Preparation method and application of water-soluble carbon fiber sizing agent

A carbon fiber and water-soluble technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of unsatisfactory hydrophilicity and dispersibility of carbon fiber, unfavorable dispersibility of carbon fiber, and low surface energy of carbon fiber, so as to facilitate the mixing of pulp Effect of sizing, improving hydrophilicity and dispersibility, and good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: A carbon fiber sizing agent, which is made of polyethyleneimine, high molecular weight polyethylene glycol ester compound, SOPE-10 standard emulsifier and ethanol aqueous solution, with a weight ratio of 25:0.5 :0.5:74. When making, first add 25 parts of polyethyleneimine to 74 parts of ethanol aqueous solution at 60-70 ° C, stir to dissolve it completely, and then add 0.5 parts of high molecular weight polyethylene glycol ester compound Add 0.5 parts of SOPE-10 emulsifier into the above solution, stir and dissolve to form an integrated solution to obtain a water-soluble carbon fiber sizing agent.

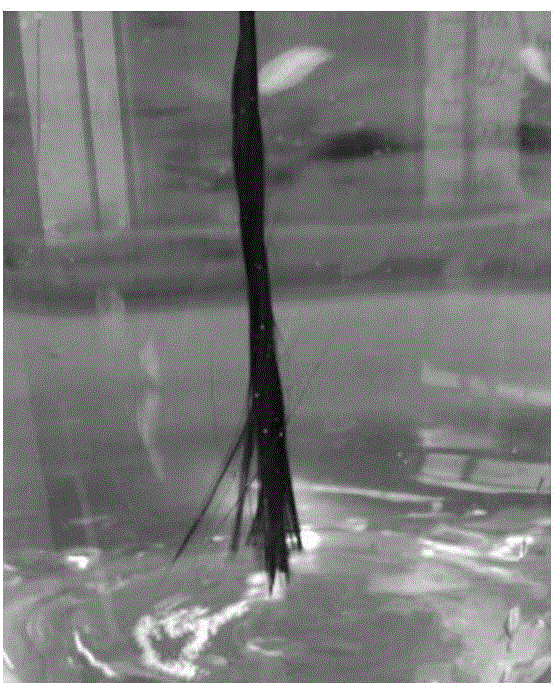

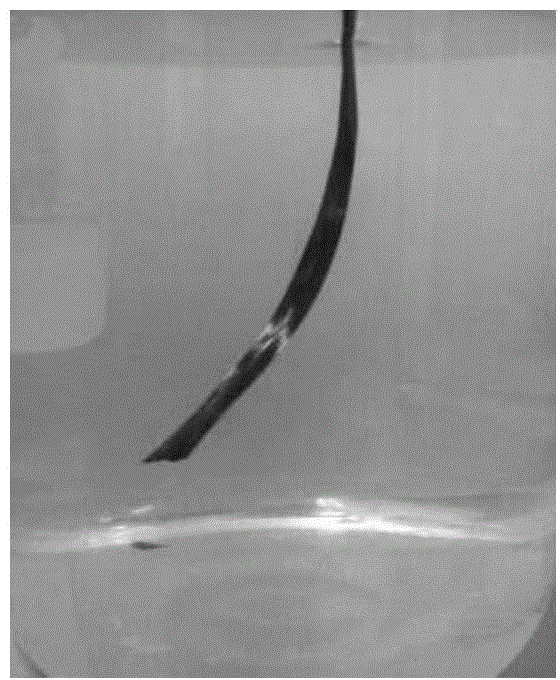

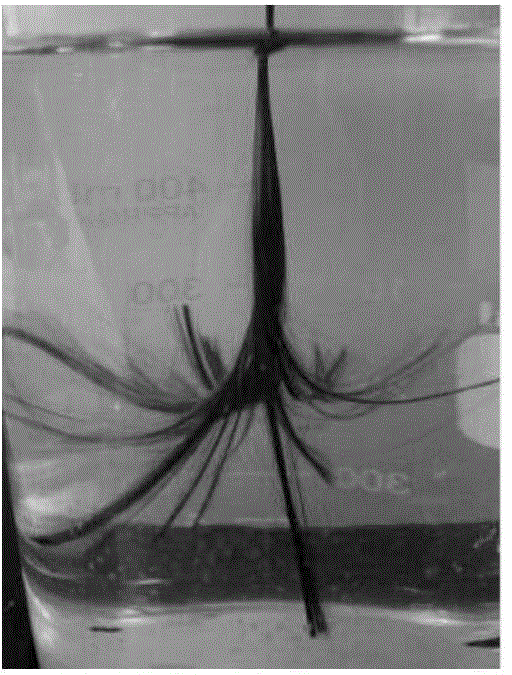

[0020] The weight fraction of the carbon fiber after sizing with this sizing agent is 3.88%; through the contact angle test, the contact angle between the carbon fiber and water after sizing is reduced by 20% compared with that before sizing, and the hydrophilicity is improved; the carbon fiber after sizing Disperses after about 10 seconds after immersion in w...

specific Embodiment approach 2

[0021] Specific embodiment two: a kind of carbon fiber sizing agent, it is made by the mixture of carboxymethylcellulose and polyvinylpyridine, polyacrylic acid ester modified by acid group, SOPE-7 standard emulsifier, ethanol aqueous solution, The weight ratio is 15:0.5:0.5:84. When making, first add 15 parts of carboxymethylcellulose and polyvinylpyridine mixture into 40 parts of ethanol aqueous solution at 70-80 ° C, stir to dissolve it completely, then add 44 parts of remaining ethanol aqueous solution, adjust the temperature to 30-50°C; then add 0.5 parts of acid group-modified polyacrylate and 0.5 parts of SOPE-7 emulsifier into the above solution, stir and dissolve to form an integrated solution, and obtain a water-soluble carbon fiber Sizing agent.

[0022] The weight fraction of the carbon fiber after sizing with this sizing agent is 1.96%; through the contact angle test, the contact angle between the carbon fiber and water after sizing is reduced by 27% compared wit...

specific Embodiment approach 3

[0023] Specific embodiment three: a kind of carbon fiber sizing agent, it is made by the mixture of polyethyleneimine and vinyl acetate, polyacrylic acid sodium salt, the emulsifier of SOPE-15 specification, deionized water, and the weight ratio is 6: 0.3:0.2:94. When making it, first add the mixture of 6 parts of polyethyleneimine and vinyl acetate to 94 parts of deionized water at 80-100 ° C, stir to dissolve it completely, and then add 0.3 parts of polyacrylic acid sodium salt Add 0.2 parts of SOPE-15 emulsifier into the above solution, stir and dissolve to form an integrated solution to obtain a water-soluble carbon fiber sizing agent.

[0024] The weight fraction of the carbon fiber after sizing with this sizing agent is 1.86%; through the contact angle test, the contact angle between the carbon fiber and water after sizing is reduced by 30% compared with that before sizing, and the hydrophilicity is improved; the carbon fiber after sizing Disperses after about 2 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com