Ammonia method desulfurizing method and device

An ammonia desulfurization and desulfurization tower technology is applied in the field of ammonia desulfurization, which can solve the problems of unsuitability for large flue gas volume, uneconomical, and excessive ammonia release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

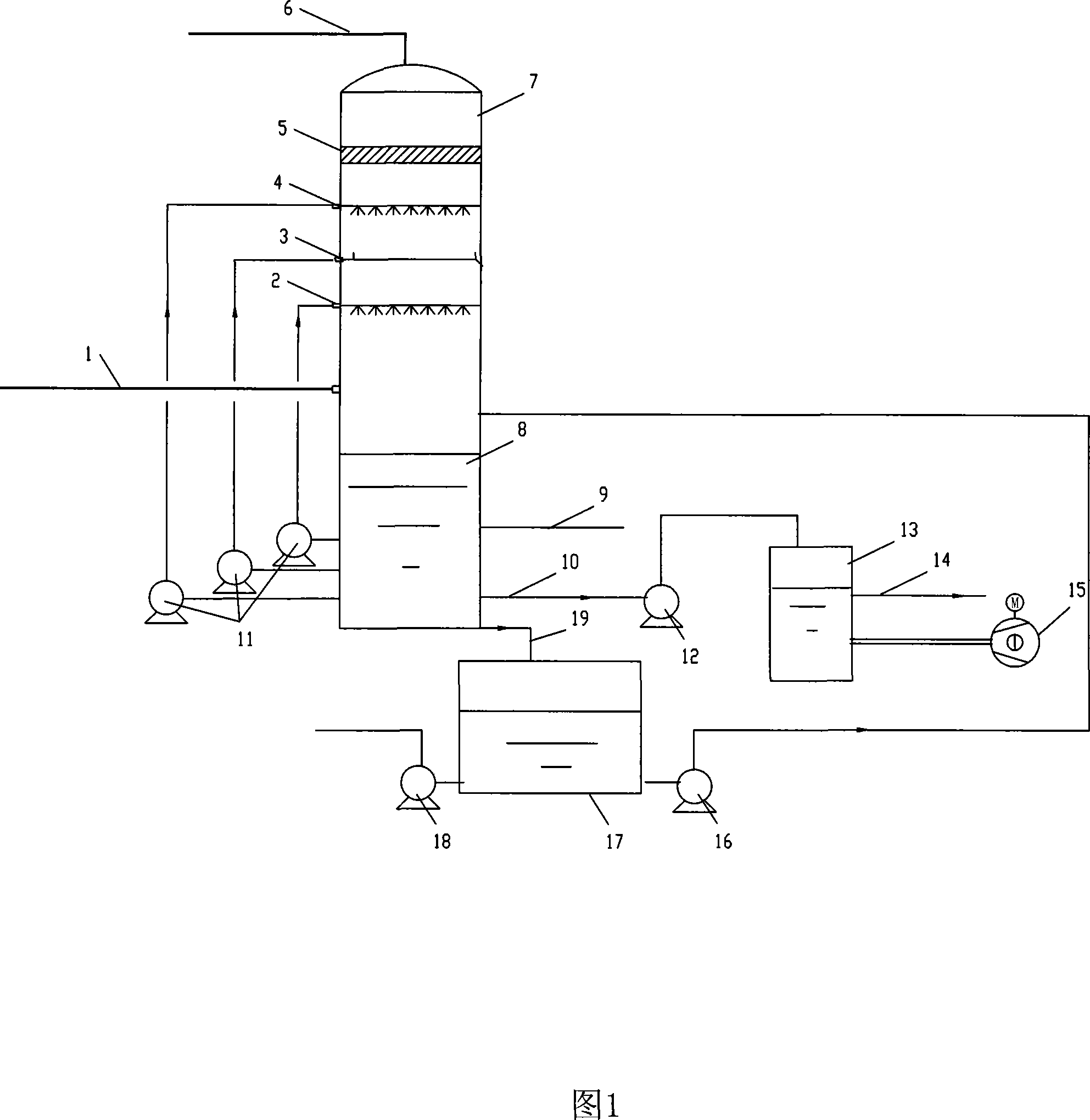

[0050] A desulfurization tower 7, including a solution pool 8 at the bottom of the desulfurization tower, a primary spray section 2, a tray layer 3, and a secondary spray section 4 from bottom to top, wherein the primary spray section 2 includes 1-3 layers of spray The shower device, the tray layer 3 includes 1-2 trays, and the demister 5 is installed above the secondary spray section 4, which is connected with the flue gas outlet 6 at the top of the desulfurization tower; the primary spray section in the middle of the desulfurization tower 2 is provided with a flue gas inlet 1 below; the side of the solution pool 8 at the bottom of the desulfurization tower is connected to the ammonia injection pipe 9; three circulation pumps 11 are arranged outside the tower, and the outlets of the above-mentioned circulation pumps 11 are respectively connected to the primary spray The shower section 2, the tray layer 3, and the secondary spray section 4 are connected, and the inlets of the c...

Embodiment 2

[0054] The rest is the same as that of Example 1, except that the flue gas inlet channel contains a cooling heat exchanger.

Embodiment 3

[0056] Flue gas from the boiler with a temperature of 120°C 1×10 4 The standard cubic meter per hour enters the desulfurization tower 7 from the flue gas inlet 1, and the sulfur oxides in the flue gas are 1600ppm. First, it is cooled to 65-70°C through the primary spray section 2, and part of the sulfide is absorbed, and then The flue gas passes through the tray layer containing 1 tray, and the liquid film flowing on the tray fully reacts with the flue gas when the flue gas passes through, removing most of the sulfides in the flue gas, and then the flue gas The gas continues to rise and then passes through the secondary spray section 4, absorbing a small amount of escape ammonia contained in the flue gas. The absorption liquid of the spray section and the tray layer is 30% ammonium salt solution, and finally ammonium sulfite is entrained. When the flue gas of liquid droplets passes through the demister 5 at the top of the tower, the ammonium sulfate droplets entrained in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com