Hydrocracking catalyst for preparing fuel oil from coal tar and preparation and application methods thereof

A hydrocracking and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc. and other problems, to achieve the effect of improving quality, long service life, and meeting the requirements of long-term industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

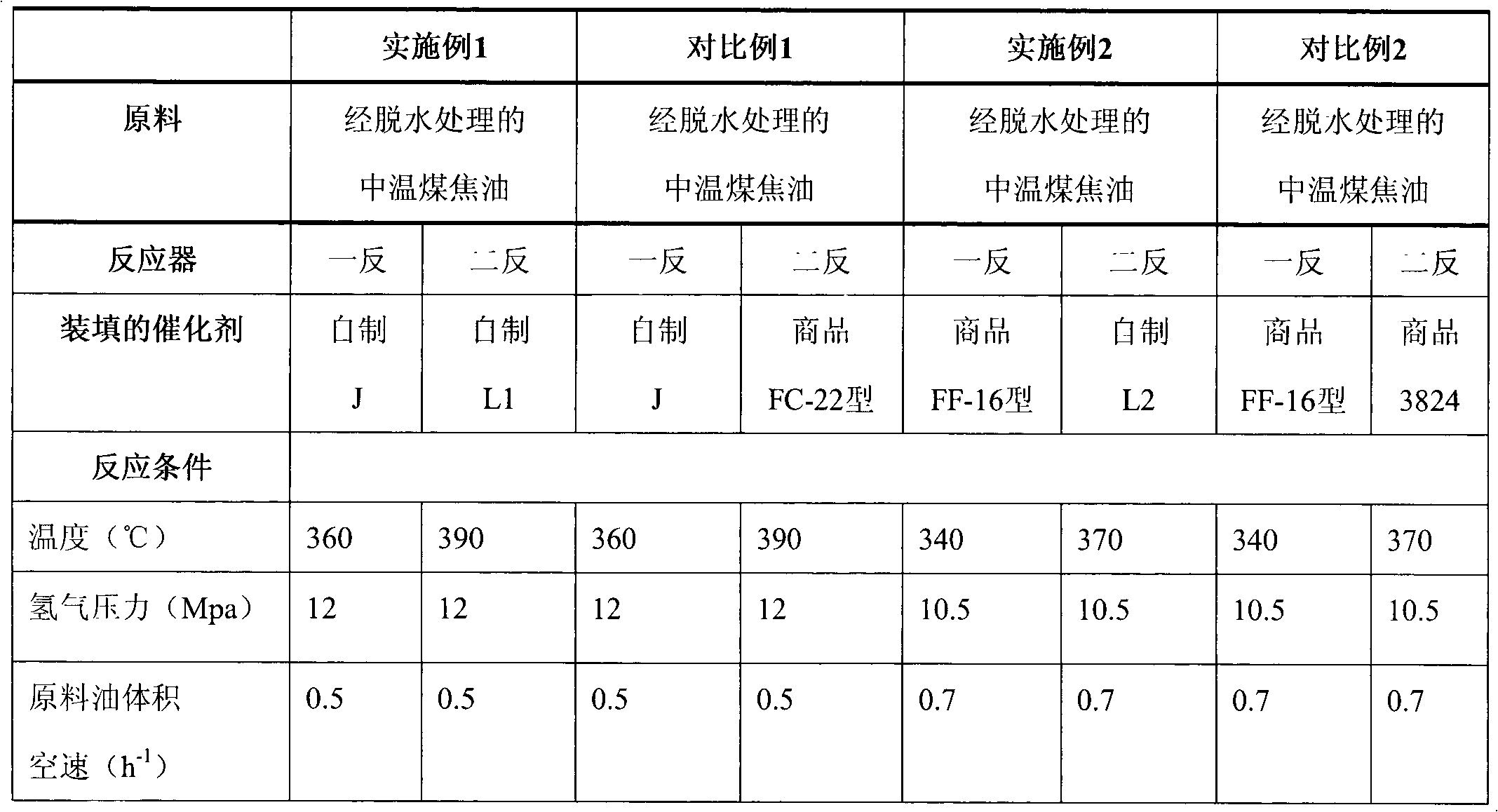

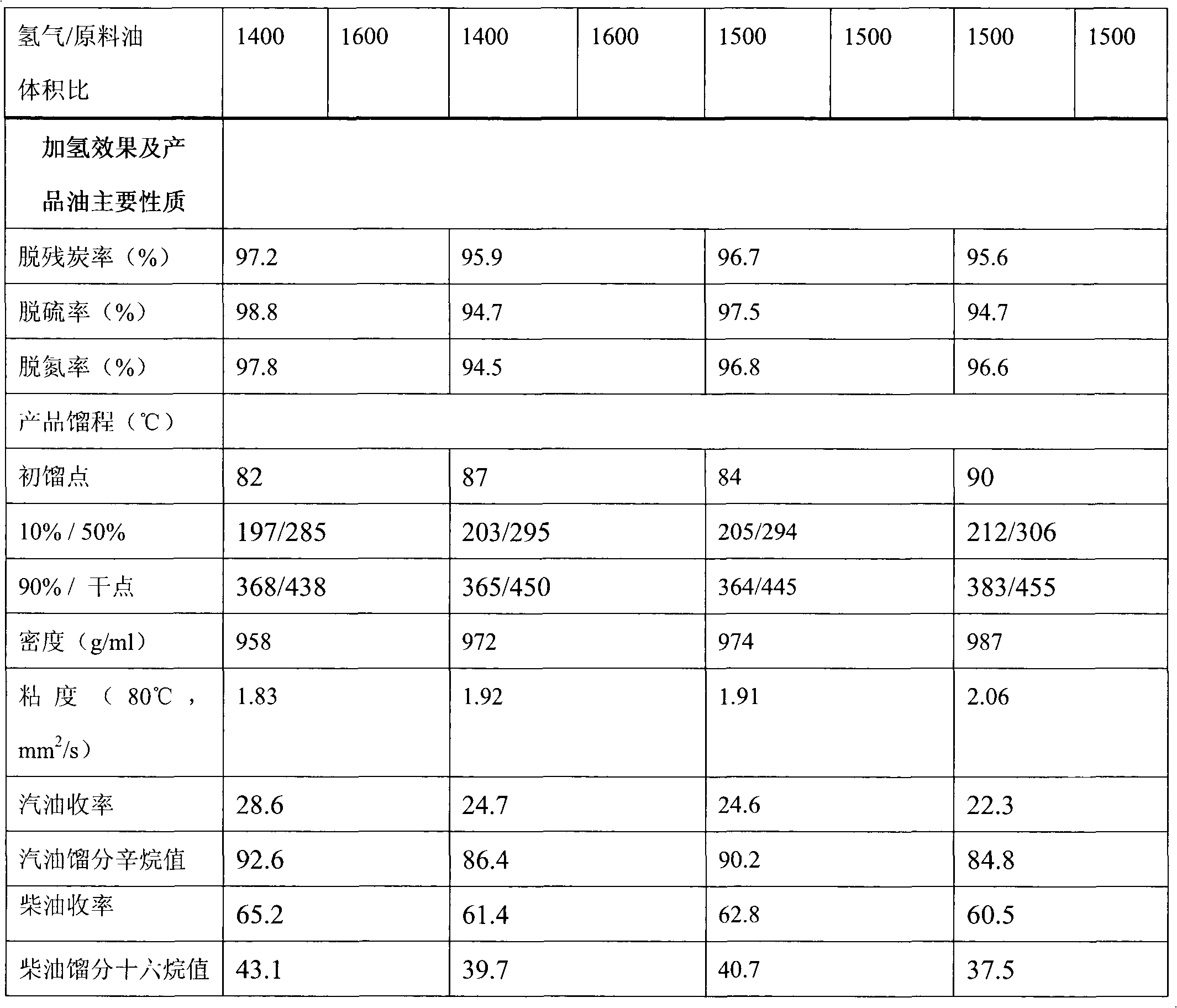

Embodiment 1

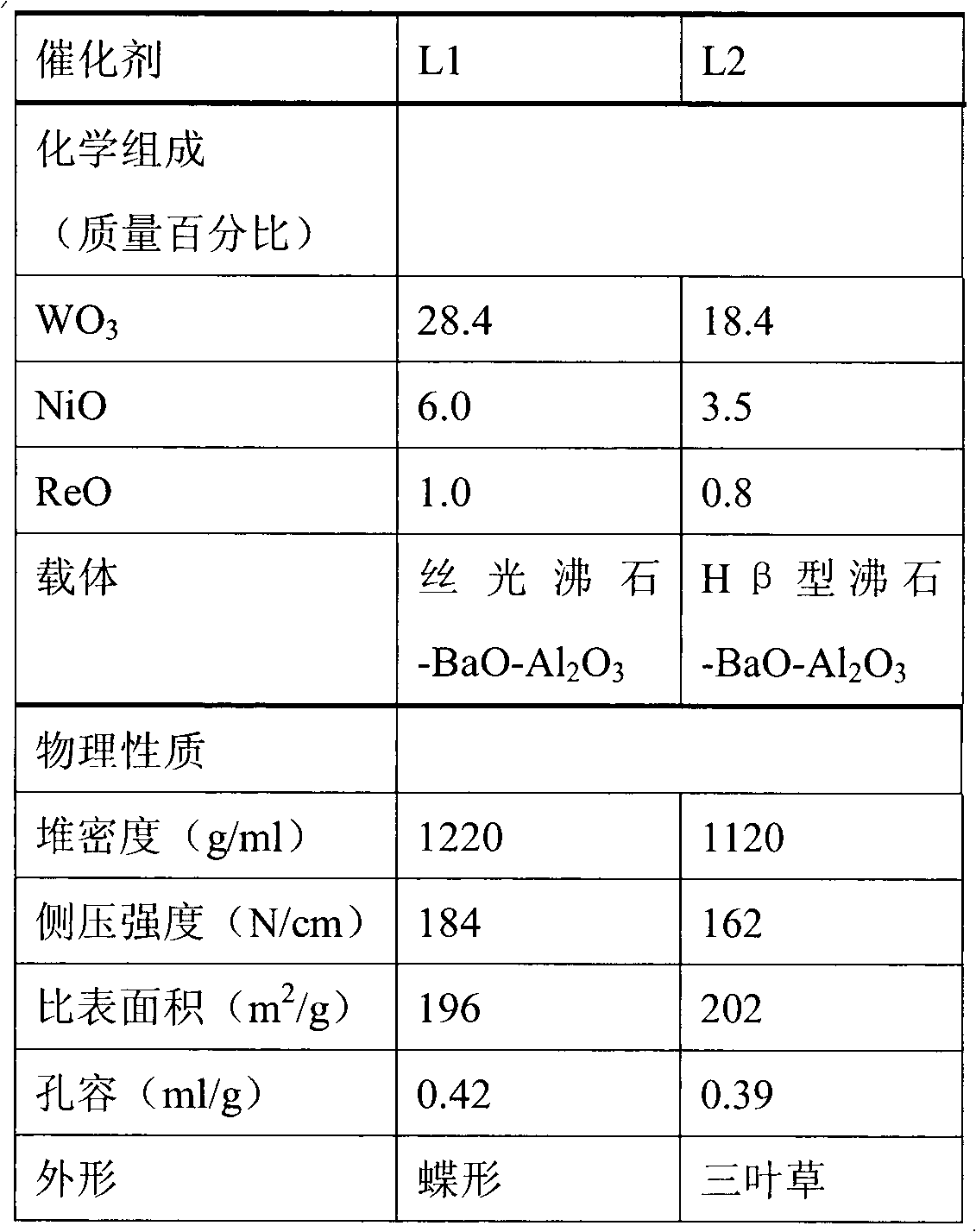

[0029] The preparation of hydrocracking catalyst L1 is as follows:

[0030] At room temperature, 2.4 g of ammonium nitrate was added to 20 g of deionized water to form a solution. Then 15 g of mordenite were added. Stir evenly and place in a 95°C water bath for 12 hours. Filtrate the slurry, dry the filter cake at 130°C, and then roast it