Catalyst for preparing vinyl fluoride through gas phase removal of HF by virtue of 1,1-difluoroethane as well as preparation method and application of catalyst

The technology of difluoroethane and catalyst is applied in the field of preparation of organic fluorine compounds, which can solve the problems that the catalyst selectivity needs to be improved, the carbon deposition resistance of the catalyst and the unrecorded service life, etc., so as to improve the carbon deposition resistance and application effect, Improve service life and application performance, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

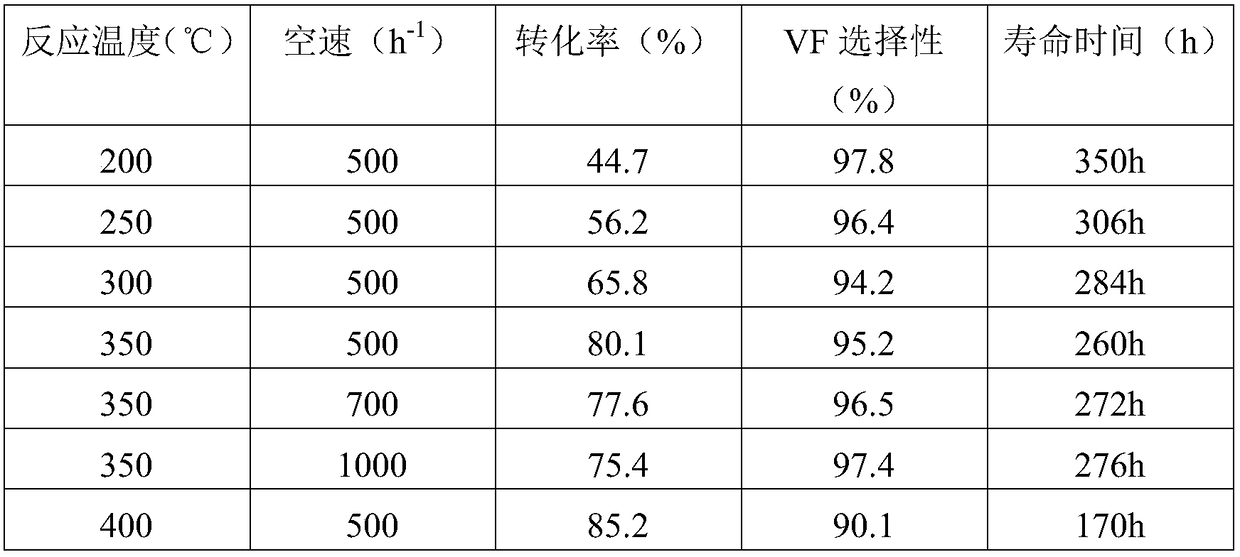

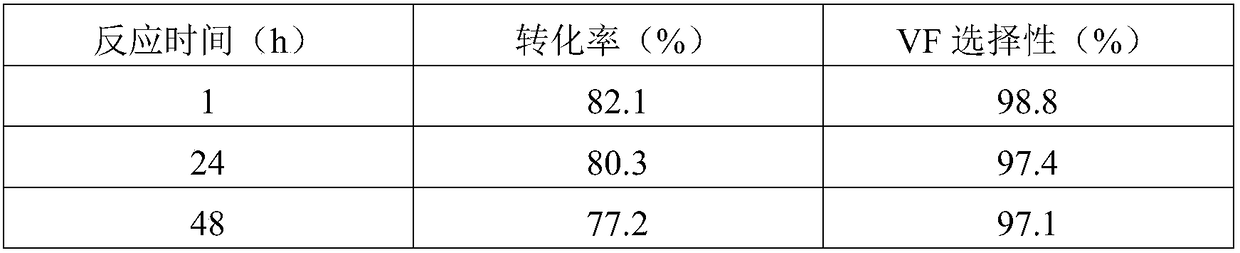

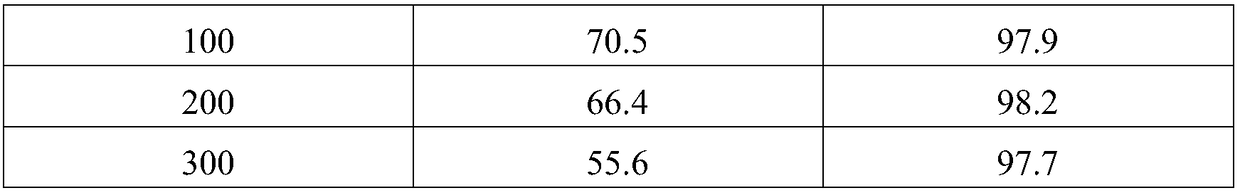

Examples

Embodiment 1

[0037] A method for preparing a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0038] Take 100 g of activated carbon with a particle diameter of 0.5 mm, put it in a drying oven, and dry it at 100° C. for 3 hours to obtain dried activated carbon. 13.35g Mg(NO 3 ) 2Dissolve in 100ml of pure water to make an impregnation solution; put the dried activated carbon into the impregnation solution, take it out after impregnation for 20 minutes, put it in a drying oven and dry it at 100°C for 3 hours to obtain a precursor; take it out, put it in a roasting furnace, Calcined at 400°C for 6h in a nitrogen atmosphere. Take out the roasted precursor and put it into In the reaction tube, N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then pass trifluoromethane gas at 300°C for fluorination at a flow rate of 6L / min, and turn off the nitrogen gas after 2h; pass trifluoromethane alone...

Embodiment 2

[0045] A method for preparing a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0046] Take 100 g of activated carbon with a particle diameter of 1 mm, put it in a drying oven, and dry it at 100° C. for 3 hours to obtain dried activated carbon. 13.35g Mg(NO 3 ) 3 Dissolve in 100ml of pure water to make an impregnation solution; put the dried activated carbon into the impregnation solution, impregnate for 20 minutes, put it in a drying oven and dry it for 3 hours at 100°C to obtain a precursor; take it out, put it in a roasting furnace, and Calcined at 400°C for 6h in a nitrogen atmosphere. Take out the roasted precursor and put it into In the reaction tube, N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then pass trifluoromethane gas for fluorination at 300°C at a flow rate of 6L / min, turn off the nitrogen gas after 2h, pass trifluoromethane alone at a flow rate of 6L...

Embodiment 3

[0053] A method for preparing a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0054] Take 100 g of activated carbon with a particle diameter of 1 mm, put it in a drying oven, and dry it at 100° C. for 3 hours to obtain dried activated carbon. 13.35g La(NO 3 ) 3 Dissolve in 100ml of pure water to prepare an impregnating solution. Put the dried activated carbon into the impregnating solution. After impregnating for 20 minutes, put it in a drying oven and dry it at 100°C for 3 hours to obtain a precursor; take it out, put it in a roasting furnace, and Calcined at 400°C for 6h in a nitrogen atmosphere. Take out the roasted precursor and put it into In the reaction tube, N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then pass trifluoromethane gas for fluorination at 300°C at a flow rate of 6L / min, turn off the nitrogen gas after 2h, pass trifluoromethane alone at a flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com