Flue gas desulfurizing device adopting ammonia-ammonium sulfite method

A technology of ammonium sulfite method and desulfurization device, which is applied in the direction of ammonium sulfite, separation methods, chemical instruments and methods, etc., can solve the problems of large energy consumption and cost increase, and achieve high desulfurization efficiency, low energy consumption, The effect of excellent quality of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

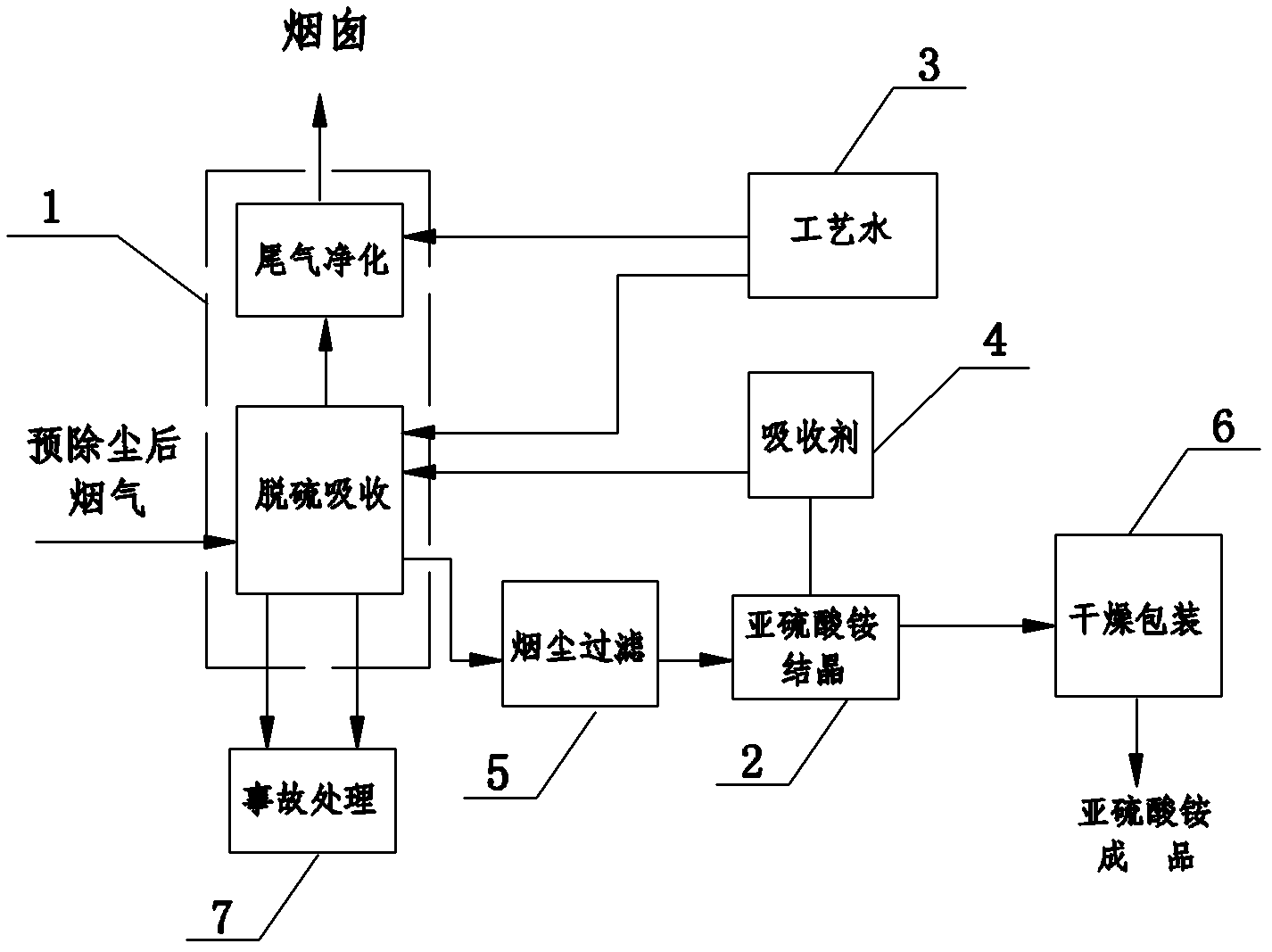

[0035] see figure 1System block diagram of the system, the ammonia-ammonium sulfite flue gas desulfurization device of the present invention mainly includes a desulfurization absorption system 1, an ammonium sulfite crystallization system 2 connected with the desulfurization absorption system 1, a process water system 3 and an absorbent system 4, And the emergency treatment system 7 of the desulfurization unit. The flue gas enters the desulfurization absorption system, and after desulfurization absorption, the exhaust gas is purified and discharged through the chimney. The absorption liquid flowing out of the desulfurization absorption system 1, after dust removal by the smoke filter system 5, enters the ammonium sulfite crystallization system 2 for crystallization, and finally is dried and packaged System 6 obtains ammonium sulfite finished product.