at a constant temperature of 600°C for 4 hours in an air atmosphere containing 40% molar concentration of water vapor. The volume ratio of air to agent is 1200 to obtain modified zeolite, which is crushed and ground into fine powder spare. Commercially available SB aluminum hydroxide dry rubber powder 100g, mixed with 2g of dichlorobenzene, then poured into 100g of hydrochloric acid aqueous solution, the mass concentration of hydrochloric acid aqueous solution is 1.8%. Stir until it becomes gelatinous, filter, dry at 120°C, and bake in dry air at 500°C for 5 hours to obtain activated alumina powder. Mix the above-mentioned modified molecu...

Embodiment 2

[0038] The preparation of hydrocracking catalyst L2 is as follows:

[0039] At room temperature, add 3 g of ammonium nitrate to 20 g of deionized water to form a solution. Then 14 g of Hβ zeolite were added. Stir evenly and place in a 90°C water bath for 6 hours. Filtrate the slurry, dry the filter cake at 110°C, and then roast it in an air atmosphere containing 30% molar concentration of water vapor at a constant temperature of 600°C for 4 hours. The volume ratio of gas to agent is 600 to obtain modified zeolite, which is crushed and ground into fine powder spare. Commercially available SB aluminum hydroxide dry rubber powder 100g, mixed with 1.8g of dichlorobenzene, then poured into 100g of hydrochloric acid aqueous solution, the mass concentration of hydrochloric acid aqueous solution is 3%. Stir until it becomes gelatinous, filter, dry at 120°C, and bake in dry air at 500°C for 5 hours to obtain activated alumina powder. Mix the above-mentioned modified molecular sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com