Environmental protection type refrigerant for replacement of CFC-12

A refrigerant and environmentally friendly technology, applied in the field of refrigerants, can solve the problems of large global warming effect, achieve the effect of reducing the charging amount and good environmental performance

Active Publication Date: 2006-11-22

SINOCHEM LANTIAN +1

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, HFC-134a has a serious environmental problem, that is, the greenhouse effect on the earth. Its global warming potential GWP (Global Warming Potential) value is 1300 (with CO2 as the benchmark value of 1.0), and the global warming effect is relatively large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

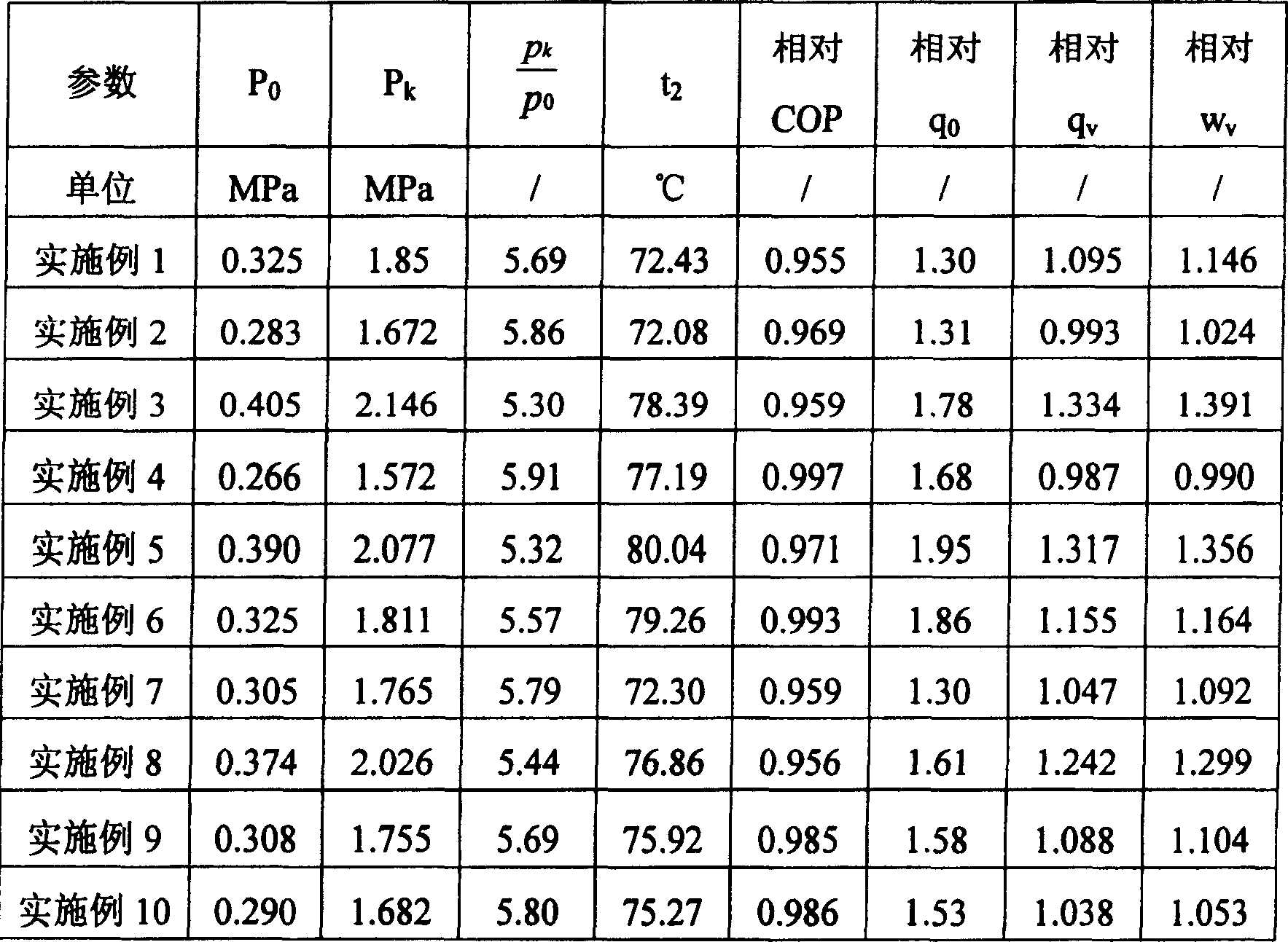

[0026] Example 1: Physically mix HFC-161, HFC-152a and HFC-134a in a liquid phase at a mass percentage of 9:1:90.

Embodiment 2

[0027] Example 2: Physically mix HFC-161, HFC-152a and HFC-134a in a liquid phase at a mass percentage of 1:9:90.

Embodiment 3

[0028] Example 3: Physically mix HFC-161, HFC-152a and HFC-134a in a liquid phase at a mass percentage of 50:1:49.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an environment-friendly refrigerant replacing CFC-12. The refrigerant contains three components of fluoroethane (HFC-161), 1,1-difluoroethane (HFC-152a) and 1,1,1,2-tetrafluoroethane (HFC-134a). Its mass percentage is: HFC-161: 1%-50%; HFC-152a: 1%-50%; HFC-134a: 30%-90%. The ODP value of this refrigerant is zero, and it does not destroy the atmospheric ozone layer. Compared with CFC-12 and its existing main substitute HFC-134a, the GWP value is smaller, and it is more in line with the requirements of environmental protection. The working pressure and pressure ratio of this refrigerant are similar to that of HFC-134a, the main substitute of CFC-12. Under the premise of basically not changing the main components of the system, it can be directly used in the system that originally used HFC-134a, and it can reduce the charge. Filling volume. This refrigerant can be used as a long-term substitute for CFC-12.

Description

technical field [0001] The invention relates to a refrigerant, in particular to an environment-friendly refrigerant replacing CFC-12. technical background [0002] Among chlorofluorocarbon (CFC) refrigerants, CFC-12 has long been widely used in automotive air conditioners, household refrigerators and industrial cold storage due to its excellent thermal performance, stable chemical performance, non-toxicity, and non-flammability. [0003] However, because CFC-12 has a certain destructive effect on the ozone layer in the atmospheric stratosphere, its ODP (Ozone Depletion Potential) value is 0.90 (with CFC-11 as the benchmark value of 1.0), so "About Ozone Depletion The Montreal Protocol on Substances includes it as the first batch of substances to be phased out. At present, developed countries have stopped the production of CFC-12, and our country is also reducing its production and use year by year, and finally stopped production and use in additio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K5/04

Inventor 郭智恺郭心正

Owner SINOCHEM LANTIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com