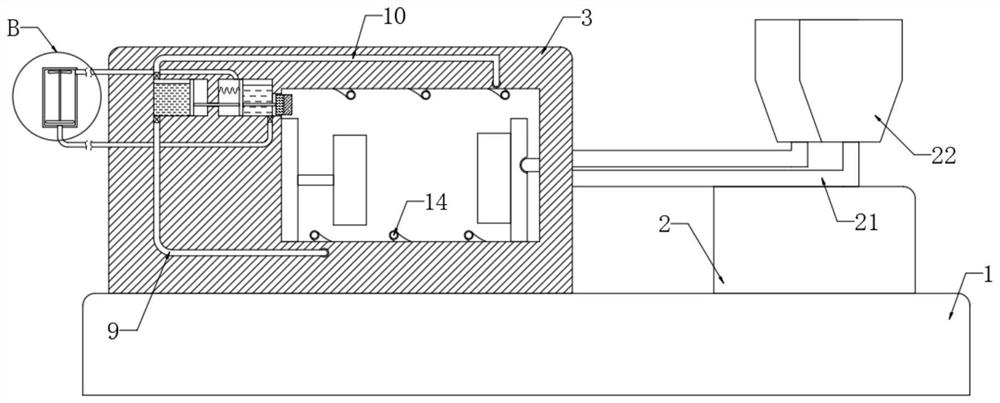

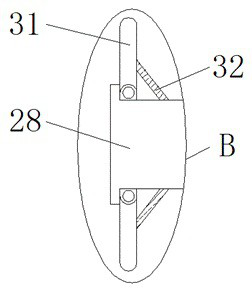

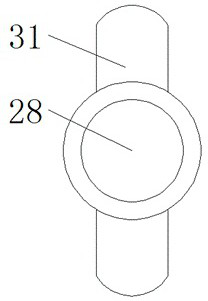

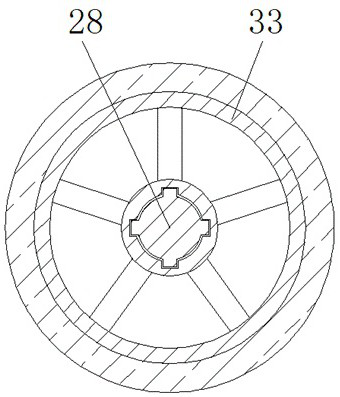

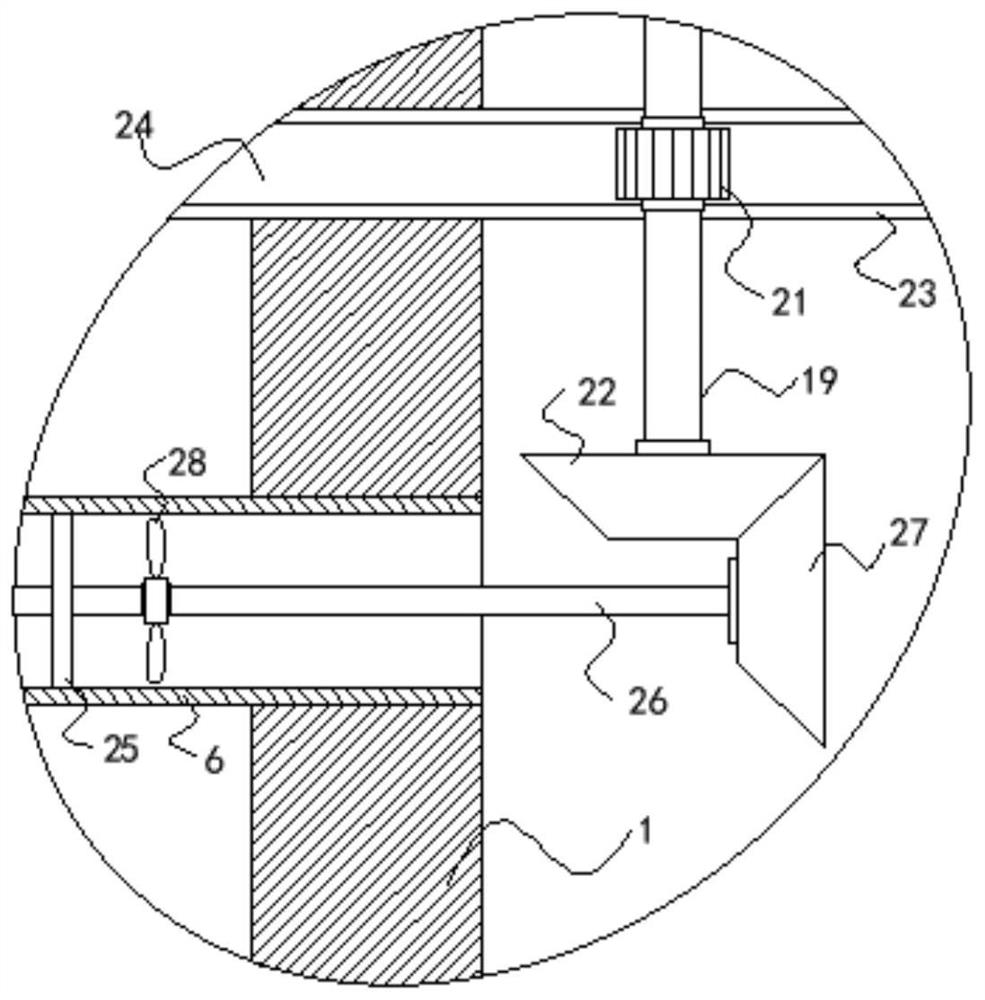

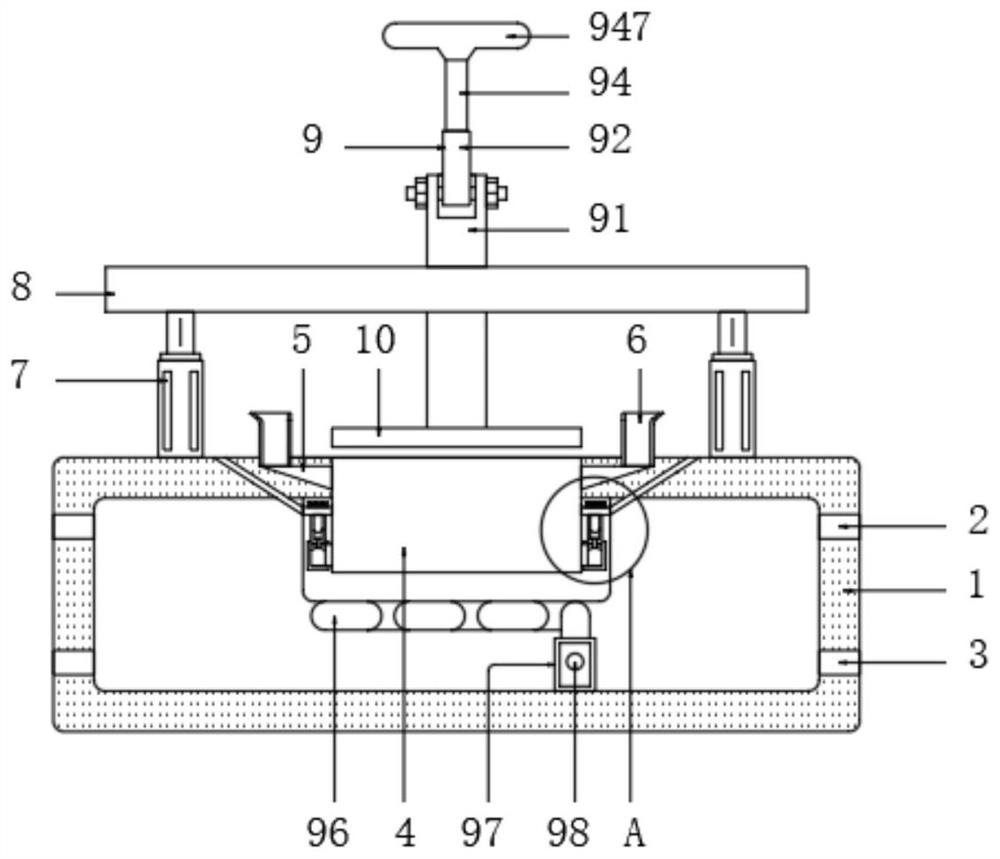

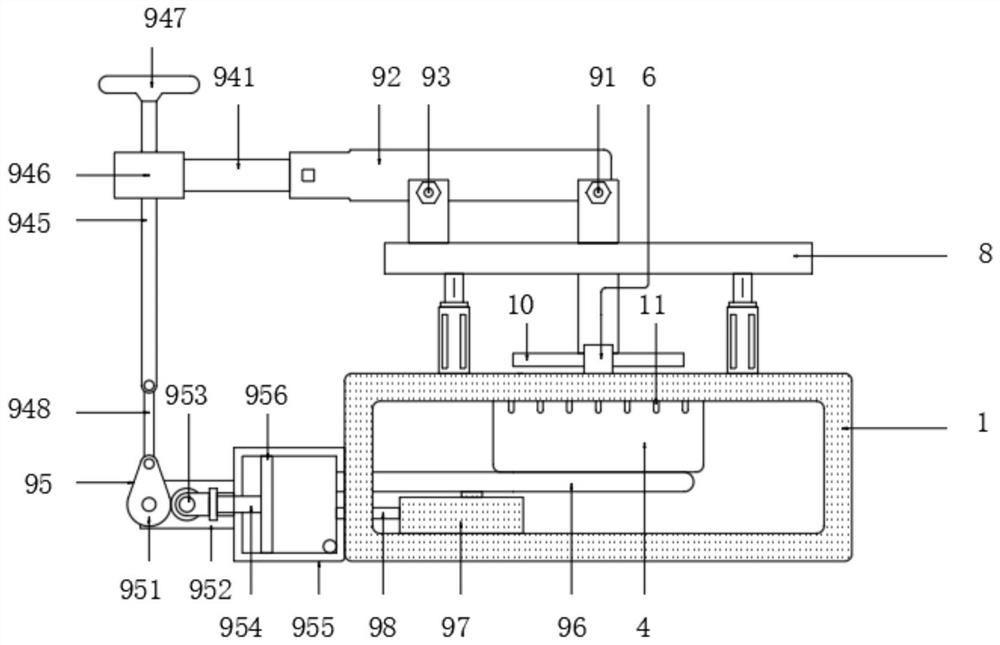

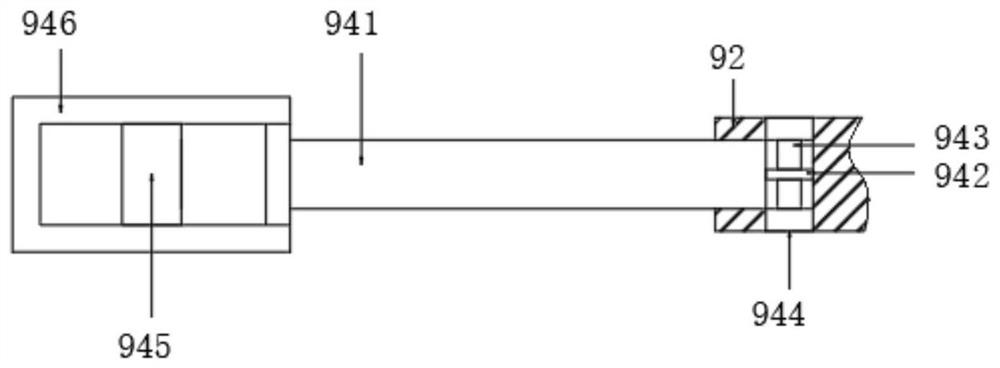

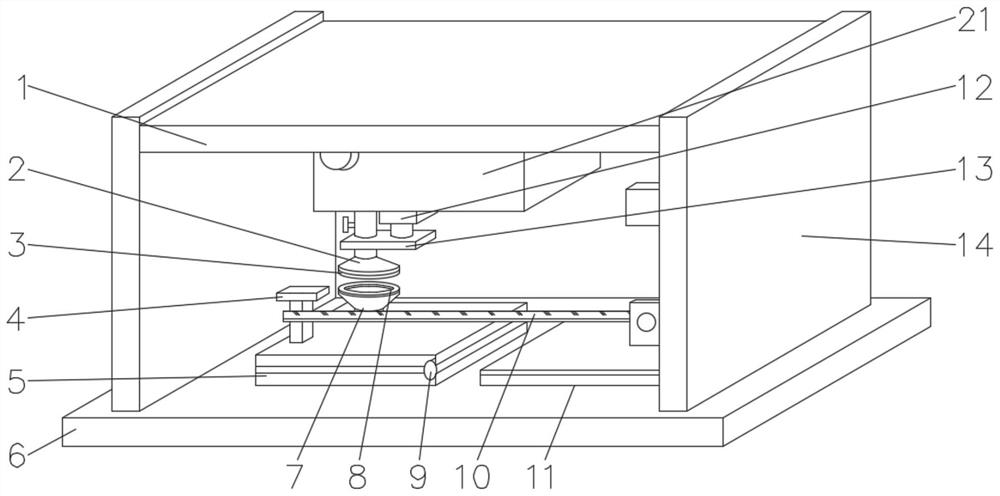

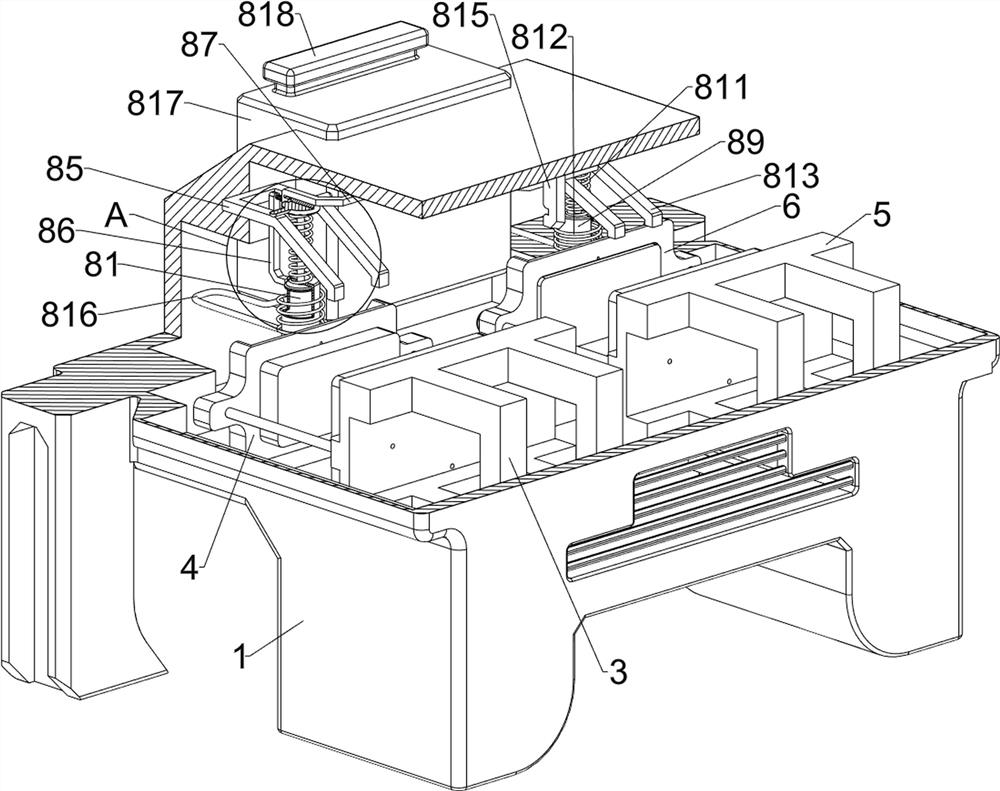

Injection molding machine with safety device

ActiveCN109262961ARange of activitiesAchieve safe ejectionInjection molding machineMechanical engineering

The invention discloses an injection molding machine with a safety device. The injection molding machine comprises a metal case, wherein support feet are arranged at four end corners of the bottom surface of the metal case; a rubber suction disc is arranged at the bottom end of each support foot; a hydraulic machine box is arranged above the metal case; a metal butting post is arranged at one sideof the hydraulic machine box; a safe material unloading device is arranged at the other side of the metal butting post; a cargo discharging cabin is arranged under the safe material unloading device;a buffer sponge pad is arranged at the inner wall of the cargo discharging cabin; a discharging opening is formed in the bottom end of the cargo discharging cabin; the discharging opening penetratesthrough the metal case and extends to the front end surface of the metal case; a female mold is arranged at the other side of the safe material unloading device; a cooling liquid pipeline is arrangedinside the female mold. A certain safe position limiting mechanism is installed; when a hydraulic rod is placed for a long time, the hydraulic rod exceeds the displacement, and accidents occur; the safety of the device is effectively improved.

