Process method for preparing cyanamide by catalyzing urea dehydration

A process method, the technology of cyanamide, applied in the field of urea dehydration to prepare cyanamide, and the design of new catalytic system, can solve the problem of low selectivity of cyanamide, achieve simple raw materials, improve the conversion rate of urea and cyanamide The effects of selectivity and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

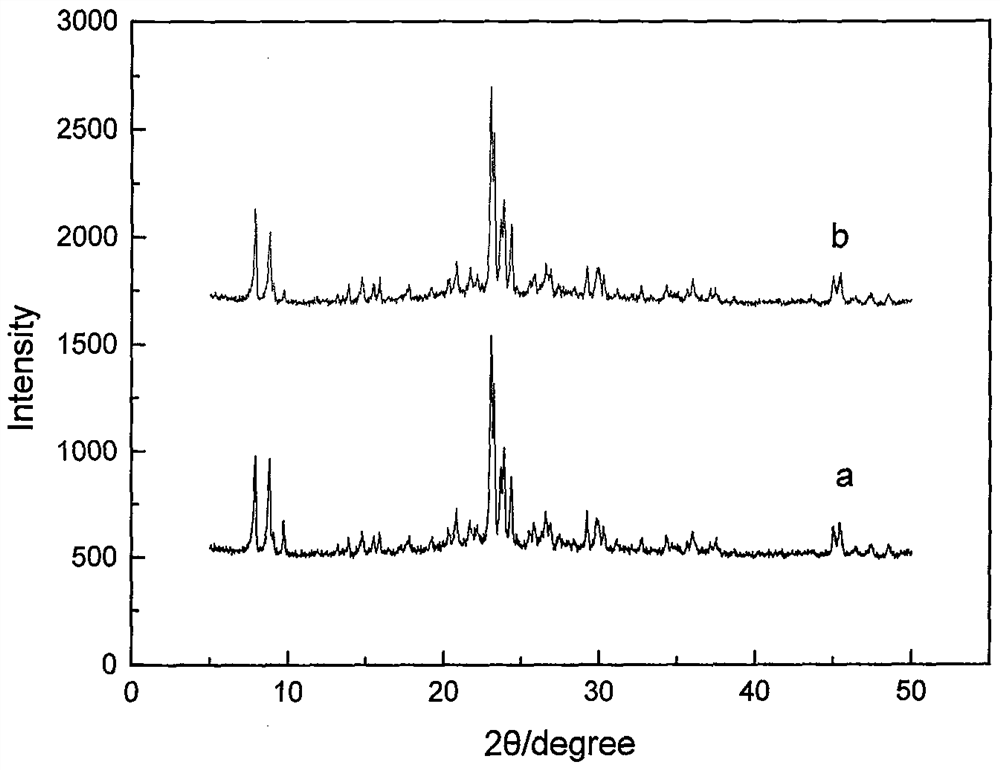

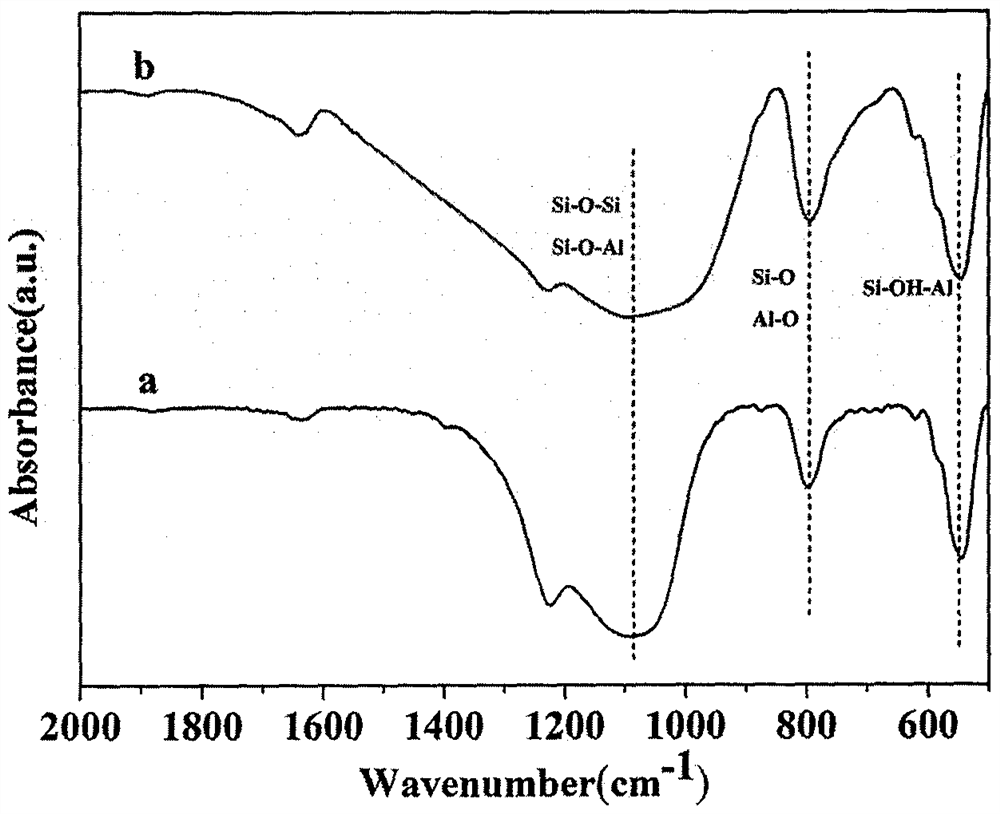

[0034] Preparation of Na-type Nano-ZSM-5 catalytic material with Si / Al ratio of 20:

[0035] Dissolve 10.0 g of template TEOS in 32.5 mL of deionized water, and use concentrated H 2 SO 4 Adjust the pH value to 1 and stir for 20h. Add 1.2g TPA-Br and 0.75gAl 2 (SO 4 ) 3 , using 1mol / L NaOH solution to adjust the pH value to 10, and aging for 10h. The aged mixed solution was put into a 100 mL crystallization kettle equipped with a polytetrafluoroethylene lining, and the temperature was kept at 180° C. in an oven for 72 hours. Suction filtration, drying at 60°C overnight. The catalyst was calcined in a muffle furnace at 550 °C for 6 h to obtain the final Na-type Namo-ZSM-5 catalyst.

