Automatic production method for prefabricated reinforced concrete hollow formwork

A production method and reinforced concrete technology, applied in molds, manufacturing tools, mold fixtures, etc., can solve problems such as incompleteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

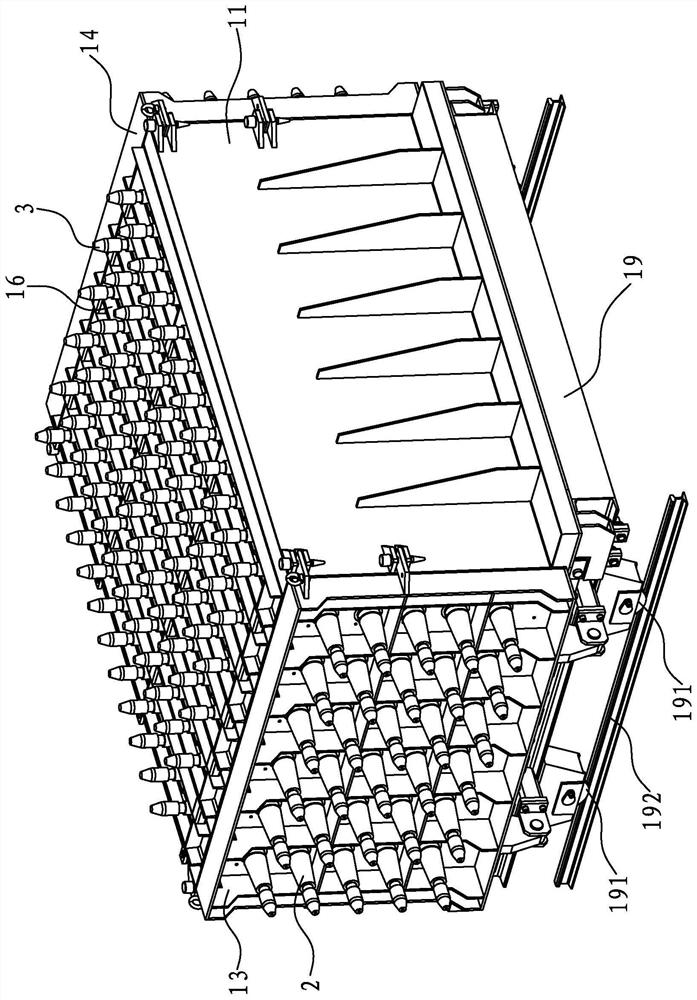

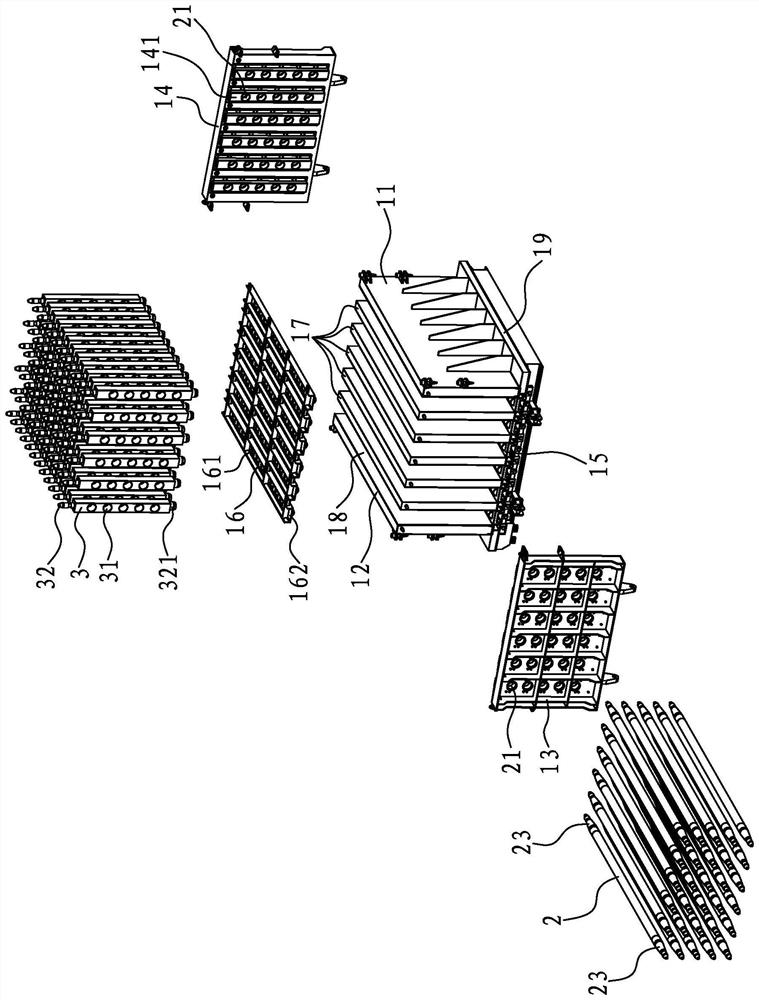

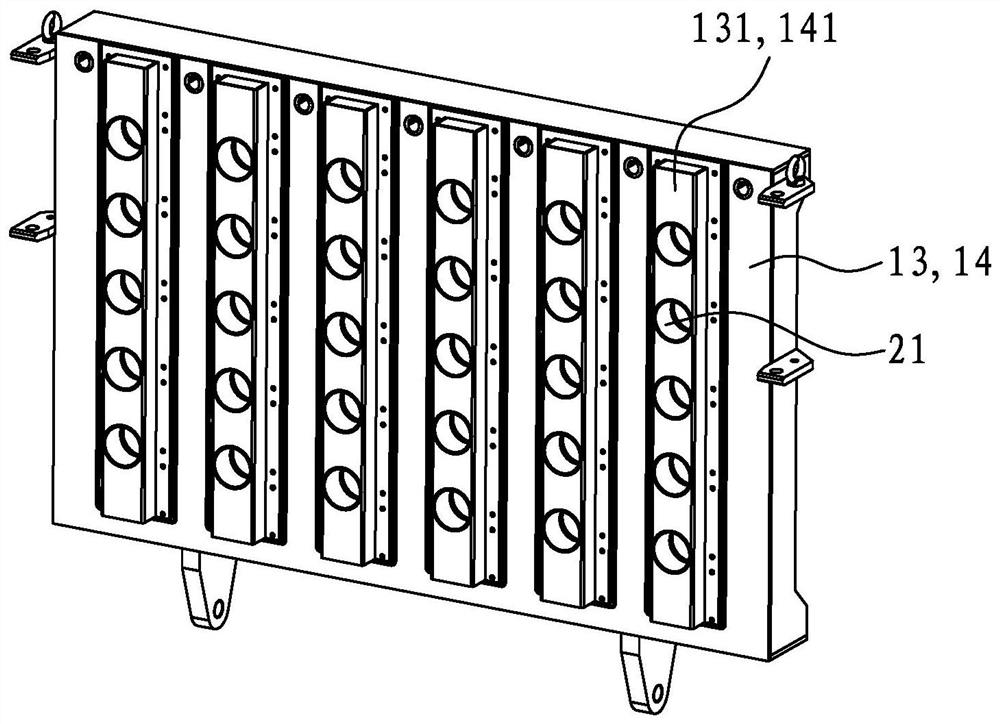

[0054] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0055] see Figure 1 to Figure 34 , the present invention discloses an automatic production method for prefabricated reinforced concrete hollow formwork. The automatic production method has the following steps: ① preparing concrete raw materials and preparing a bundled steel grid frame; , rear side plate, left side plate, right side plate, bottom side plate, and partitions are assembled together; and the mold is divided into multiple vertical cavities with openings facing upward; ③Move the mold to the mandrel Insert the mandrel into the mold at the core-piercing or core-pulling station; ④ Move the mold to the mold pouring station to pour concrete raw materials; ⑤ After the pouring is completed, move the mold to the mold top and side plate Cover the opening of the cavity; ⑥Move the mold to the first maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com