Owner:TAIZHOU BOTAI ELECTRONICS

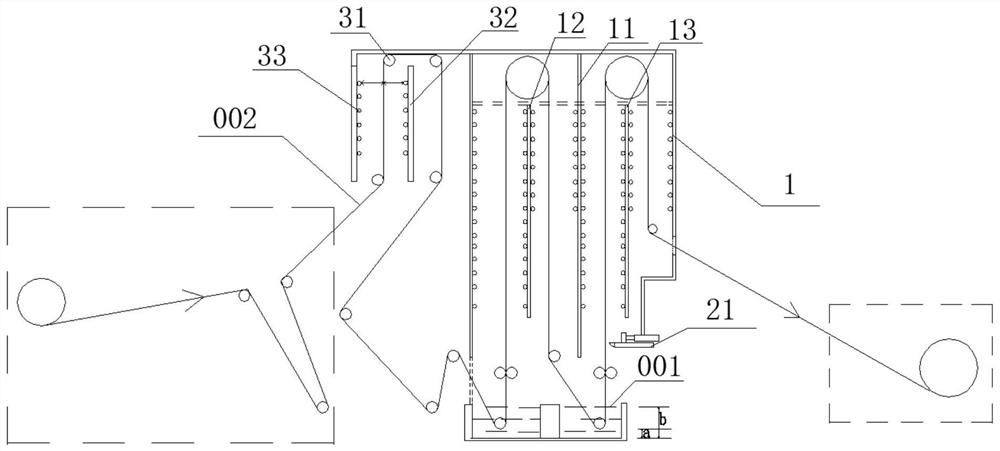

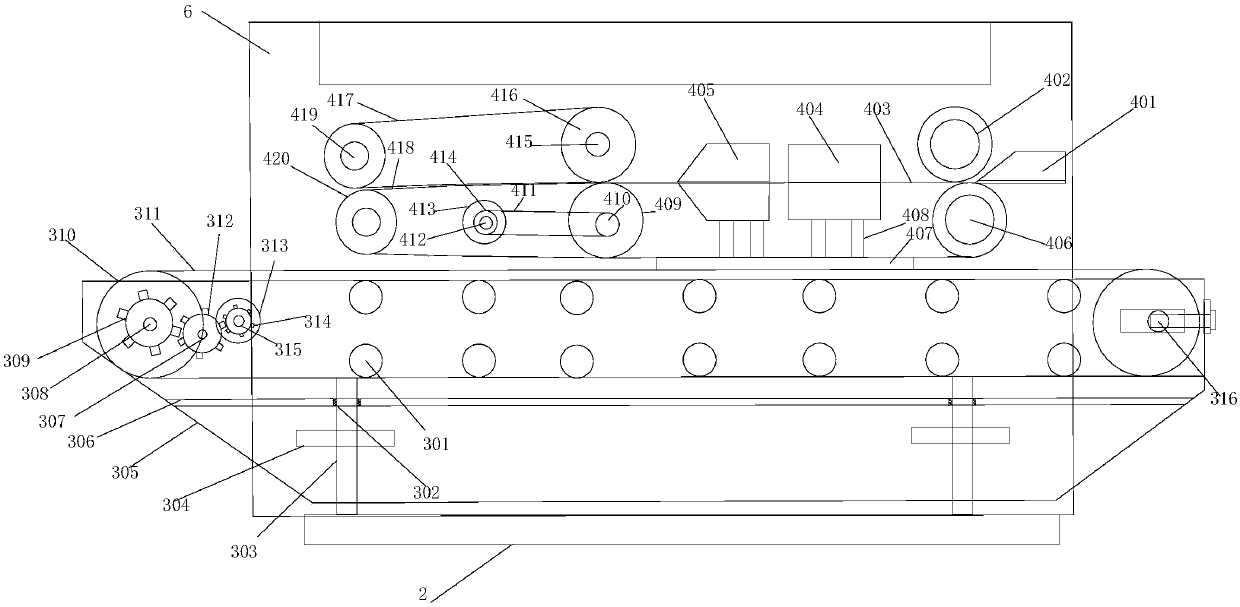

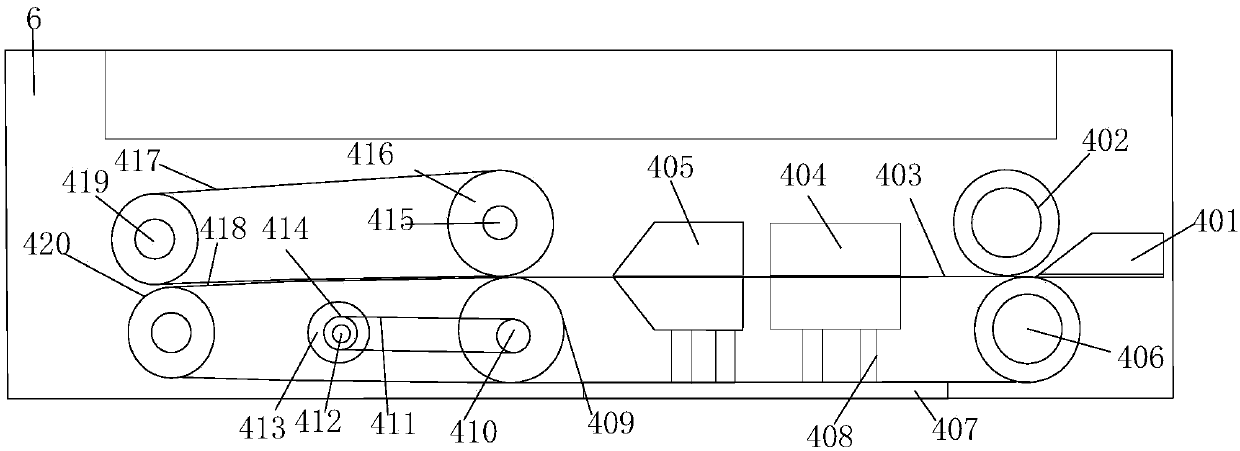

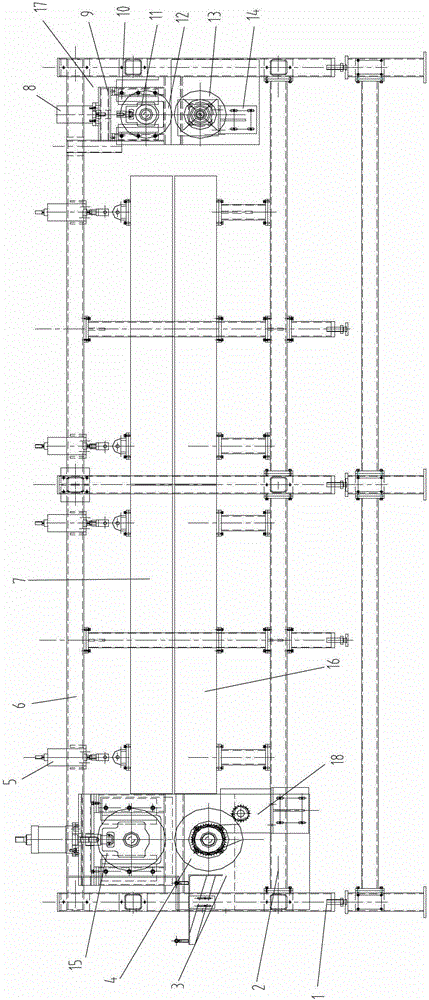

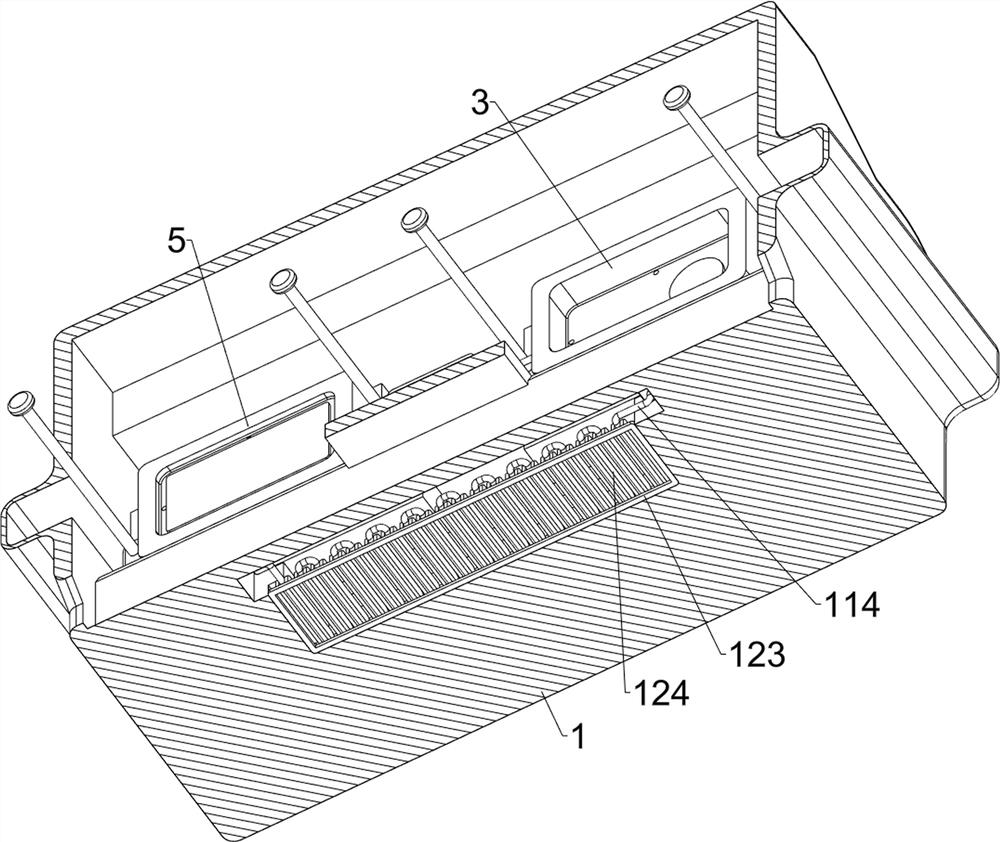

Vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator

PendingCN111790566AConvenient for advertisingImprove satisfactionLiquid surface applicatorsCoatingsPolyesterPolymer science

The invention discloses a vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator, belongs to the technical field of impregnation, and particularly relates to the vertical two-impregnation one-scraping polyester-mixed cotton cloth impregnator. The impregnator comprises a machine base, wherein a first impregnation mechanism used for impregnating polyester-mixed cotton cloth,a second impregnation mechanism used for adding rubber to the polyester-mixed cotton cloth and a rubber scraping mechanism used for scraping rubber cement on one side of the polyester-mixed cotton cloth are arranged on the machine base, the impregnator further comprises a traction mechanism used for conveying the polyester-mixed cotton cloth to the first impregnation mechanism and a winding device used for collecting the polyester-mixed cotton cloth discharged from the second impregnation mechanism, and the rubber scraping mechanism comprises a scraper fixed to the machine base through a moving device. The impregnator is simple in structure and high in practicability.

Owner:台州捷豹橡胶有限公司

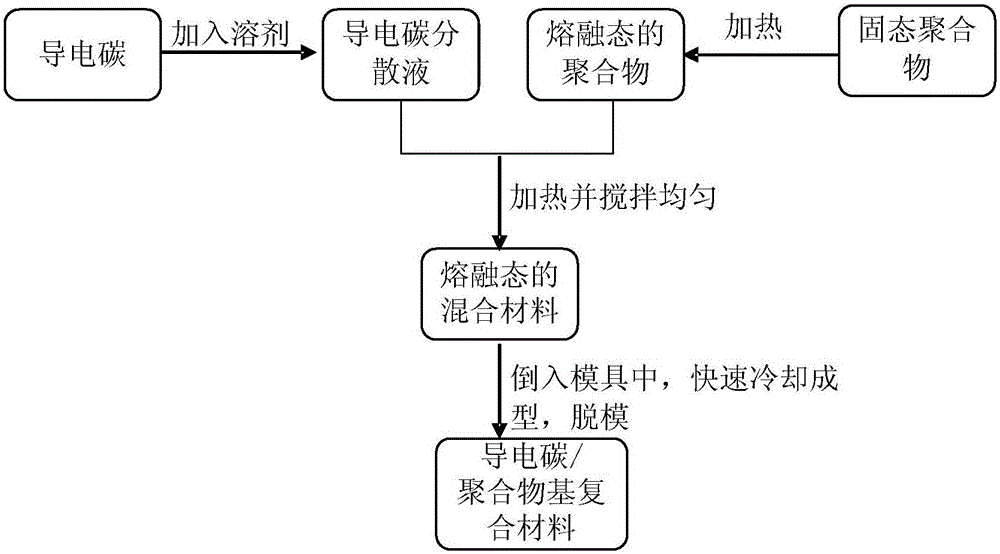

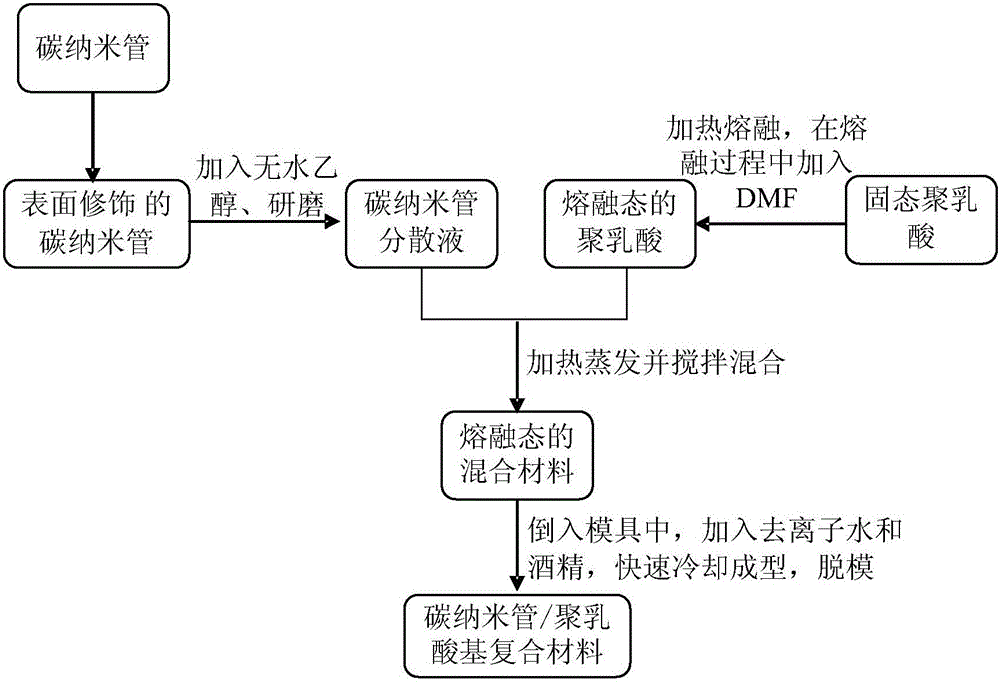

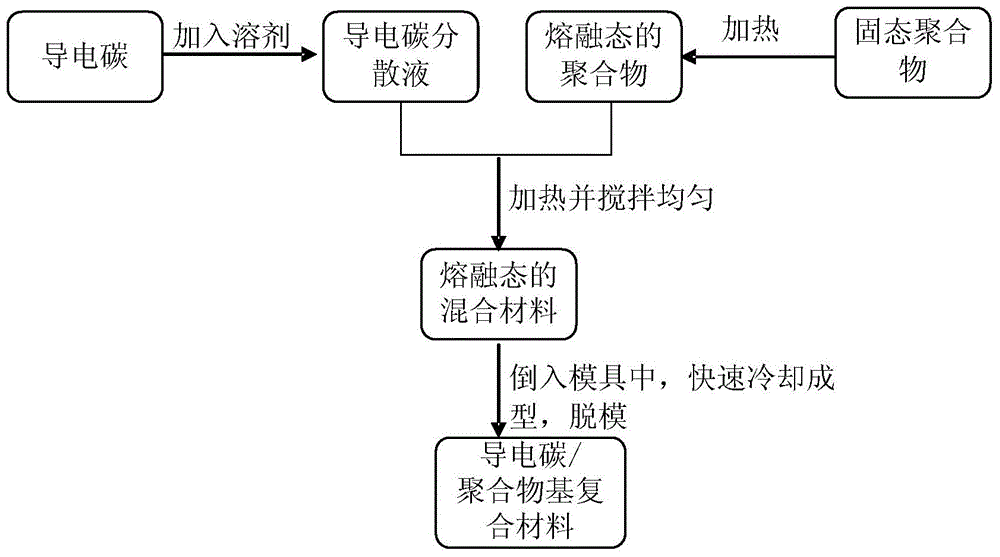

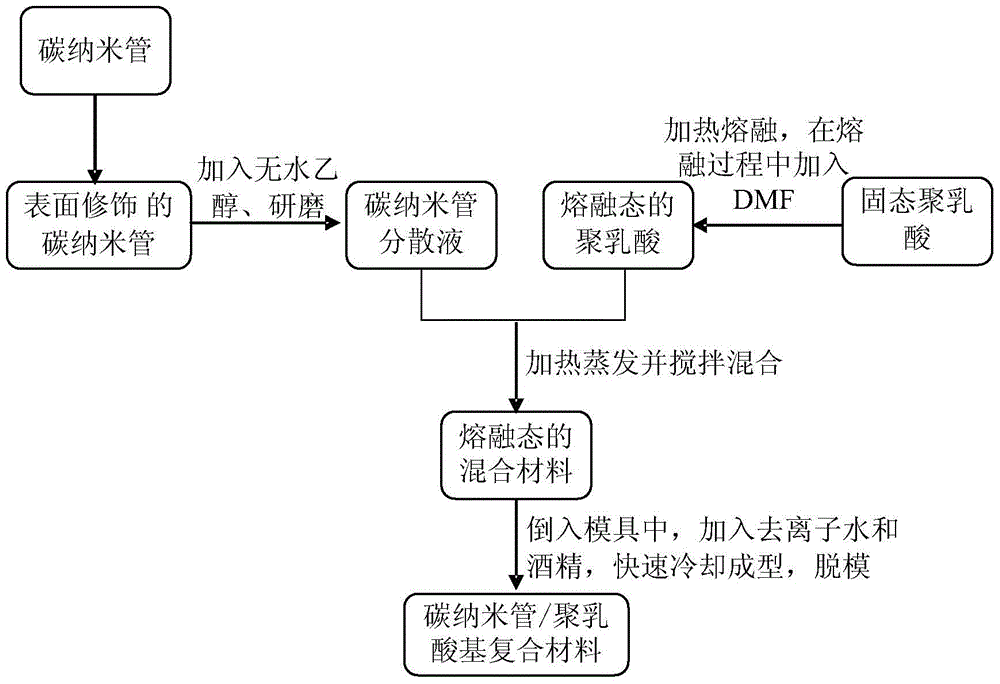

Conductive carbon/polymer based composite material and preparation method thereof

The invention provides a conductive carbon / polymer based composite material comprising conductive carbon and a polymer, wherein the weight of the conductive carbon accounts for 1-45% of that of the polymer. The invention also provides a preparation method of the composite material. The preparation method comprises the following steps: (1) dispersing the conductive carbon in a solvent to obtain conductive carbon dispersion; (2) heating a solid polymer to obtain molten dispersion; (3) adding the conductive carbon dispersion into the molten dispersion, heating and stirring uniformly to remove the solvent so as to obtain a molten mixed material, wherein the weight of the conductive carbon accounts for 1-45% of that of the solid polymer, and the heating temperature is 0-10 DEG C higher than the melting temperature of the solid polymer; and (4) pouring the molten mixed material into a mold, cooling quickly for molding, and demolding to prepare the conductive carbon / polymer based composite material. By adopting the preparation method provided by the invention, the problems of the prior art are solved; and the preparation method is simple in process, relatively low in cost and suitable for industrial production.

