Method for manufacturing planar high-voltage ultrafast soft recovery diode

A technology for recovering diodes and a manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unsuitable large-scale industrial production, high price of epitaxial silicon materials, and expensive epitaxial materials, etc. Reverse recovery characteristics, low cost, and the effect of speeding up extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

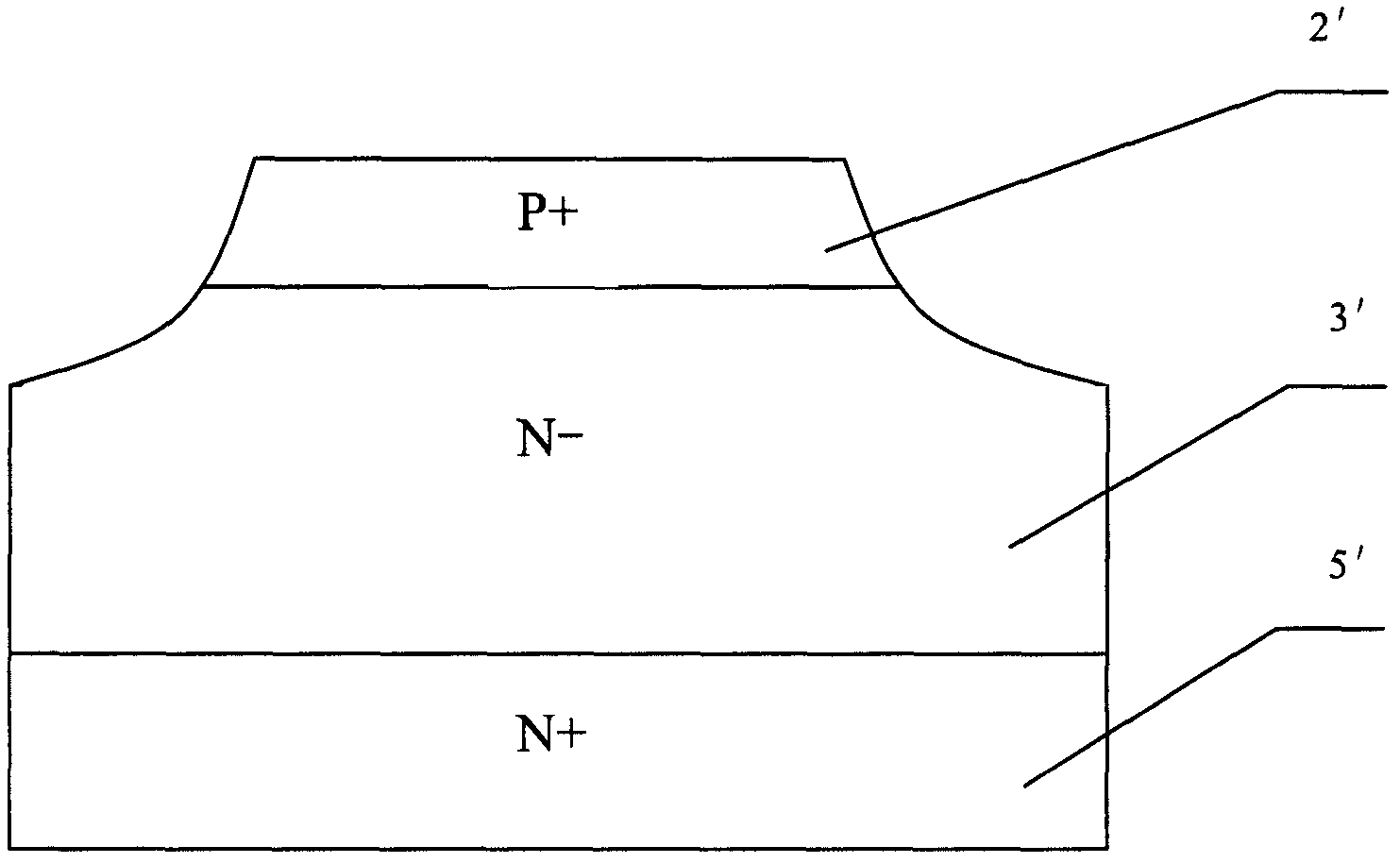

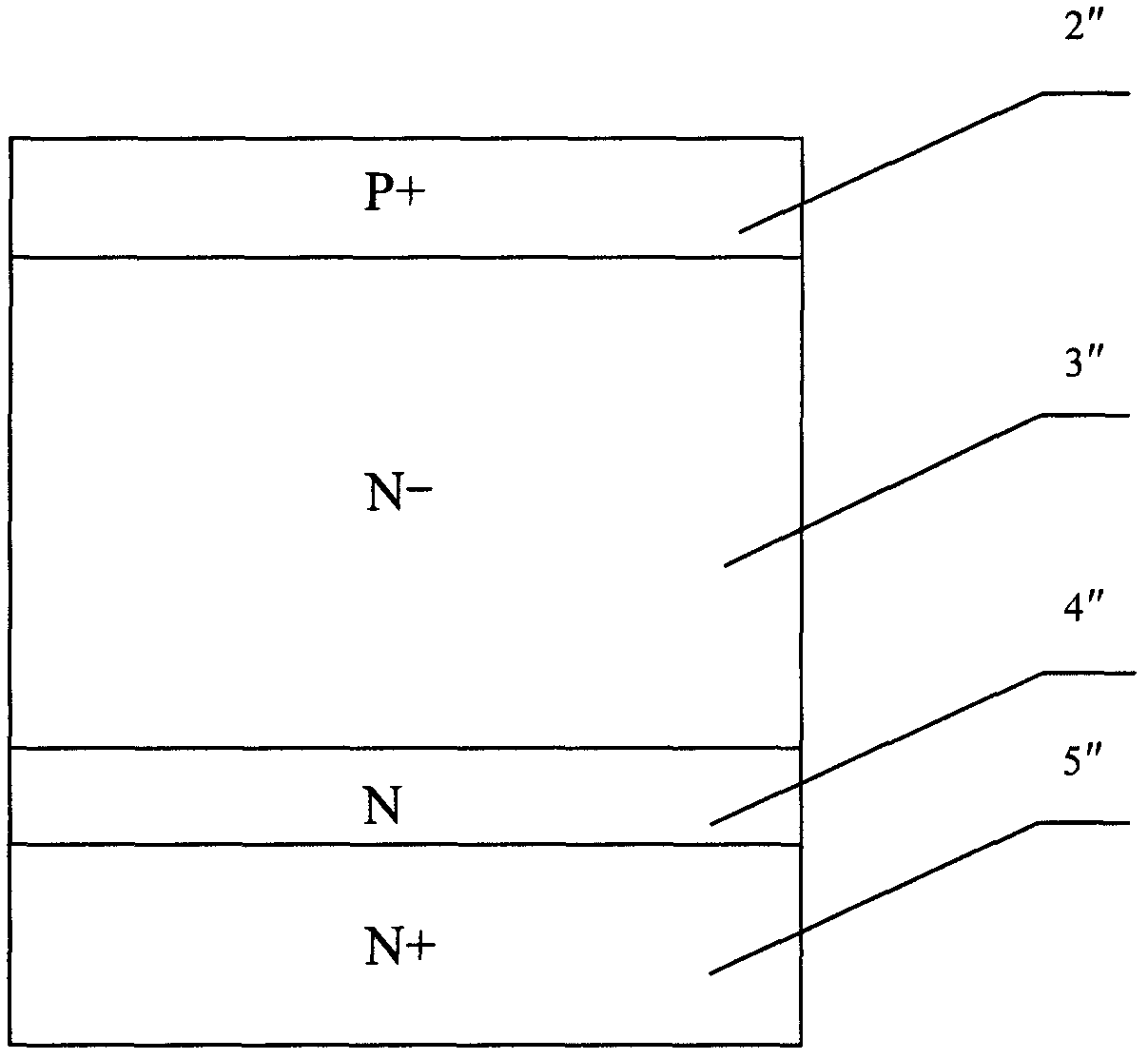

