Assembly line of paint-free film-pressing wooden door

A production line, wooden door technology, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve problems such as manual handling, reduce participation, reduce labor intensity, and meet the effects of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

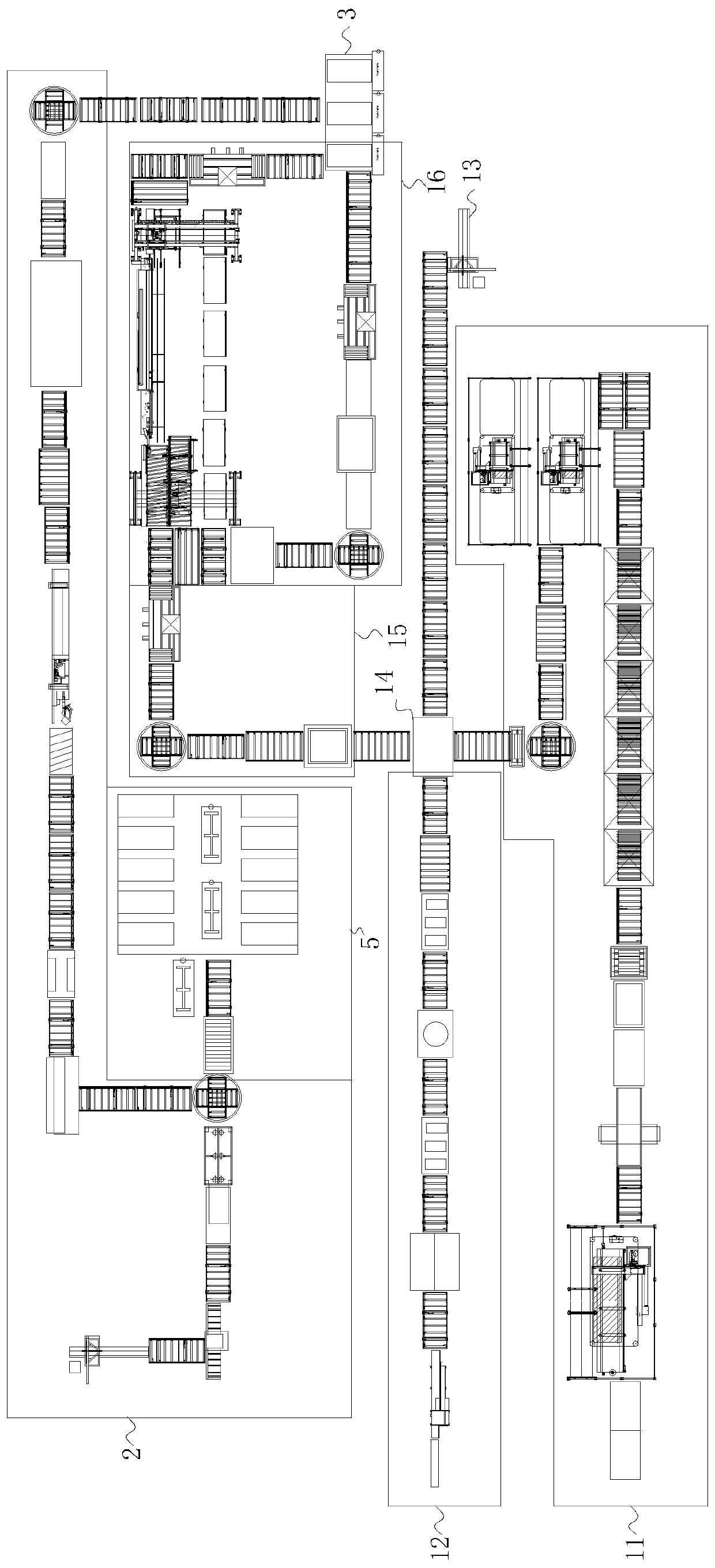

[0029] Such as figure 1 The flow production line of the paint-free film-pressed wooden door of the present invention shown in -7 includes a door panel production line 1, a door face rail production line 2, a combined packaging platform 3, a conveyor and a general controller;

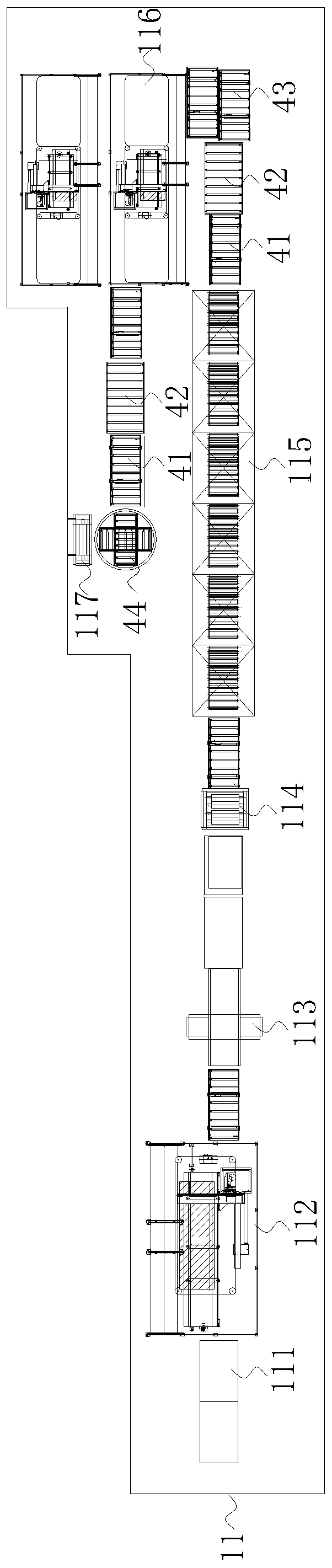

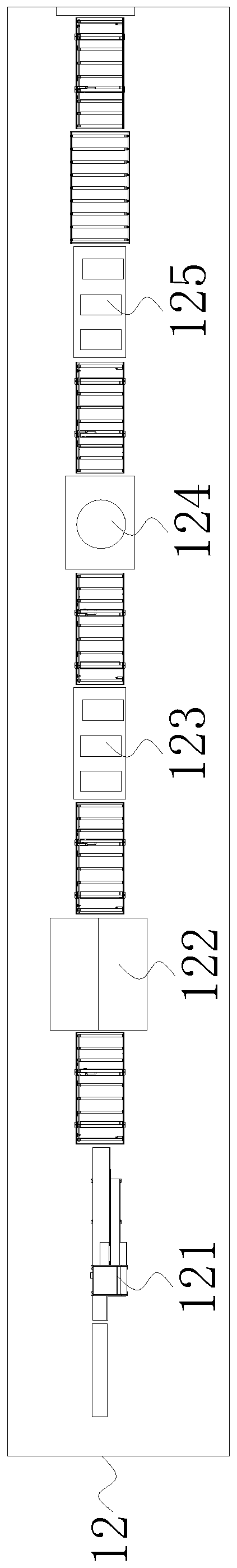

[0030] The door panel production line 1 includes a panel production line 11, a door frame production line 12, a bridge hole plate production line 13, a door panel assembly platform 14, a pressing and shaping processing line 15 and an edge sealing processing line 16, wherein the panel production line 11, the door frame production line 12, and the bridge hole plate production line 13 Run side by side and are all connected to the feed end of the door panel assembly platform 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com