Outdoor heavy bamboo and wood floorboard and preparation method thereof

A bamboo, wood and floor technology, applied in coatings, special surfaces, pretreated surfaces, etc., can solve the problems of large release of volatile organic compounds polluting the environment, poor prevention and control of cyanobacteria, and limited anti-mildew performance. Good anti-mold, high weather resistance, low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

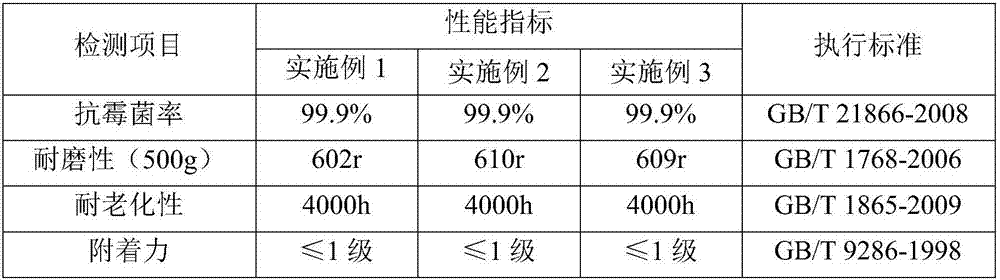

[0036] A kind of outdoor heavy bamboo wood floor of the present invention, it mainly comprises heavy bamboo wood floor base material, on this heavy bamboo wood floor base material, be provided with sealing base layer, adhesion primer layer, first top coat layer and Second coat of topcoat. Both the first topcoat layer and the second topcoat layer use the special UV topcoat of the present invention, the sealing bottom layer uses a water-based UV sealing bottom, and the adhesion primer layer uses a UV adhesion primer.

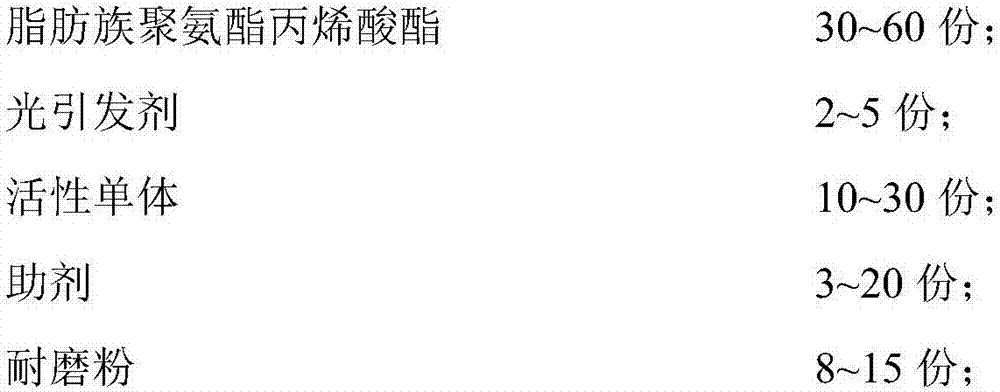

[0037] The specific composition raw materials of the UV topcoat used include: aliphatic polyurethane acrylate, 1-hydroxy-cyclohexyl-phenyl ketone, 1,6-hexanediol diacrylate, wear-resistant powder, nano-silver and additives. Among them, the wear-resistant powder has a Mohs hardness of 7 grades and a particle size of 100 mesh; the average particle size of nano-silver is below 50nm (purchased from Puda Nano Technology (Xiamen) Co., Ltd.); additives include dispersant...

Embodiment 2

[0053] A kind of outdoor heavy bamboo wood floor of the present invention, it mainly comprises heavy bamboo wood floor base material, on this heavy bamboo wood floor base material, be provided with sealing base layer, adhesion primer layer, first top coat layer and Second coat of topcoat. Both the first topcoat layer and the second topcoat layer use the special UV topcoat of the present invention, the sealing bottom layer uses a water-based UV sealing bottom, and the adhesion primer layer uses a UV adhesion primer.

[0054] The specific composition raw materials of the UV topcoat used include: aliphatic urethane acrylate, photoinitiator 819, neopentyl glycol diacrylate, wear-resistant powder, nano silver and additives. Among them, the Mohs hardness of the wear-resistant powder is 8 grades, and the particle size is 100 mesh; the average particle size of nano-silver is less than 50nm (purchased from Puda Nano Technology (Xiamen) Co., Ltd.); additives include dispersants, levelin...

Embodiment 3

[0070] A kind of outdoor heavy bamboo wood floor of the present invention, it mainly comprises heavy bamboo wood floor base material, on this heavy bamboo wood floor base material, be provided with sealing base layer, adhesion primer layer, first top coat layer and Second coat of topcoat. Both the first topcoat layer and the second topcoat layer use the special UV topcoat of the present invention, the sealing bottom layer uses a water-based UV sealing bottom, and the adhesion primer layer uses a UV adhesion primer.

[0071] The specific composition raw materials of the UV topcoat used include: aliphatic urethane acrylate, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, tripropylene glycol diacrylate, wear-resistant powder, nano silver and Auxiliary. Among them, the wear-resistant powder has a Mohs hardness of 7 grades and a particle size of 100 mesh; the average particle size of nano-silver is below 50nm (purchased from Puda Nano Technology (Xiamen) Co., Ltd.); additives incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com