A kind of conductive carbon/polymer matrix composite material and preparation method thereof

A composite material and conductive carbon technology, applied in the field of conductive carbon/polymer matrix composite materials and their preparation, can solve the problem of high cost, achieve the effects of low cost, improved electrical conductivity and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

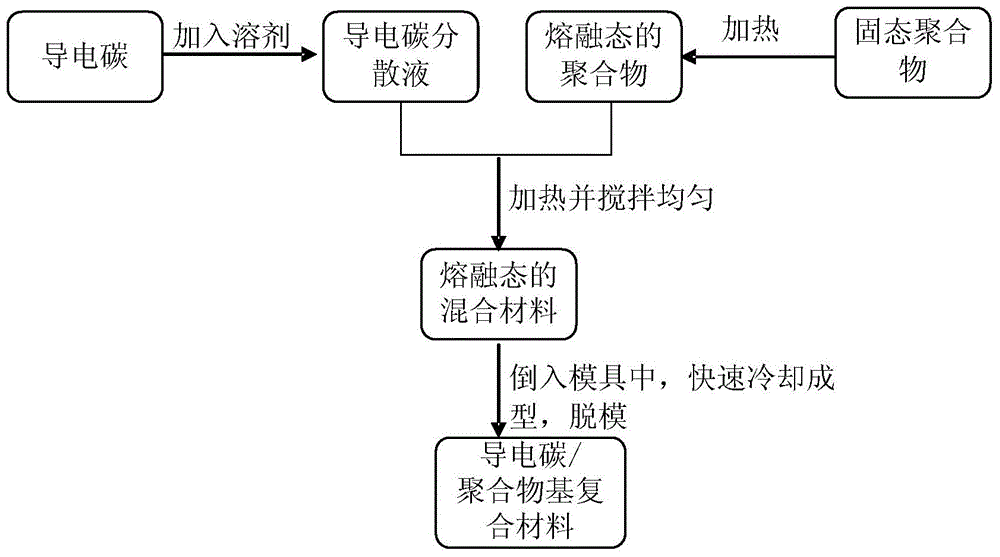

[0038] Second aspect, such as figure 1 as shown, figure 1 It is a process flow diagram of the preparation method of the conductive carbon / polymer-based composite material according to an embodiment of the present invention; it includes the following steps:

[0039] (1) dispersing the conductive carbon in a solvent to obtain a conductive carbon dispersion;

[0040] (2) heating the solid polymer to obtain a molten polymer;

[0041] (3) Add conductive carbon dispersion liquid to the polymer in molten state, the weight of conductive carbon is 1%-45% of solid polymer weight, heat and stir to remove solvent, the temperature of heating is higher than step (2) solid The heating and melting temperature of the polymer is 0-10°C higher to obtain a molten mixed material;

[0042] (4) Pour the mixed material in the molten state into the mould, rapidly cool and form, and demould to obtain a conductive carbon / polymer-based composite material. In the conductive carbon / polymer-based composi...

Embodiment 1

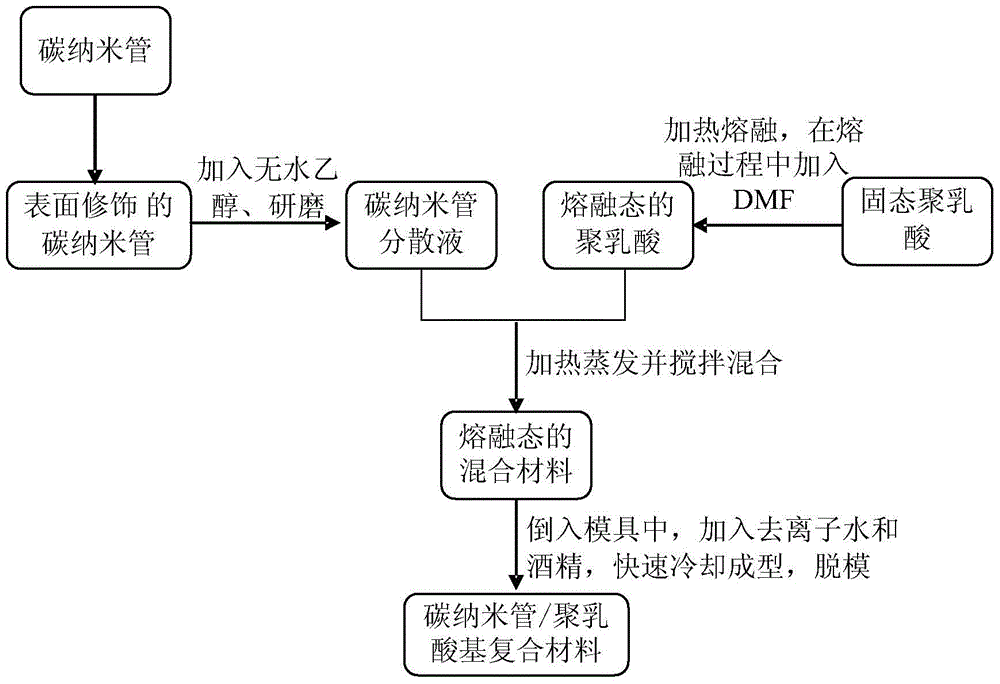

[0080] A method for the preparation of conductive carbon / polymer matrix composites, such as figure 2 as shown, figure 2 The process flow chart of the preparation method of the conductive carbon / polymer-based composite material for the implementation of the present invention includes the following steps:

[0081] (1) Take 100g of carbon nanotubes and place them in 1200mL of concentrated sulfuric acid and concentrated nitric acid in a mixed acid with a volume ratio of 3:1, react at 40°C for 2h, then filter, and wash the filter residue with water for several times until the washing solution is neutral. Carrying out vacuum drying and grinding to obtain surface-modified carbon nanotubes, taking the surface-modified carbon nanotubes and placing them in absolute ethanol, grinding for 2 hours to obtain a carbon nanotube dispersion with a mass fraction of carbon nanotubes of 5%;

[0082] (2) Heat 2000g of solid polylactic acid at 250°C to melt, and add a small amount of DMF during t...

Embodiment 2

[0088] A preparation method of conductive carbon / polymer-based composite material, comprising the following steps:

[0089] (1) Take 100g of carbon nanotubes and put them in 1000mL of concentrated sulfuric acid, react at 25°C for 5h, then filter, wash the filter residue with water several times until the washing liquid is neutral, then carry out vacuum drying and grinding to obtain surface-modified carbon For nanotubes, the surface-modified carbon nanotubes were placed in N-methylpyrrolidone (NMP), and ball milled for 2 hours to obtain a carbon nanotube dispersion with a mass fraction of carbon nanotubes of 5%;

[0090] (2) Heat 2000g of solid polycaprolactone at 120°C to melt, add NMP during the melting process to adjust the viscosity, and stir to obtain molten polylactic acid with a suitable viscosity;

[0091] (3) Add the carbon nanotube dispersion to molten polycaprolactone (PCL), heat and evaporate at 120°C and stir and mix to remove most of the solvent. The weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com