Embodiment 2

[0037] Preparation of H-type Nano-ZSM-5 catalytic material with Si / Al ratio of 20:

[0038] Use 1mol / LNH before use 4 The Cl acid was exchanged 4 times, each exchange time was 2h, the exchange temperature was 90°C, after the exchange was completed, suction filtration, and drying at 60°C overnight. The muffle furnace was activated at 550 °C for 3 h to obtain the final Namo-ZSM-5 catalyst.

Embodiment 3

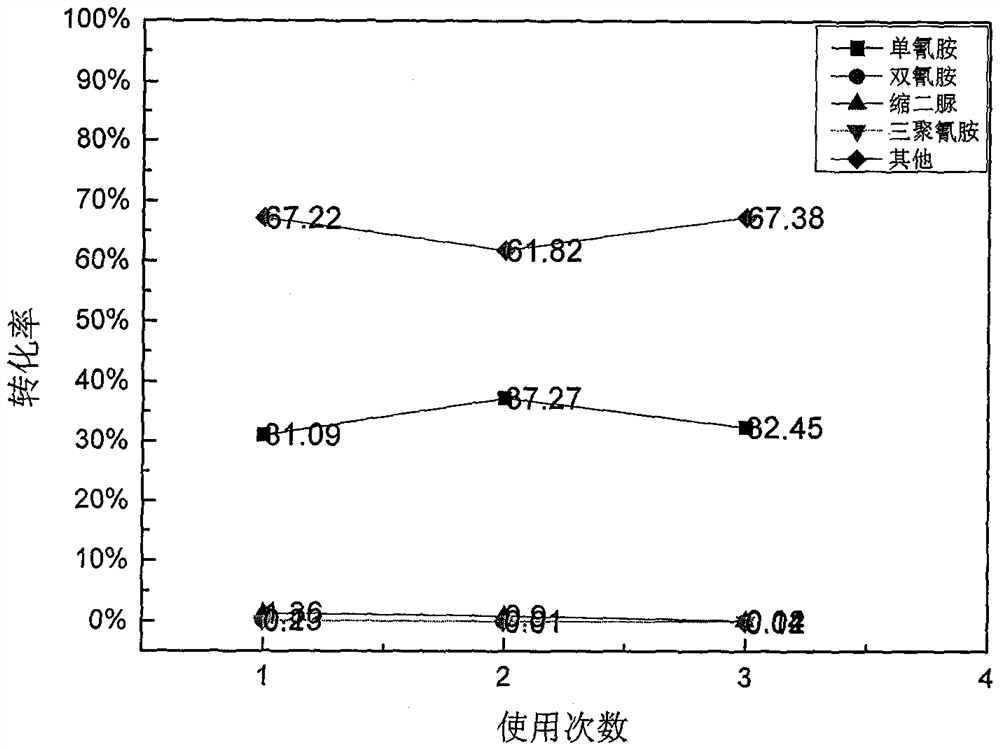

[0040] Take 8ml of the prepared H-type Nano-ZSM-5 catalytic material and fill the fixed bed reactor with 75g of glass beads, 10g of quartz sand, 8ml of catalyst and 8g of glass beads respectively in the fixed bed reactor in the order from bottom to top. Subsequently, the reaction was carried out at 550° C., the residence time was 0.5s, and the reaction time was 30min under the condition of ammonia gas atmosphere. The product was cooled by a serpentine condenser to obtain product crystallization, and the volume was constant with a 250ml volumetric flask.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com