High temp. thicking oil viscosity reducing agent and preparation process thereof

A technology of viscosity reducer and viscosity reducer for heavy oil, which can be used in earth-moving drilling, production fluids, wellbore/well components, etc., and can solve problems such as scaling, clay swelling, and potential hazards in the oil production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The first step: the preparation of N-hexadecyl-β-aminopropionitrile.

[0018] Add 0.1mol hexadecylamine and 0.4g sodium carbonate to a three-necked flask, raise the temperature to 50°C, add dropwise 0.125mol acrylonitrile, and react for 4 hours to obtain N-hexadecyl-β-aminopropionitrile, the conversion is 95%.

[0019] The second step: the preparation of N-hexadecylpropylenediamine.

[0020] Add 0.1mol N-alkyl-β-aminopropionitrile and 50ml of isopropanol into the autoclave, replace the air in the autoclave with nitrogen, then introduce hydrogen and chlorine, and react at 80°C for 2 hours to obtain N- Hexadecylpropylenediamine, the conversion rate is 97%.

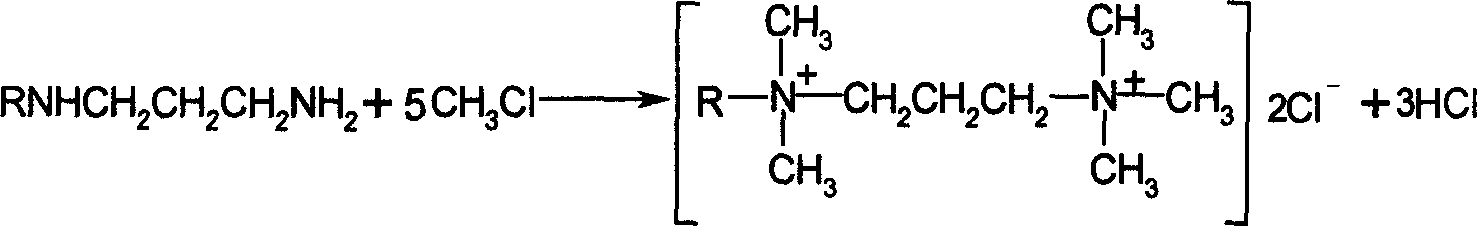

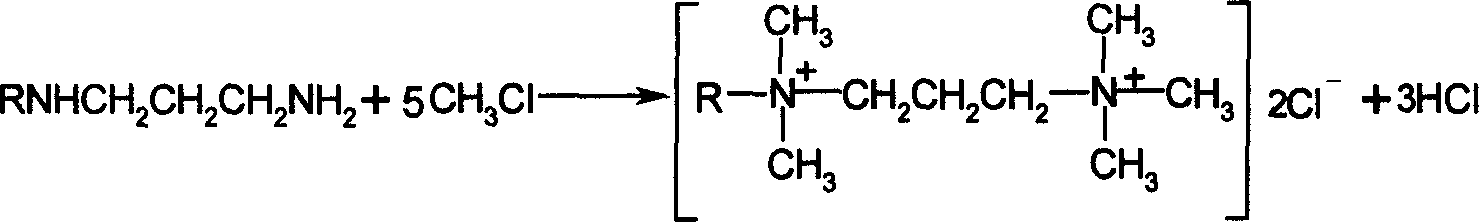

[0021] The third step: the preparation of N-hexadecane-γ-bisquaternary ammonium cationic surfactant.

[0022] Add 0.1mol N-hexadecylpropylenediamine and 0.3mol sodium carbonate to the autoclave, replace the air in the autoclave with nitrogen, then raise the temperature to 60°C and feed 0.8mol methyl chloride, at 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com