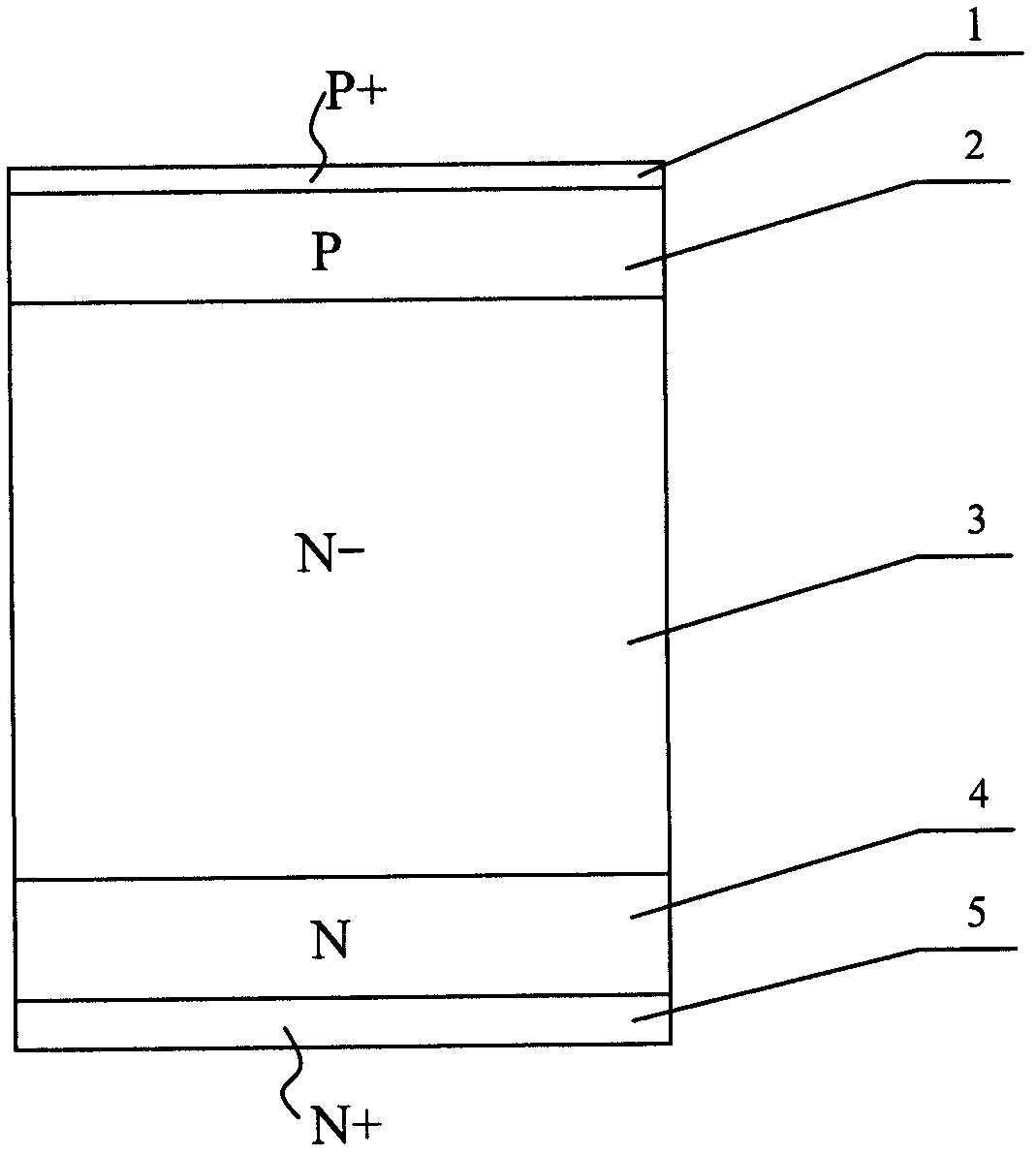

[0040] Such as image 3 As shown, the vertical structure adopted by the present invention is composed of an anode contact P+ layer 1, an anode region P type layer 2, an N- high resistance layer 3, an N type buffer layer 4, and a cathode contact N+ layer 5. The horizontal terminal structure adopted is such as Figure 4 As shown, it includes a field limiting ring 9, a polysilicon field plate 7 and an N+ type stop ring 10. One end of the polysilicon field plate 7 is in contact with the field limiting ring 9, and the other end is under the initial oxide layer 8, and the passivation layer 6 covers the entire terminal. .

[0041] The longitudinal structure of the chip adopts the P+PN-NN+ structure, such as image 3 As shown, the P+ layer 1 and the N+ layer 5 are the contact layers of the anode and the cathode respectively, which form a good ohmic contact with the metal electrode and reduce the forward voltage drop; the P-type layer 2 in the anode region adopts the anode emission efficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com