Preparation method of 2-(4-bromomethylphenyl) propionic acid

A technology of bromomethylphenyl and phenylpropionic acid, applied in the field of 2-propionic acid preparation, can solve the problems of complex production process, high production cost, low yield of finished products and the like, and achieves simple production process, low production cost, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

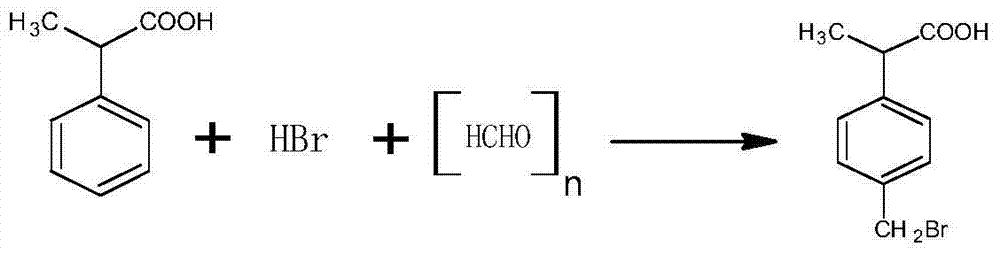

[0027] The preparation method of the present embodiment 2-(4-bromomethylphenyl)propionic acid comprises 2-phenylpropionitrile preparation stage, 2-phenylpropionic acid preparation stage and 2-(4-bromomethylphenyl) Propionic acid stage, the specific steps are as follows:

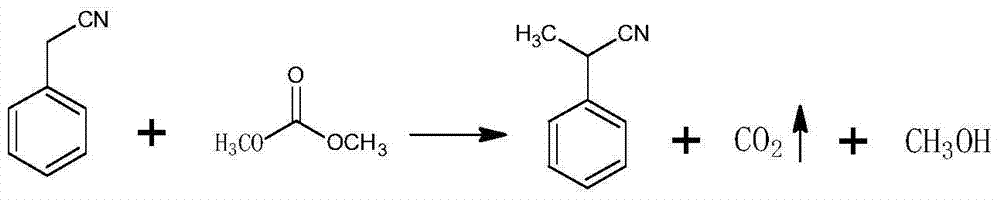

[0028] 1) 2-phenylpropionitrile preparation stage

[0029] Add phenylacetonitrile: dimethyl carbonate: potassium carbonate at a molar ratio of 10:40:2 into a dry autoclave, slowly heat up to 180°C under stirring, keep the pressure below 2MPa, and keep warm for 30 hours to complete the reaction; liquid through pressure filtration, washing the reaction solution to neutrality, then distilling off excess dimethyl carbonate, and high vacuum rectification to obtain 2-phenylpropionitrile;

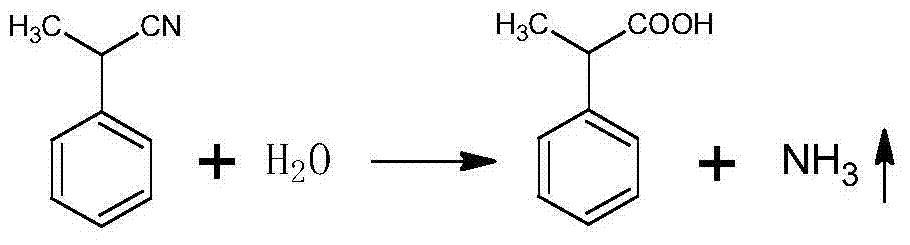

[0030] 2) 2-phenylpropionic acid preparation stage

[0031] Add liquid caustic soda: water: 2-phenylpropionitrile in 2:1:1 parts by weight to the hydrolysis reaction kettle, then heat up to 95°C, stir, reflux for 15 hours, cool...

Embodiment 2

[0035] The preparation method of the present embodiment 2-(4-bromomethylphenyl)propionic acid comprises 2-phenylpropionitrile preparation stage, 2-phenylpropionic acid preparation stage and 2-(4-bromomethylphenyl) Propionic acid stage, the specific steps are as follows:

[0036] 1) 2-phenylpropionitrile preparation stage

[0037] Add phenylacetonitrile: dimethyl carbonate: potassium carbonate at a molar ratio of 5:30:3 into a dry autoclave, slowly heat up to 220°C under stirring, control the pressure below 2.5MPa, and keep it warm for 20 hours to complete the reaction; The reaction solution is filtered through pressure, washed with water to neutrality, and then excess dimethyl carbonate is removed by distillation, and high vacuum rectification is carried out to obtain 2-phenylpropionitrile;

[0038] 2) 2-phenylpropionic acid preparation stage

[0039] Add liquid caustic soda: water: 2-phenylpropionitrile in 5:2:1 parts by weight to the hydrolysis reaction kettle, then raise ...

Embodiment 3

[0043] The preparation method of the present embodiment 2-(4-bromomethylphenyl)propionic acid comprises 2-phenylpropionitrile preparation stage, 2-phenylpropionic acid preparation stage and 2-(4-bromomethylphenyl) Propionic acid stage, the specific steps are as follows:

[0044] 1) 2-phenylpropionitrile preparation stage

[0045] Add phenylacetonitrile: dimethyl carbonate: potassium carbonate at a molar ratio of 2:35:3.5 into a dry autoclave, slowly heat up to 250°C under stirring, keep the pressure below 4MPa, and keep warm for 15 hours to complete the reaction; Liquid was removed by pressure filtration to remove solid potassium carbonate and washed the reaction solution to neutrality, then distilled to remove excess dimethyl carbonate, and high vacuum rectification obtained 2-phenylpropionitrile;

[0046] 2) 2-phenylpropionic acid preparation stage

[0047] Add liquid caustic soda: water: 2-phenylpropionic acid in 7:3:1 parts by weight to the hydrolysis reaction kettle, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com