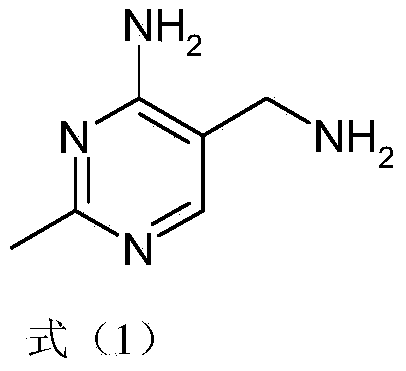

Simple and quick method for synthesizing improved vitamin B1 intermediate 2-methyl-4-amino-5-aminomethylpyrimidine

A technology of formylaminomethylpyrimidine and aminomethylpyrimidine, which is applied in the field of production of vitamin B1 and its derivatives, can solve the problems of difficulty in removing o-chloroaniline, high requirements for the operating environment, and poor reaction selectivity, achieving fewer steps, Effect of reduced decomposition and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

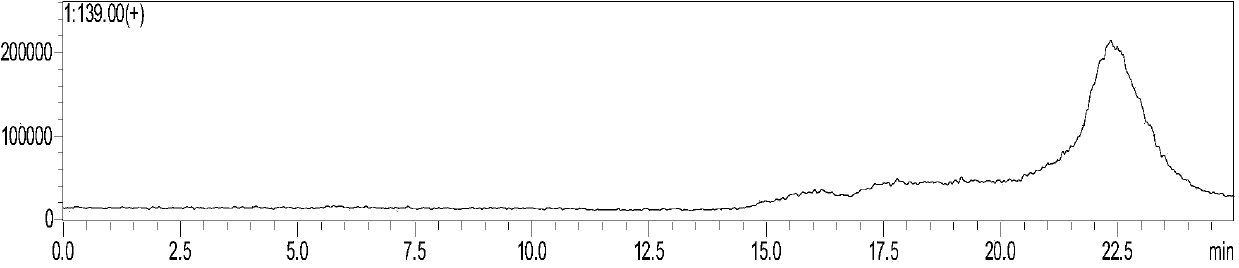

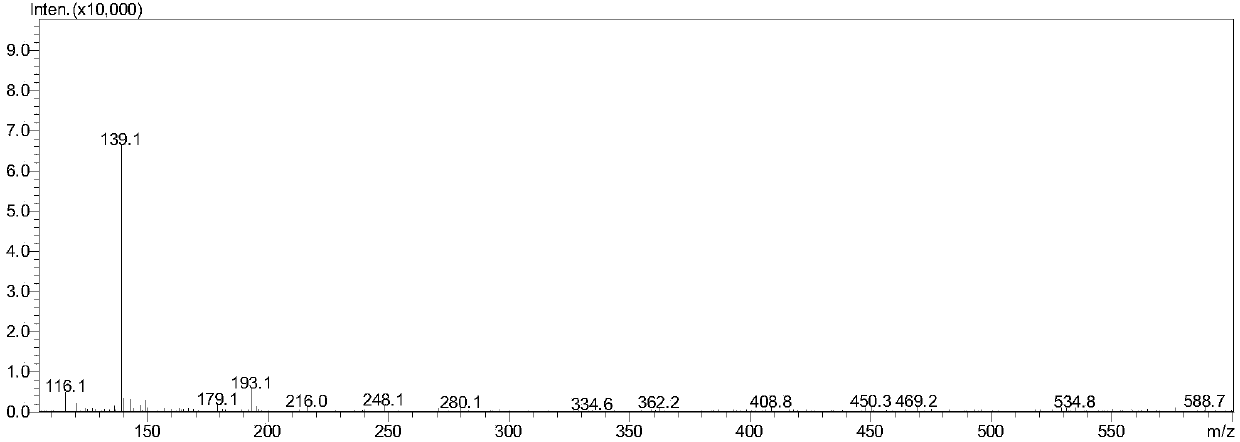

Image

Examples

Embodiment 1

[0062] Embodiment 1: Taking the 3-acetamidopropionitrile of formula (2) as an example, the reaction formula is as follows:

[0063]

[0064] Proceed as follows:

[0065] Preparation of acetamidine free base: add 104.5 g of acetamidine hydrochloride and 220 g of 27 wt% sodium methoxide methanol solution in a 1000 ml glass reaction vessel, react at 10-20°C for 30 minutes, filter, and the filtrate is a methanol solution of acetamidine;

[0066] Add 112 grams of 3-acetamidopropionitrile, 520 grams of toluene, and 27.2 grams of anhydrous zinc chloride into a 1000 ml four-necked flask; heat, and the internal temperature rises to 75-80°C; dropwise add the acetamidine alcohol solution obtained above , the dropping rate is about 10mL / min; the reaction is carried out under stirring conditions, so that the azeotropic removal of water and alcohol is carried out, and the reaction of 3-acetamidopropionitrile is completely detected by gas phase detection. Then add an accurately weighed i...

Embodiment 2

[0070] As described in Example 1, the difference is that 112 grams of 3-acetylaminopropionitrile in Example 1 is replaced with 126 grams of 3-ethylformamidopropionitrile to react, and the preparation steps and conditions are the same as in Example 1. The purity and yield of the obtained product are shown in Table 1.

Embodiment 3

[0072] As described in Example 1, the difference is that 140 grams of 3-n-propylformylaminopropionitrile is used to replace 112 grams of 3-acetylaminopropionitrile in Example 1 to react, and the preparation steps and conditions are the same as in Example 1 , the resulting product purity and yield are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com