Desulfurization and denitrification system and method by adopting ozone oxidation in cooperation with ammonia method

A desulfurization, denitrification and ozone oxidation technology, which is applied in the field of desulfurization and denitrification systems of ozone oxidation and ammonia method, can solve the problems of ammonia escape, waste of energy consumption, high investment and operating costs, and achieves enhanced oxidation efficiency, reduced equipment corrosion, and alleviated whitening. effect of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

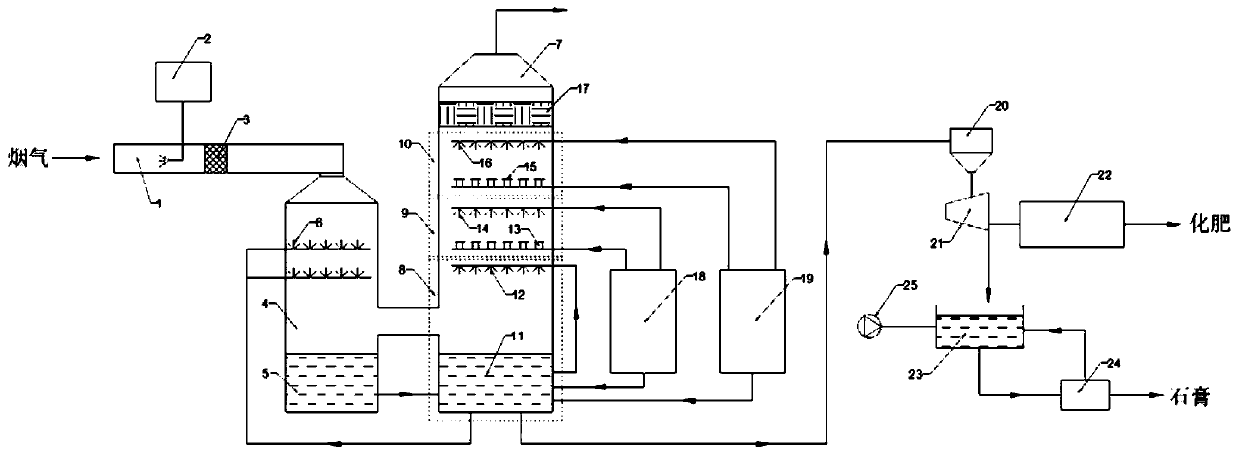

[0091] This embodiment provides a desulfurization and denitrification method of ozone oxidation in cooperation with ammonia method, and the desulfurization and denitrification method specifically includes:

[0092] (1) The ozone generating device 2 feeds ozone into the inlet flue 1, and the flue gas passes into the inlet flue 1 and contacts with ozone countercurrently, and the mol ratio of the ozone passing into the inlet flue 1 to NO in the flue gas is 0.8, After mixed and fully oxidized by the mixing device 3, it is sent to the first absorption device 4; the first absorbent storage tank 18 and the second absorbent storage tank 19 respectively inject quicklime and ammonia water into the circulating spray pool 11 of the second absorption device 7, The mixed absorbent formed in the circulating spray tank 11 passes into the spray device 6 of the first absorption device 4, the pH of the mixed absorbent sprayed in the first absorption device 4 is controlled at 5.3, and the oxidized...

Embodiment 2

[0097] This embodiment provides a desulfurization and denitrification method of ozone oxidation in cooperation with ammonia method, and the desulfurization and denitrification method specifically includes:

[0098] (1) The ozone generating device 2 feeds ozone into the inlet flue 1, and the flue gas passes into the inlet flue 1 and contacts with the countercurrent flow of ozone, and the mol ratio of the ozone passing into the inlet flue 1 to NO in the flue gas is 0.9, After being fully oxidized by the mixing device 3, it is sent to the first absorption device 4; the first absorbent storage tank 18 and the second absorbent storage tank 19 respectively inject limestone and ammonia water into the circulating spray pool 11 of the second absorption device 7, The mixed absorbent formed in the circulating spray tank 11 is passed into the spray device 6 of the first absorption device 4, the pH of the mixed absorbent sprayed in the first absorption device 4 is controlled at 5.6, and the...

Embodiment 3

[0103] This embodiment provides a desulfurization and denitrification method of ozone oxidation in cooperation with ammonia method, and the desulfurization and denitrification method specifically includes:

[0104] (1) The ozone generating device 2 feeds ozone into the inlet flue 1, and the flue gas passes into the inlet flue 1 and contacts with ozone countercurrently, and the mol ratio of the ozone passing into the inlet flue 1 to NO in the flue gas is 1, After mixed and fully oxidized by the mixing device 3, it is sent to the first absorption device 4; the first absorbent storage tank 18 and the second absorbent storage tank 19 respectively inject steel slag and ammonia water into the circulating spray pool 11 of the second absorption device 7, The mixed absorbent formed in the circulating spray tank 11 is passed into the spray device 6 of the first absorption device 4, and the pH of the mixed absorbent sprayed in the first absorption device 4 is controlled at 6, and the oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com