Patents

Literature

50results about How to "Reduce desulfurization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

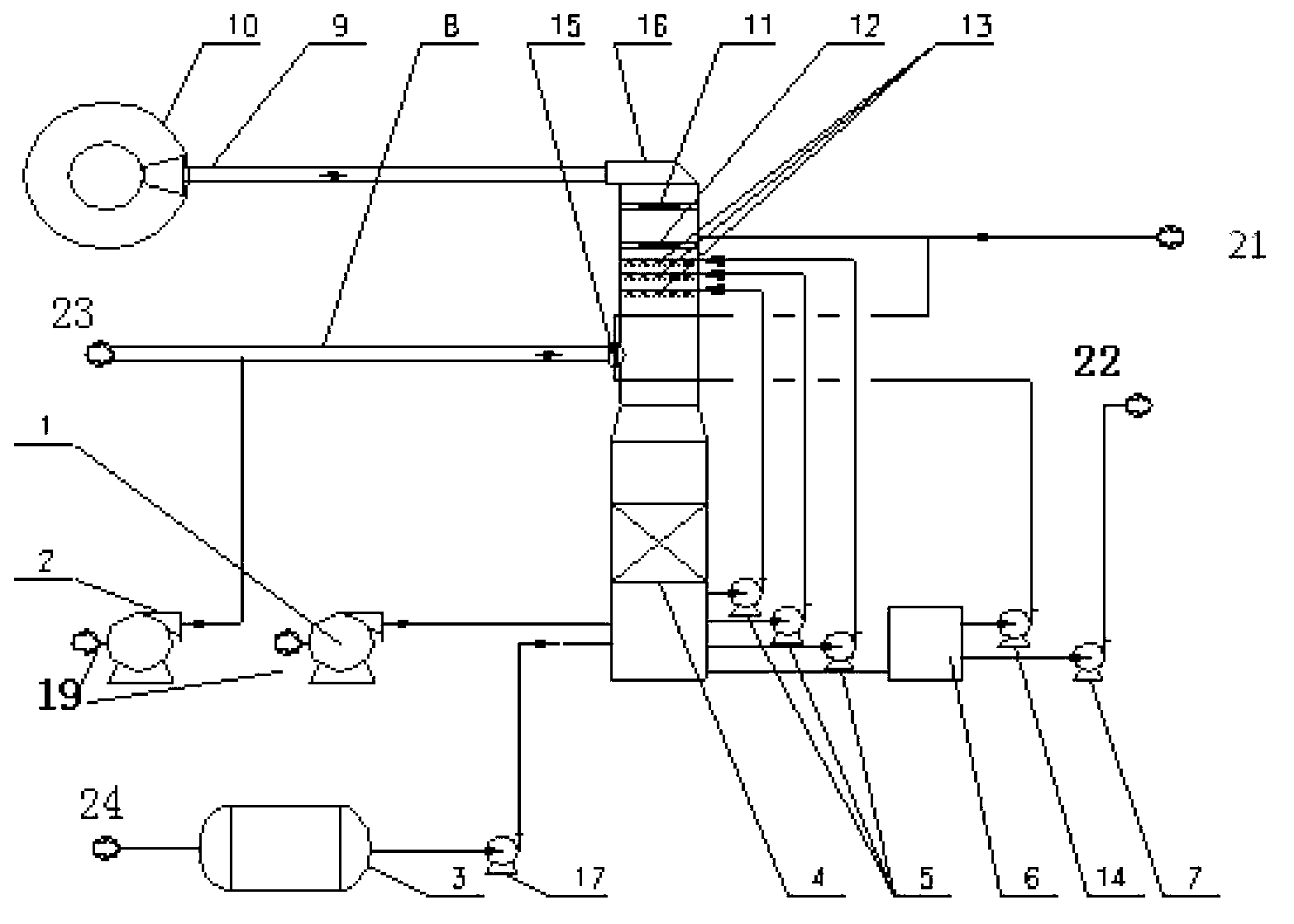

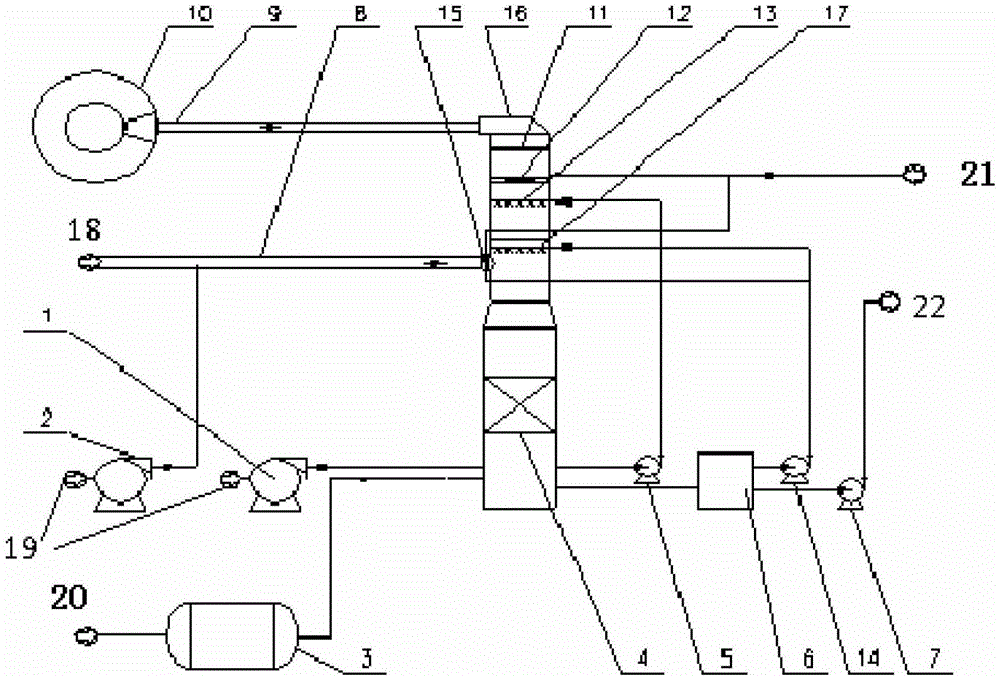

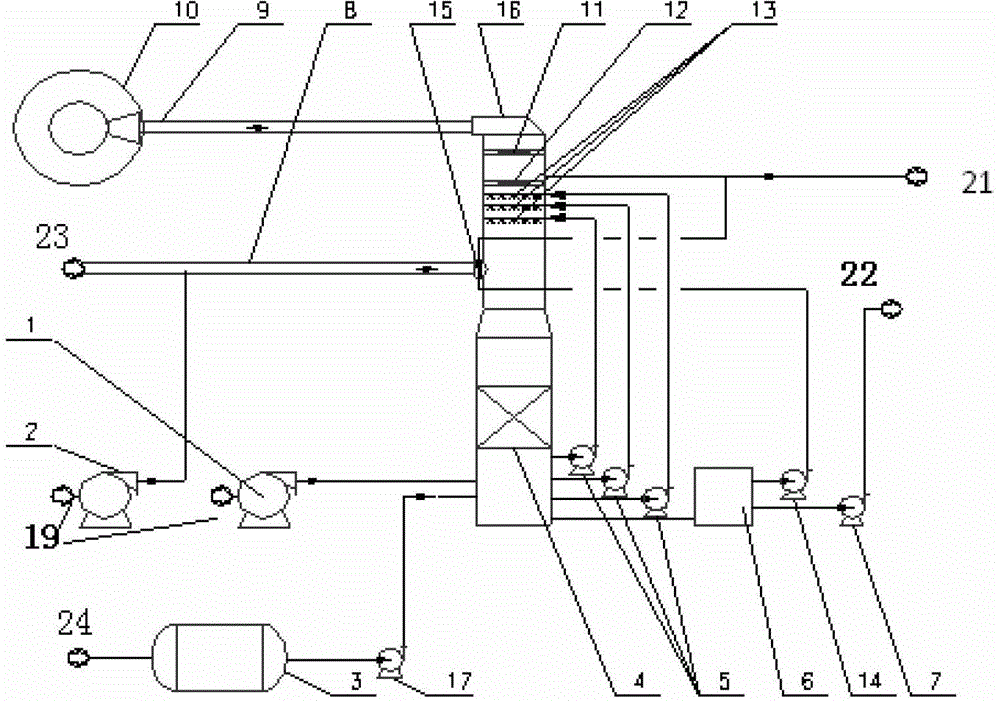

