A catalyst for the gas phase removal of HF from 1,1-difluoroethane to prepare vinyl fluoride, its preparation method and application

A technology of difluoroethane and catalyst, which is applied in the field of preparation of organic fluorine compounds, can solve the problems of catalytic selectivity to be improved, catalyst anti-carbon deposition ability, and service life without record, so as to improve anti-carbon deposition ability and application effect, Improved service life and application performance, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

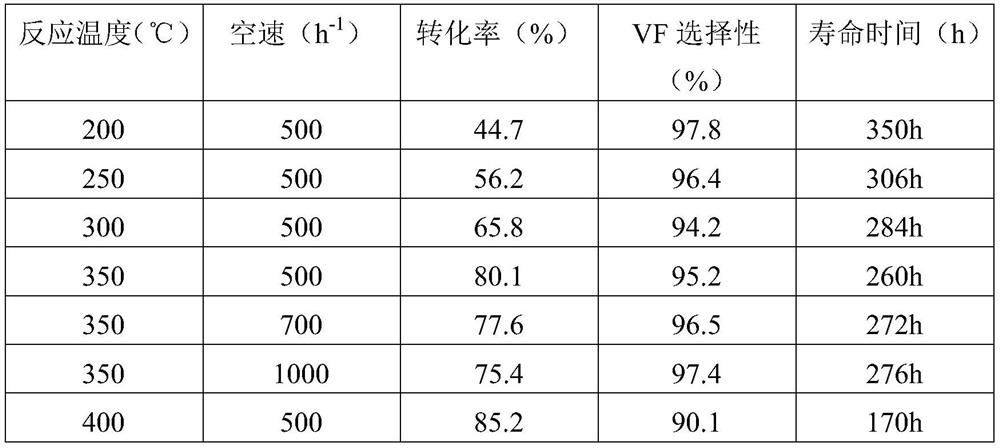

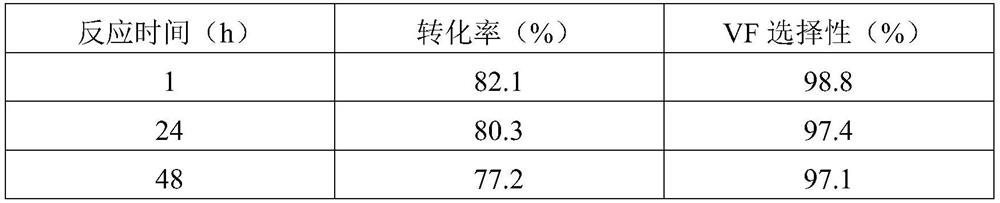

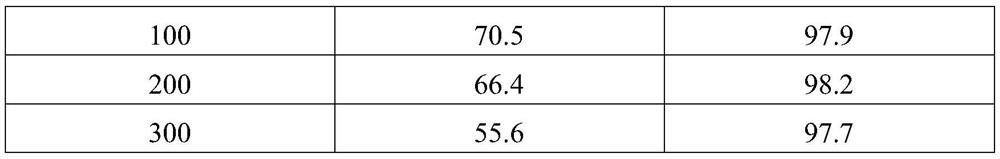

Embodiment 1

[0037] A preparation method of a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0038] Take 100 g of activated carbon with a particle diameter of 0.5 mm, put it in a drying box, and dry it at 100 °C for 3 hours to obtain dried activated carbon. 13.35g Mg(NO 3 ) 2Dissolve in 100ml of pure water to prepare an impregnation solution; put the dried activated carbon into the impregnation solution, soak it for 20 minutes, take it out, put it in a drying box and dry it at 100 ℃ for 3 hours to obtain the precursor; take it out, put it in a roasting furnace, It was calcined at 400 °C for 6 h in a nitrogen atmosphere. Take out the calcined precursor and put it in In the reaction tube, pass N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then pass trifluoromethane gas at 300°C for fluorination at a flow rate of 6 L / min, and turn off nitrogen after 2 h; pass trifluoromethane alone...

Embodiment 2

[0045] A preparation method of a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0046] Take 100 g of activated carbon with a particle diameter of 1 mm, put it in a drying box, and dry it at 100 °C for 3 hours to obtain dried activated carbon. 13.35g Mg(NO 3 ) 3 Dissolve in 100ml of pure water and configure it into an impregnation solution; put the dried activated carbon into the impregnation solution, after dipping for 20min, put it in a drying box and dry it at 100℃ for 3h to obtain the precursor; take it out, put it in a roasting furnace, It was calcined at 400 °C for 6 h in a nitrogen atmosphere. Take out the calcined precursor and put it in In the reaction tube, pass N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then, trifluoromethane gas was introduced for fluorination at 300°C at a flow rate of 6L / min. After 2 hours, nitrogen was turned off, and trifluorometha...

Embodiment 3

[0053] A preparation method of a catalyst for 1,1-difluoroethane gas phase removal of HF to prepare vinyl fluoride, comprising the steps of:

[0054] Take 100 g of activated carbon with a particle diameter of 1 mm, put it in a drying box, and dry it at 100 °C for 3 hours to obtain dried activated carbon. 13.35g La (NO 3 ) 3 Dissolve in 100ml of pure water, configure it into an impregnation solution, put the dried activated carbon into the impregnation solution, after dipping for 20 minutes, put it in a drying box and dry it at 100 ° C for 3 hours to obtain the precursor; take it out, put it in a roasting furnace, It was calcined at 400 °C for 6 h in a nitrogen atmosphere. Take out the calcined precursor and put it in In the reaction tube, pass N 2 , N 2 The flow rate is 300ml / min, and it is dried at a temperature of 300°C for 24h. Then, trifluoromethane gas was introduced for fluorination at 300°C at a flow rate of 6L / min. After 2 hours, nitrogen was turned off, and tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com