Line pressing door assembling production line

An assembly line and crimping technology, which is applied in the direction of multi-purpose machinery, wood processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, large door volume and weight, and is not suitable for mass production, so as to reduce physical strength and improve Production efficiency and labor cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

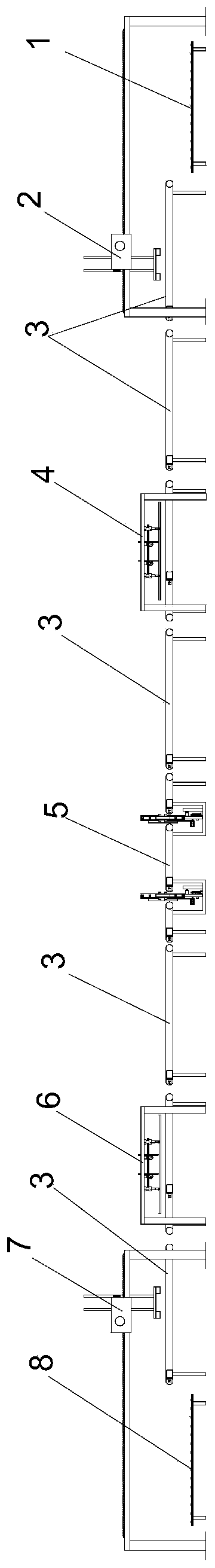

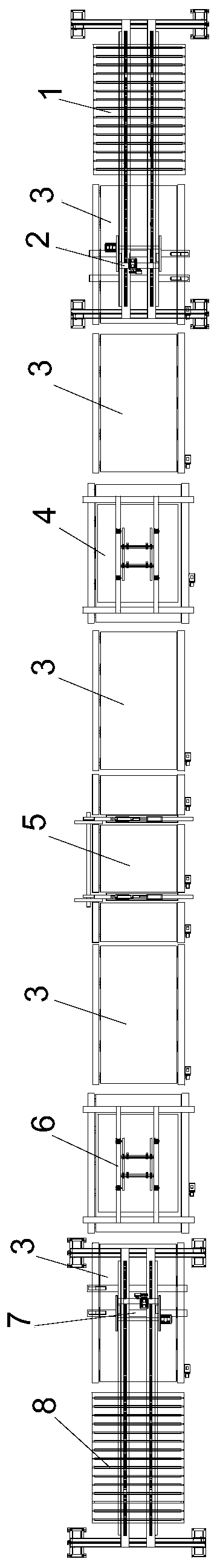

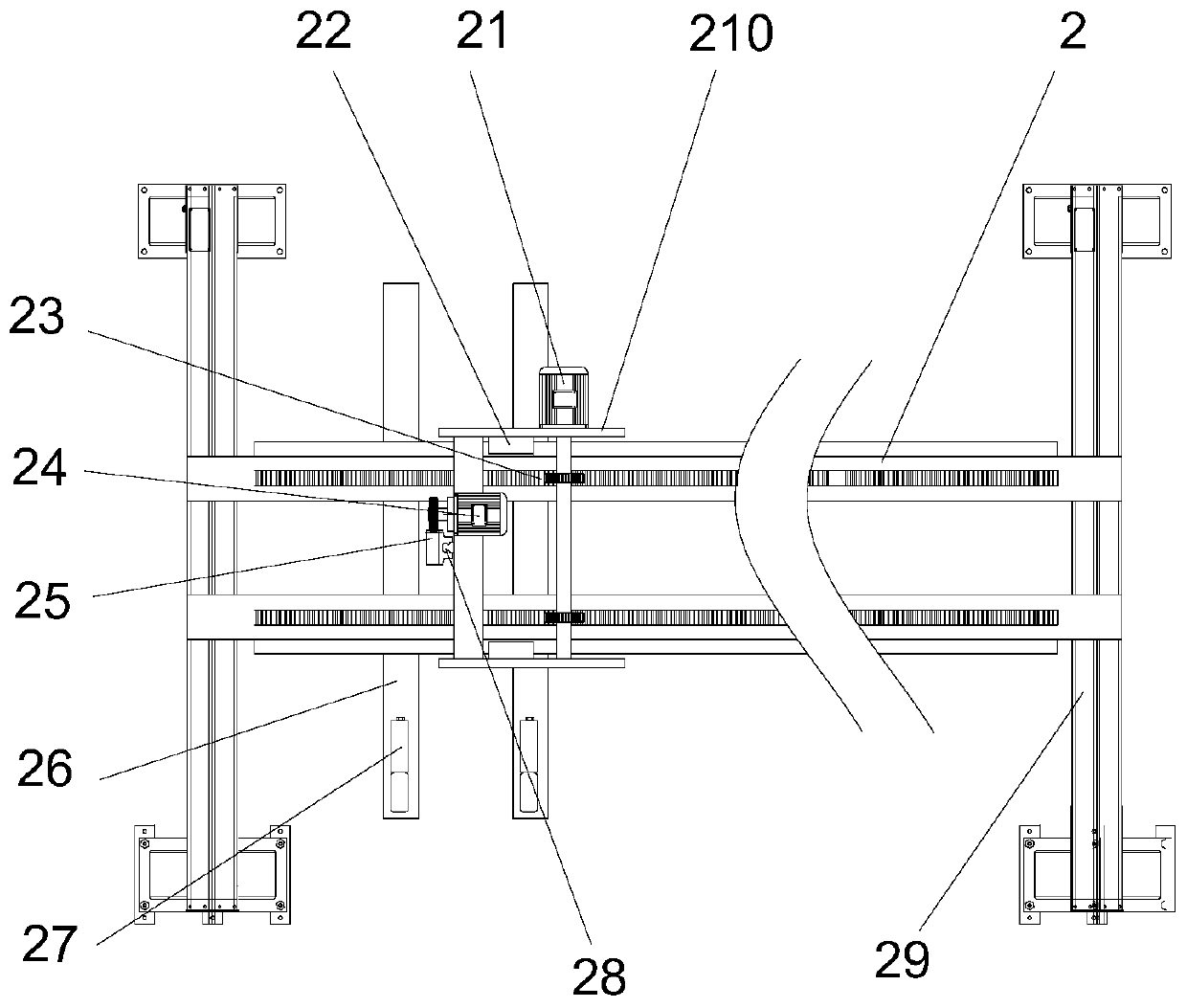

[0034] Such as Figure 1-2 As shown, a press line door assembly production line provided by the present invention includes a suction cup type automatic feeder 2, a pneumatic press I4, a turning machine 5, a pneumatic press II6, and a suction cup type which are sequentially arranged along the conveying direction of the conveying line 3. Automatic blanking machine 7, in which the suction cup type automatic loader 2 is used to transport the door panels to be pressed to the conveyor line 3, and the door panels to be pressed are transported to each station through the conveyor line 3; the pneumatic press I4 is used to The side surface of the door panel to be crimped delivered to the first press-fitting station is pressed; the turning machine 5 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com