Method for treating wastewater of dilute thiamine containing acrylonitrile

A treatment method and technology of acrylonitrile, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of low quality of ammonium sulfate recovery, solid waste and organic nitrile impurities It is difficult to solve the problems of low concentration of ammonium sulfate, etc., to achieve the effect of quality improvement, recovery quality improvement, and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

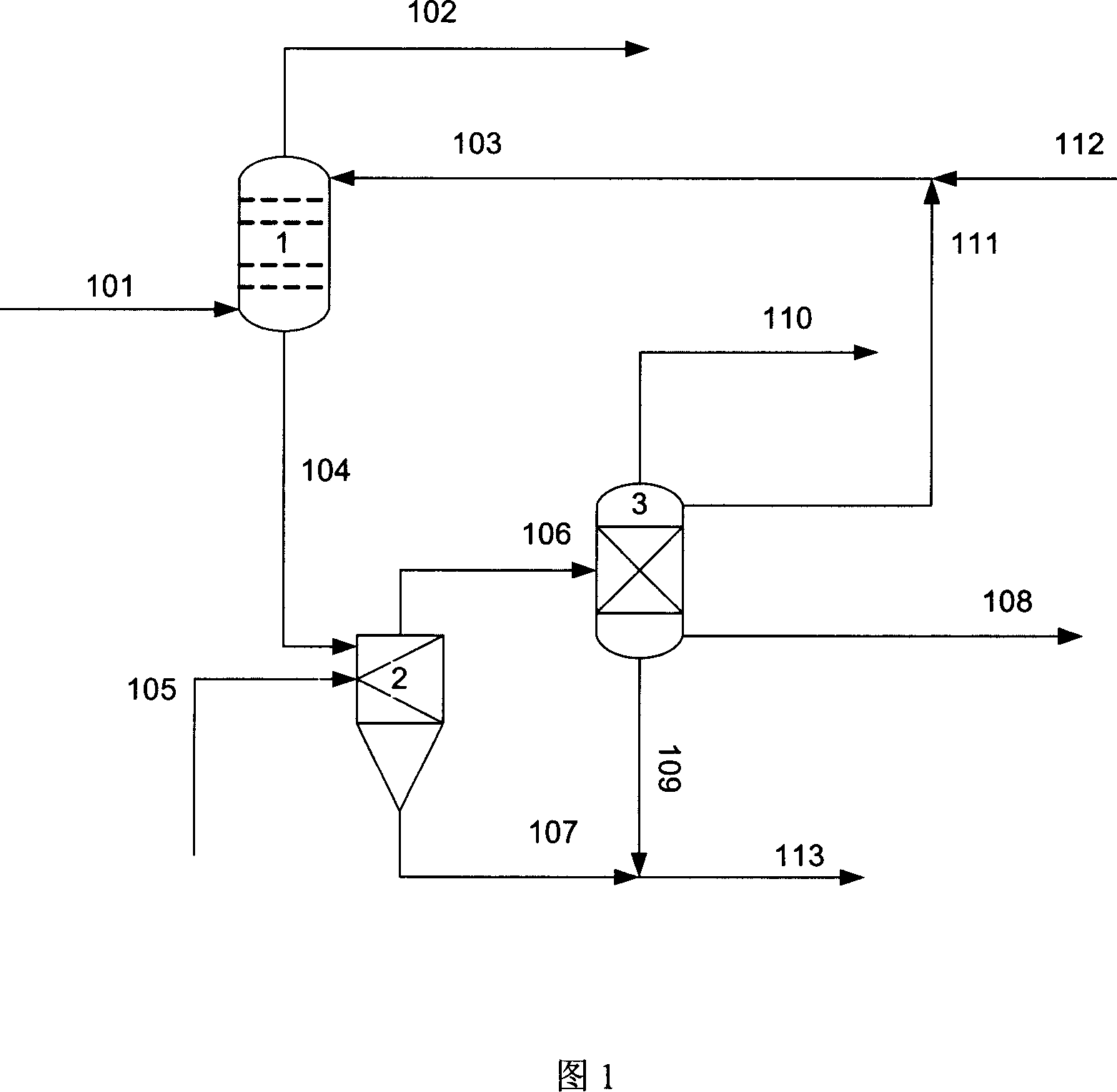

[0021]Adopt the technical process of Fig. 1, the weight percent of one-stage method acrylonitrile quenching dilute ammonium sulphate waste water is composed of: acrylonitrile 0.19%, hydrocyanic acid 0.19%, water 78.36%, ammonium sulphate 13.82%, polymer 7.44%, wherein also contains A small amount of catalyst dust. After the waste water is separated from the solid and liquid by the hydrocyclone, the catalyst dust and most of the polymers are removed, and the mass composition of acrylonitrile 0.20%, hydrocyanic acid 0.20%, water 84.67%, ammonium sulfate 14.93% and trace polymers are obtained. liquid and adjust its pH value to 6.6, the clear liquid is separated by 20 theoretical plate rectification towers, the rectification tower top temperature is 85.2 ℃, and under the condition of tower still temperature 110 ℃, the total weight of 2% raw materials at the top of the tower is obtained. The weight composition is an organic solution of 40% of hydrocyanic acid, 35% of acrylonitrile,...

Embodiment 2

[0023] Adopt the same flow process and condition of embodiment 1, just change the theoretical plate number of rectifying tower to be 30, the tower still temperature of rectifying tower is 115 ℃, and the ammonium sulfate solution is taken out from the side line at the 4th tray place on the upper part of the tower still , take out the organic solution from the side line at the 7th tray at the lower part of the tower top, and adjust the pH value of the clear liquid after removing solid impurities to 7.5. Obtaining the organic solution that the tower top weight is composed of 43% of hydrocyanic acid, 40% of acrylonitrile, water 17%, the 3rd tray side line extraction of tower top lower part is the aqueous solution containing 0.01% acrylonitrile, the 4th block of tower still top The 25% ammonium sulfate solution is extracted from the side line of the tray, and the tower still flows out 10% raw material weight containing polymer-containing ammonium sulfate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com