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

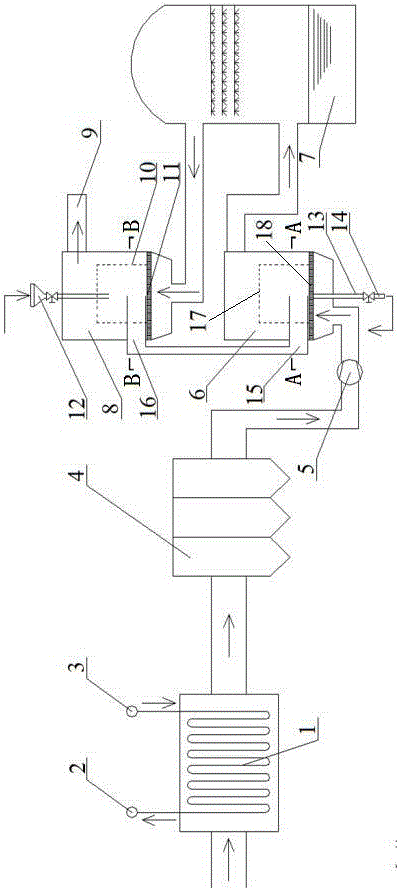

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

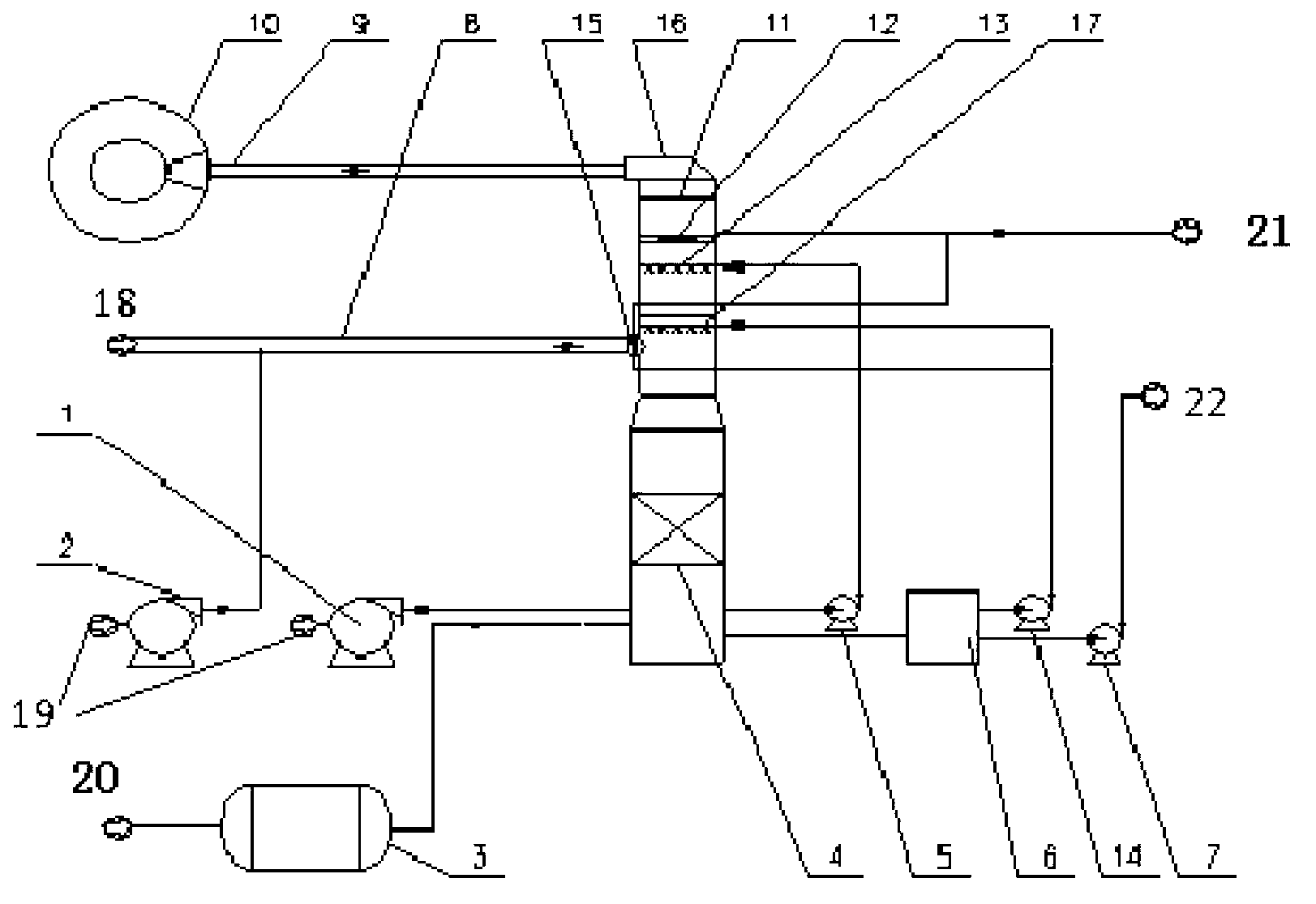

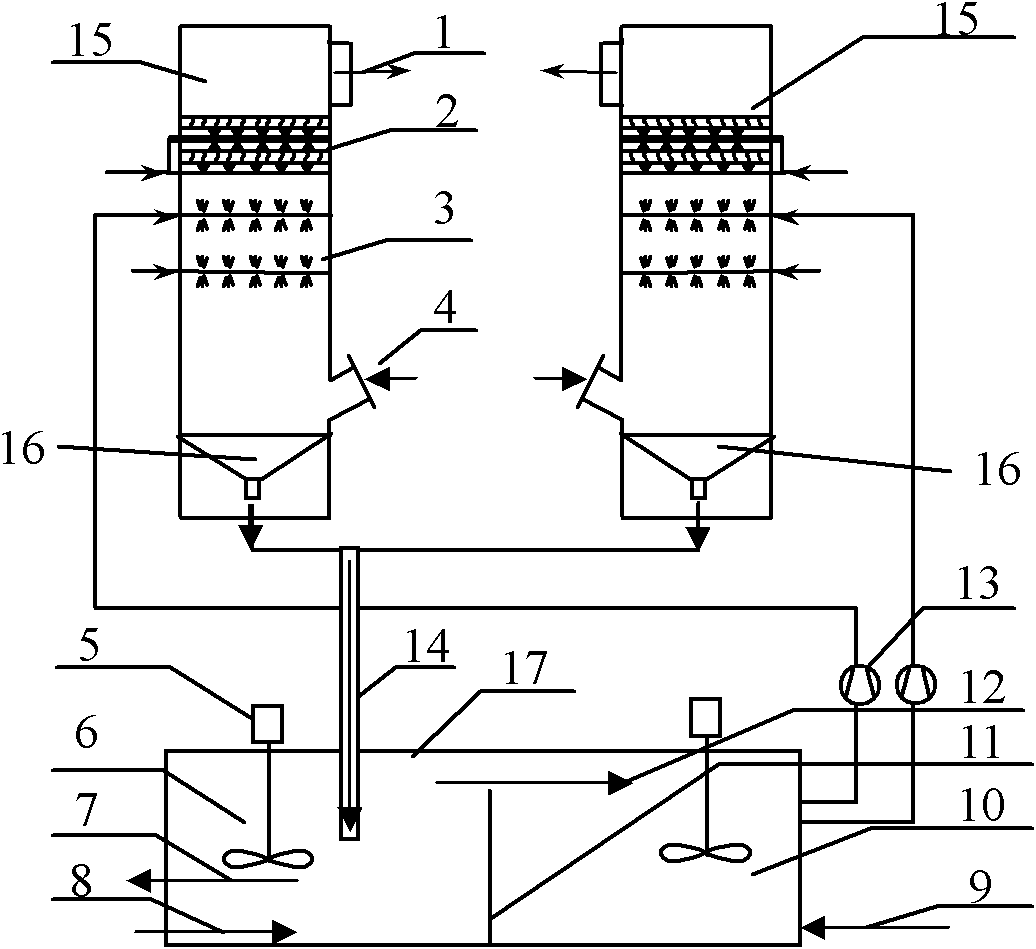

Double-groove wet-process flue gas desulfuration device and method operating on basis of two pH values

InactiveCN102091519AAvoid badSolve the problem of operation safety and stabilityDispersed particle separationSulfurCalcium sulfite

