Production process of shuttlecock heads

A production process and badminton technology, applied in the field of badminton equipment, can solve problems such as unstable quality distribution of badminton ball heads, inability to effectively ensure the quality stability of ball heads, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

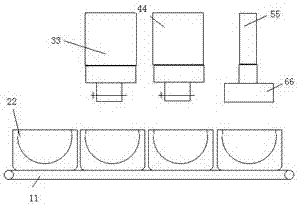

[0026] Such as figure 1 Shown is a production system for badminton heads, including a transmission mechanism, a batching mechanism, a compacting mechanism and a glue injection machine arranged above the transmission mechanism;

[0027] The transmission mechanism includes a ball mold 22 and a vibrating conveyor 11; the ball mold 22 is a finished product and is purchased; before use, the ball mold 22 is placed in a heating mechanism (in this embodiment, it can be a muffle furnace, a box type high temperature furnace or oven), used to heat the ball mold 22 to a certain temperature; the ball mold 22 is placed on the vibration conveyor 11, and can move with the vibration conveyor 11; in order to ensure that the ball mold 22 will not be caused by Vibration causes displacement deviation. The vibration conveyor 11 is provided with a ball head mold 22 installation groove, and the ball head mold 22 is located in the installation groove.

[0028] The batching mechanism comprises a feede...

Embodiment 2

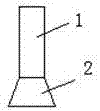

[0032] The difference from Example 1 is that, as Figure 2-3 The glue injection machine shown includes a glue feeding mechanism 1 and a glue melting mechanism 2 arranged vertically:

[0033] The glue delivery mechanism 1 includes a glue delivery inlet and a glue delivery outlet; in this embodiment, the glue delivery mechanism 1 can use a glue delivery gun in the prior art, but here the end of the glue delivery gun is not equipped with a heating device, and only realizes uniform delivery of glue role;

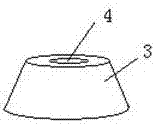

[0034] The glue melting mechanism 2 includes a heating body 3; the heating body 3 is arranged on the glue feeding outlet side of the glue feeding mechanism 1, and the heating body 3 is insulated between the glue feeding mechanism 1 (there is no heat between the heating body 3 and the glue feeding mechanism 1 in this embodiment). In contact, a heat insulating layer / insulation layer can also be laid between the heating body 3 and the glue feeding mechanism 1), the heating body 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com