Heat transfer medium, and heat transfer medium composition suitable for applications in coolers

A heat transfer medium and composition technology, applied in the directions of lubricating compositions, heat exchange materials, chemical instruments and methods, etc., can solve the problems of small temperature and temperature glide of heat transfer medium, and achieve the effect of simplifying system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

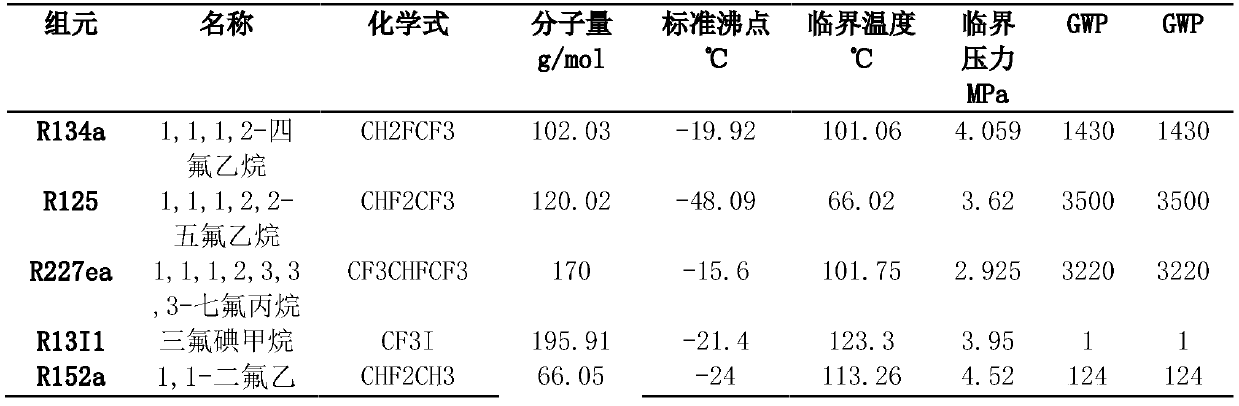

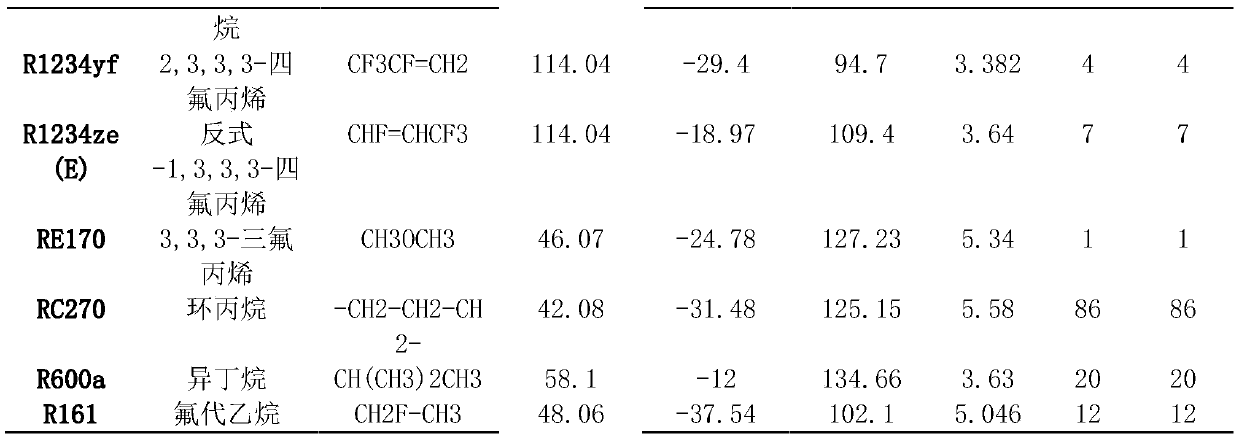

[0022] The preparation method of the heat transfer medium of the present invention is as follows: the first step: select one material respectively from the first, second and third components provided by the technical solution of the present invention to combine, wherein: the first component The substances provided are 1,1,1,2-tetrafluoroethane (R134a), 1,1,1,2,2-pentafluoroethane (R125), 1,1,1,2,3,3, One of 3-heptafluoropropane (R227ea) and trifluoroiodomethane (R13I1); the second component provides substances such as 1,1-difluoroethane (R152a), 2,3,3,3-tetrafluoropropene (R1234yf) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)); The substances provided by the third component are fluoroethane (R161), cyclopropane (RC270), dimethyl ether ( RE170) and isobutane (R600a). The substances provided by the first component are all non-flammable substances, and the substances provided by other components are A2 flammable and weakly flammable A2L. By controlling the mass percentage of...