The invention discloses a double-groove wet-process flue gas desulfuration device and a double-groove wet-process flue gas desulfuration method operating on the basis of two pH values, which relate to a flue gas desulfuration device and a flue gas desulfuration method. The aim of the invention is to remove SO2 from the flue gas under a high pH value condition by using desulfurating spray slurry and to dissolve limestone and oxidize calcium sulfite under a low pH value condition so as to improve desulfuration efficiency and quality of gypsum and reduce limestone consumption, investment and operation cost. In the invention, a circulating oxidization tank at the bottom of an absorption tower is divided into two parts, an oxidation pond receives desulfurizating slurry flowing out from a desulfurization tower, the oxidation pond operates in a pH range from 4.0 to 5.5, and in the oxidation pond, sulfite ions are oxidized, and byproduct of desulfuration is led out from the oxidation pond; and fresh limestone slurry is added into a circulating pond, the circulating pond operates in a pH range from 6 to 6.5, and slurry is led from the circulating pound into the absorption tower to be sprayed for deselfuration. The device and the method contribute to improving quality of gypsum, desulfuration efficiency, reducing limestone consumption and lowering investment and operation cost, and are suitable for flue gas desulfuration when sulfur coal is burnt or different kinds of fire coal are burnt.

Owner:HARBIN INST OF TECH

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292BImprove efficiencyLess investmentDispersed particle separationAmmonium sulfatesAmmonia storageEnvironmental engineering

