Sulfur dioxide fresh-keeping laminate, preparation method and application

A technology of sulfur dioxide and laminates, which is applied in chemical instruments and methods, applications, and preservation of fruits and vegetables. Complicated and other issues, to achieve easy quality control, low production cost, and good fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

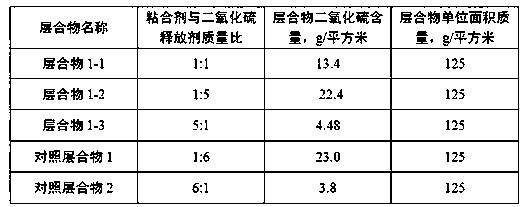

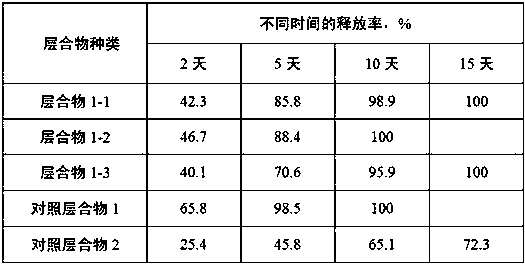

Embodiment 1

[0062] In this embodiment, the laminate and the contrast laminate all adopt the following raw materials: the first substrate: non-woven fabric, 40g / square meter; the second substrate: paper-plastic composite film, 45g / square meter; adhesive: EVA Rubber powder; sulfur dioxide release agent: sodium metabisulfite.

[0063] In all the laminates in this example, the mixed addition amount of adhesive and sulfur dioxide releasing agent is 40g / square meter.

[0064] The preparation method of all laminates in this example is as follows:

[0065] A, prepare described first base material and second base material;

[0066] B, prepare described adhesive;

[0067] C, prepare described sulfur dioxide releasing agent, raw material is used after pulverizing, crossing 50 mesh sieves;

[0068] D, the binding agent and the sulfur dioxide releasing agent are mixed evenly according to the ratio to form a mixture;

[0069] E. Spread the mixture prepared in step D evenly on the first base materia...

Embodiment 2

[0087] The composition of Laminate 2 is:

[0088] The first substrate: non-woven fabric, 35g / square meter; the second substrate: absorbent paper, 42g / square meter;

[0089] Binder: TPU rubber powder; Sulfur dioxide release agent: sodium metabisulfite and potassium metabisulfite, the mass ratio is 1:1;

[0090] The mass ratio of the adhesive to the sulfur dioxide releasing agent is 5:1, and the amount of the mixture of the adhesive and the sulfur dioxide releasing agent added to the laminate is 60 g / square meter.

[0091] The amount of the sulfur dioxide releasing agent of the laminate is 6.24g / square meter as sulfur dioxide, and the mass per unit area of the laminate is 137g / square meter.

[0092] Preparation method of laminate 2:

[0093] A, prepare described first base material and second base material;

[0094] B, prepare described adhesive;

[0095] C, prepare described sulfur dioxide releasing agent, after mixing, raw material is used after pulverizing, crossing 60 ...

Embodiment 3

[0100] The composition of laminate 3 is:

[0101] The first substrate: non-woven fabric, 35g / square meter; the second substrate: polyester film, 15g / square meter;

[0102] Adhesive: LDPE rubber powder and EVA rubber powder, the mass ratio of the two is 1:1; sulfur dioxide release agent: sodium metabisulfite and sodium bisulfite, the mass ratio of the two is 4:1;

[0103] The mass ratio of the adhesive to the sulfur dioxide releasing agent is 1:5, and the addition amount of the mixture of the adhesive and the sulfur dioxide releasing agent in the laminate is 30 g / square meter.

[0104] The amount of the sulfur dioxide releasing agent of the laminate is 16.53 g / square meter as sulfur dioxide, and the mass per unit area of the laminate is 80 g / square meter.

[0105] Preparation method of laminate 3:

[0106] A, prepare described first base material and second base material;

[0107] B, prepare described adhesive;

[0108] C, prepare described sulfur dioxide releasing agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com