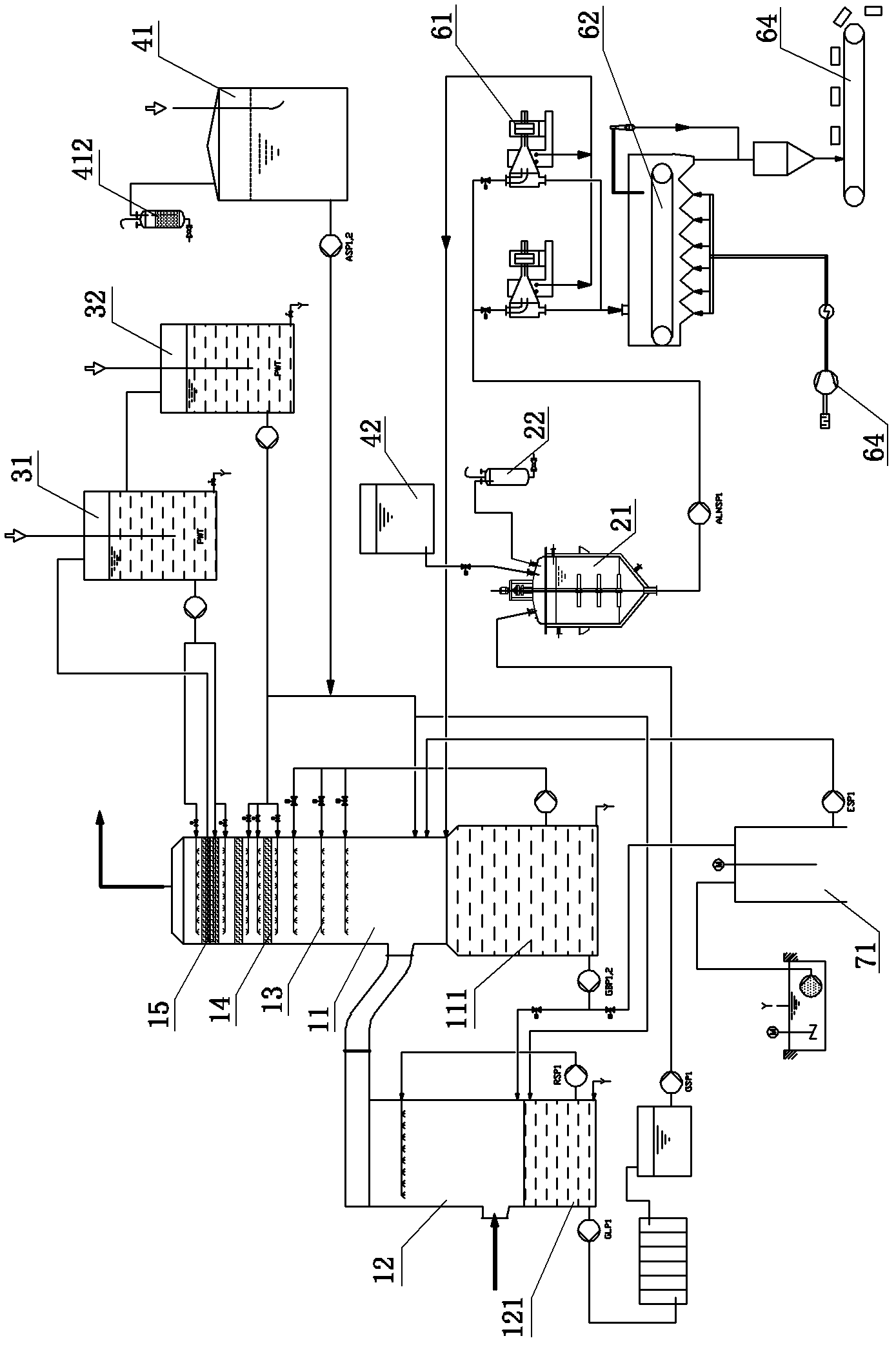

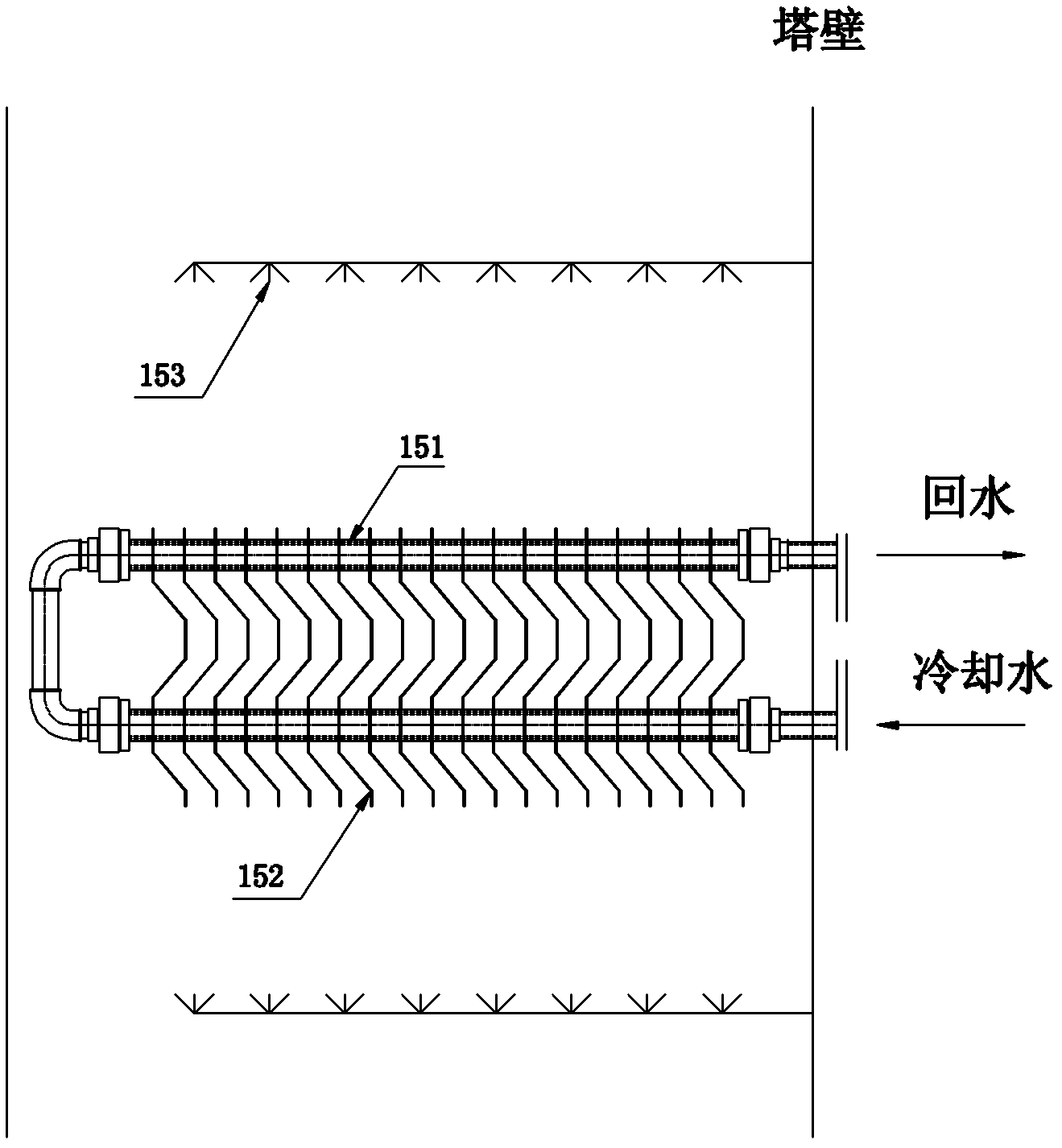

[0036] like figure 2 Shown is the process flow diagram of embodiment 1 of the present invention, the desulfurization absorp...

Embodiment II

[0047] In the second embodiment of the present invention, except that the desulfurization absorption system of the ammonia-ammonium sulfite flue gas desulfurization device is different from that of Example 1, all the other structures are the same.

[0048] The absorption tower of the desulfurization absorption system in this embodiment adopts the structure of single tower and double sections. like Figure 5 As shown, it is an absorption tower with a single-tower double-section structure. Its upper section 11' and lower section 12' are separated by a partition 16 located above the flue gas inlet, and a circular pipe 17 passing through the upper and lower sections of the tower is arranged on the partition. A shower-proof cover 18 is also provided above the circular duct 17 .

[0049] An absorption liquid storage tank 121' is arranged at the bottom of the lower section 12' of the tower, and the upper section 11' of the single tower is connected with the absorption liquid storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com