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

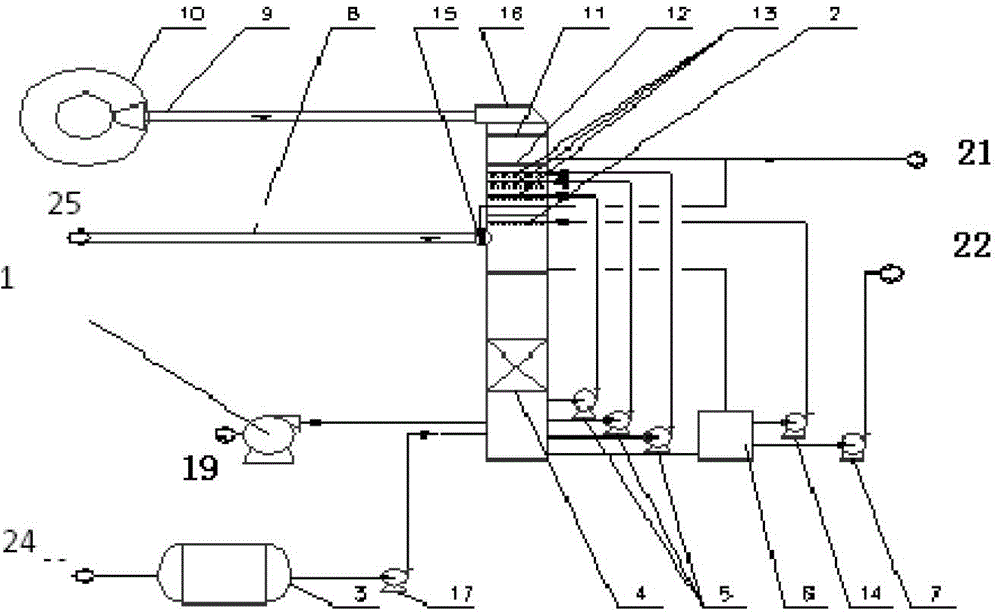

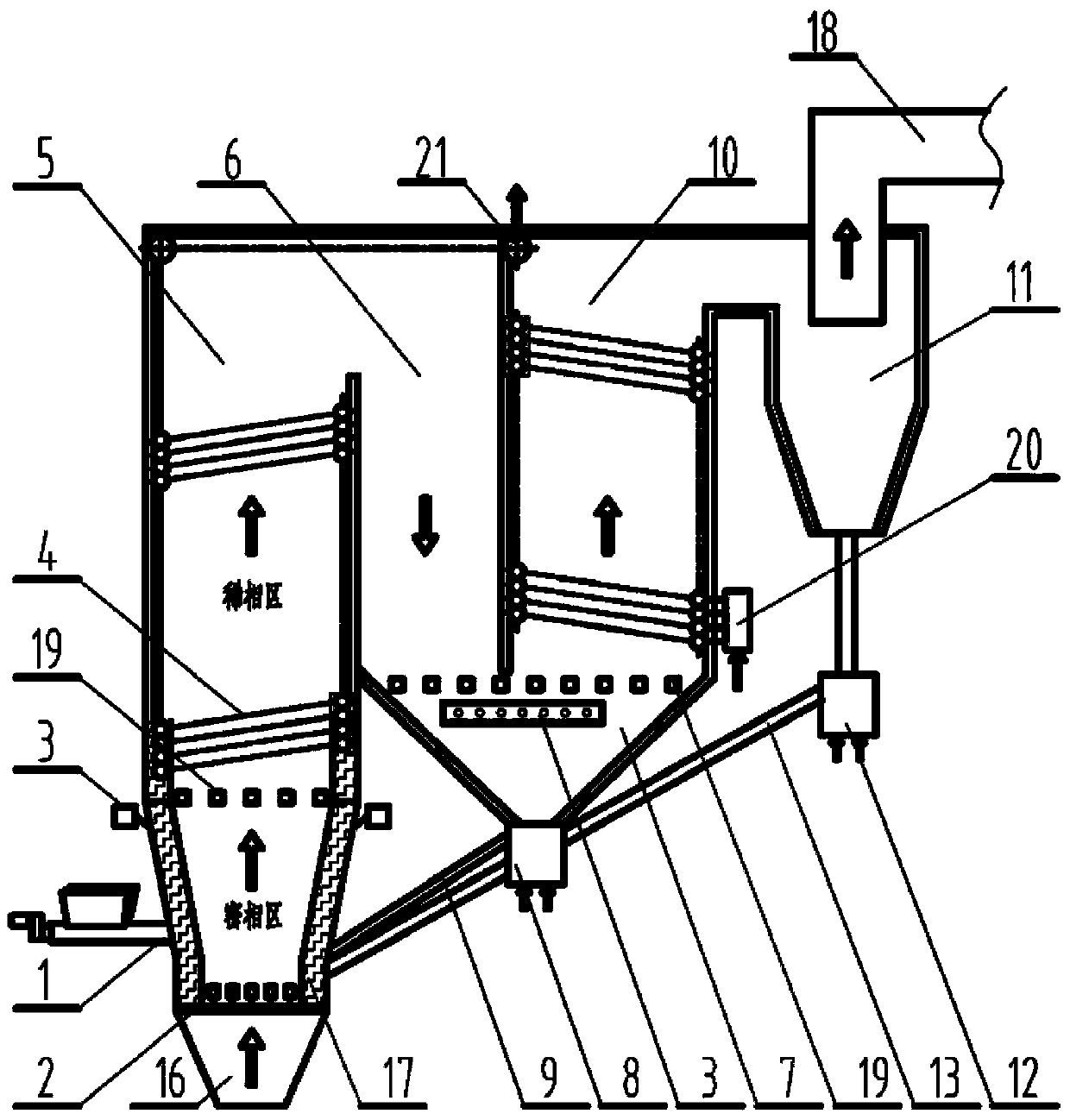

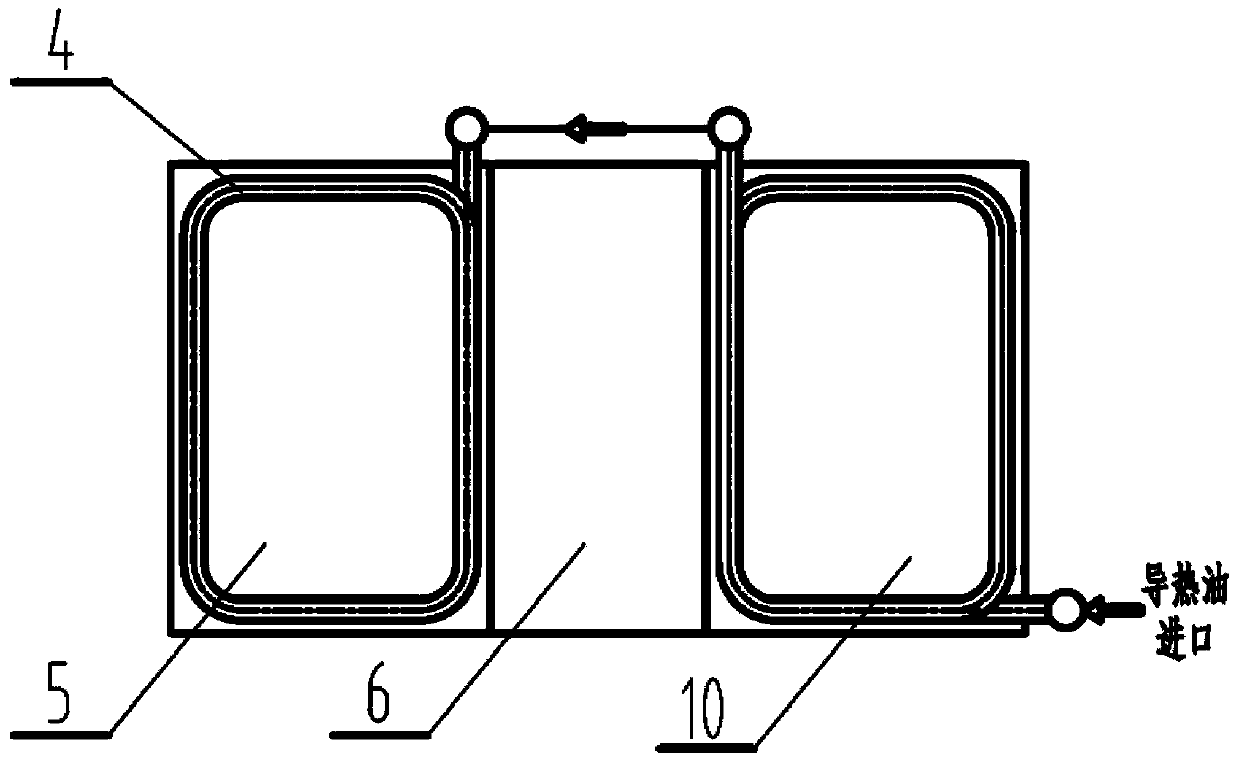

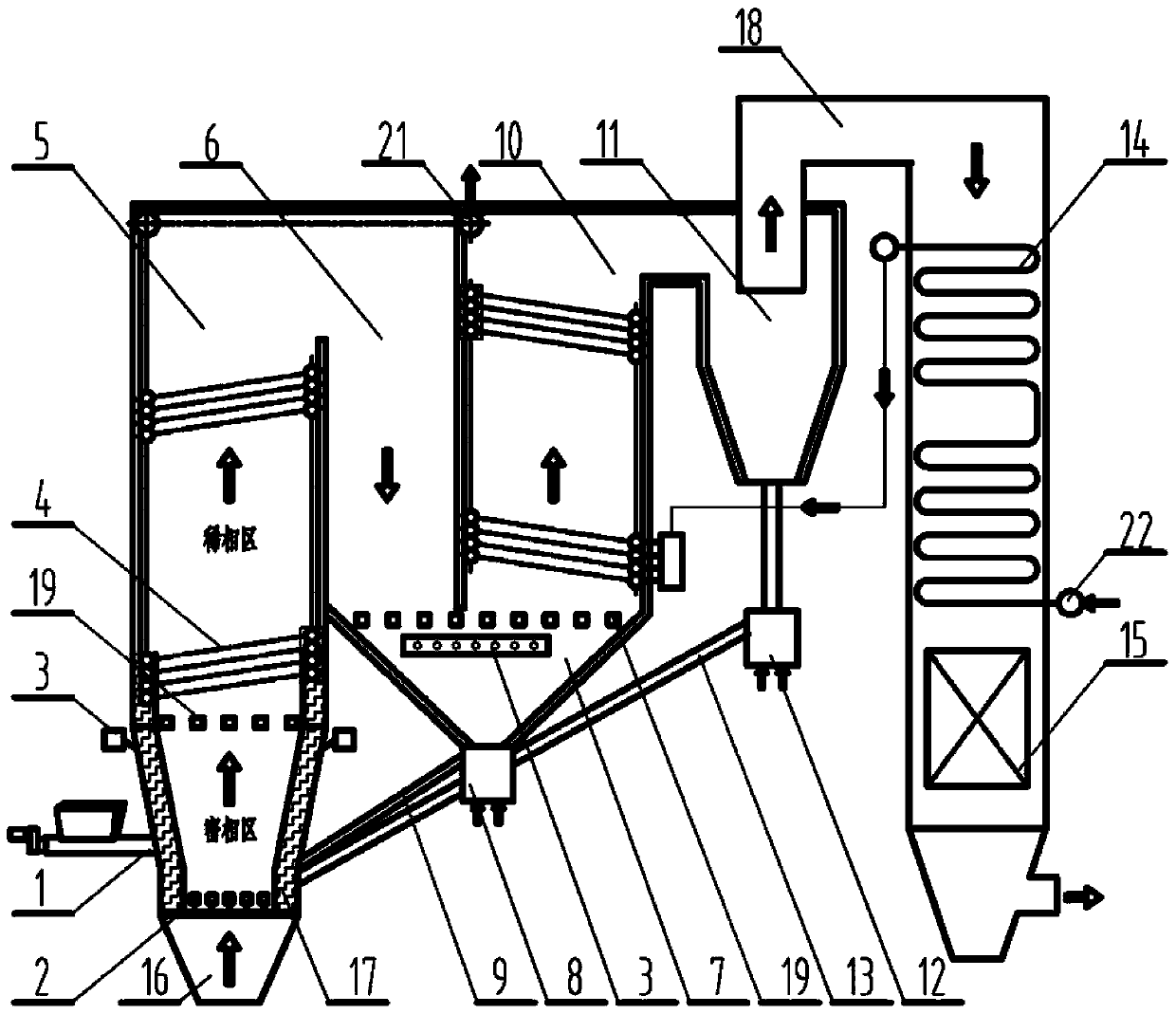

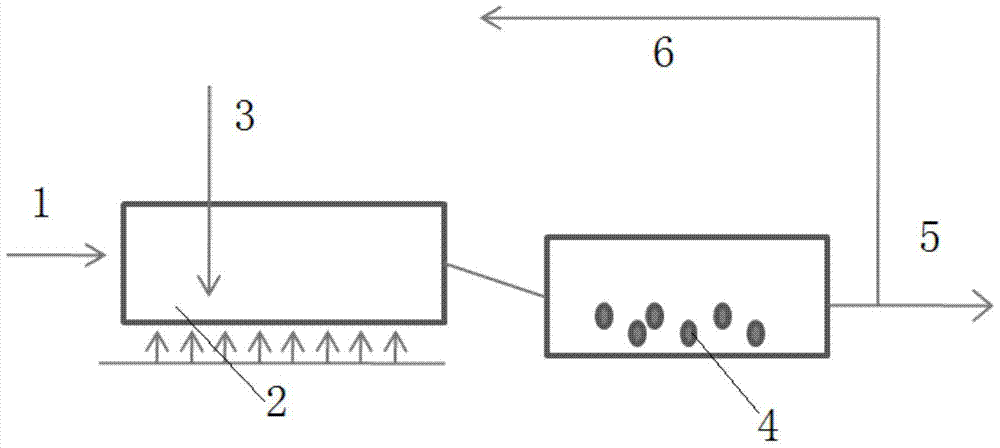

Heat-conduction oil furnace of horizontal circulating fluidized bed

ActiveCN103423869AWide fuel adaptabilityHigh temperature flue gas process is longFluidized bed combustionStorage heatersCirculating fluidized bed boilerCombustion chamber

The invention discloses a heat-conduction oil furnace of a horizontal circulating fluidized bed, and relaters to combustion equipment of the circulating fluidized bed for inferior coal, solid wastes, urban and industrial sludge and biomass fuels, in particular to a heat-conduction oil heating device. The heat-conduction oil furnace is mainly composed of a feeding device, a main combustion chamber, an auxiliary combustion chamber, an after-combustion chamber and a cyclone separator, wherein heat-conduction oil coils are arranged in the main combustion chamber and the after-combustion chamber, an economizer and an air pre-heater can be arranged behind the cyclone separator, and a waste heat boiler can also be arranged behind the cyclone separator. The heat-conduction oil heating device adopts a horizontal circulating fluidized bed technology, changes the traditional structural style adopting a chain grate furnace to heat, changes the single-stage and vertical circulating structure of the traditional fluidized bed boiler, effectively reduces the height of the boiler, and reduces the requirement on the construction height of plants. Through reasonable structural layout, the problem that the circulating fluidized bed boiler is easily abraded is effectively solved, and the heat-conduction oil heating device has wide adaptability to fuels, has high combustion efficiency, and has lower pollutant discharging quantity.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

Production method of high-cleanliness sulfur-containing and aluminum-containing steel