Owner:SHENZHEN DYNANONIC +1

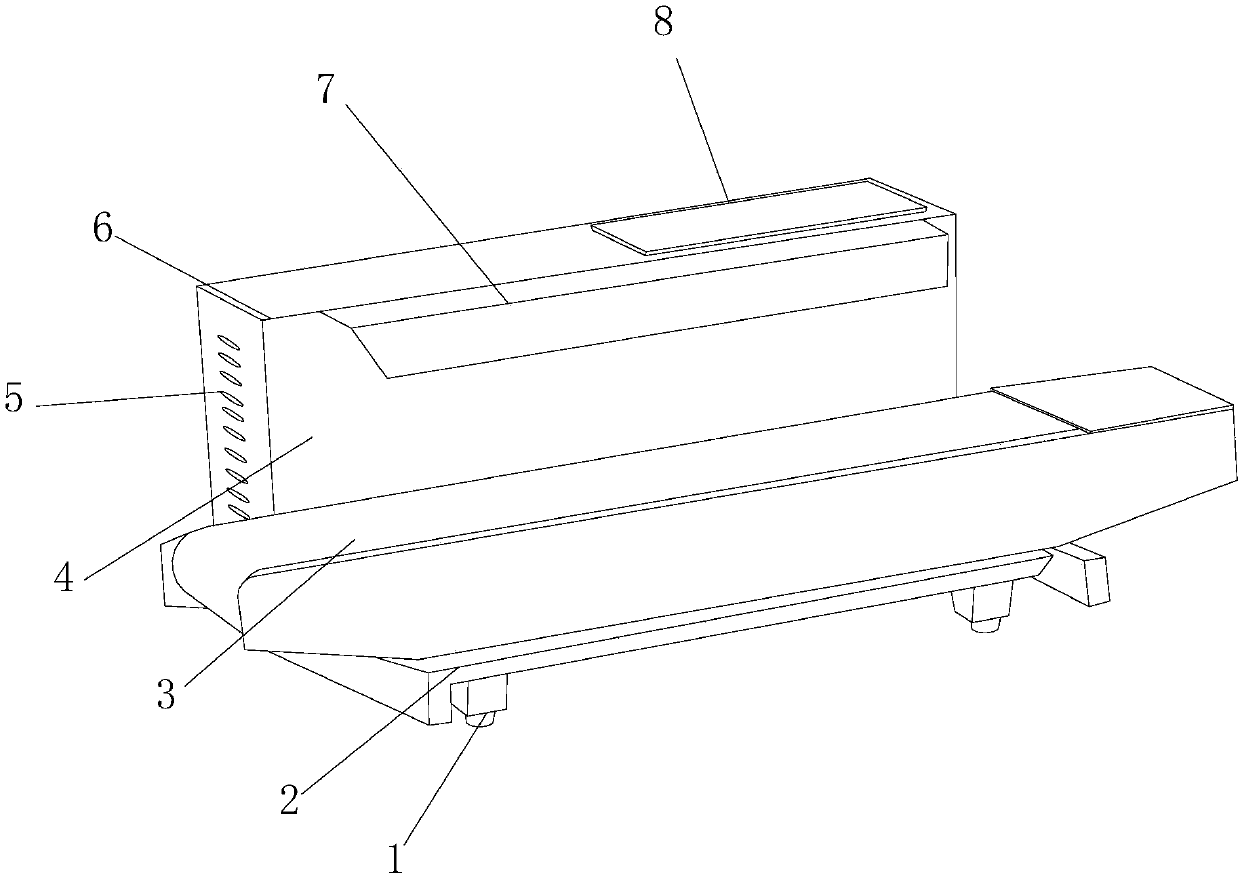

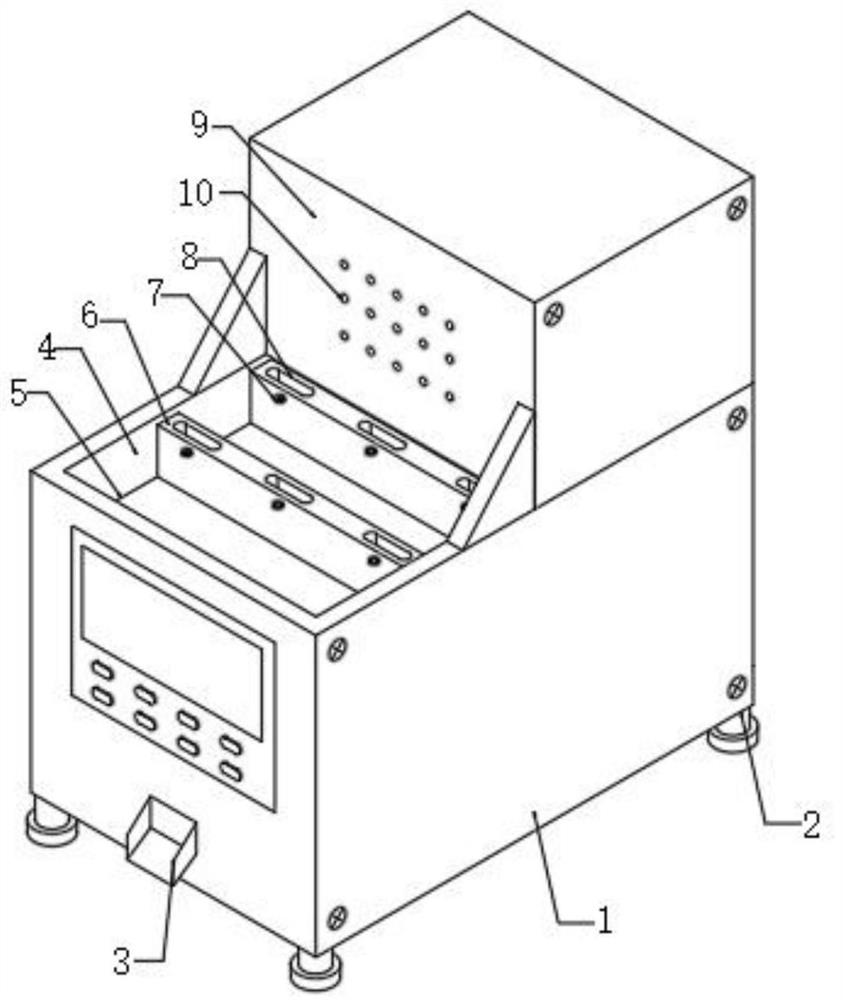

Sealing machine for toy packaging bag

InactiveCN107758001ARapid Cooling FormingChange heightWrapper twisting/gatheringPackaging machinesAssembly lineEngineering

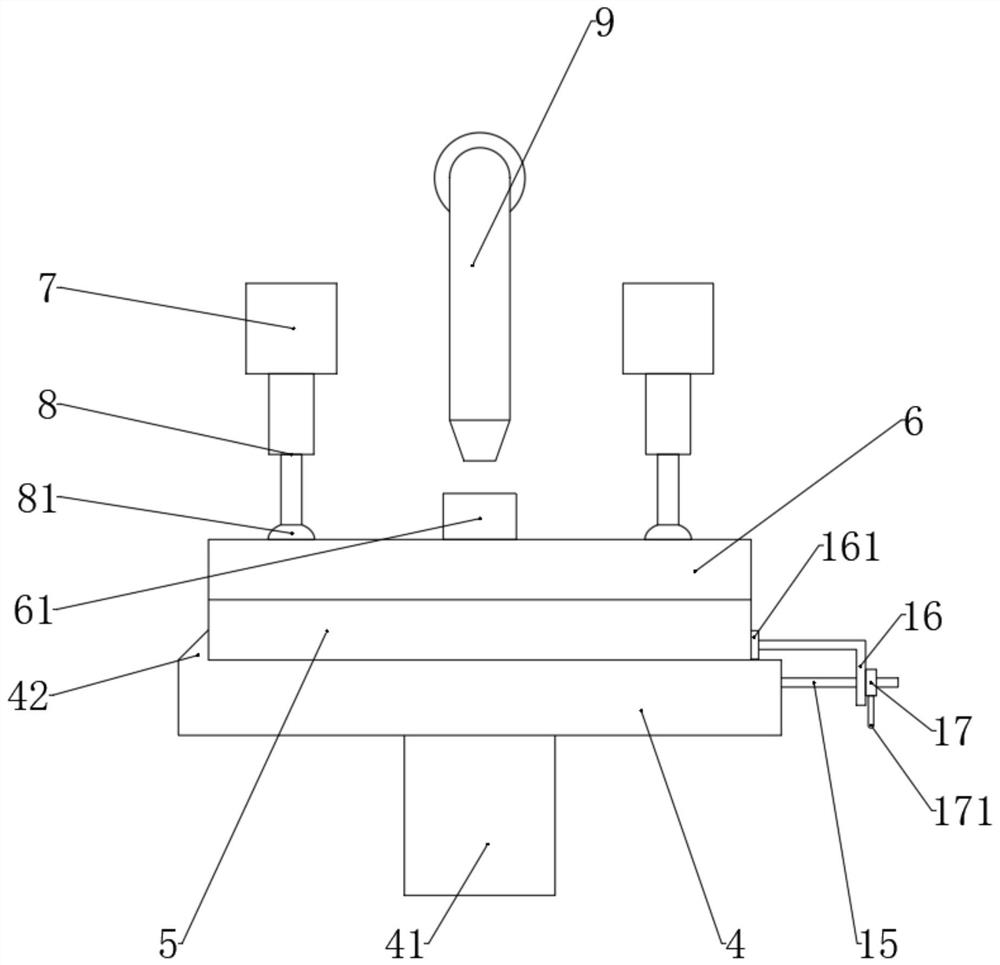

The invention discloses a sealing machine for a toy packaging bag. The machine structurally comprises supporting legs, a base, a conveying device, a sealing linkage device, heat dissipation ports, a machine body, a protective cover and a control panel, wherein the bottom of the control panel is welded to the right side of the top of the machine body; the bottom of the machine body is vertically connected with the rear half part of the top of the base; the bottom of the conveying device is vertically connected with the front half part of the top of the base; the supporting legs are sequentiallyconnected into a rectangular structure and are fixed to the bottom of the base; the heat dissipation ports are sequentially arranged on the left side of the machine body from top to bottom at equal intervals; and the back of the protective cover is welded to the front side of the top end of the machine body. According to the sealing machine for the toy packaging bag, the sealing linkage device isadditionally arranged, thus rapid sealing and cooling forming can be carried out, and assembly line type production can be achieved; and meanwhile, the conveying device is additionally arranged, theheight of the conveying device can be quickly adjusted according to actual situations, and the production efficiency is improved.

Owner:费军

Rotary stripping type injection mold

Owner:广东伟力环保实业有限公司

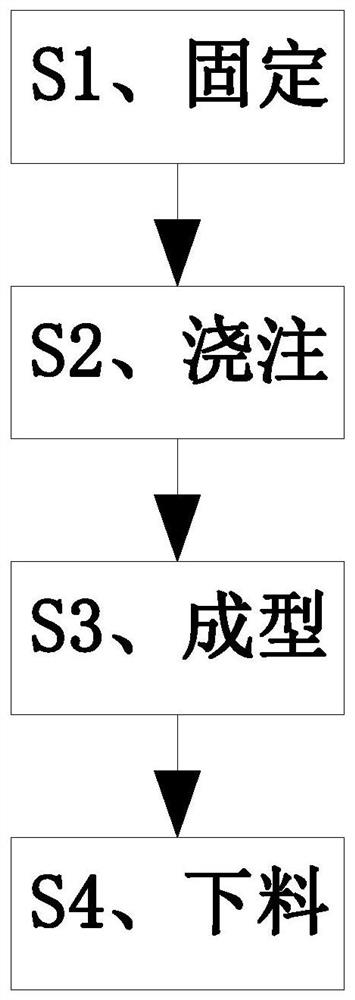

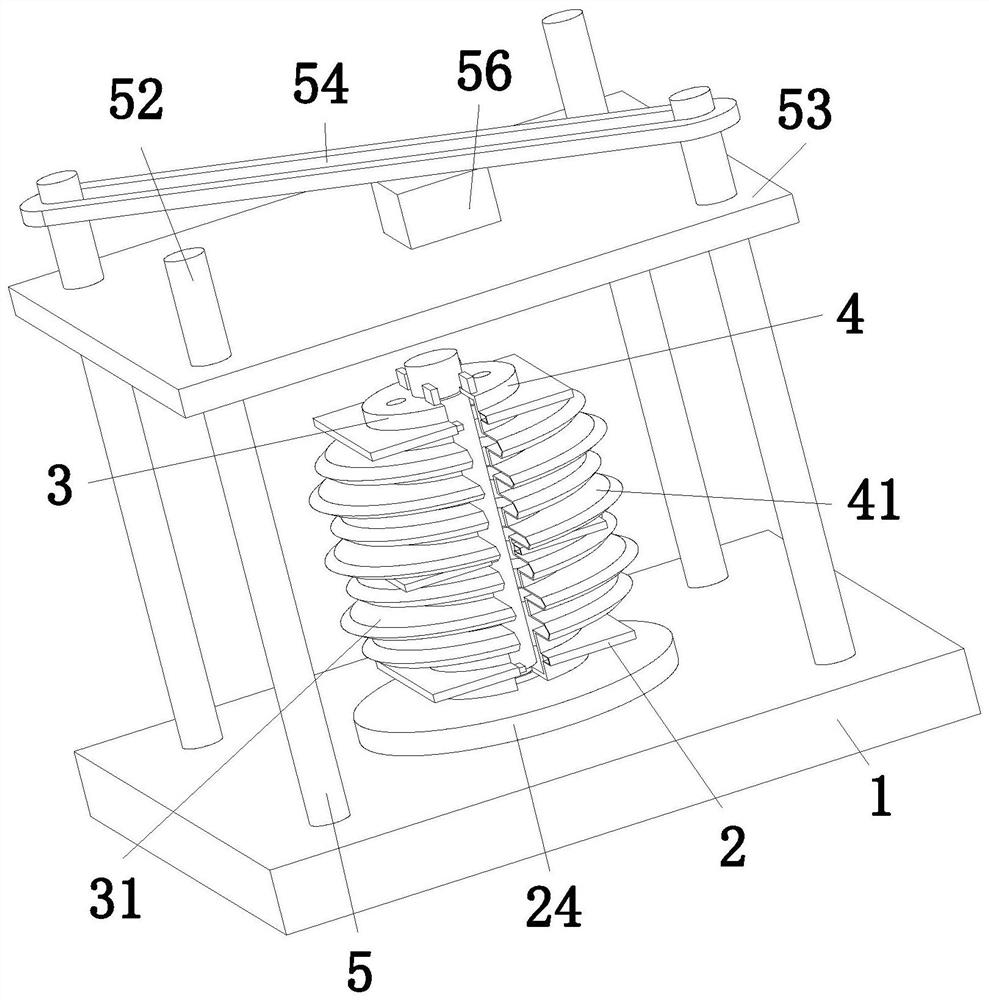

Epoxy resin electric power insulator casting molding method

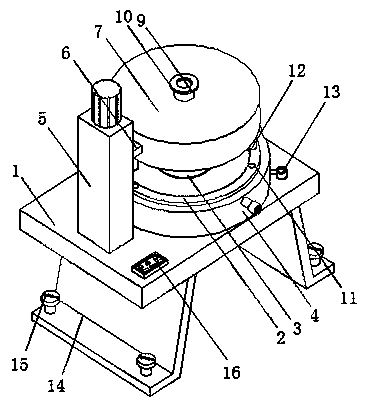

The invention relates to an epoxy resin electric power insulator casting molding method, which comprises a workbench, a fixing device, a first mold, a second mold and a moving device, and is characterized in that the fixing device comprises a placing groove, a driving motor, a circular rod, an annular plate, an annular clamping groove and a clamping frame; through cooperation of the workbench, the fixing device, the first mold, the second mold and the moving device, firstly, the first mold and the second mold of the epoxy resin electric power insulator needing to be subjected to casting molding are rapidly closed through the fixing device, so that traditional tedious mold closing and demolding are avoided, and the mechanical adaptability and working efficiency are improved; and the mold cavity is poured through the moving device, and the molten resin material can uniformly flow to the whole edge structure of the mold cavity through the matching of the fixing device, so that the qualified rate of the machine is improved.

Owner:谭宗尧

Efficient cooling type plastic mold

PendingCN110171105AImprove cooling effectHigh-efficiency cooling plastic mold, through the cooling of the settingMaterials scienceRaw material

The invention discloses an efficient cooling type plastic mold. The efficient cooling type plastic mold comprises a lower mold plate, wherein a lower mold body is fixedly installed on the outer surface of the upper end of the lower mold plate, a lower mold cavity is formed in the inner surface of the lower mold body, and a jacking motor is arranged in the middle of the interior of the lower mold plate; fixing bases are welded to the outer surfaces of the two sides of the jacking motor, and the jacking motor is fixedly connected to the lower mold plate through the fixing bases; and an ejectioncolumn penetrates through the interior of the lower mold plate, a cooling box is fixedly arranged at the position, close to one side, of the outer surface of the upper end of the lower mold plate, anda water delivery tank is welded to the position, close to the other side, of the outer surface of the upper end of the lower mold plate. According to the efficient cooling type plastic mold, the injected raw materials can be better and rapidly cooled, and the friction among mold parts is reduced, the service life of the mold is prolonged, moreover, the formed raw materials can be better ejected out, and the situation that the formed raw materials are damaged in the ejection process is effectively avoided.

Owner:东莞市竣詹机械科技有限公司

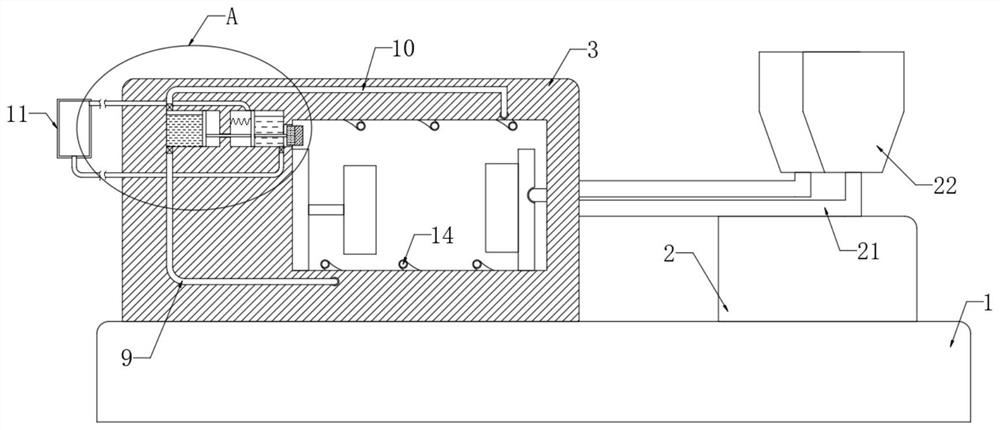

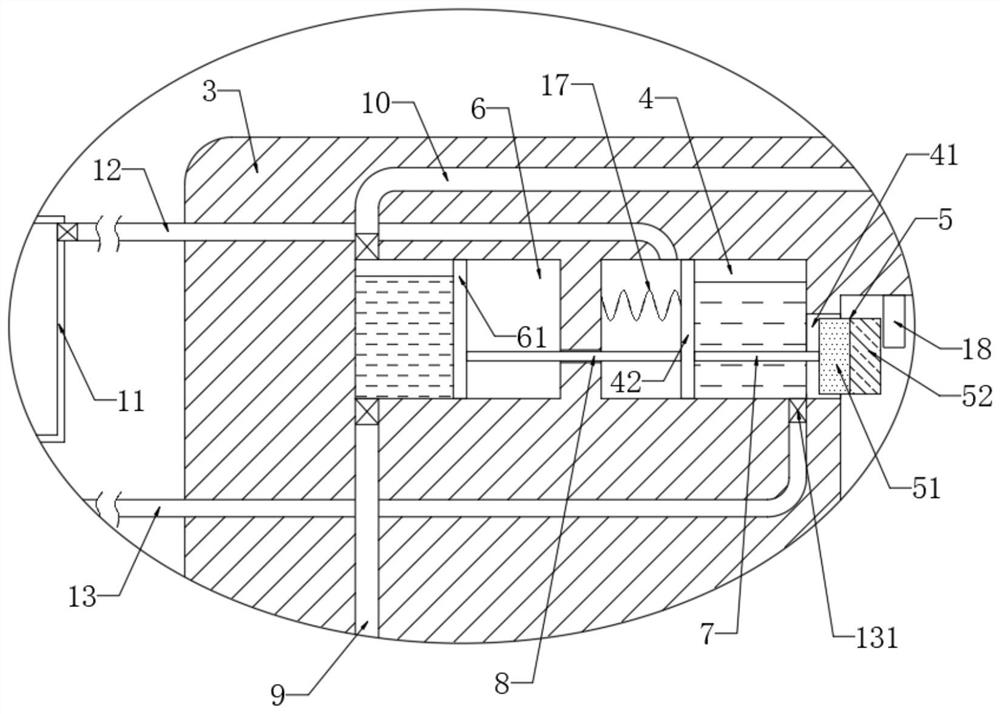

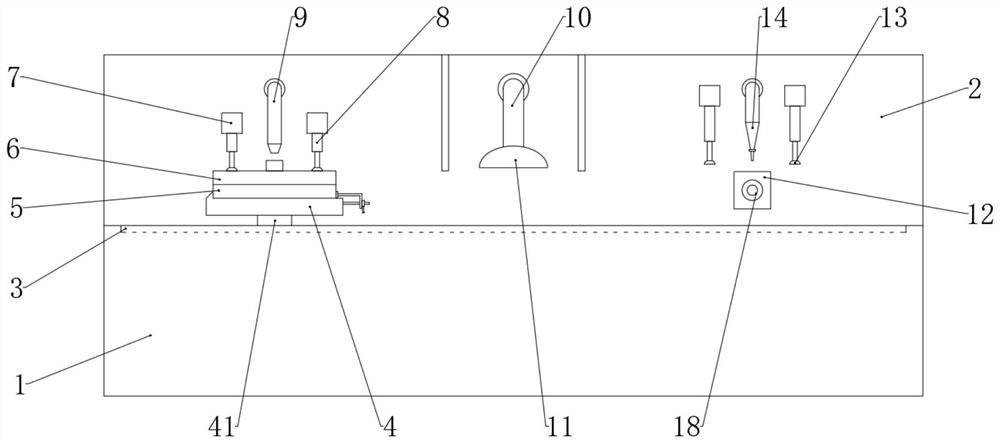

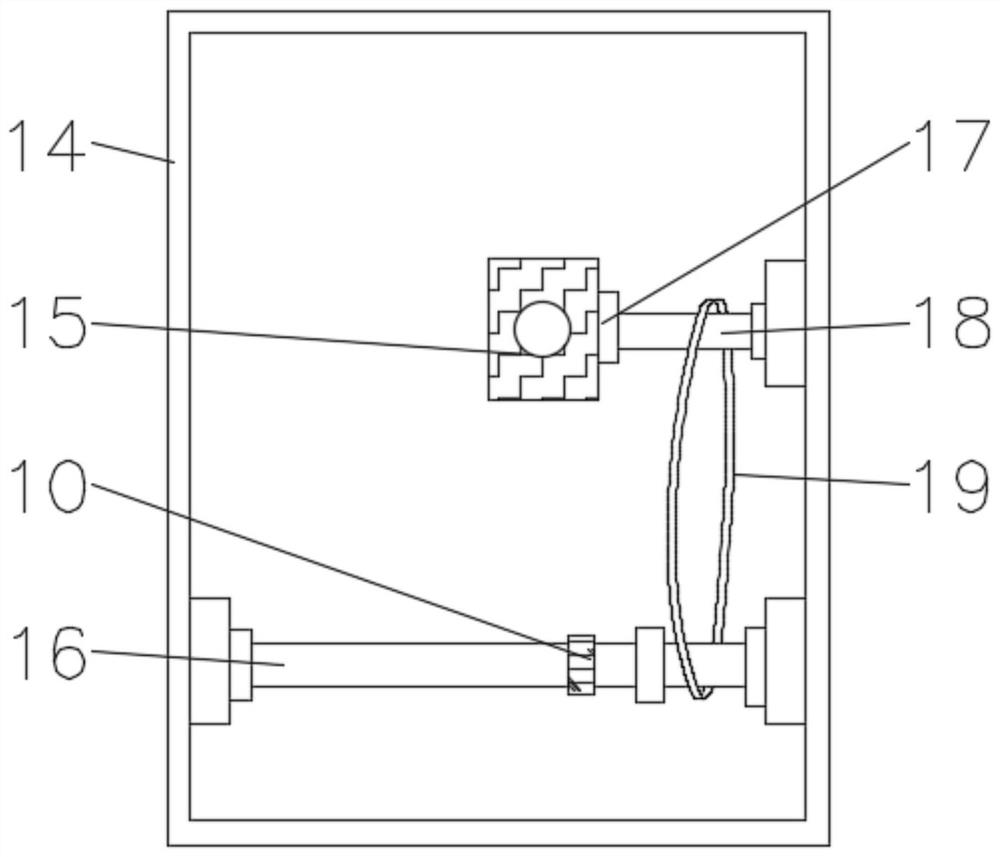

Double-shot molding technology based on self-cooling type injection molding machine

