Andrographolidi natrii bisulfis and preparation method thereof

A technology of andrographolide and sodium bisulfite, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, antibacterial drugs, etc., can solve the problems of increasing the difficulty of operation and increasing costs, and achieve good stability and impurity The effect of less, high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take andrographolide 6kg, and add 120L of 95% ethanol, heat and stir to dissolve, and maintain at 70°C; then take 2.2Kg of sodium bisulfite, add water to 73L, stir and dissolve; Pour the solution into the aqueous sodium bisulfate solution in step 2), mix evenly and heat to 70°C; then reflux for 36 minutes, recover the ethanol until there is no alcohol smell, and place it in a refrigerator at 1°C to 9°C for 12 to 48 hours. And extract 3 times with appropriate amount of chloroform, after filtration, concentrate the filtrate in vacuum; place the concentrated solution in step 3) in a crystallization pot with stirring paddle, cool with jacketed cooling water, stir with the paddle paddle at 3°C to 19°C and let stand Crystallize, then filter with suction, and dry the filter cake in vacuum to obtain white sodium bisulfite andrographolide adduct. Its purity is 99.6% as measured by liquid chromatography.

Embodiment 2

[0020] Weigh andrographolide 10kg, and add 145L of 95% ethanol, heat and stir to dissolve, and maintain at 80°C; then take 2.5Kg of sodium bisulfite, add water to 80L, stir and dissolve; Pour the solution into the aqueous solution of sodium bisulfate in step 2), mix evenly and heat to 85°C; then reflux for 30 minutes, recover the ethanol until there is no alcohol smell, and place it in a refrigerator at 1°C to 9°C for 12 to 48 hours. And extract 4 times with appropriate amount of chloroform, after filtration, concentrate the filtrate in vacuum; place the concentrated solution in step 3) in a crystallization pot with stirring paddle, cool with jacketed cooling water, stir with the paddle paddle at 3°C to 19°C and let stand Crystallize, then filter with suction, and dry the filter cake in vacuum to obtain white sodium bisulfite andrographolide adduct. Its purity is 99.8% as measured by liquid chromatography.

Embodiment 3

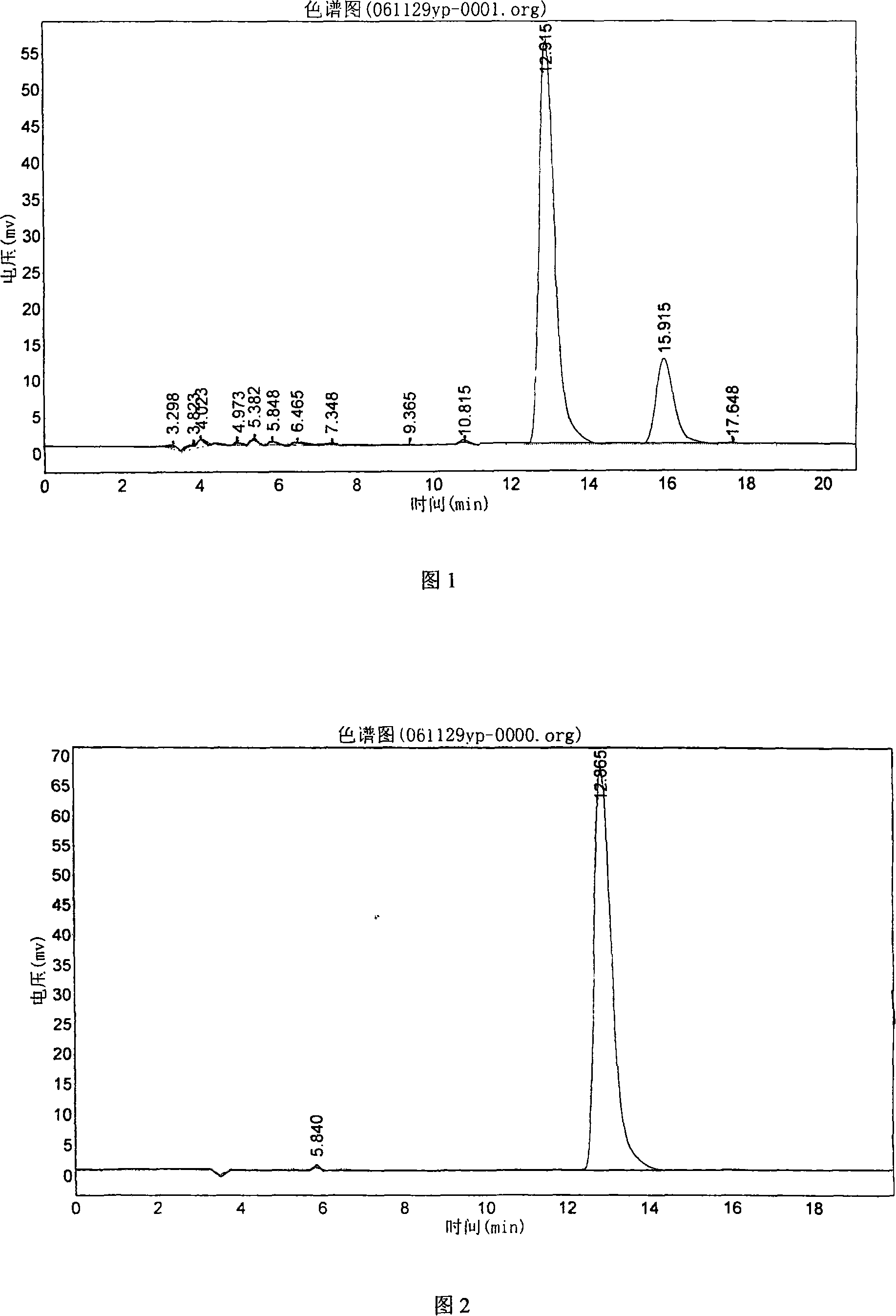

[0022] Weigh andrographolide 12kg, add 95% ethanol 165L, heat and stir to dissolve, and maintain at 85°C; then take sodium bisulfite 3.2Kg, add water to 86L, stir and dissolve; and the andrographolide ethanol of step 1) Pour the solution into the aqueous solution of sodium bisulfate in step 2), mix evenly and heat to 65°C; then reflux for 36 minutes, recover ethanol until there is no alcohol smell, and place it in a refrigerator at 1°C to 9°C for 12 to 48 hours. And extract 4 times with an appropriate amount of chloroform, after filtration, concentrate the filtrate in vacuum; place the concentrated solution in step 3) in a crystallization pot with a stirring paddle, cool with jacketed cooling water, stir with a paddle paddle at 3°C to 19°C and let stand After crystallization, suction filtration, and vacuum drying of the filter cake, a white sodium bisulfite andrographolide adduct was obtained, and its purity was 99.74% as measured by liquid chromatography (as shown in Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com