Embodiment 1

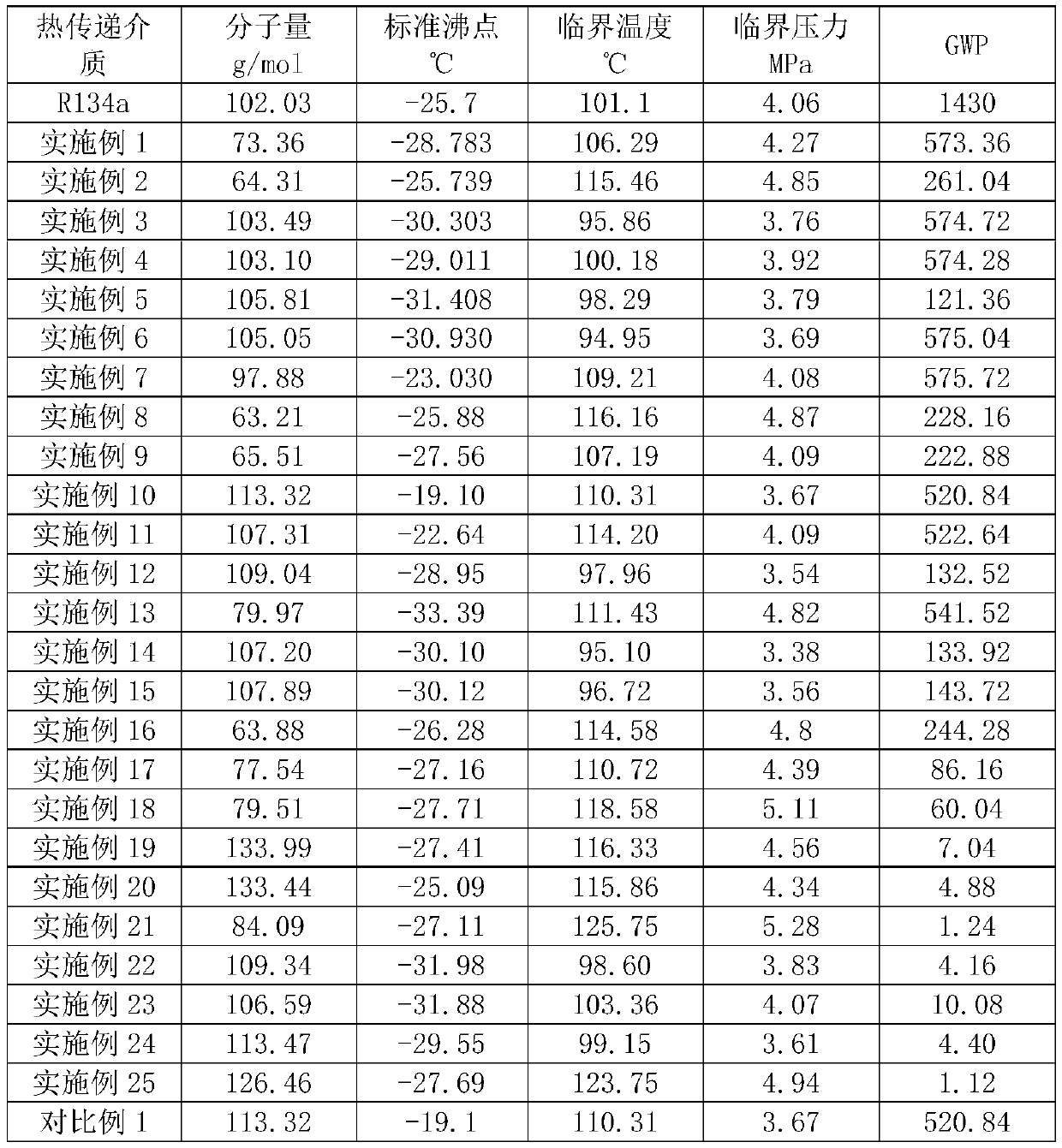

[0029] Example 1, three components of 1,1,1,2-tetrafluoroethane (R134a), 1,1-difluoroethane (R152a) and isobutane (R600a) were mixed under normal temperature and pressure liquid phase Physically mix according to the mass percentage of 36:44:20, and use it as a heat transfer medium after mixing evenly.

Embodiment 2

[0030]Example 2, three components of 1,1,1,2-tetrafluoroethane (R134a), 1,1-difluoroethane (R152a) and dimethyl ether (RE170) were mixed under normal temperature and pressure liquid phase Perform physical mixing according to the mass percentage of 12:72:16, and use it as a heat transfer medium after mixing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com