The invention discloses a double-shot molding technology based on a self-cooling type injection molding machine. The double-shot molding technology based on the self-cooling type injection molding machine comprises the following steps of S1, material placement; S2, material conveying operation; S3, material injection; S4, cooling forming operation, specifically, the internal heat is continuously emitted by a cooling water channel in the double-shot injection molding machine, and molten raw materials in a mold are gradually cooled and formed; and S5, material taking operation, specifically, theS3 and the S4 continues to be carried out. The double-shot injection molding machine used in a double-shot molding forming method comprises a base. An injection molding facility is installed at the upper end of the base, and an outer cover body is further installed at the upper end of the base. A forming mechanism is arranged in the outer cover body, and a first liquid storage groove and a secondliquid storage groove are formed in the side wall of the outer cover body. According to the double-shot molding technology based on the self-cooling type injection molding machine, a driving device can operate through a large amount of heat generated in the injection molding process, and therefore cooling liquid in the second liquid storage groove can circularly flow in condensation pipes, a large amount of electric energy consumption can be reduced, rapid cooling forming operation of the molten raw materials can be promoted, and the processing efficiency of double-shot molding products is improved.

Owner:徐青

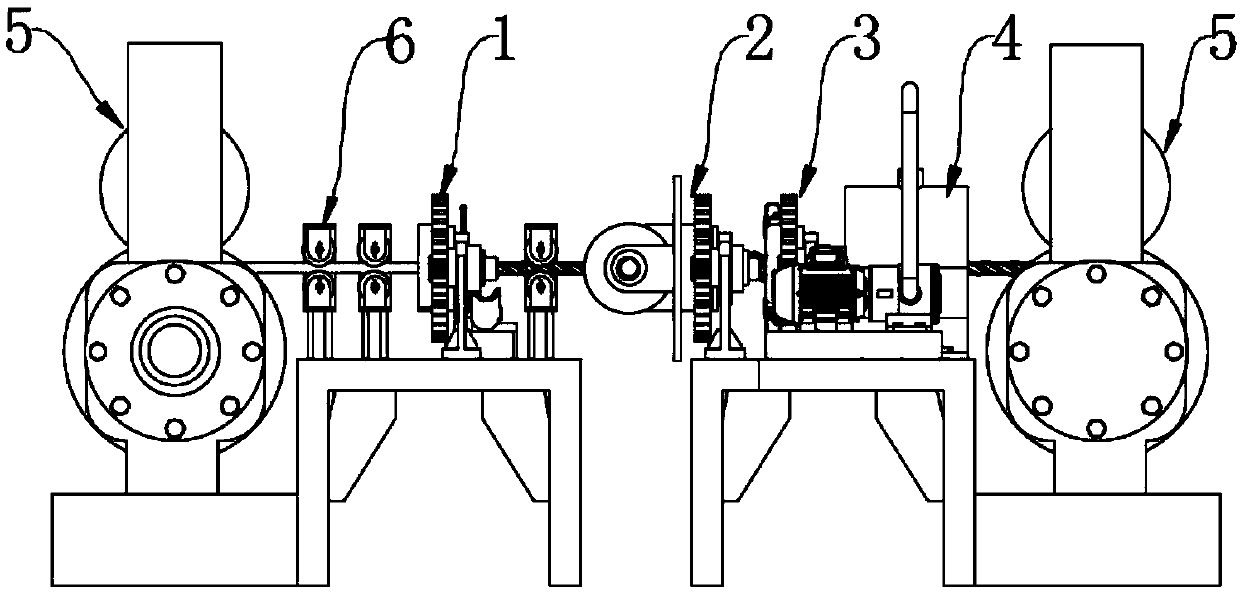

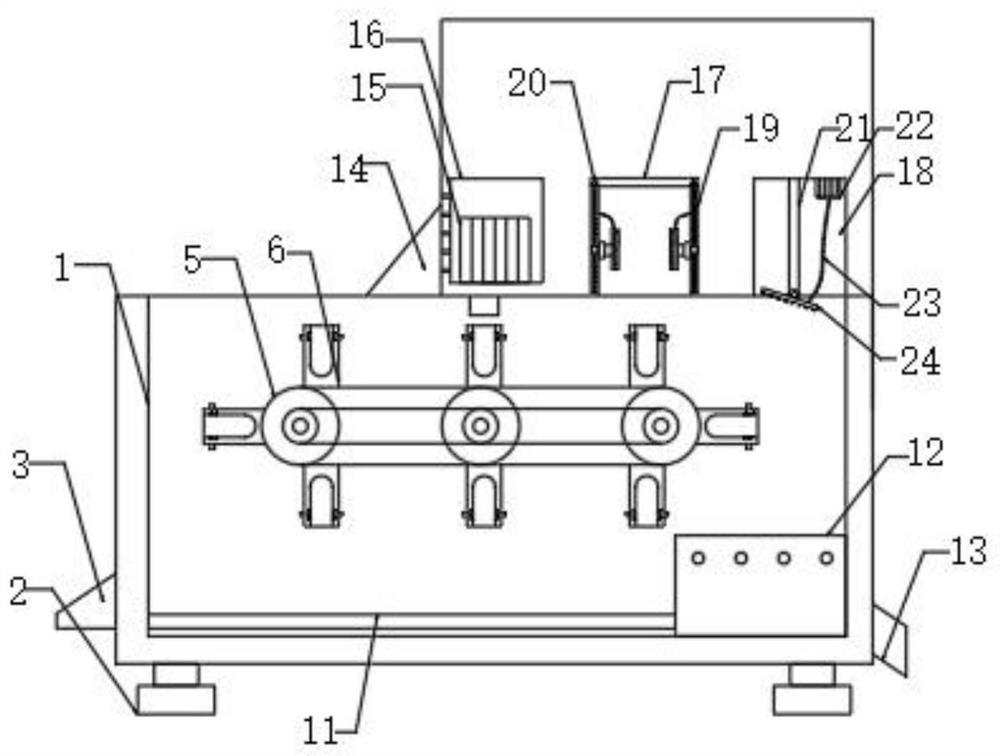

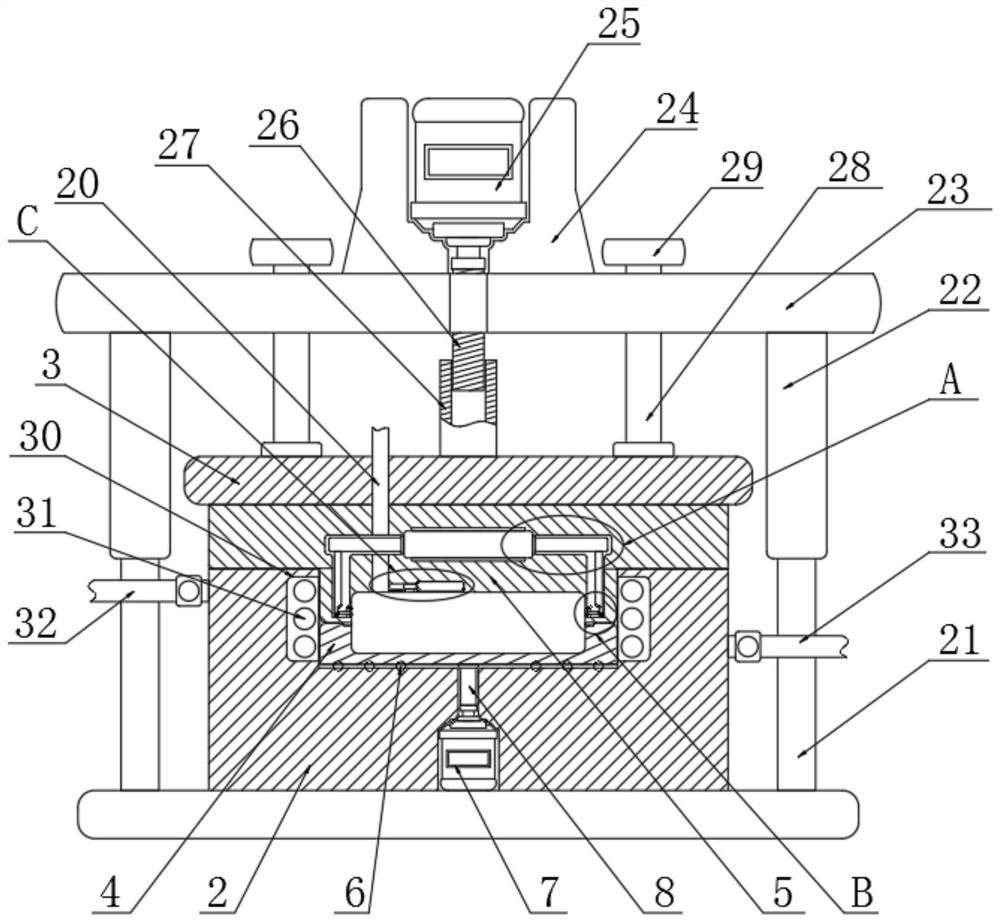

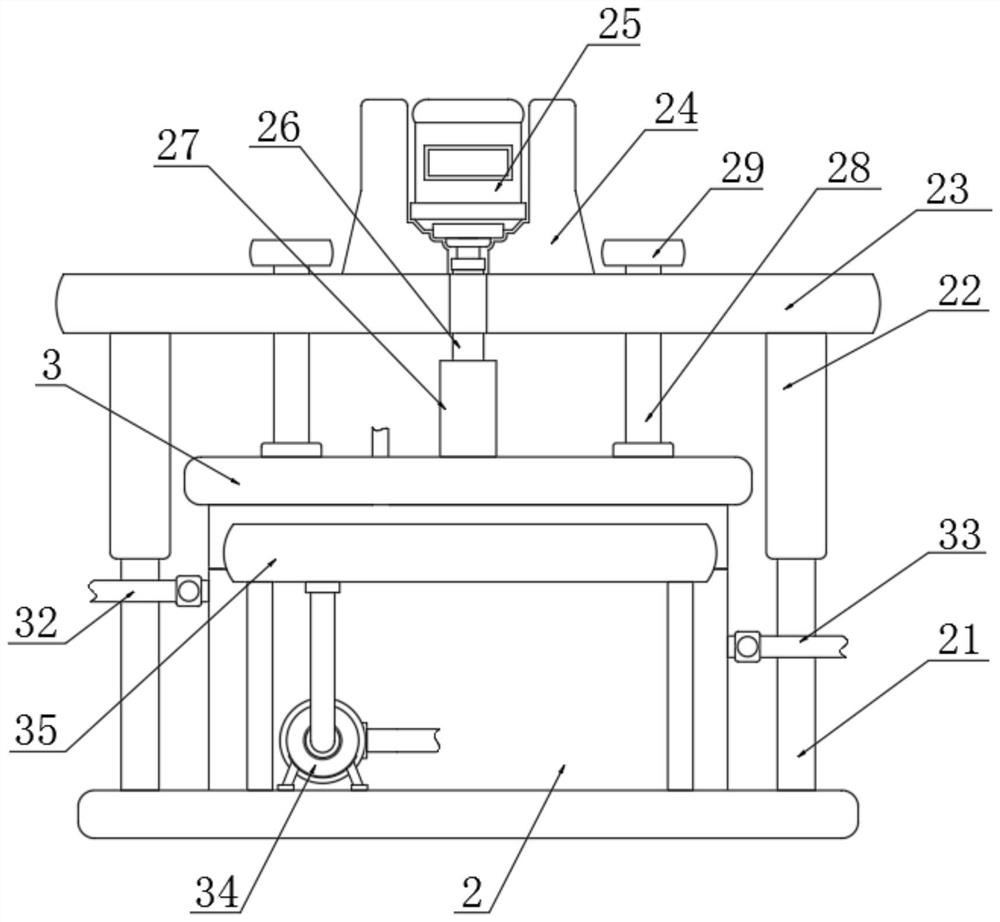

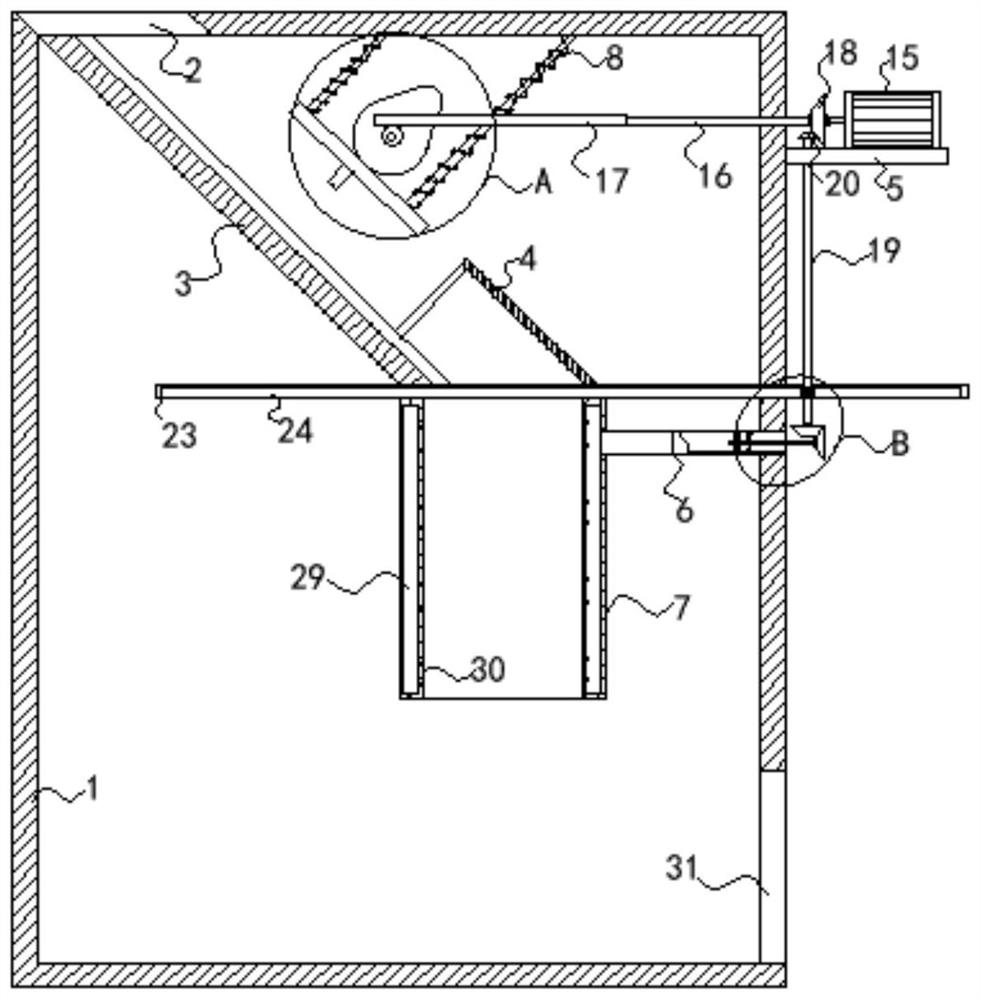

Steel bridge asphalt pavement shear fatigue detection equipment

ActiveCN111735689AEasy laying workFacilitate experimental workMaterial strength using steady shearing forcesTransmission beltClassical mechanics

The invention discloses steel bridge asphalt pavement shear fatigue detection equipment. The equipment comprises a device shell, a clamping plate, a heat dissipation frame, rolling wheels and supporting rods; and a worm is rotationally connected into the device shell, a first driving motor is fixedly welded to the heat dissipation frame, the output end of the first driving motor is connected witha transmission belt in a meshed mode, the output end of the first driving motor is connected with a cooling fan through a shaft, a storage box is connected into the heat dissipation frame through screws, a small water pump is connected to the storage box through a flange, and a cooling pipe is connected to the small water pump through bolts. The steel bridge asphalt pavement shear fatigue detection equipment is provided with the heat dissipation frame, under the action of the small water pump, cooling liquid in the storage box can be conveyed into a cooling pipe, air around a cooling fan can be rapidly cooled, an asphalt sample can be rapidly and effectively cooled and formed, and the use efficiency of the equipment is effectively improved.

