Injection molding equipment for vehicle-mounted electronic product processing

A technology of injection molding and on-board electronics, which is applied in applications, household appliances, household components, etc., can solve problems such as troubles, and achieve the effect of fast cooling molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

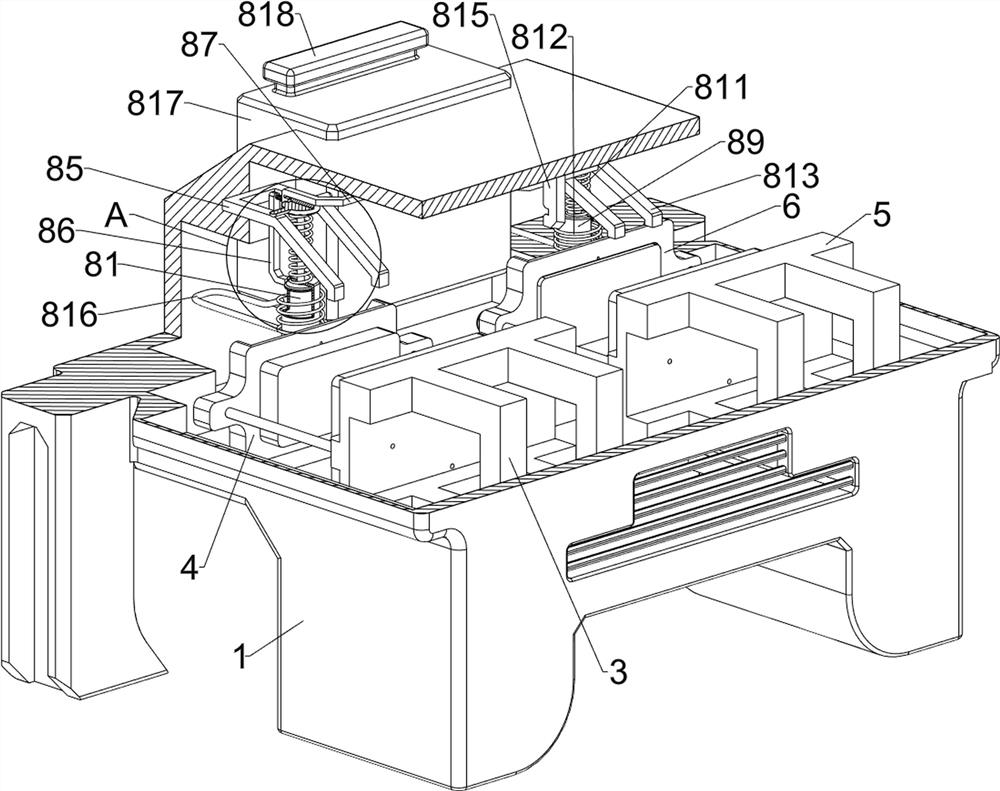

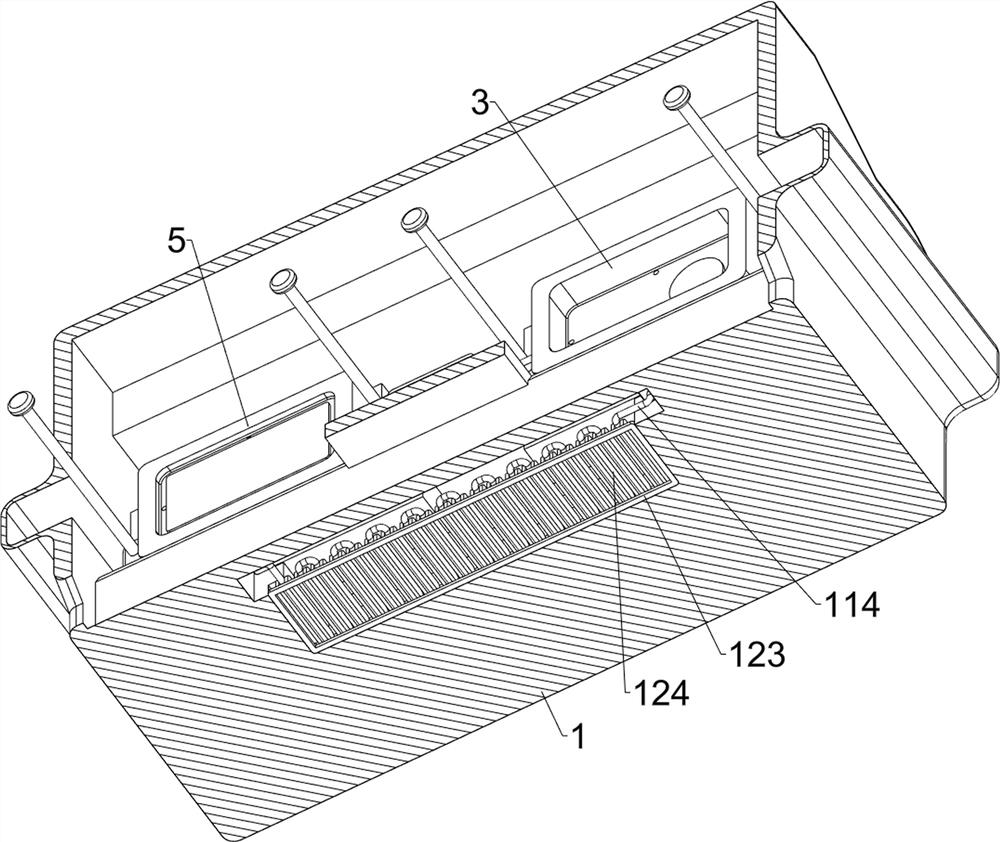

[0040] An injection molding equipment for automotive electronic product processing, refer to Figure 1-Figure 14 , including a shell 1, a discharge plate 2, a first lower mold 3, a first upper mold 4, a second lower mold 5, a second upper mold 6, a push assembly 7, a feed assembly 8 and a discharge assembly 9, the shell 1. There is a discharge plate 2 in the middle of the left and right sides of the lower part, and a first lower mold 3 is welded on the upper right rear side of the inner shell 1. The front part of the first lower mold 3 is slidingly provided with a first upper mold 4. A second lower mold 5 is welded on the upper left rear side of the inner side. The front of the second lower mold 5 is slidably provided with a second upper mold 6. When the raw material is transferred between the first lower mold 3 and the first upper mold 4 and After the second lower mold 5 and the second upper mold 6 are between the second lower mold 5 and the second upper mold 6, wait for the ...

