Liquid phase purification method for 1,1- difluoroethane

A kind of technology of difluoroethane and purification method, applied in 1 field, can solve the problem that high purity cannot be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

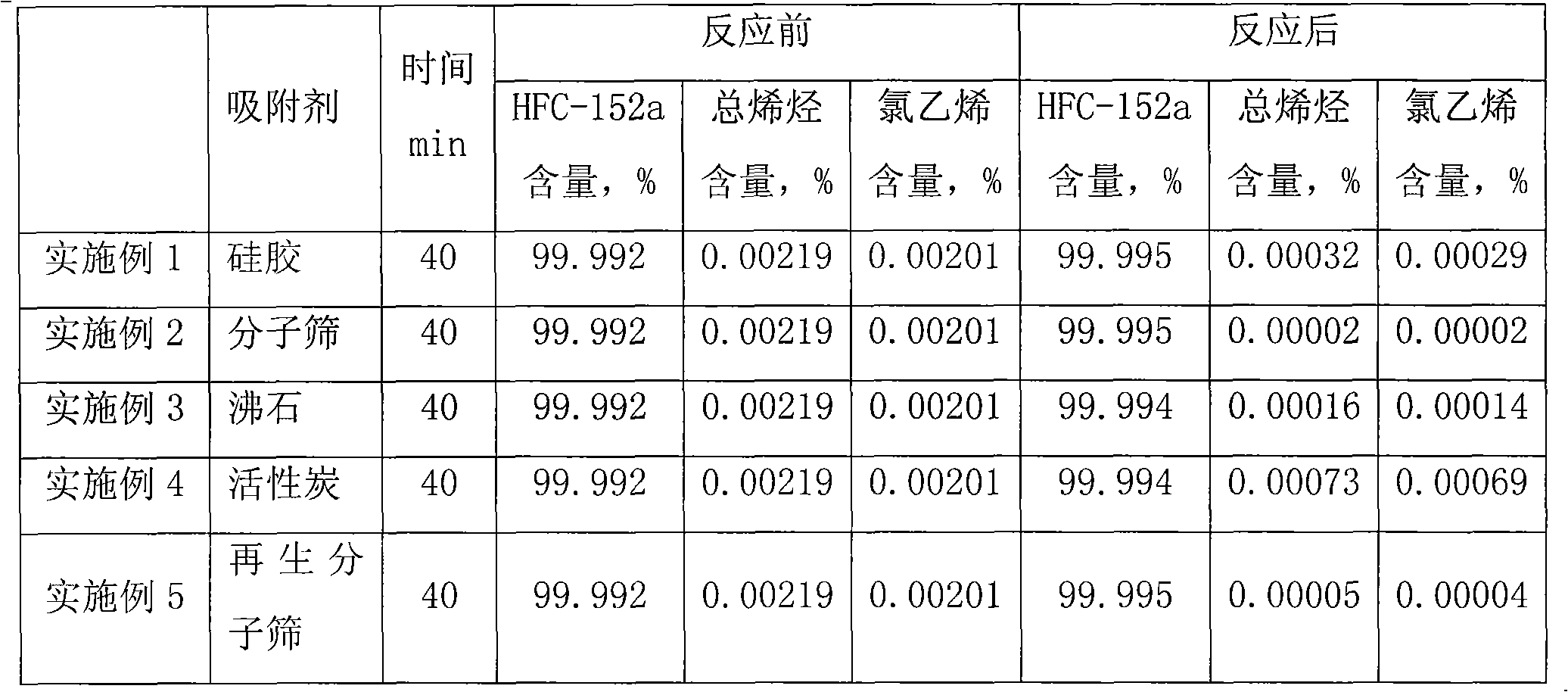

Embodiment 1

[0028] Add 108g of silica gel to the reaction tube, specific surface area: 750-850m 2 / g, average pore diameter: 22- Heating to keep the temperature in the reaction tube at about 10°C, and the pressure at about 2 atmospheres, feed chlorine gas into the reaction tube at a flow rate of 0.05 L / min for 2 hours, close the valve of the reaction tube, and seal it for 2 hours. Heating was stopped, the valve was opened, the reaction tube was purged with nitrogen, vacuumized, and the reaction tube was naturally cooled to normal temperature. Pass 97g of 1,1-difluoroethane crude product containing vinyl chloride into the reaction tube, the content of 1,1-difluoroethane is 99.992%, the content of vinyl chloride is 0.00201%, and the content of total olefins is 0.00219% , close the valve, and take a sample for gas chromatography analysis after contacting for 40 minutes. The content of 1,1-difluoroethane is 99.995%, the content of total olefins is 0.00032%, and the content of vinyl chloride...

Embodiment 2

[0030] Add 115g molecular sieve to the reaction tube, specific surface area: 830-860m 2 / g, average pore diameter: 14- Heating to keep the temperature in the reaction tube at about 350°C, and the pressure at about 5 atmospheres, feed chlorine gas into the reaction tube at a flow rate of 0.05 L / min for 3 hours, close the valve of the reaction tube, and seal it for 2 hours. Heating was stopped, the valve was opened, the reaction tube was purged with nitrogen, vacuumized, and the reaction tube was naturally cooled to normal temperature. 150 g of 1,1-difluoroethane crude product containing vinyl chloride was passed into the reaction tube, the content of 1,1-difluoroethane was 99.992%, the content of vinyl chloride was 0.00201%, and the content of total olefins was 0.00219%. Close the valve, take a sample after 40 minutes of contact and conduct gas chromatography analysis. The content of 1,1-difluoroethane is 99.995%, the content of total olefins is 0.00002%, and the content of v...

Embodiment 3

[0032] Add 85g zeolite to the reaction tube, specific surface area: 620-750m 2 / g, average pore diameter: 22- Heating to keep the temperature in the reaction tube at about 25°C, and the pressure at about 8 atmospheres, feed chlorine gas into the reaction tube at a flow rate of 0.05 L / min for 10 hours, close the valve of the reaction tube, and seal it for 2 hours. Heating was stopped, the valve was opened, the reaction tube was purged with nitrogen, vacuumized, and the reaction tube was naturally cooled to normal temperature. Pass 140 g of crude 1,1-difluoroethane containing vinyl chloride into the reaction tube, the content of 1,1-difluoroethane is 99.992%, the content of vinyl chloride is 0.00201%, and the content of total olefins is 0.00219% , close the valve, and take a sample after 40 minutes of contact for gas chromatography analysis. The content of 1,1-difluoroethane is 99.994%, the content of total olefins is 0.00016%, and the content of vinyl chloride is 0.00014%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com