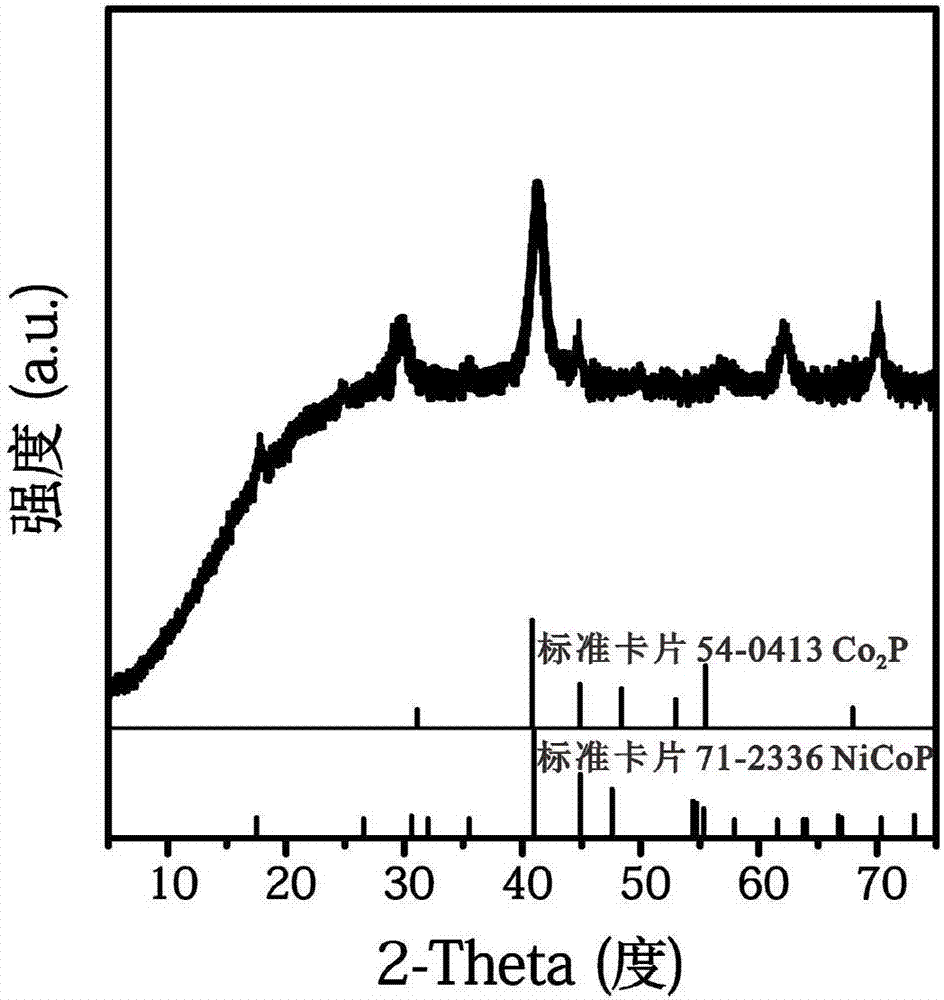

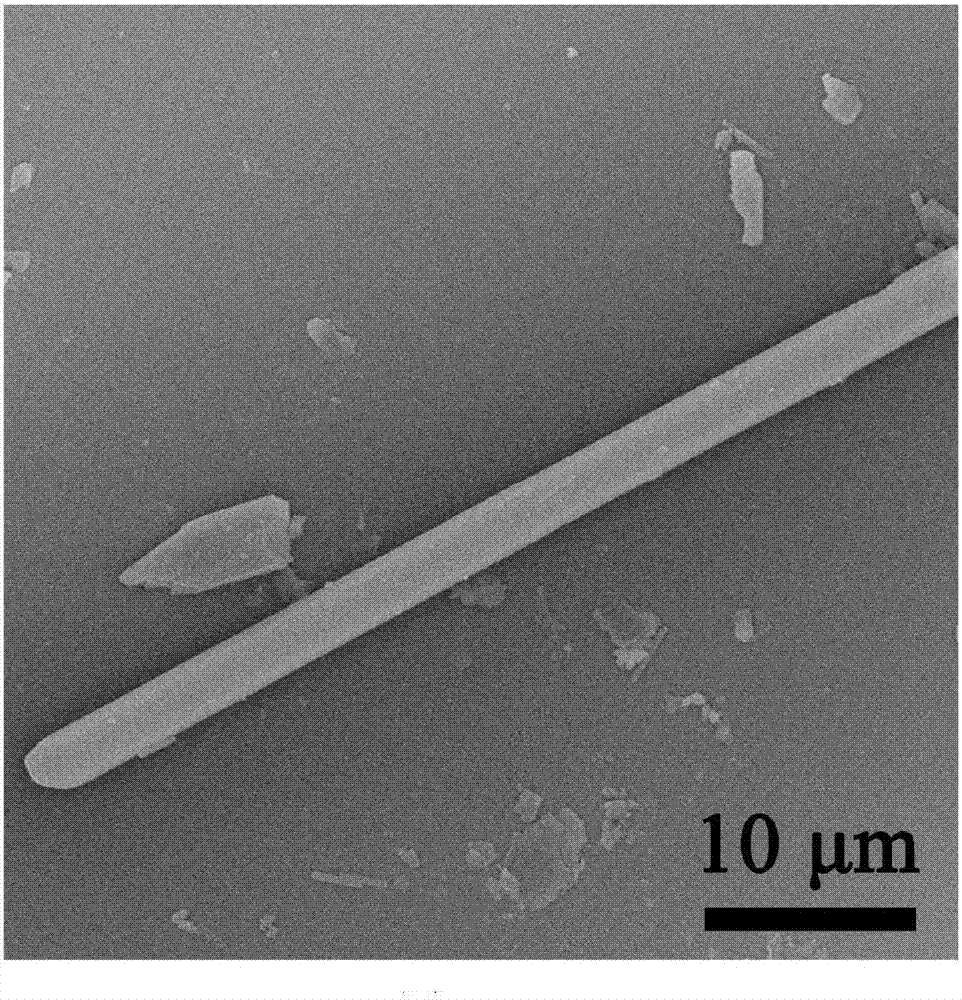

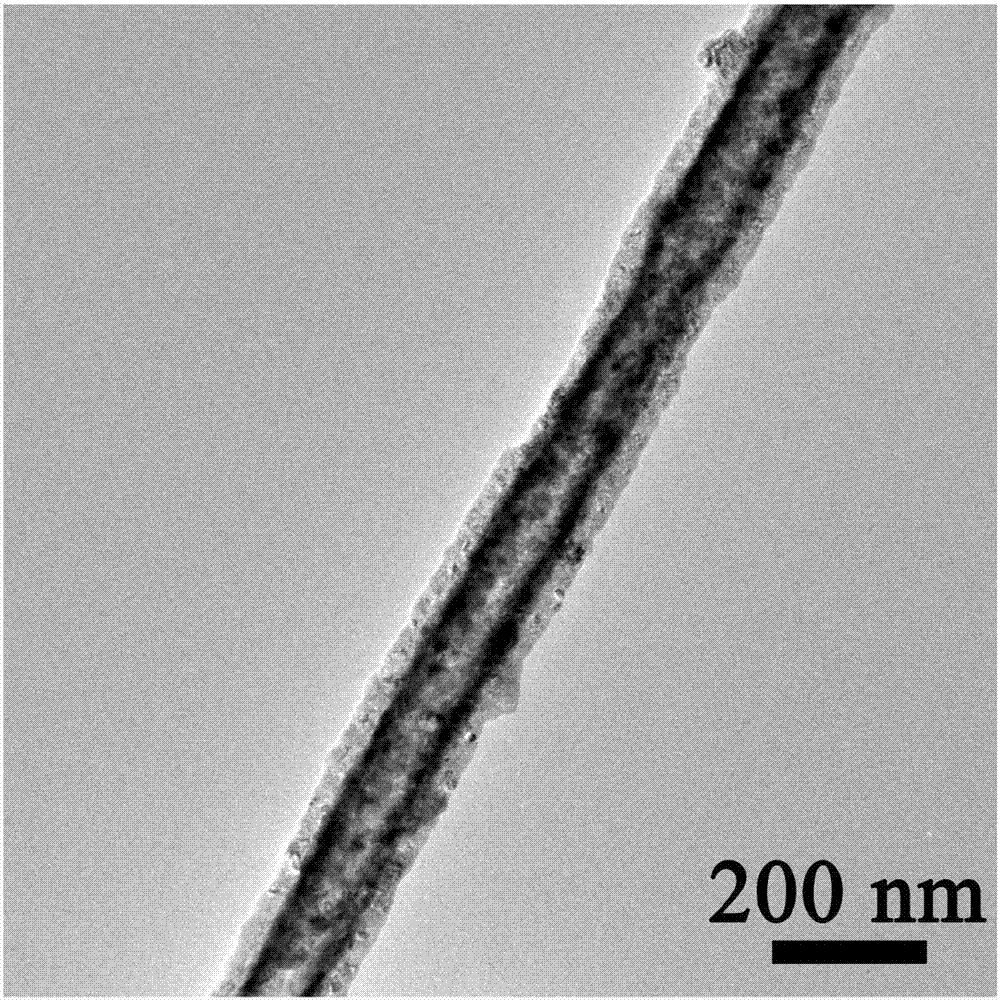

Multi-metal phosphide nanotube catalyst with evenly distributed catalytic centers and low-temperature preparation method

A technology of uniform distribution and catalytic center, applied in catalyst activation/preparation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problem of uniform dispersion of active center and catalyst phase, etc., and achieve the distribution of phosphide catalyst. Uniform, large pore volume, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A low-temperature preparation method of a polymetallic phosphide nanotube catalyst with uniform distribution of catalytic centers, the steps are as follows:

[0054] 1) Preparation of MOF-74 precursor: Weigh 0.5972 g of cobalt acetate tetrahydrate and 0.1495 g of nickel acetate tetrahydrate and dissolve them in 30 ml of deionized water to obtain solution a; weigh 0.5944 g of 2,5-dihydroxyterephthalic acid Dissolve in 30 ml of tetrahydrofuran to obtain solution b; mix solution a and solution b at a ratio of 1:1 by volume, stir thoroughly and transfer to a high-pressure reactor with a polytetrafluoroethylene liner, react at 110°C for 24 hours, and The product was centrifuged and washed three times with deionized water and ethanol to obtain the metal MOF-74 precursor.

