Locking device for machining mechanical parts

A technology for locking devices and mechanical parts, applied in metal processing mechanical parts, positioning devices, metal processing equipment, etc., can solve the problems of limiting the working range of the locking device, inability to process mechanical parts, poor operability, etc., to simplify circuit design, Improve the quality of processing and the effect of convenient and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

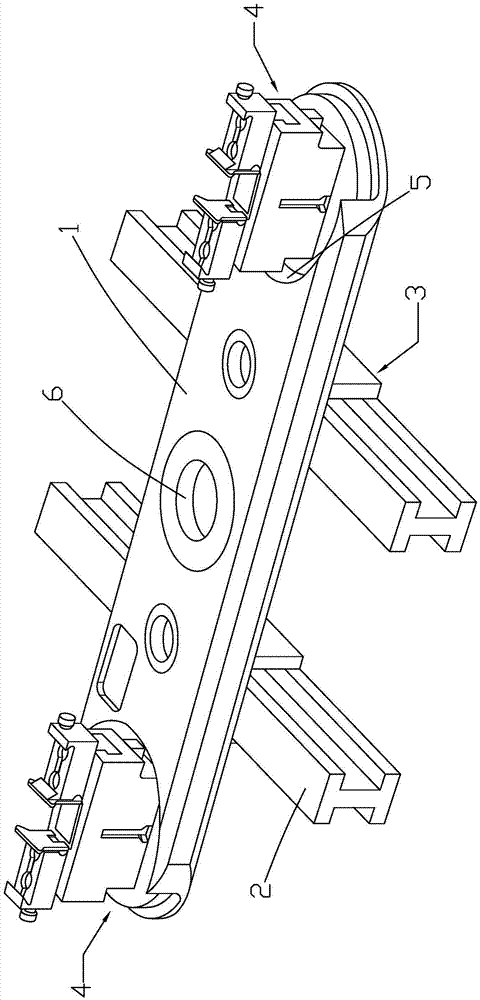

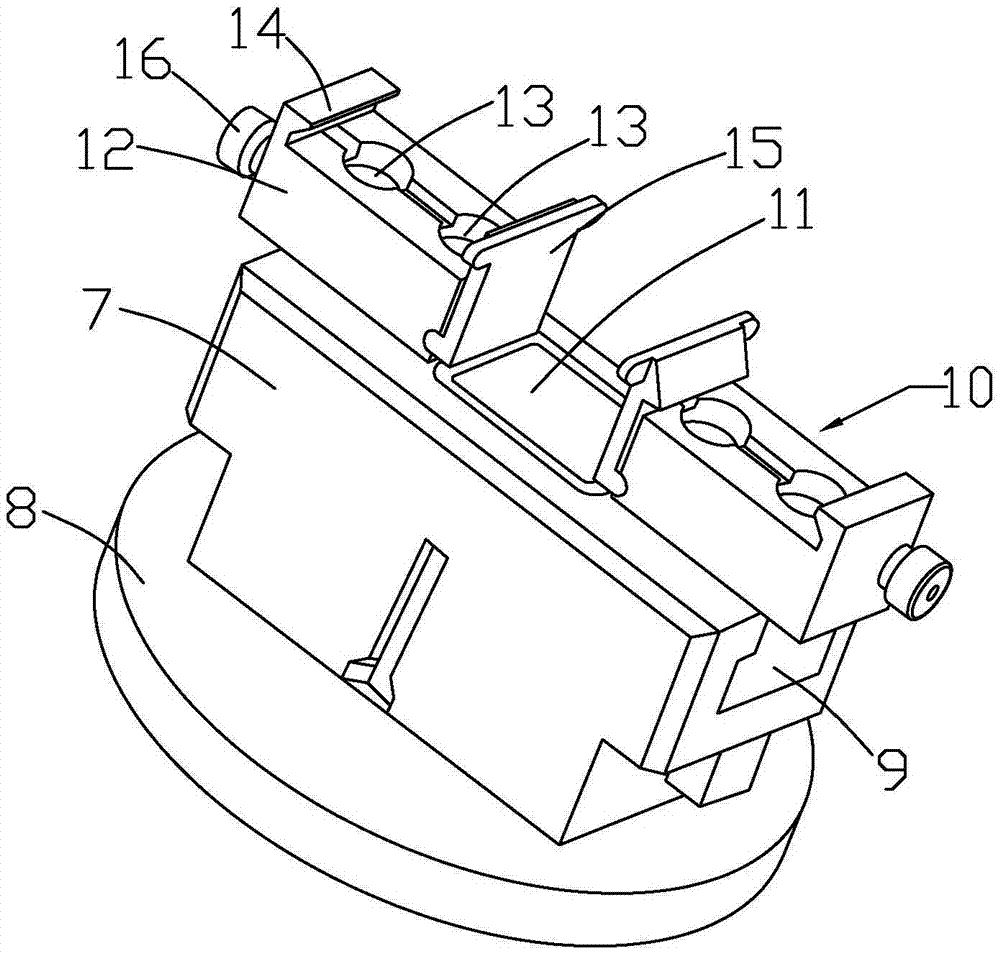

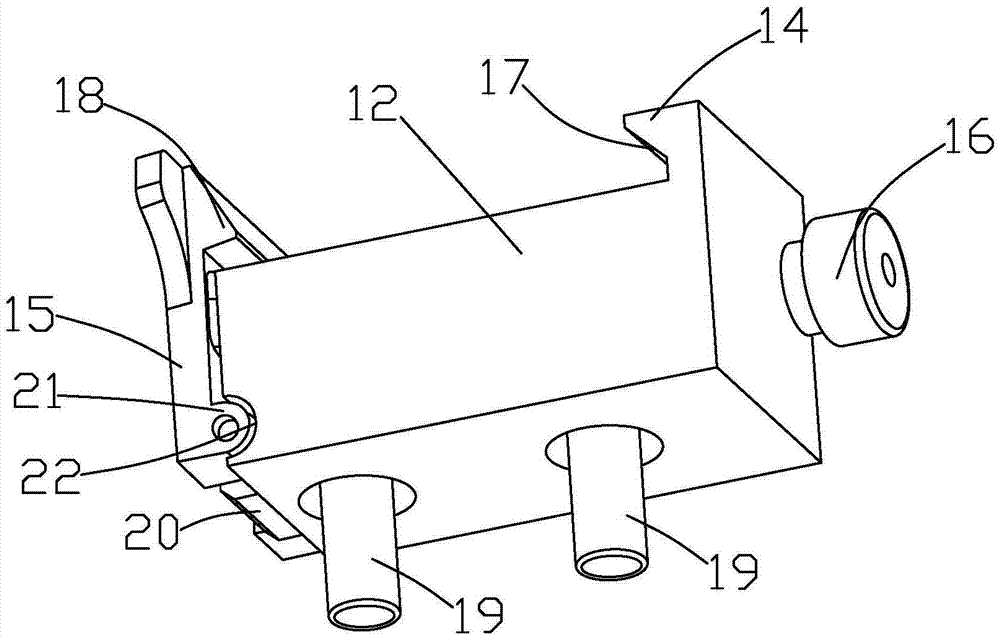

[0028] like Figure 1 to Figure 5As shown, it is a locking device for mechanical parts processing according to the present invention, which includes a supporting positioning plate 1, an I-shaped guide rail 2, a sliding mechanism 3 and a locking system 4, and the supporting positioning plate 1 is moved and connected to the I-shaped On the type guide rail 2, the sliding mechanism 3 includes a horizontal plate 27, a turntable 31 and two sets of limit mechanisms. The turntable 31 is rotatably connected to the top surface of the horizontal plate 27. The top surface of the turntable 31 is provided with a column 32, and the end of the column 32 The end cover 33 is arranged on the top, and the column 32 is matched with the positioning hole 6. The turntable 31 can drive the support positioning plate 1 to rotate together through the column 32 and the end cover 33, which increases the working radius of the support positioning plate 1 and simplifies the process of assembly line production....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com