Owner:安徽荣港建筑工程有限公司

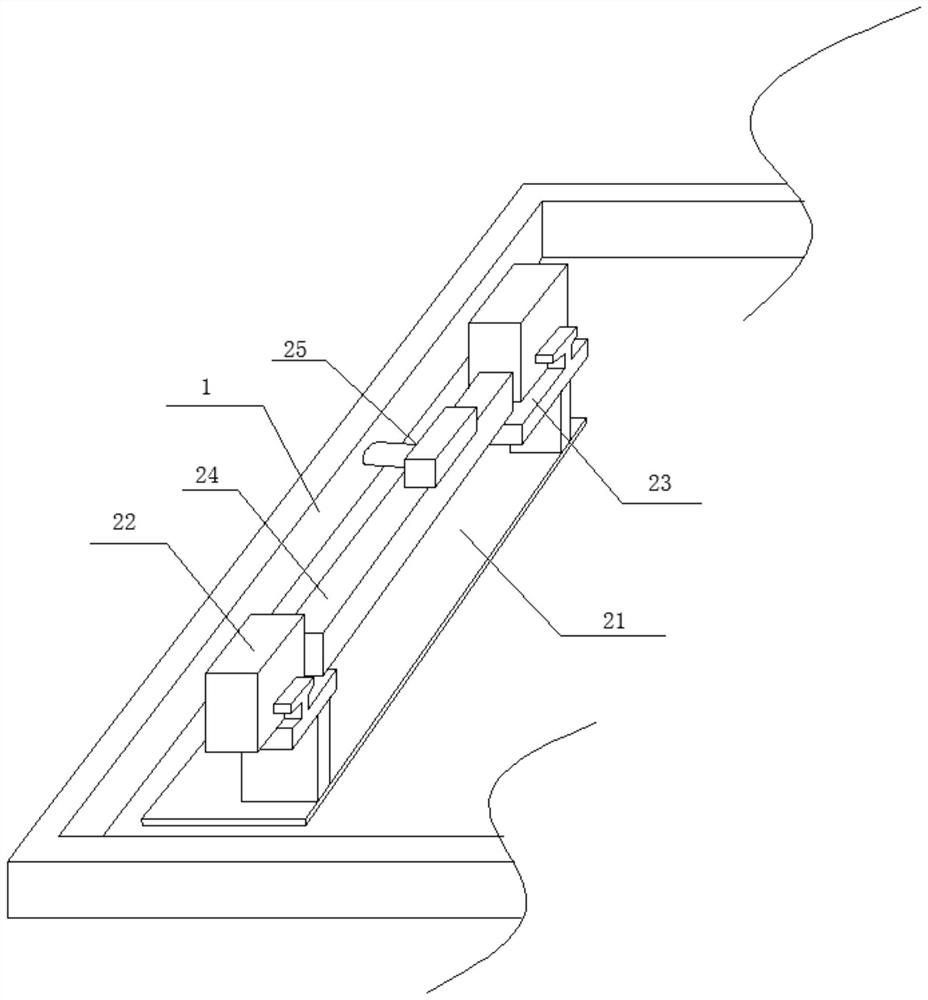

Manufacturing process of embedded metal strip type cable

ActiveCN109637746ALabor savingIncrease productivityApparatus for heat treatmentFormation of corrugations on cables/conductorsMetal stripsLinear motion

The invention discloses a manufacturing process of an embedded metal strip type cable. The process comprises the following steps of: uniformly coating a rubber layer on a bearing cable to form the cable; the released cable entering a rolling groove device; four high-temperature rolling wheel mechanisms are obliquely arranged in the rolling groove device; through uniform linear motion of the cableand revolution motion of the two groups of rolling wheel mechanisms; Two groups of spiral grooves are processed on the cable, when the metal clamping groove strip is close to the spiral groove on thecable, the metal clamping groove strip and the bottom surface of the spiral groove are coated with adhesive by the adhesive coating device and the adhesive coating device, and the adhesive is quicklydried by the cable embedded with the metal clamping groove strip through the drying device. According to the manufacturing process, the spiral guide rail groove and the spiral groove can be automatically formed in the outer surface of the cable sleeve in a rolling mode, the metal clamping groove strip is automatically glued and embedded into the spiral groove, labor is saved, and production efficiency is improved.

Owner:金华市正通线缆有限公司

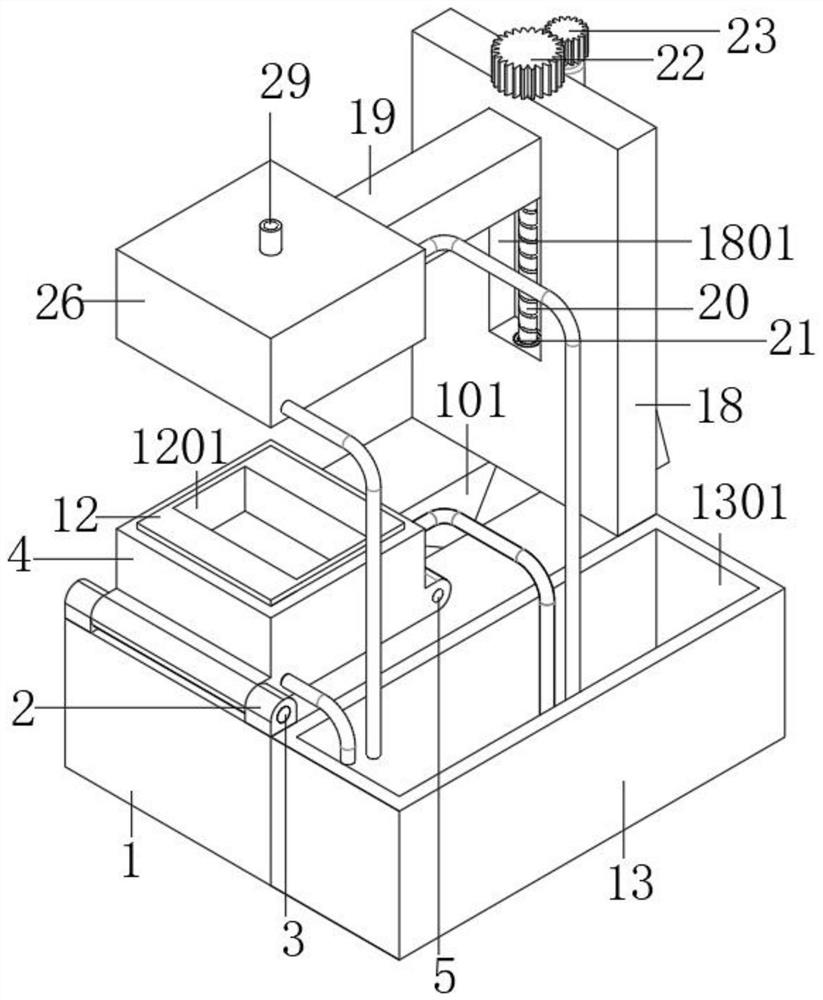

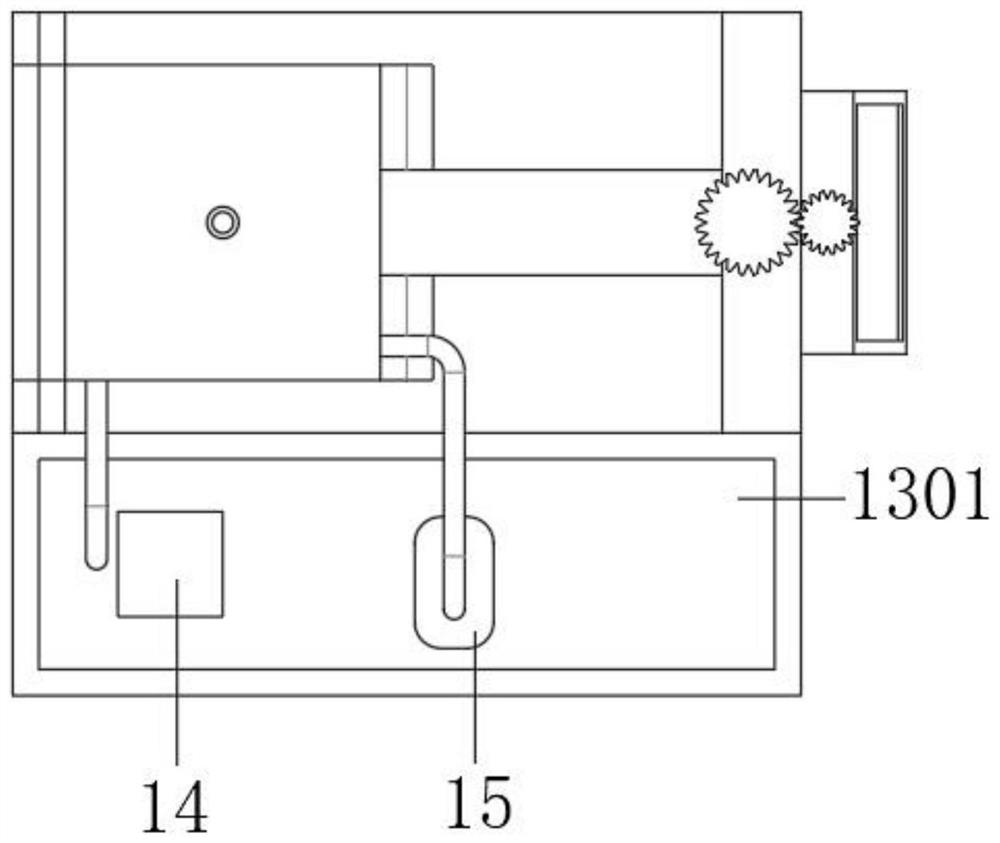

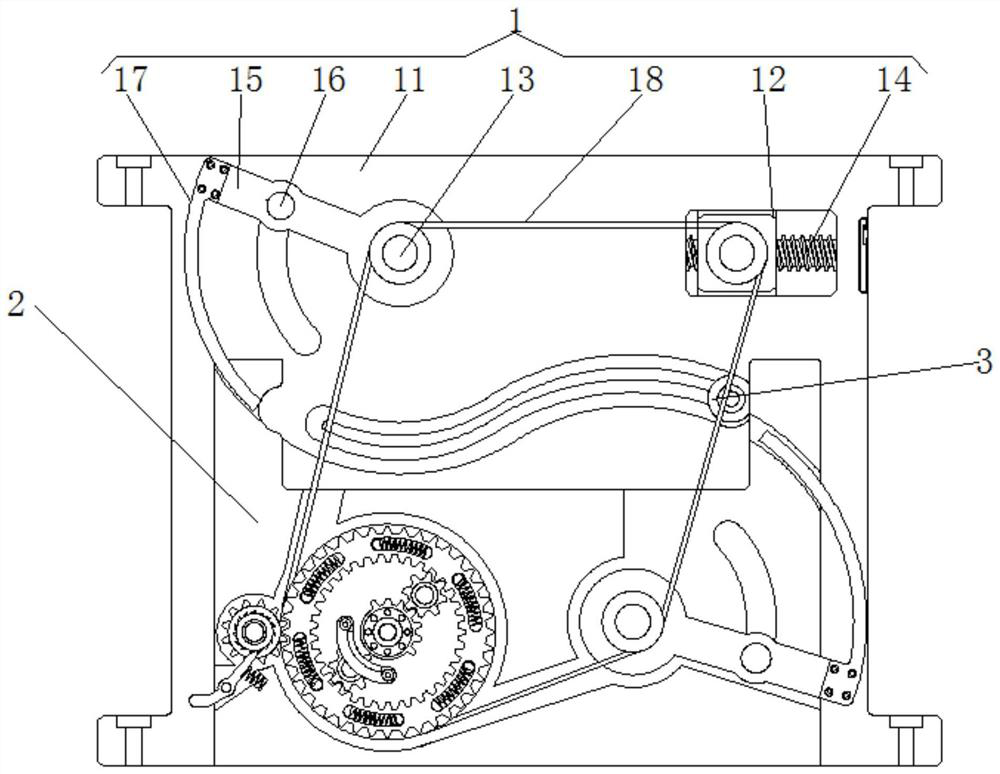

Continuous vacuum packaging machine

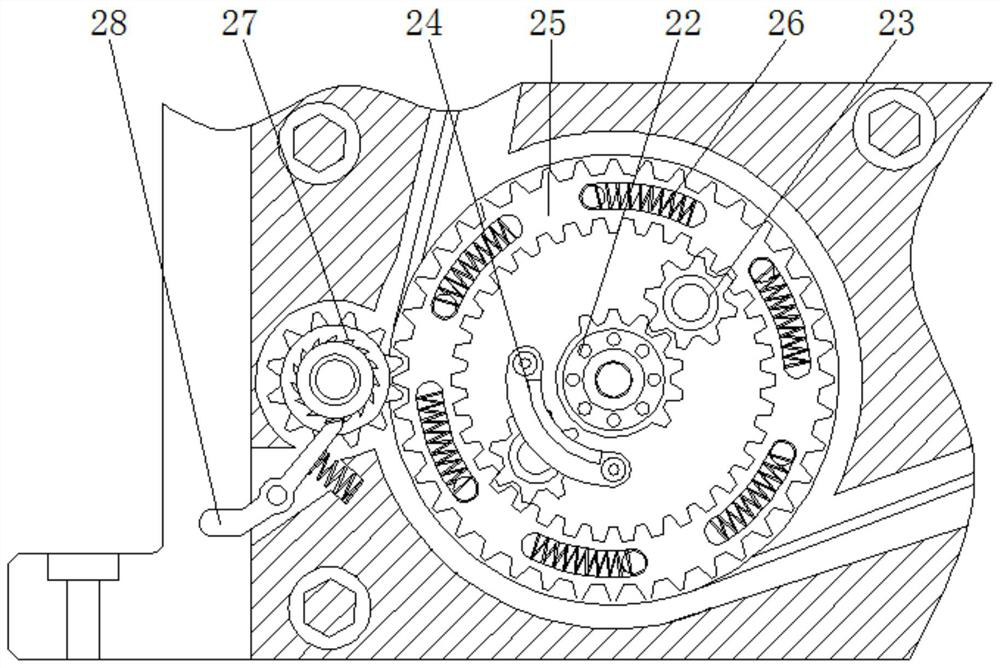

InactiveCN112498861AQuality assuranceGuaranteed tightnessConveyorsPackaging by pressurising/gasifyingGear wheelAir pump

The invention discloses a continuous vacuum packaging machine which comprises a base, wherein a mounting slot is formed in the top end of the base, a plurality of belt wheels are rotatably connected to the slot walls at the two sides of the mounting slot through embedded bearings, a gear is fixedly mounted at one end of each belt wheel, and a chain is in transmission connection among the gears. Agas tightness detector is mounted at the bottom of the mounting slot, so that gas tightness of vacuum-packaged materials is detected through the gas tightness detector, the quality of packaged products is effectively guaranteed, and materials which are not packaged completely are conveyed out of the mounting slot through a conveyor belt, and thus, secondary packaging is facilitated, the sealing performance and quality of packaged products are effectively guaranteed; a fixed plate is mounted at the bottom end of a fixed rod and a spray head mounted at the bottom end of the fixed plate communicates with a gas pump, so that a hot-melting sealing portion is cooled, rapid cooling forming of the hot-melting sealing portion is facilitated, and the problem that product quality is affected as the sealing portion deforms or opens in the falling process due to the fact that hot melting is not cooled is avoided.

Owner:李贵

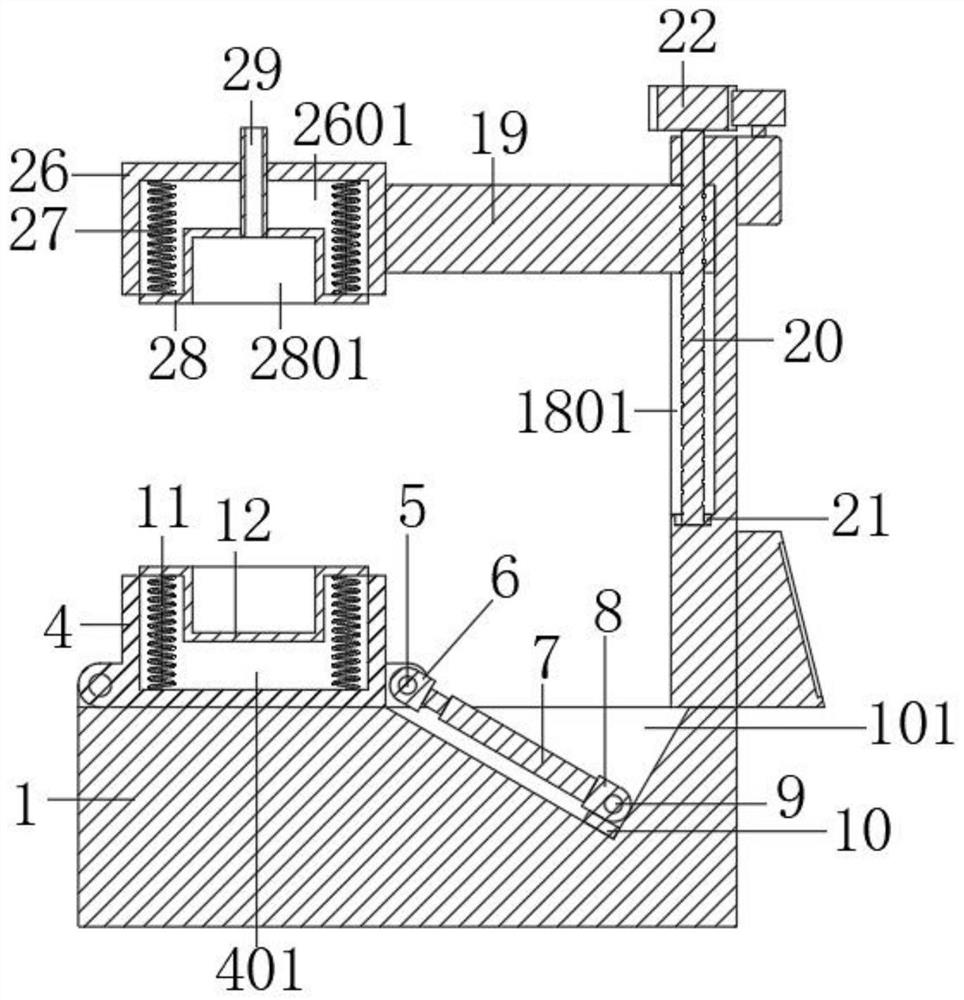

Rapid forming die for machining parts with holes

The invention relates to the technical field of dies, in particular to a rapid forming die for machining parts with holes. The die comprises a base platform, a vertical plate and a die set, the vertical plate is fixed to the rear side of the top of the base platform, a base plate is slidably mounted on the front side of the top of the base platform, and the die set comprises a lower die and an upper die. A clamping device for fixing the lower die is installed on the right side of the base plate, a hole channel is formed in the end, close to the vertical plate, of the base plate, a cylindricalrod is movably installed at the bottom of the lower die, a material receiving pipe is fixed to the top of the upper die, a cold air pipe is installed in the middle of the front end of the vertical plate, an air outlet is fixedly formed in the end, away from the vertical plate, of the cold air pipe, transverse rods are fixed to the left side and the right side of the front end of the vertical plate, first electric telescopic rods are installed at the bottoms of the other sides of the transverse rods, suction cups are installed at the bottoms of the first electric telescopic rods on the right side, a material injection pipe matched with the material receiving pipe is installed on the left side of the front end of the vertical plate, and an air gun pipe matched with the material receiving pipe is installed on the right side. The die is provided with three demolding mechanisms. The demolding effect is good.

