Method for preparing microwave high-frequency multi-layer circuit board

A multi-layer circuit board and manufacturing method technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of reducing the stability of the circuit board, large dielectric loss, large dielectric constant, etc., to meet mass production, improve bonding force, The effect of improving the bonding force between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

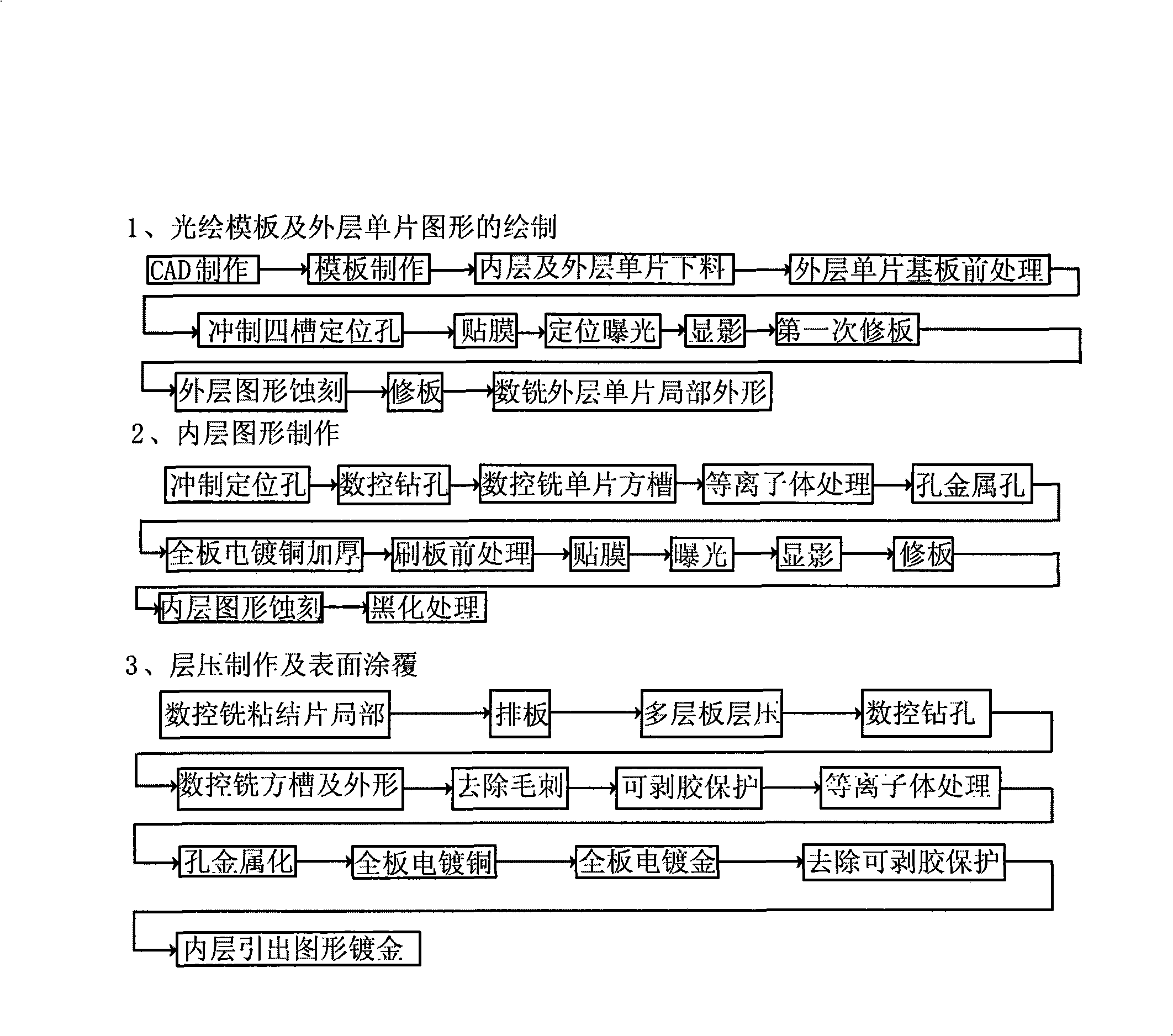

[0009] exist figure 1 Among them, the present invention provides a kind of manufacture method of microwave high-frequency multilayer circuit board, and it comprises the following steps: Step 1, the making of optical drawing template and outer layer figure: 1, adopt CAD in the inner and outer layer monolithic of template Graphic design on the board, the inner monolithic board and the outer monolithic board are made of glass fiber reinforced tetrafluoroethylene copper clad board, ceramic filled PTFE copper clad board or ceramic filled thermosetting resin copper clad board , 2. Blanking the inner and outer monolithic boards of the template, 3. Punching four slot positioning holes on the outer monolithic board, 4. Sticking a film on the outer monolithic board, performing positioning exposure and developing, according to the image Such as repairing the outer monolithic board, 5. Etching according to the designed graphics on the outer monolithic board, and then performing the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com