[0055] 2) Weigh 0.5 g of the MOF-74 precursor in step 1), put it in a corundum porcelain boat, put the porcelain boat into a tube furnace, and heat it to 350°C in an air atmosphere at a heating rate of 1°C ...

Embodiment 2

[0062] A method for preparing polymetallic phosphide nanotube catalyst at low temperature, comprising steps as follows:

[0063] 1) Preparation of MOF-74 precursor: Weigh 0.6719 g of cobalt acetate tetrahydrate and 0.0747 g of nickel acetate tetrahydrate and dissolve them in 30 ml of deionized water to obtain solution a; weigh 0.5944 g of 2,5-dihydroxyterephthalic acid Dissolve in 30 ml of tetrahydrofuran to obtain solution b; mix solution a and solution b at a ratio of 1:1 by volume, stir thoroughly and transfer to a high-pressure reactor with a polytetrafluoroethylene liner, react at 110°C for 24 hours, and The product was centrifuged and washed three times with deionized water and ethanol to obtain multimetallic MOF-74 precursors with different metal ratios.

[0064] 2) Weigh 0.5 g of the MOF-74 precursor in 1) and place it in a corundum porcelain boat, put the porcelain boat into a tube furnace, and heat it to 350°C in an air atmosphere at a heating rate of 1°C per minute ...

Embodiment 3

[0067] A method for preparing polymetallic phosphide nanotube catalyst at low temperature, comprising steps as follows:

[0068]1) Preparation of MOF-74 precursor: Weigh 0.5972 g of cobalt acetate tetrahydrate and 0.1495 g of nickel acetate tetrahydrate and dissolve them in 30 ml of deionized water to obtain solution a; weigh 0.5944 g of 2,5-dihydroxyterephthalic acid Dissolve in 30 ml of tetrahydrofuran to obtain solution b; mix solution a and solution b at a ratio of 1:2 by volume, stir thoroughly and transfer to a high-pressure reactor with a polytetrafluoroethylene liner, react at 110°C for 48 hours, and The product was centrifuged and washed three times with deionized water and ethanol to obtain multimetallic MOF-74 precursors with different metal ratios.

[0069] 2) Weigh 0.5 g of the MOF-74 precursor in step 1), put it in a corundum porcelain boat, put the porcelain boat into a tube furnace, and heat it to 350°C in an air atmosphere at a heating rate of 1°C per minute f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com