Owner:辛集市儒意建筑装饰有限公司

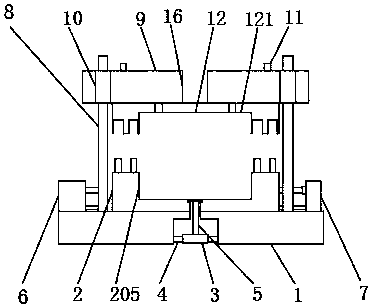

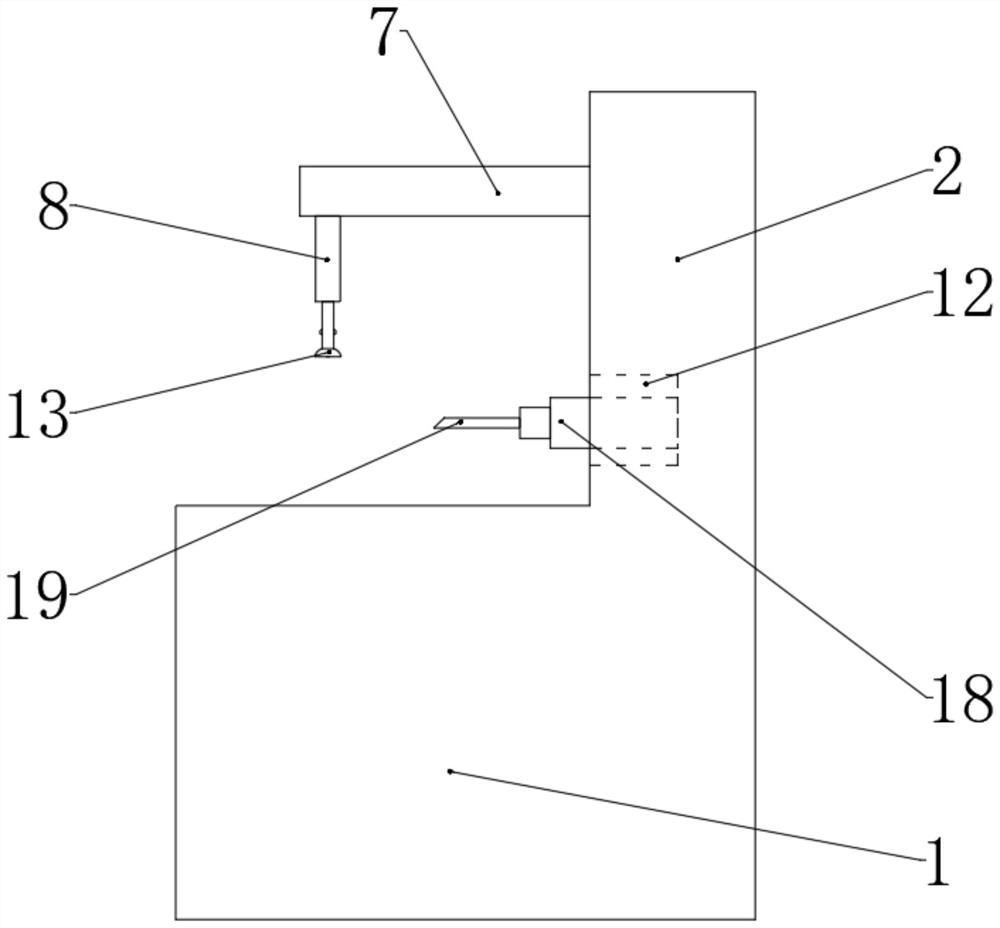

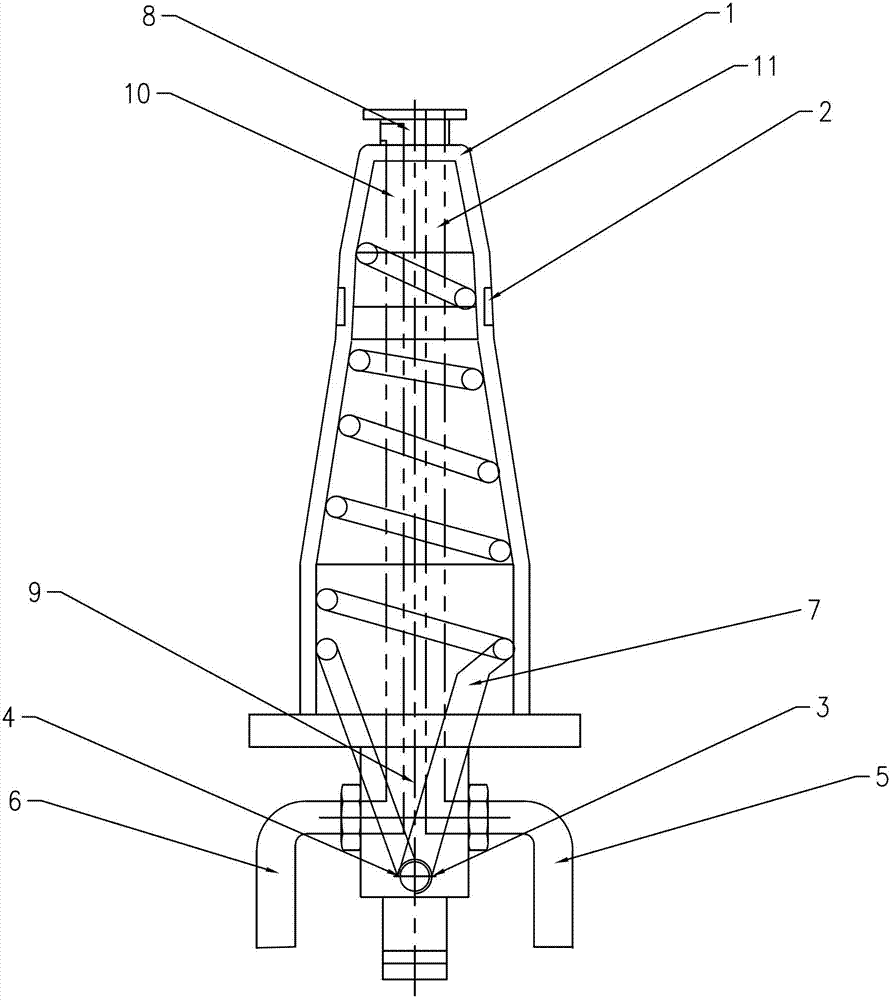

Advanced ceramic part injection mold and injection molding method

ActiveCN109648684ASimple structureUniform and efficient injectionDischarging arrangementInjection molding machineMaterials science

The invention discloses an advanced ceramic part injection mold and injection molding method. The advanced ceramic part injection mold comprises a base plate. A lower mold plate is arranged at the right side of the upper end of the base plate. An ejection device is arranged inside the lower mold plate. The outer surface of the lower mold plate is provided with a cooling device. A closed separatingdevice is arranged at the left side of the upper end of the base plate. A connecting plate is arranged at the side, close to the center of the lower mold plate, of a support block in the closed separating device. Under the effect of locating pillars and locating holes, an upper mold plate and the lower mold plate are closed through the closed separating device; mixed and compounded slurry is located and guided through a locating annular piece. According to the advanced ceramic part injection mold and injection molding method, the injection mold is simple in structure and convenient to operate; the slurry is injected uniformly and efficiently; the mold can achieve rapid cooling and molding, and materials are convenient and fast to pick; the injection molding method is reasonable and efficient; the injection molding quality of parts is guaranteed; the work load of personnel is lowered; and the injection and molding efficiency is improved.

Owner:湖南犀鸟陶瓷有限公司

Plastic mould with cooling mechanism

InactiveCN109109291AIncrease contact surfaceImprove heat transfer efficiencyCooling chamberInjection product

The invention relates to the technical field of plastic moulds and especially relates to a plastic mould with a cooling mechanism. The plastic mould comprises a lower mould and an upper mould, whereina cooling chamber is formed in the lower mould; a metal pattern slot plate is blocked in a square opening; a lower mould slot is formed on the top surface of the metal pattern slot plate; a lower semicircular feeding slot is formed on the lower mould slot and the middle part of a side wall of the lower mould; a water feeding pipe and a water draining pipe are respectively penetrated through the middle parts on the two sides of the cooling chamber; an upper mould slot is formed on the middle part of the bottom of the upper mould; an upper semicircular feeding slot is formed on one side of theupper mould; a connecting base is welded on the middle part of the top surface of the semicircular feeding slot; a guiding mechanism is arranged on the upper mould and the lower mould. The plastic mould with the cooling mechanism is capable of greatly increasing the production efficiency of injection products, is low in yield of wastes and is beneficial to the injection molding of plastics.

Owner:HUANGSHAN MINGSHENG DIE MATERIAL CO LTD

Building steel formwork adapting to high vibration load

InactiveCN111622490AQuick pourFast pouring completedAuxillary members of forms/shuttering/falseworksForming/stuttering elementsClassical mechanicsEngineering

Owner:安徽黎搏装饰工程有限公司

A rotary mold injection mold

The invention discloses a rotary mold release injection mold, comprising a base, the top of the base is fixedly connected with a lower mold base, the top of the lower mold base is movably connected with an upper mold base, and the inner cavity of the lower mold base is movable The lower mold cavity is connected, and the upper mold cavity is opened at the bottom of the upper mold base, and the inner wall of the lower mold base is rollingly connected with balls, and the surface of the ball penetrates the inner wall of the lower mold base and extends to the inner cavity of the lower mold base , The invention relates to the technical field of injection molds. The rotation of the mold release injection mold starts the first drive motor, and the lower mold cavity is driven to rotate through the first drive shaft, so that it is separated from the upper mold cavity, and then the top block is driven to collide with the surface of the injection molded part. At this time, the first drive is started. The drive motor drives the lower mold cavity to rotate through the drive shaft. At this time, the injection molded part is fixed by the top block, so that the lower mold cavity and the injection molded part can be demoulded, and the injection molded part can be demoulded quickly, which is very convenient to use.

Owner:广东伟力环保实业有限公司

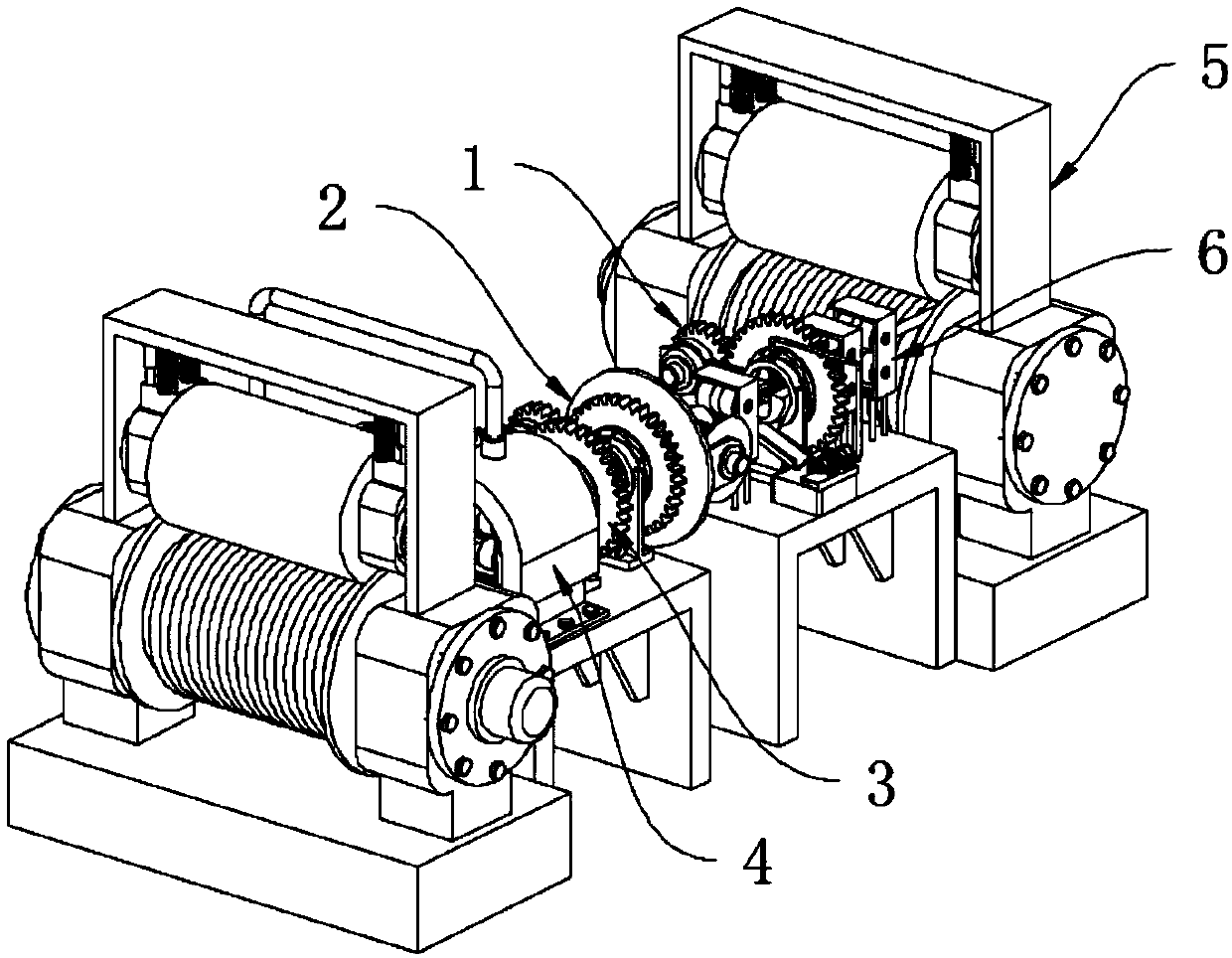

Blowing mechanism of IBC (Intermediate Bulk Container) liner blow molding machine

InactiveCN102825777ARapid Cooling FormingSimple structureHollow articlesBlow moldingIntermediate bulk container

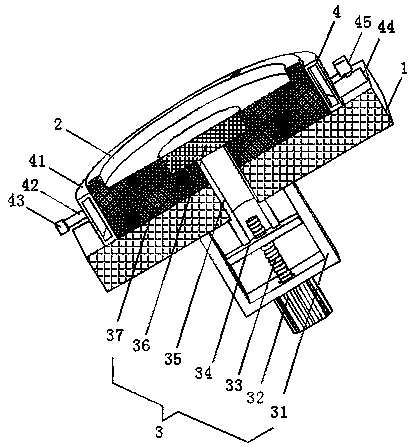

The invention relates to a blowing mechanism of an IBC (Intermediate Bulk Container) liner blow molding machine, in particular to the blowing mechanism for injecting refrigerated and compressed air into a mold cavity, and belongs to the technical field of the blowing machine. The blowing mechanism comprises a blowing head, a water inlet, a water outlet, a cooling water pipe, an air pipe and a blowing head base, wherein the rear end of the blowing head is fixed on the blowing head base; the air pipe is positioned in the blowing head; the front end of the air pipe extends out of the blowing head and the rear end of the air pipe is fixed on the blowing head base; the air pipe is internally provided with communicated air inlet holes and communicated air outlet holes; one end of the blowing head base is connected with an air outlet, and the other end of the blowing head base is connected with an air inlet; the cooling water pipe is positioned in the blowing head; and a pipe body of the cooling water pipe winds in the blowing head by a plurality of rings. The blowing mechanism has the advantages that the structure is simple, compact and reasonable, the blank can be quickly cooled and molded, the cooling speed is fast and the quality of a product is improved.

Owner:WUXI SIFANG YOUXIN

Production line process for producing steel pellets of different sizes

The invention discloses a production line process for producing steel pellets of different sizes. The production line process comprises the following steps of 1, cleaning raw materials; 2, pulverizingthe raw materials; 3, melting the raw materials; 4, adding auxiliary raw materials; 5, conducting centrifugal pelleting; and 6, conducting sorting and packaging. By means of the production line process, strength and toughness of the produced steel pellets can be effectively improved, and quality of the steel pellets is improved; and thus, the service life of each steel pellet is remarkably prolonged, energy consumption is lowered, and the cost is lowered.

Owner:ZIBO LUBAO METAL PROD CO LTD

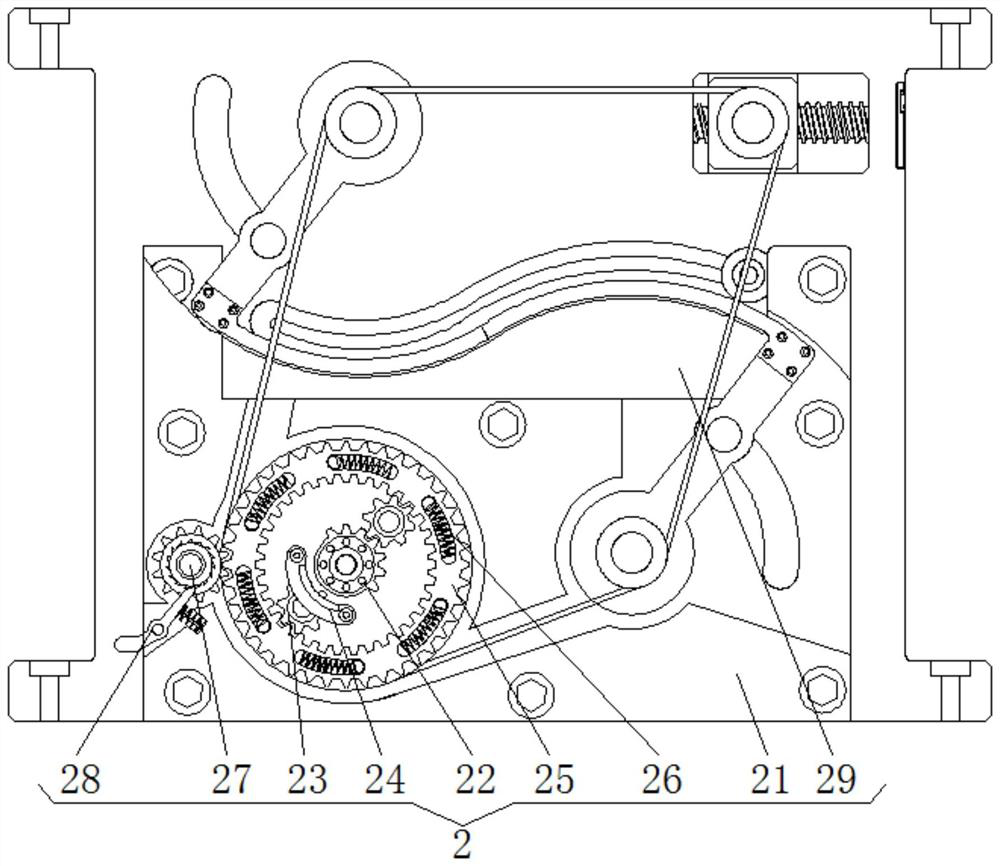

Sealing device for packaging of lithocarpus litseifolius sweet tea

InactiveCN111846451AImprove convenienceImprove efficiencyWrapper twisting/gatheringEngineeringSliding contact

The invention discloses a sealing device for packaging of lithocarpus litseifolius sweet tea. The sealing device comprises a box body, wherein a feeding opening is formed in the top surface of the boxbody; a material guiding plate which is obliquely arranged is mounted in the box body, and is located under the feeding opening; a protective cover is fixedly connected to the material guiding plate;a sealing mechanism with an elastic function is fixedly connected to the top surface of the box body; a cam mechanism for driving the sealing mechanism is rotatably arranged in the box body; a horizontal plate is fixedly connected to a side wall of the box body; a driving mechanism is arranged on the horizontal plate, rotatably penetrates through the side wall of the box body, and is in transmission connection with the cam mechanism; a transmission mechanism is rotatably arranged on the horizontal plate; a supporting mechanism is arranged on the side wall of the box body in a sliding and penetrating manner; and the upper end of the supporting mechanism is in sliding contact with the material guiding plate and the lower end of the protective cover. Through the sealing device disclosed by the invention, tea bags are convenient to seal, and the sealing efficiency is improved favorably; and in addition, the sealed tea bags can also be effectively cooled, so that quick cooling and shapingof sealing are facilitated.

Owner:重庆华丛农业科技有限公司

Rapid-formed die casting device for die of metal anti-vibration engine precision accessory

The invention discloses a rapidly-formed die casting device for a die of a metal anti-vibration engine precision accessory in the technical field of engine precision accessories. The rapidly-formed die casting device comprises a base, an upper ventilation opening is formed in the upper part of the side wall of the base, a lower ventilation opening is formed in the lower part of the side wall of the base, a cavity is formed in the inner wall of the base, the top of the cavity communicates with the base, an inclined liquid inlet cavity is formed in the top of the base, the top of the inclined liquid inlet cavity is communicates with a liquid feeding port, and the top end of the liquid feeding port penetrates through the base. When a guide rod moves up and down, an eccentric wheel rotates through a movable rod, then through a rolling wheel, a the piston plate can intermittently squeeze water in a water tank into a cooling pipe, and therefore, for one thing, the water does not need to be supplied through a water pump, and vibration can be avoided from a vibration source in the prior art again; and for another thing, the contact time of water flow and the cavity can be prolonged, more heat in the cavity can be conveniently taken away, and rapid cooling forming of molten metal is facilitated.