ActiveCN111235341ARaise the initial sulfur contentReduce production process costsManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses a production method of high-cleanliness sulfur-containing and aluminum-containing steel. The production method comprises the following steps: a top-bottom blowing combined converter is used for blowing, and molten steel is subjected to composite deoxidation, alloying and slagging in the tapping process; heating in the LF refining process, diffusing and deoxidizing of a slagsurface, and precipitating and deoxidizing of molten steel are performed, desulfurizing is not deliberate, the flow of ladle bottom blowing and stirring argon in the whole refining process is controlled, and calcium treatment and soft blowing are performed on the molten steel before the refining is finished; the molten steel is transferred to an RH station, a sulfur line is fed according to the residual sulfur content of the molten steel to a resulfurization target value of the molten steel, vacuum treatment is performed, and micro-calcium treatment denaturation is performed again after the molten steel is broken; and standing and soft blowing are performed on the molten steel; and an arc continuous casting machine performs protective casting. According to the method, the original sulfurcontent of the molten steel is improved, the refining process is not supplemented with slag materials for deliberate desulfurization, only molten steel diffusion and precipitation deoxidation are adopted, weak bottom blowing stirring and calcium treatment are adopted to promote inclusion removal, the sulfur line is fed before the molten steel enters the RH station, so that no component adjustmentis needed after the molten steel RH circulation, secondary pollution of the molten steel is avoided, and high cleanliness control of the molten steel is realized.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Method for preparing high-sulfur iron-containing series desulfurizing agent

InactiveCN101126115AReduce desulfurization efficiencyTo achieve the purpose of recyclingGas emission reductionVulcanizationActive component

A preparation method of high sulfur capacity ferrous desulfurizer belongs to the field of coal chemical industry and preparation and application of desulfurizer, in particular to a preparation of a high temperature ferrous desulfrizer in the field of preparation and gas purification. The main active component of the desulfurizer is a nanometer frric oxide treated by a particularly technique process as that: the nanometer frric oxide is added with component such as vulcanization accelerator, carbon resistant promoter, strength enhancer and binder, then uniformly mixed by grinding and kneaded to shape, finally, dried or roasted to shape strip, granule or flake. The desulfurizer is characterized by high desulfurating efficiency, stable circulation and high sulfur capacity, etc. At least the desulfurizer removes H2S from 2000-5000ppm in entrance to 1ppm, and is suitable for removing H2S in surlfur gas of coal gas or natural gas under the temperature of 350-450 DEG C.

Owner:TAIYUAN UNIV OF TECH

Desulfurization process of blast furnace gas

InactiveCN110129102AAchieve recyclingAdvanced technologyGas treatmentDispersed particle separationMolecular sieveDesorption

The invention discloses a desulfurization process of a blast furnace gas, which comprises the following steps: 1) preparing two same adsorption towers filled with molecular sieve resin, denoted as anadsorption tower A and an adsorption tower B; 2) introducing the cooled blast furnace gas into the adsorption tower A for adsorption, when the sulfur content of gas at the outlet of the adsorption tower A is more than 5 mg / m<3>, switching the blast furnace gas into an adsorption tower B for continuous adsorption, and stopping the operation of the adsorption tower A at the same time; 3) guiding outand heating a small amount of completely desulfurized coal gas, introducing the desulfurized coal gas into the adsorption tower A for high-temperature desorption regeneration, treating the gas afterthe high-temperature desorption regeneration through a recovery process of a sulfur-containing compound, and cooling the regenerated adsorption tower A for later use; and 4) alternately using the regenerated adsorption tower A and the adsorption tower B so as to complete continuous removal of the sulfur-containing compounds in the blast furnace gas. The method disclosed by the invention can realize recycling of sulfur resources, and is low in equipment investment and low in operation cost.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

