Dissolving system

A reaction tank and circulating stirring technology, applied in the field of dissolving systems, can solve problems such as difficulty in mass production, and achieve the effects of satisfying mass production, convenient operation and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

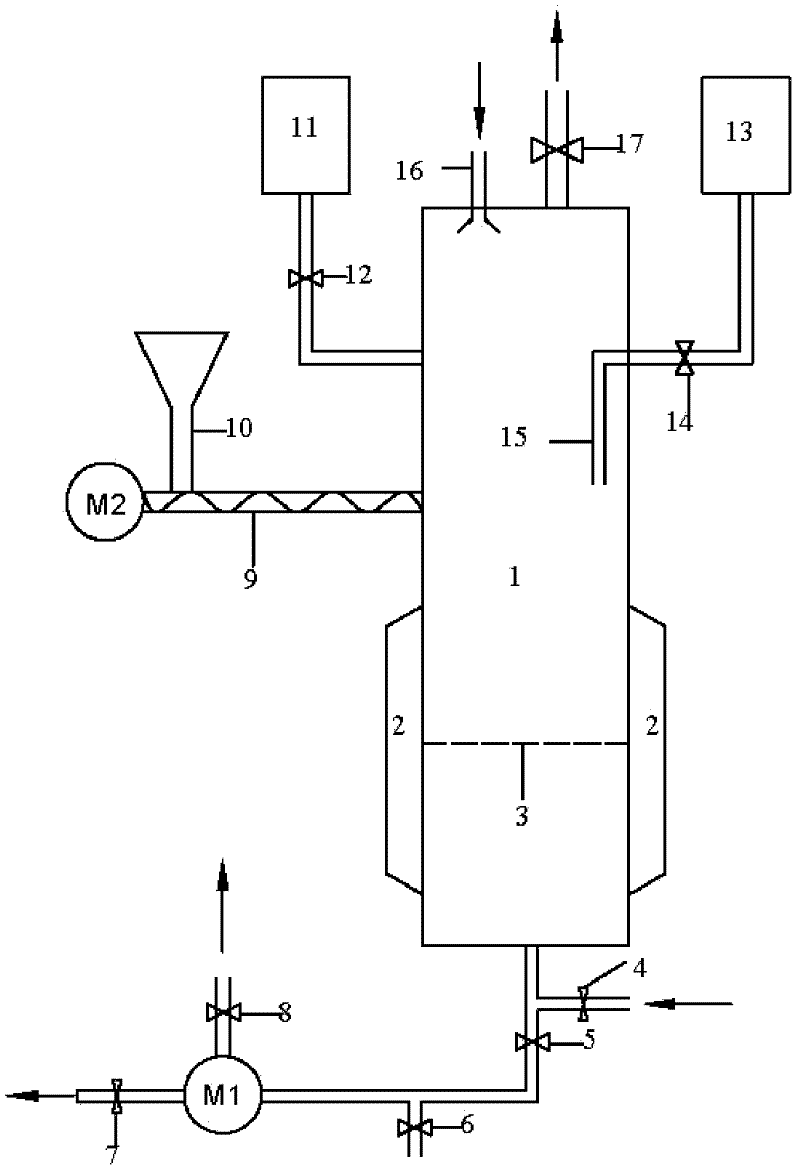

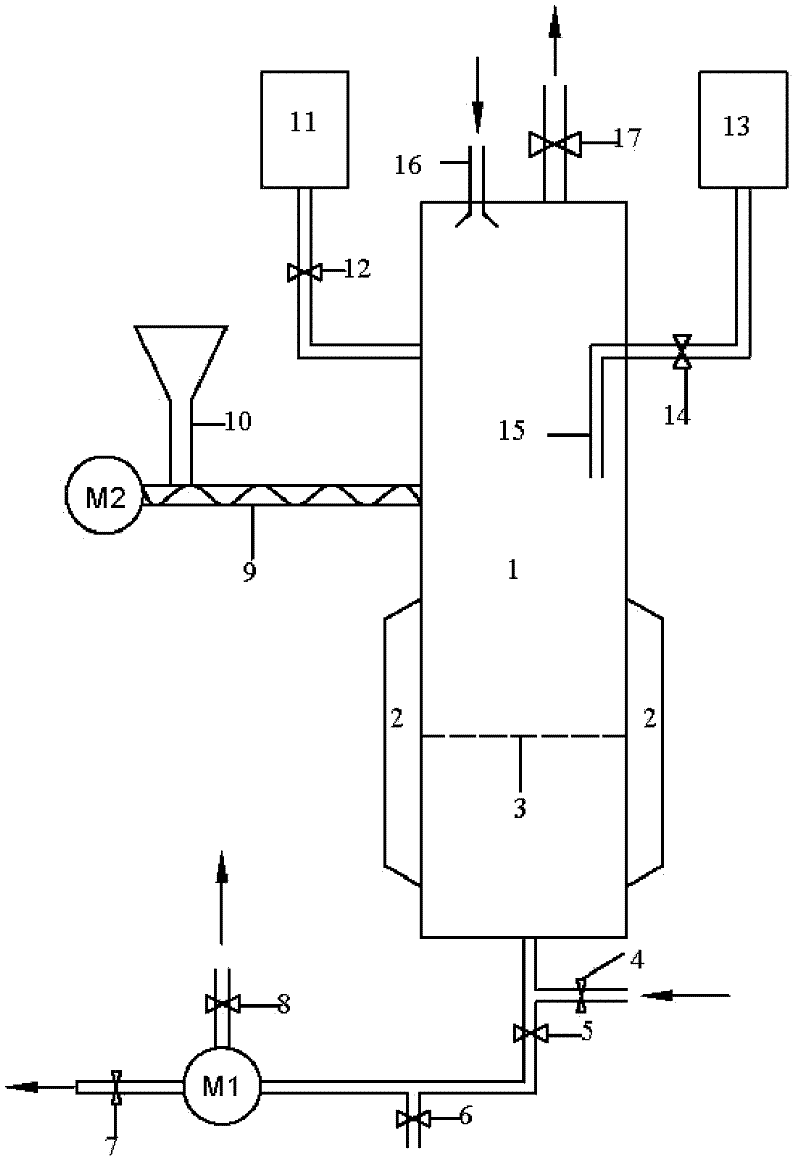

[0032] like figure 1 As shown, the dissolving device of the embodiment of the present invention includes: a sealed reaction tank 1, a feeder 9 connected to the reaction tank 2, a liquid inlet pipeline, a circulation stirring system, an air flow stirring device and an exhaust pipe.

[0033] Among them, the reaction tank 1 is made of stainless steel and is cylindrical, which is used to store reactants and provide a reaction place. The diameter of the cylinder is calculated according to the critical safety of the material, and it meets the critical safety under the maximum production capacity. Discharge pipe 7 for discharge. A heating jacket 2 is installed on the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com