Owner:郝杰

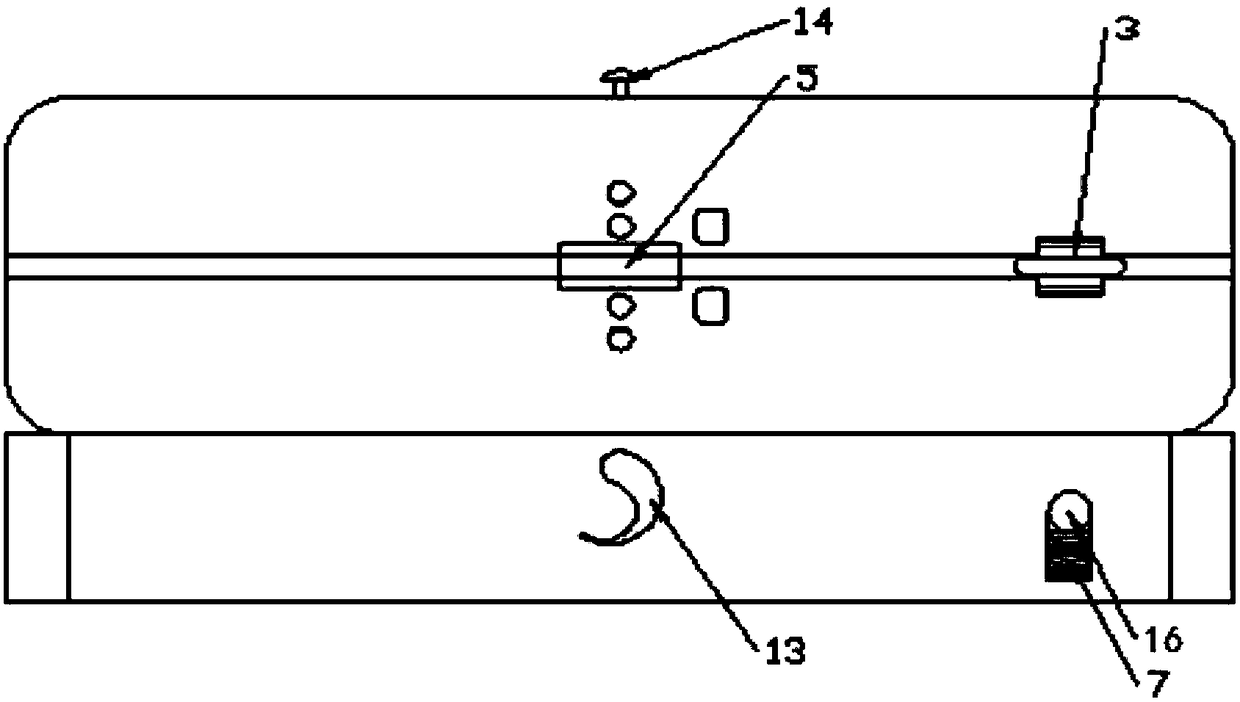

Device for welding 3D printing consumables and welding method of device

The invention discloses a device for welding 3D printing consumables and a welding method of the device. After one time of printing, if a small quantity of printing consumables are left, the small quantity of left printing consumables are insufficient for the second time of printing and thus cannot be used, and consequentially, a large quantity of printing consumables are wasted. The device for easily and conveniently welding 3D printing consumables comprises a first main body block, a second main body block, a first wheel, a second wheel, a first heat conduction block, a second heat conduction block, a first squeezing spring, a second squeezing spring, a first wheel shaft, a second wheel shaft, a cooling fan, a heat transfer block, a pressing block, a heating bar and heating reset springs. The first main body block is hinged to the edge of one side of the inner side face of the second main body block. A first wire rod groove is formed in the inner side face of the first main body block. A second wire rod groove is formed in the inner side face of the second main body block. According to the device for welding 3D printing consumables and the welding method of the device, two rollsof 3D printing consumables can be welded; and the welding temperature can be controlled, and the device and method are suitable for different types of 3D printing consumables.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

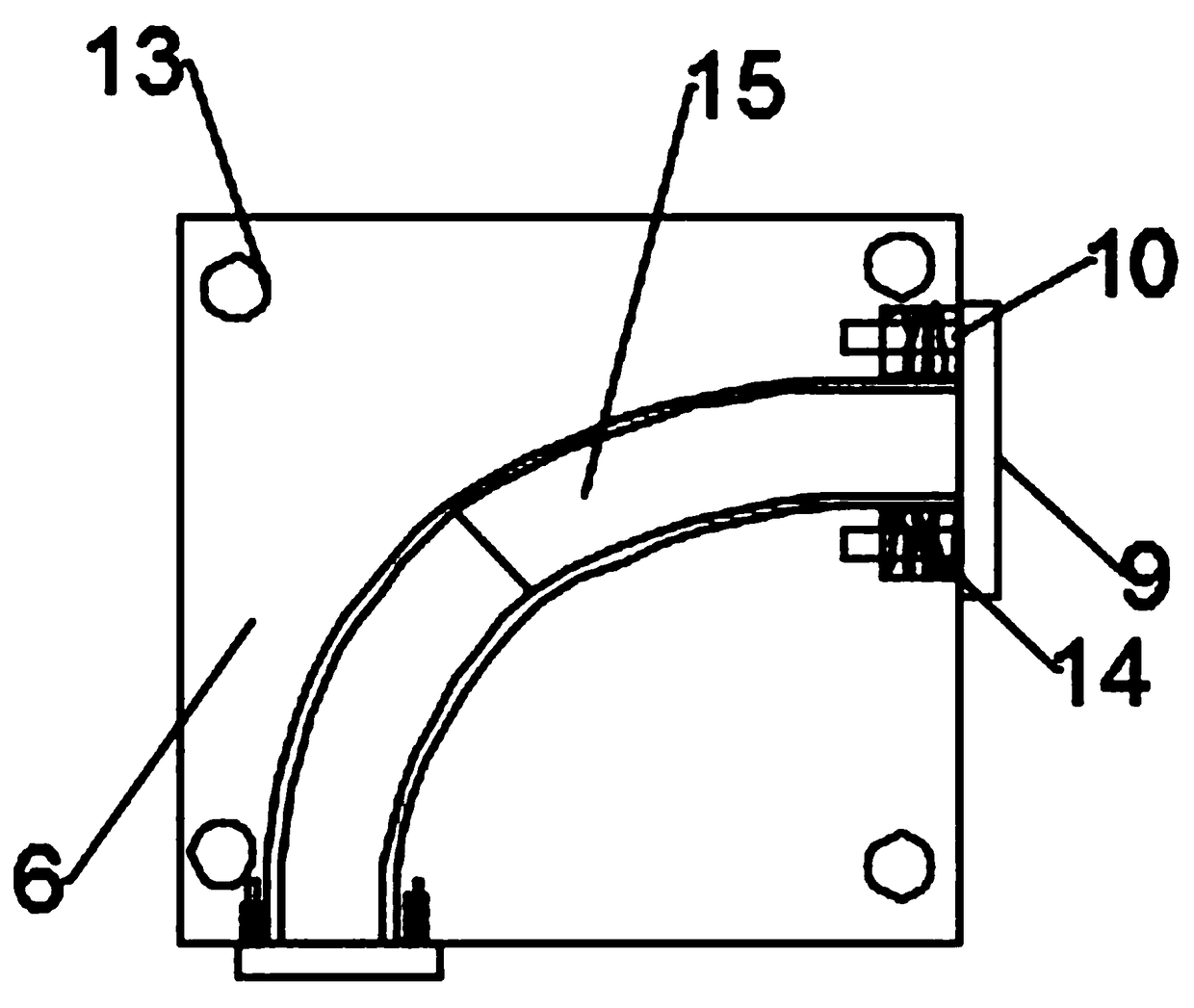

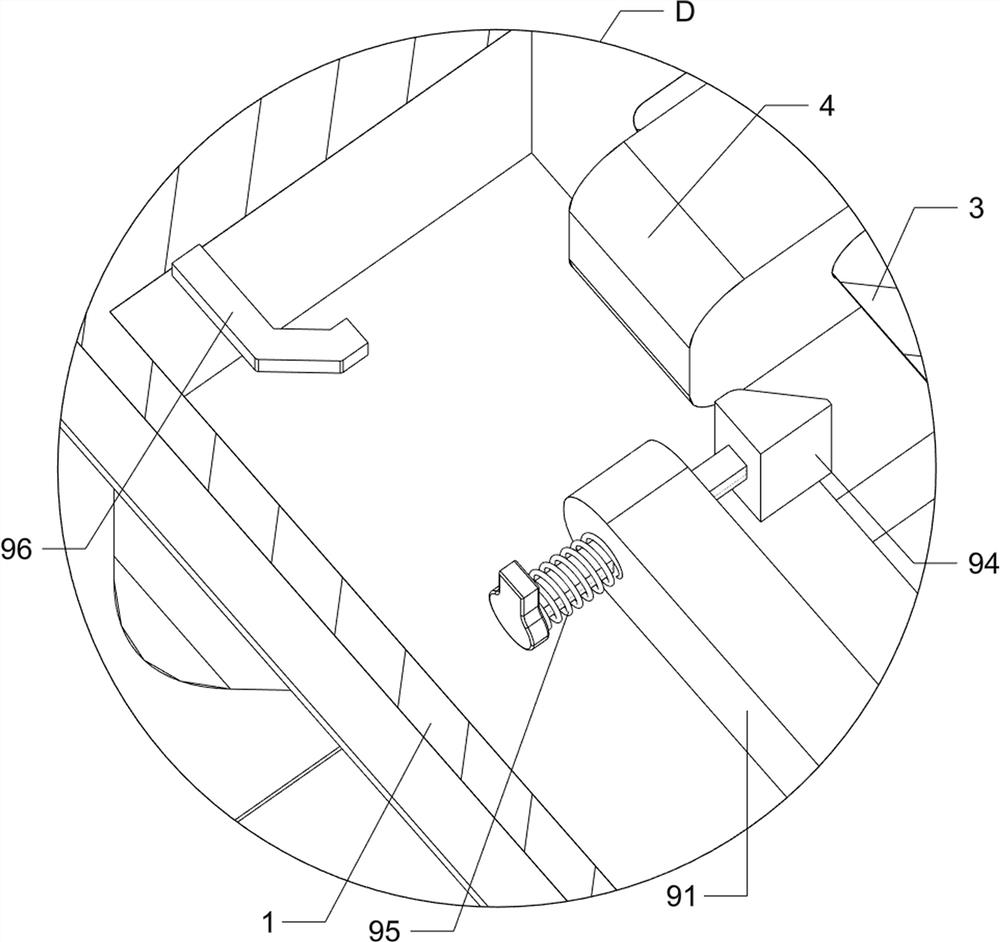

Injection die for plastic elbow

InactiveCN109421224APrevent the situation that cannot be taken outRapid Cooling FormingPush outCooling channel

The invention discloses an injection die for a plastic elbow. The injection die for the plastic elbow comprises a base, wherein a push component is installed above the base; a rebound rod and a push rod are installed above the push component; a recovery spring is installed at the bottom of the rebound rod; a cooling channel is formed in the middle of the rebound rod; a movable die plate is installed above the cooling channel; a fixed die plate is installed above the movable die plate; a pouring port is formed in the middle of the fixed die plate; a pouring cavity is formed above the pouring port; a die core push plate is installed at the right side of the fixed die plate; and die core rebound rods are installed at the two sides of the die core push plate. According to the injection die forthe plastic elbow and used for a building, due to the arrangement for the push rod, the injected elbow can be pushed out, so that manual operation is reduced, and an operator is prevented from beingscalded; due to the arrangement for the die core rebound rods, a die core in the injection-formed elbow can be rebounded out, so that the case that the elbow cannot be taken out, is prevented; and through the formation for the cooling channel, the elbow can be rapidly cooled-formed.

