Blowing mechanism of IBC (Intermediate Bulk Container) liner blow molding machine

A technology of blowing mechanism and molding machine, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of poor cooling effect and low product quality, and achieve the effects of fast cooling speed, improved quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

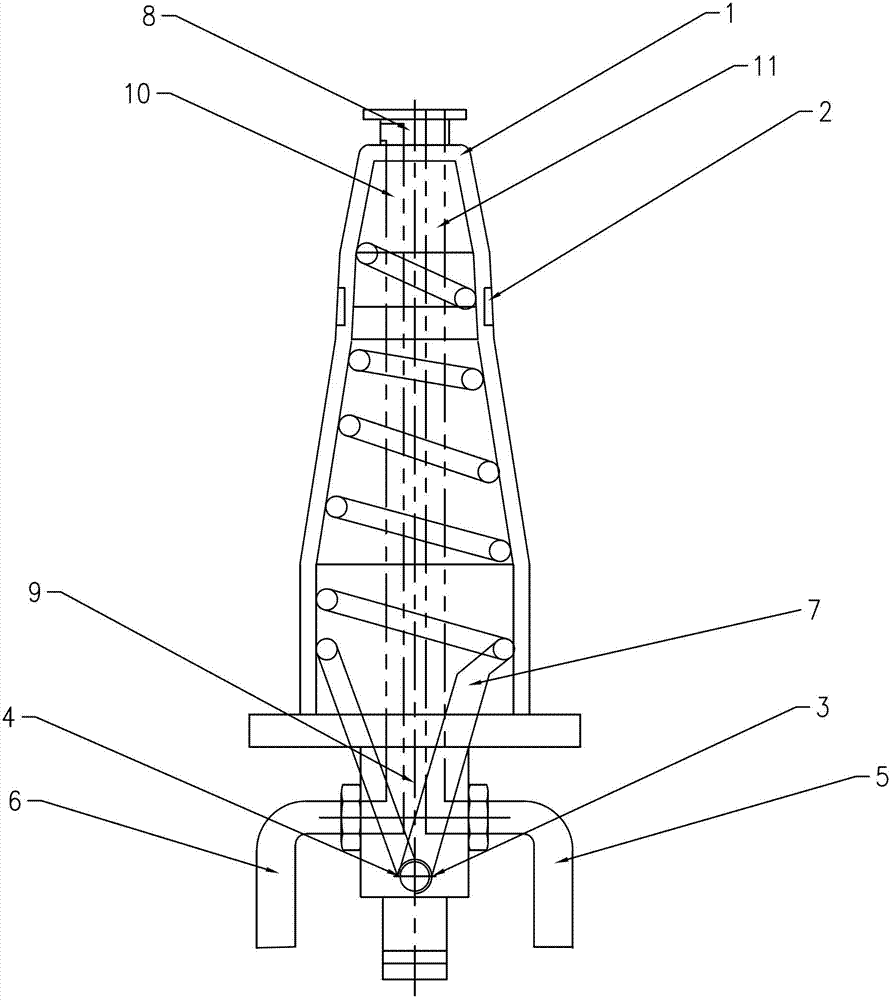

[0012] like figure 1 As shown, the present invention mainly includes an air blowing head 1 , a water inlet 3 , a water outlet 4 , a cooling water pipe 7 , an air pipe 8 and an air blowing head base 9 .

[0013] The rear end of the blowing head 1 is fixed on the blowing head base 9 . The air tube 8 is located in the blowing head 1 , the front end of the air tube 8 extends out of the blowing head 1 , and the rear end of the air tube 8 is fixed on the blowing head base 9 . The air pipe 8 is provided with a through air inlet hole 10 and a through air outlet hole 11 .

[0014] One end of the blowing head base 9 is connected to the air outlet 5 , and the other end is connected to the air inlet 6 , the air inlet 6 communicates with the air inlet 10 , and the air outlet 5 communicates with the air outlet 11 . The cold air enters the air inlet 10 from the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com