Embodiment 2

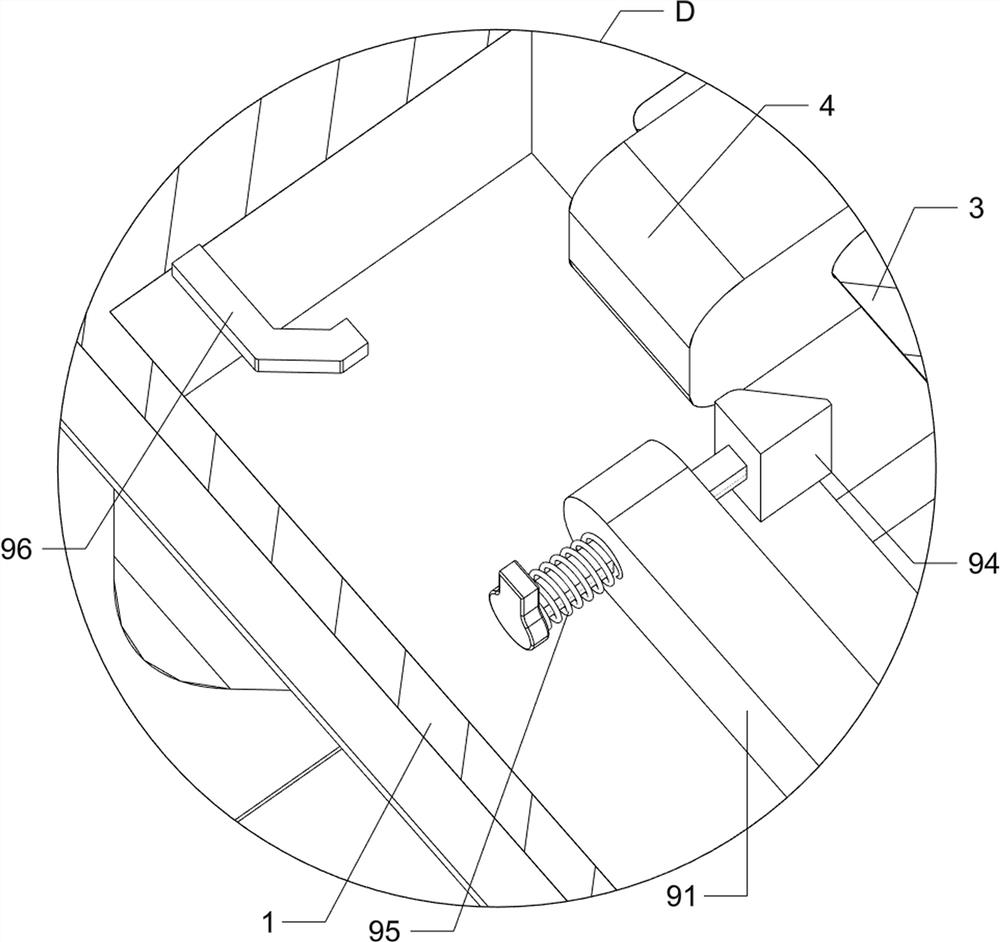

[0046] On the basis of Example 1, refer to figure 2 and Figure 15 , and also includes a disengagement assembly 10, the disengagement assembly 10 includes a fifth link 101, a third push rod 102 and an eighth spring 103, the top of the third link 92 is provided with a fifth link 101, the first lower mold 3 A third push rod 102 is slidably provided between the upper front side of the second lower die 5 and the upper front side of the second lower mold 5. When the third push rod 102 moves downward, the finished product can be pushed down, and the fifth link 101 moves forward. The movement will be in contact with the third push rod 102 , and two eighth springs 103 are provided between the first lower mold 3 and the second lower mold 5 and the third push rod 102 .

[0047] When the third link 92 moves forward, it drives the fifth link 101 to move forward, the fifth link 101 squeezes the third push rod 102 to move downward, and the eighth spring 103 compresses. Both the rod 91 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com