Owner:李升高

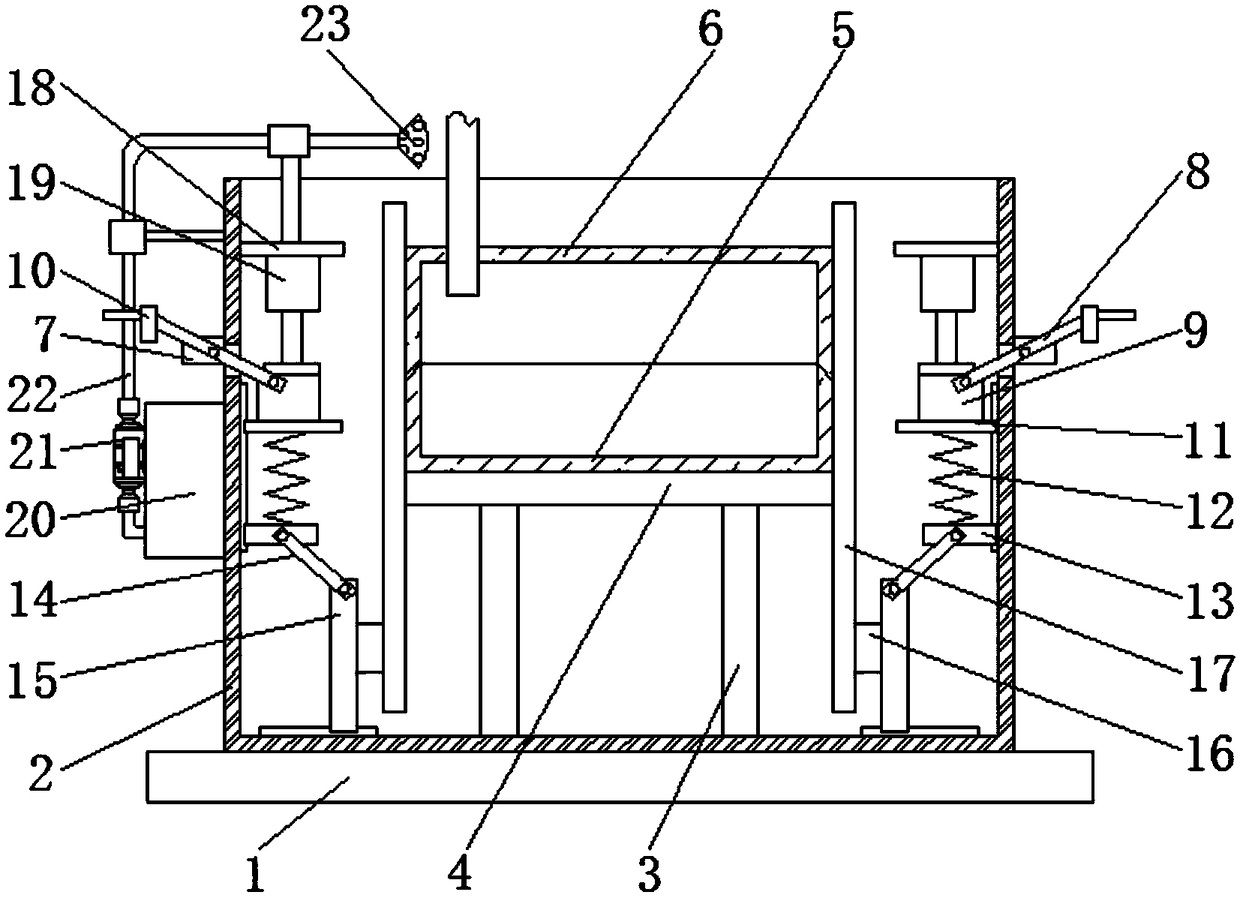

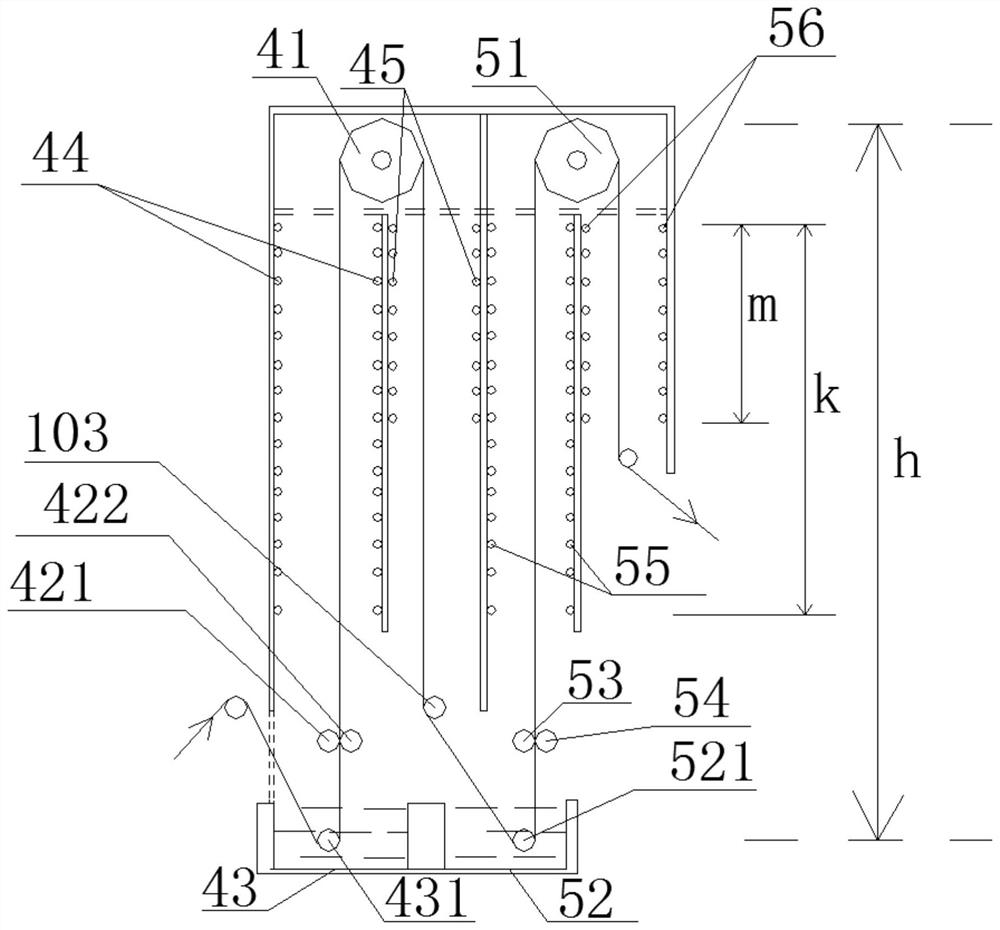

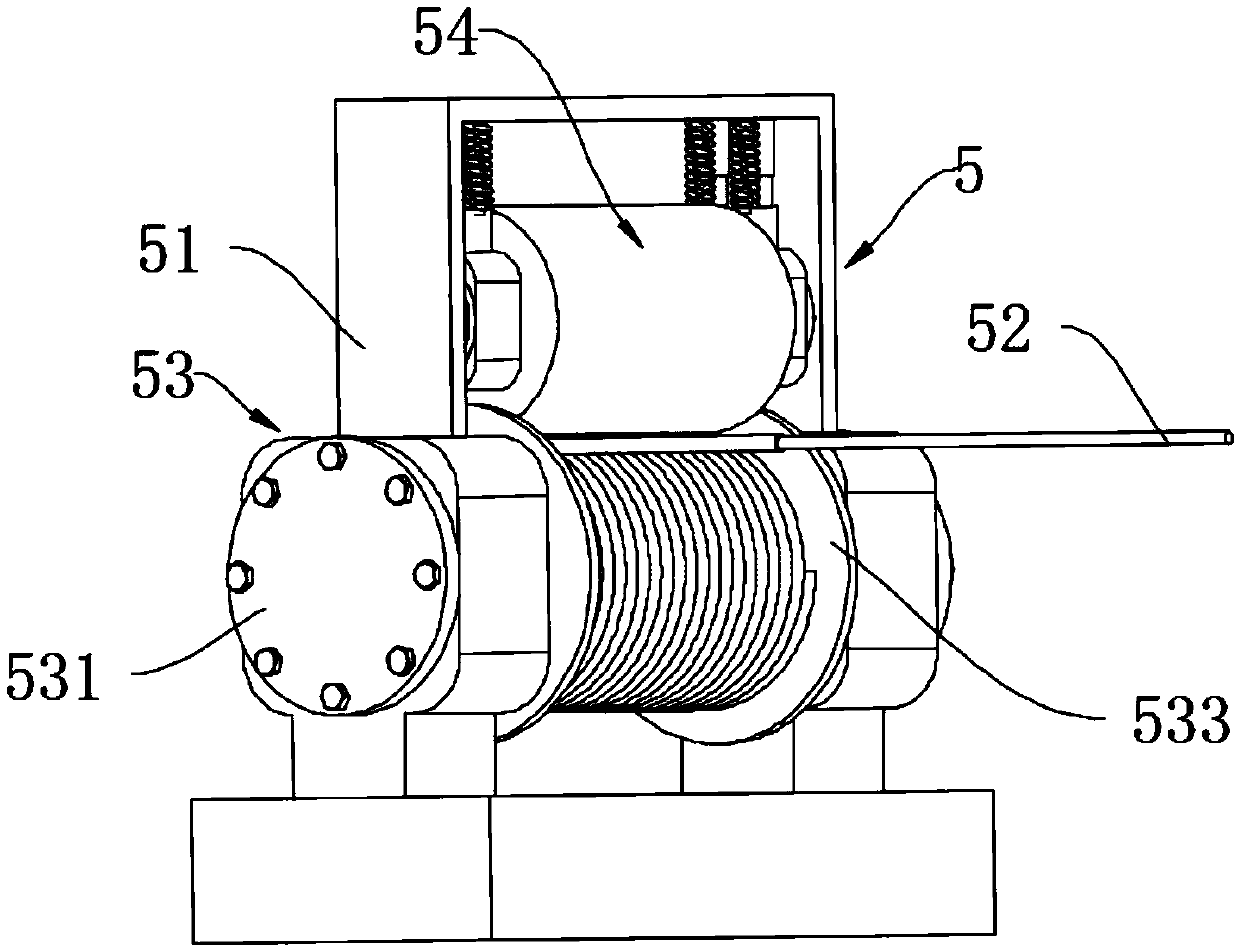

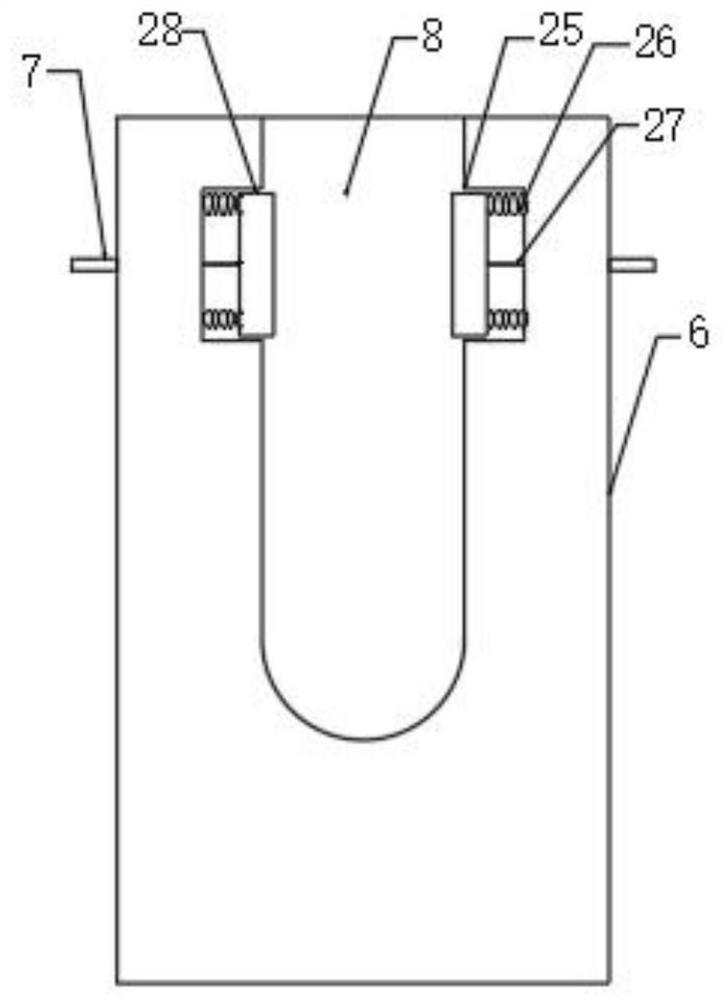

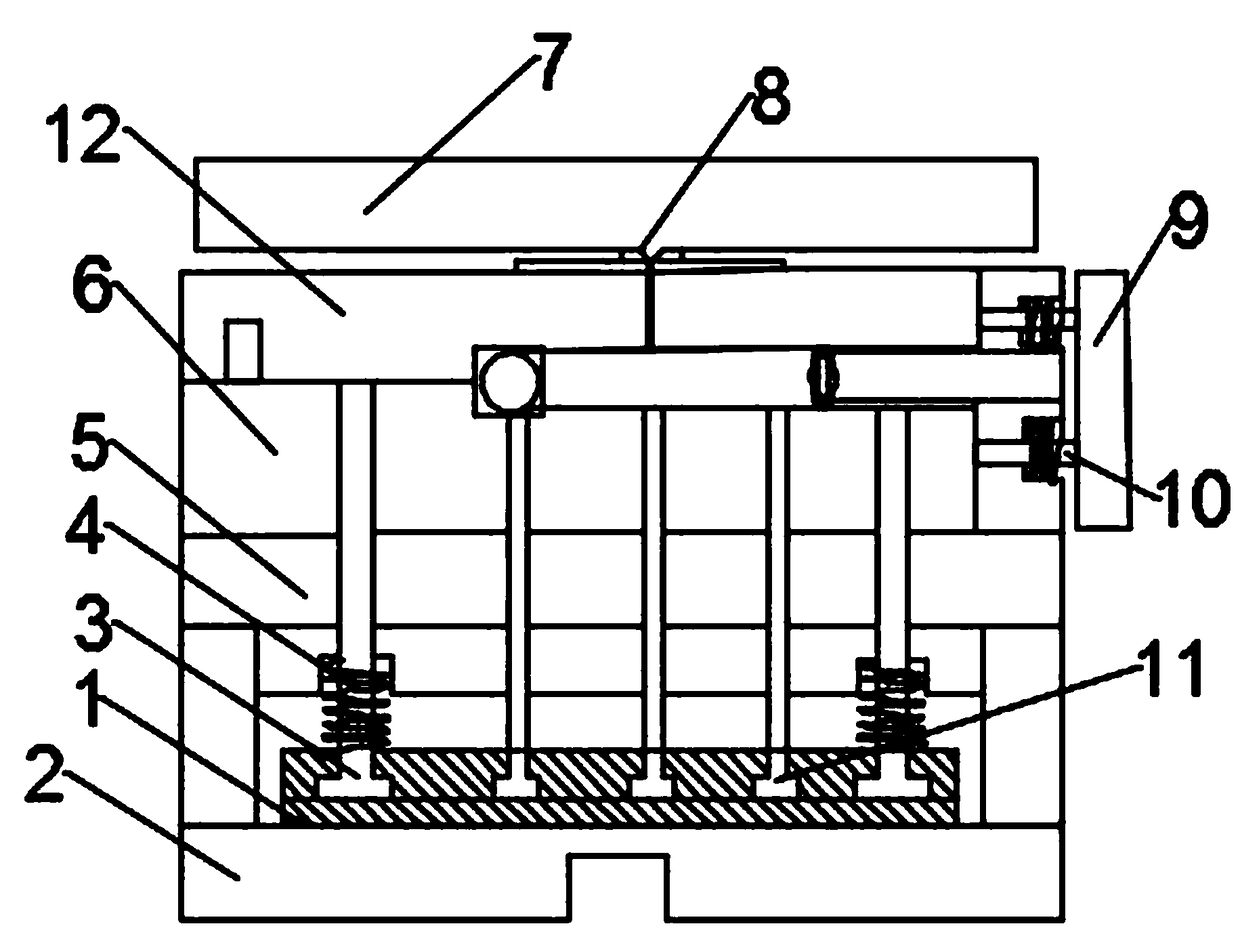

Lamination cooling equipment

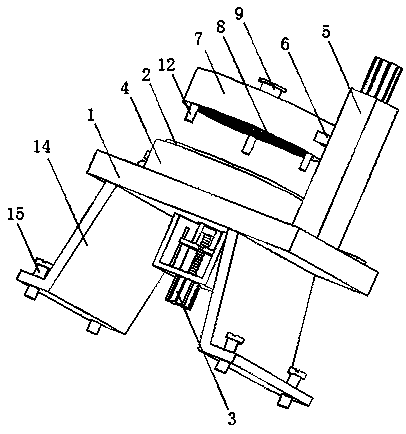

The invention belongs to the field of production equipment of thermoplastic plates, and in particular relates to cooling equipment for cooling the thermoplastic plates. The lamination cooling equipment comprises a support, wherein an upper crossbeam is arranged at the top part of the support; a middle crossbeam is arranged at the middle part of the support; mounting plates are arranged on the support; a left mounting plate is arranged on the left side of the support, and a feed mechanism is arranged on the left mounting plate; a right mounting plate is arranged on the right side of the support, and a material receiving mechanism is arranged on the right mounting plate; a height adjusting mechanism is arranged on each of the left mounting plate and the right mounting plate; the material receiving mechanism and the feed mechanism are connected with the height adjusting mechanisms; a cooling mechanism is arranged between the upper crossbeam and the middle crossbeam and comprises a lower cooling plate which is fixedly connected to the middle crossbeam, and a cooling plate adjusting cylinder which is arranged on the upper crossbeam; and an upper cooling plate is connected at an output end of the cooling plate adjusting cylinder. The cooling equipment is large in contact area and good in cooling effect.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

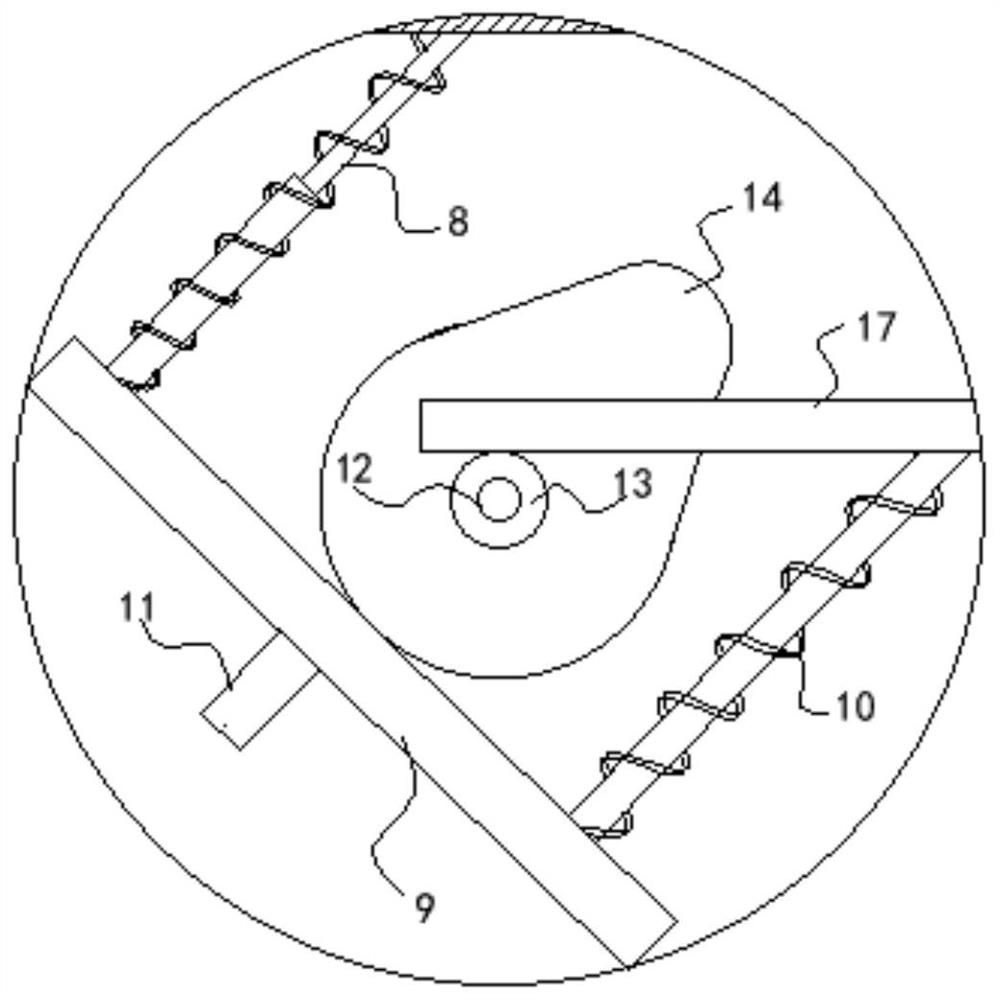

Rotational molding device and process for children's slide part

InactiveCN113561387AEven by forceRapid hot melt settingHelter-skeltersCoatingsDrive wheelEngineering

The invention relates to the technical field of rotational molding, and discloses a rotational molding device and process for a children's slide part. The rotational molding device comprises a mold mechanism, wherein the mold mechanism comprises a rack, an adjusting sliding block is slidably connected to the interior of the rack, and the adjusting sliding block is rotatably connected with a synchronous pulley. According to the rotational molding device and process for the children's slide part, a driven wheel of a driving wheel rotates, the driven wheel drives a transmission wheel to rotate, the transmission wheel drives a synchronous belt to rotate, the synchronous belt drives a synchronous belt wheel to rotate, the synchronous belt wheel drives a mold closing rocker to rotate, the mold closing rocker drives a decomposition mold to rotate, meanwhile a feeding chain wheel drives a feeding chain to rotate, the feeding chain drives a supporting frame and a rotational molding assembly to move by rotating a rotary knob, then a strong magnetic stator drives a rotating coil to rotate, the rotating coil drives a rotational molding shaft to rotate, and the rotational molding shaft drives a rotating roller to rotate, so that the effects of automatic mold forming, automatic rotational molding and internal stress elimination are achieved.

Owner:浙江飞友康体设备有限公司

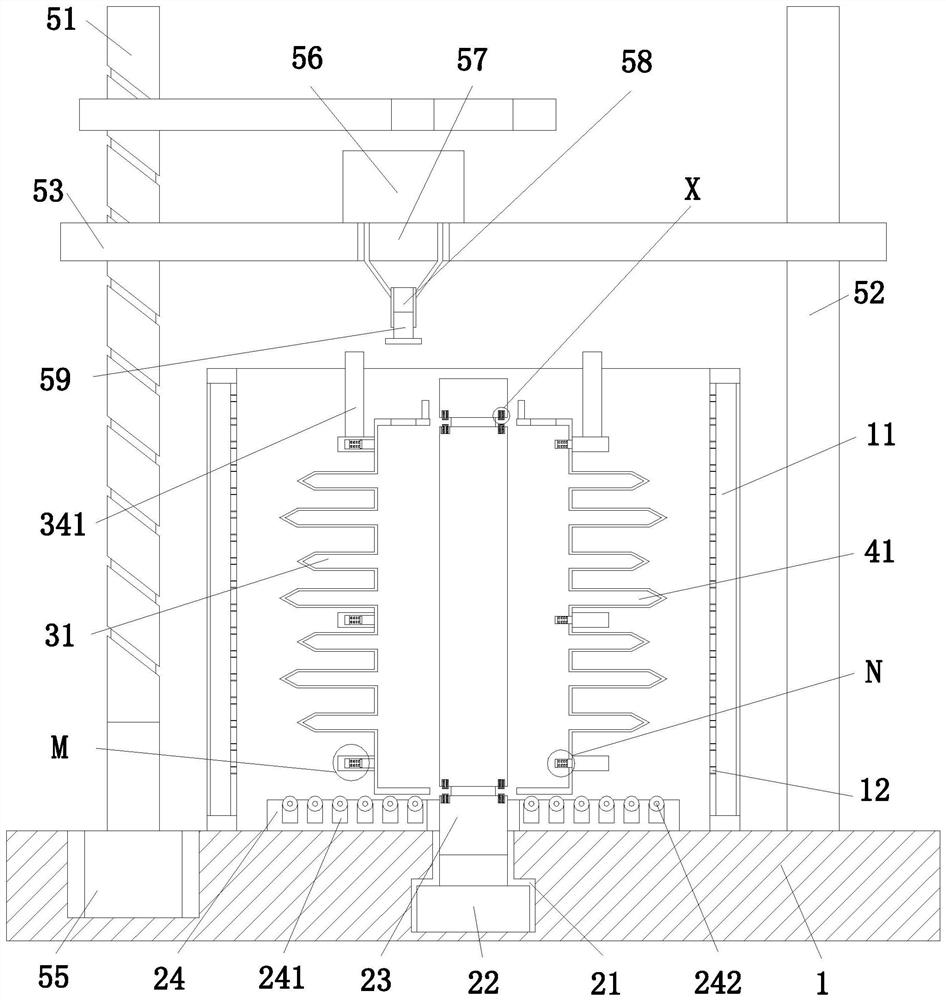

Rapid pouring device for dry-type transformer production

PendingCN113192744APrevent leakageRapid Cooling FormingEncapsulation/impregnationTransformerEngineering

The invention discloses a rapid pouring device for dry-type transformer production which comprises a bottom plate, a transverse plate and a tank body, wherein the lower portion of the transverse plate is in bolted connection with the tank body, a pipeline A is connected to the lower portion of the tank body in an inserted mode, a magnet A is detachably connected to the lower portion of the pipeline A, and a fixing plate is fixedly installed on the outer side of the pipeline A; an electric telescopic rod is installed above the fixing plate, a mold is detachably connected to one side of the bottom plate, a pipeline B is detachably connected to the upper portion of the mold, a magnet B is installed above the pipeline B, and a refrigeration piece is detachably connected to the inner side of the mold. Through the installed electric telescopic rod, the pipeline A, the magnet A, the pipeline B, the magnet B and the refrigeration piece, raw material leakage can be avoided, meanwhile, raw materials in the mold can be rapidly cooled and formed, and the working efficiency is improved.

Owner:TIANJIN XIANGYUAN ANGAO INTERMEDIATE FREQUENCY POWER TRANSFORMER CO LTD

Injection molding equipment for vehicle-mounted electronic product processing

The invention relates to injection molding equipment, in particular to injection molding equipment for vehicle-mounted electronic product processing. The invention aims to provide the injection molding equipment for vehicle-mounted electronic product processing, which can automatically discharge finished products. The injection molding equipment for vehicle-mounted electronic product processing comprises a shell, discharging plates, a first lower mold, a first upper mold, a second lower mold, a second upper mold and the like, the discharging plates are arranged in the middles of the left side and the right side of the lower portion of the shell, the first lower mold is arranged on the right rear side of the upper portion of the inner side of the shell, and the first upper mold is arranged on the front portion of the first lower mold in a sliding mode; a second lower die is arranged on the left rear side of the upper portion of the inner side of the shell, and a second upper die is slidably arranged on the front portion of the second lower die. When the first upper die moves forwards, the first push rod and the second push rod can be driven to move forwards, so that a finished product can be pushed forwards, the automatic discharging function is completed, and time and labor are saved.

Owner:深圳市凯迪炫电子科技有限公司

A kind of conductive carbon/polymer matrix composite material and preparation method thereof

Owner:SHENZHEN DYNANONIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com