Electrode structure for capacitive touch screens and preparation method thereof

A capacitive touch screen, electrode structure technology, applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problem of poor conductivity or adhesion performance, adhesion, conductivity and corrosion resistance/ Oxidation can not achieve better results at the same time, not corrosion resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

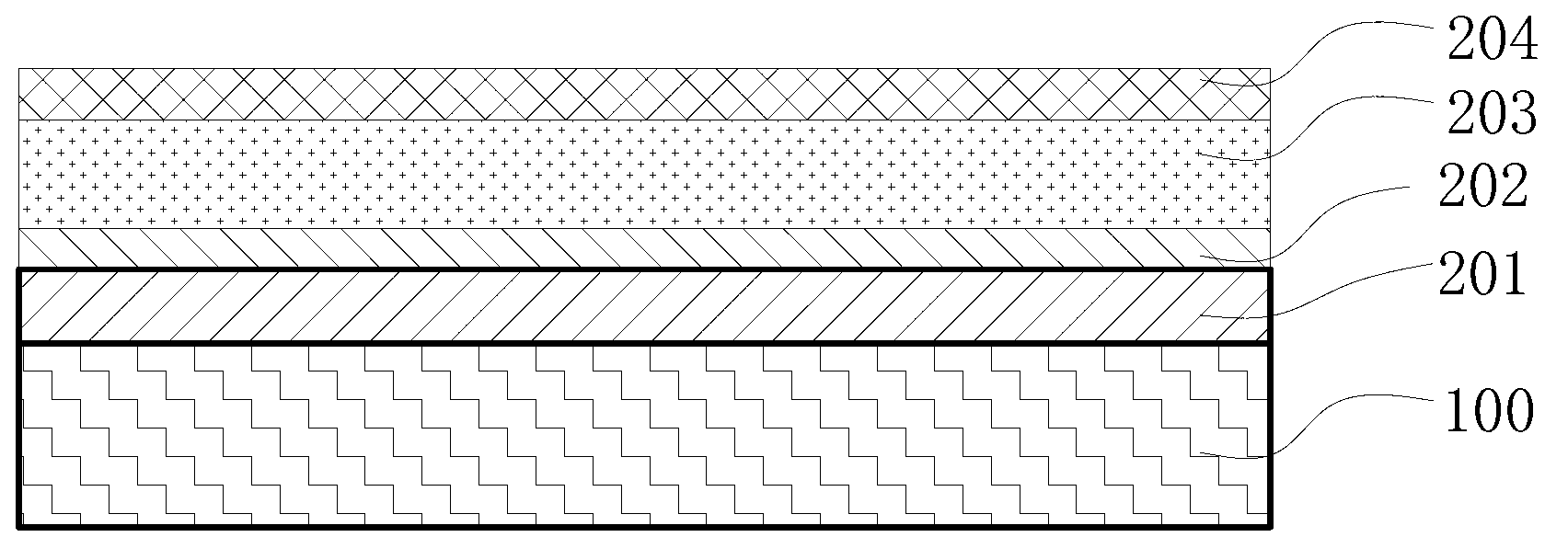

[0121] An electrode structure for a capacitive touch screen, the electrode structure sequentially includes a glass substrate, a graphene layer, a NiCu alloy layer, an Al metal layer and a Mo metal layer from bottom to top;

[0122] Wherein, the thickness of the NiCu alloy layer is 30nm; the thickness of the Al metal layer is 140nm; the thickness of the Mo metal layer is 30nm; the thickness of the glass substrate is 2mm; the thickness of the graphene layer is 0.5nm; image 3 It is a schematic structural view of the transparent conductive film layer used in the capacitive touch screen described in Embodiment 1.

[0123] Preparation:

[0124] The preparation method of the electrode structure of the capacitive touch screen:

[0125] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the metal substrate in a vacuum tube furnace, injecting hydrogen into the vacuum chamber while removing oxygen in the vacuum chamber, and raising the temp...

Embodiment 2

[0134] An electrode structure for a capacitive touch screen, the electrode structure sequentially includes a glass substrate, a graphene layer, a NiCu alloy layer, an Al metal layer and a Mo metal layer from bottom to top;

[0135] Wherein, the thickness of the NiCu alloy layer is 150nm; the thickness of the Al metal layer is 700nm; the thickness of the Mo metal layer is 150nm; the thickness of the glass substrate is 0.3mm; the thickness of the graphene layer is 3nm.

[0136] Preparation:

[0137] The preparation method of the electrode structure of the capacitive touch screen:

[0138] (1) Using the method disclosed in CN102220566A to prepare a graphene film, specifically: placing the metal substrate in a vacuum tube furnace, injecting hydrogen into the vacuum chamber while removing oxygen in the vacuum chamber, and raising the temperature to 1000°C, Then methane gas is injected into the vacuum chamber to obtain a metal substrate deposited with graphene; the number of atomic...

Embodiment 3

[0147] An electrode structure for a capacitive touch screen, the electrode structure sequentially includes a PET substrate, a graphene layer, a NiCu alloy layer, an Al metal layer and a Mo metal layer from bottom to top;

[0148] Wherein, the thickness of the NiCu alloy layer is 120nm; the thickness of the Al metal layer is 500nm; the thickness of the Mo metal layer is 180nm; the thickness of the PET substrate is 1.6mm; the thickness of the graphene layer is 2nm.

[0149] Preparation:

[0150] The preparation method is the same as in Example 1, except that the process conditions for the magnetron sputtering deposition coating of the NiCu alloy layer in step (3) are: vacuum degree 0.4Pa, voltage 450V, target material is NiCu alloy, and working gas is argon The process conditions of the magnetron sputtering deposition coating of the Al metal layer are: vacuum degree 0.4Pa, voltage 320V, the material of the target is metal Al, and the working gas is argon; the process conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com