Hot melting adhesive membrane for adhering ethylene propylene diene monomer

A technology of EPDM rubber and hot melt adhesive film, applied in the direction of rubber layered products, adhesives, adhesive types, etc., can solve the problems of low yield, long process flow, and unhealthy workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

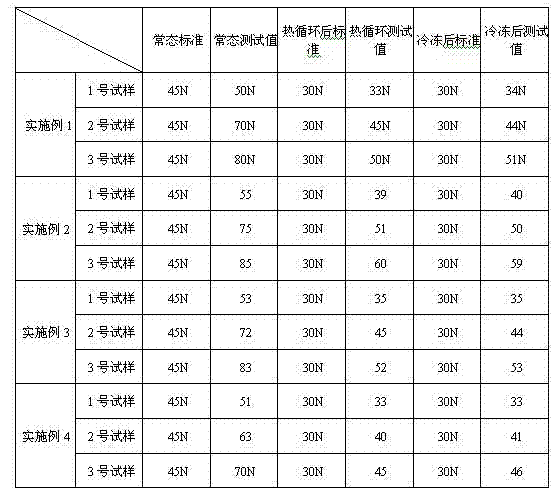

Embodiment 1

[0027] In Example 1, the modified SEBS resin is formed by mixing SEBS and hydrogenated naphthenic oil in a mass ratio of 100:20, and the maleic anhydride modified petroleum resin is maleic anhydride grafted C5 hydrogenated petroleum resin; the coupling agent is A silane coupling agent;

Embodiment 2

[0028] The modified SEBS resin in Example 2 is made by mixing SEBS and hydrogenated naphthenic oil at a mass ratio of 100:30, and the maleic anhydride-modified petroleum resin is a maleic anhydride-grafted cycloaliphatic resin (DCPD); the coupling agent It is a silane coupling agent;

Embodiment 3

[0029] In Example 3, the modified SEBS resin is made by mixing SEBS and hydrogenated naphthenic oil in a mass ratio of 100:40, and the maleic anhydride modified petroleum resin is maleic anhydride grafted aromatic resin (C9); the coupling agent It is a silane coupling agent;

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com