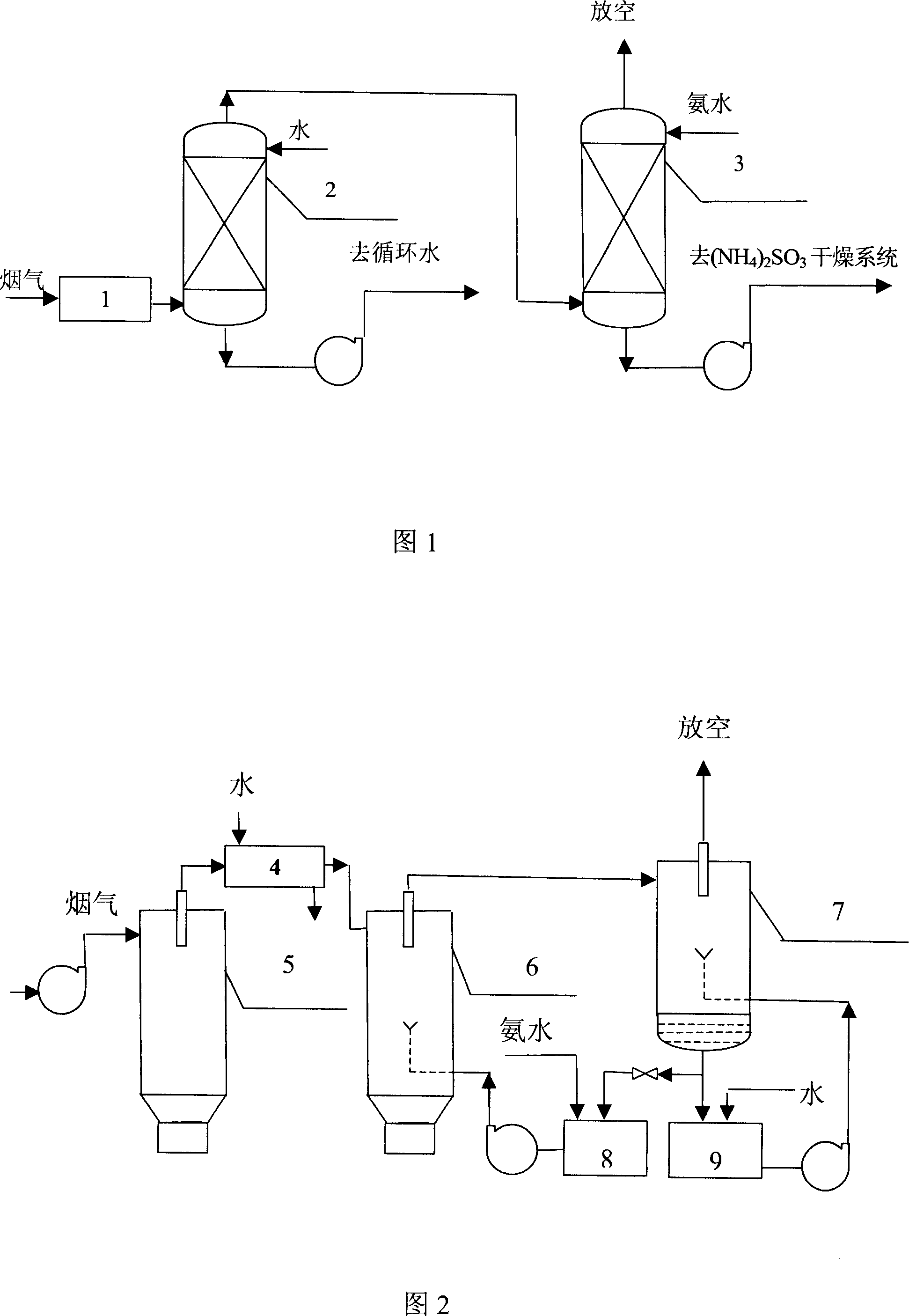

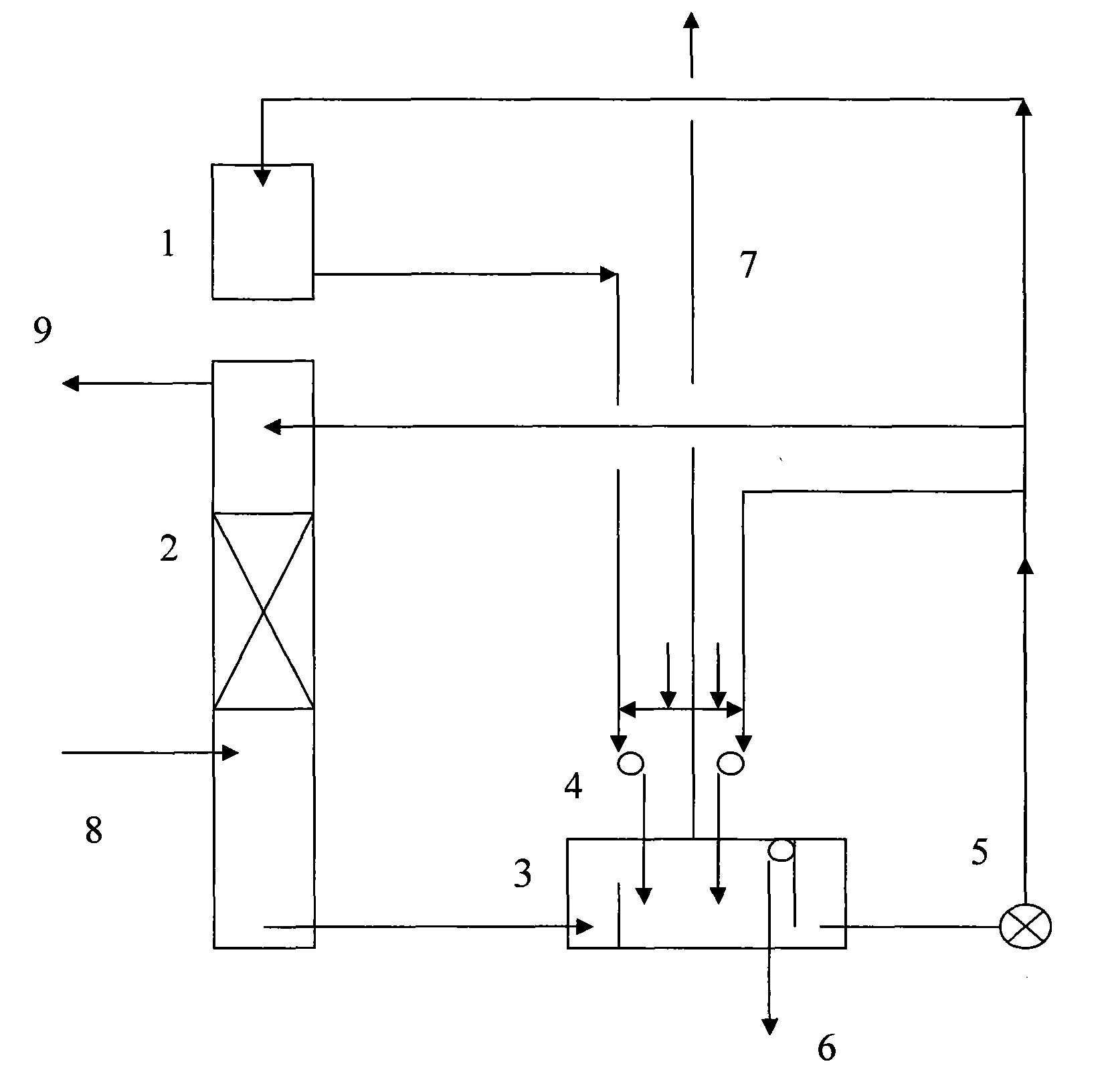

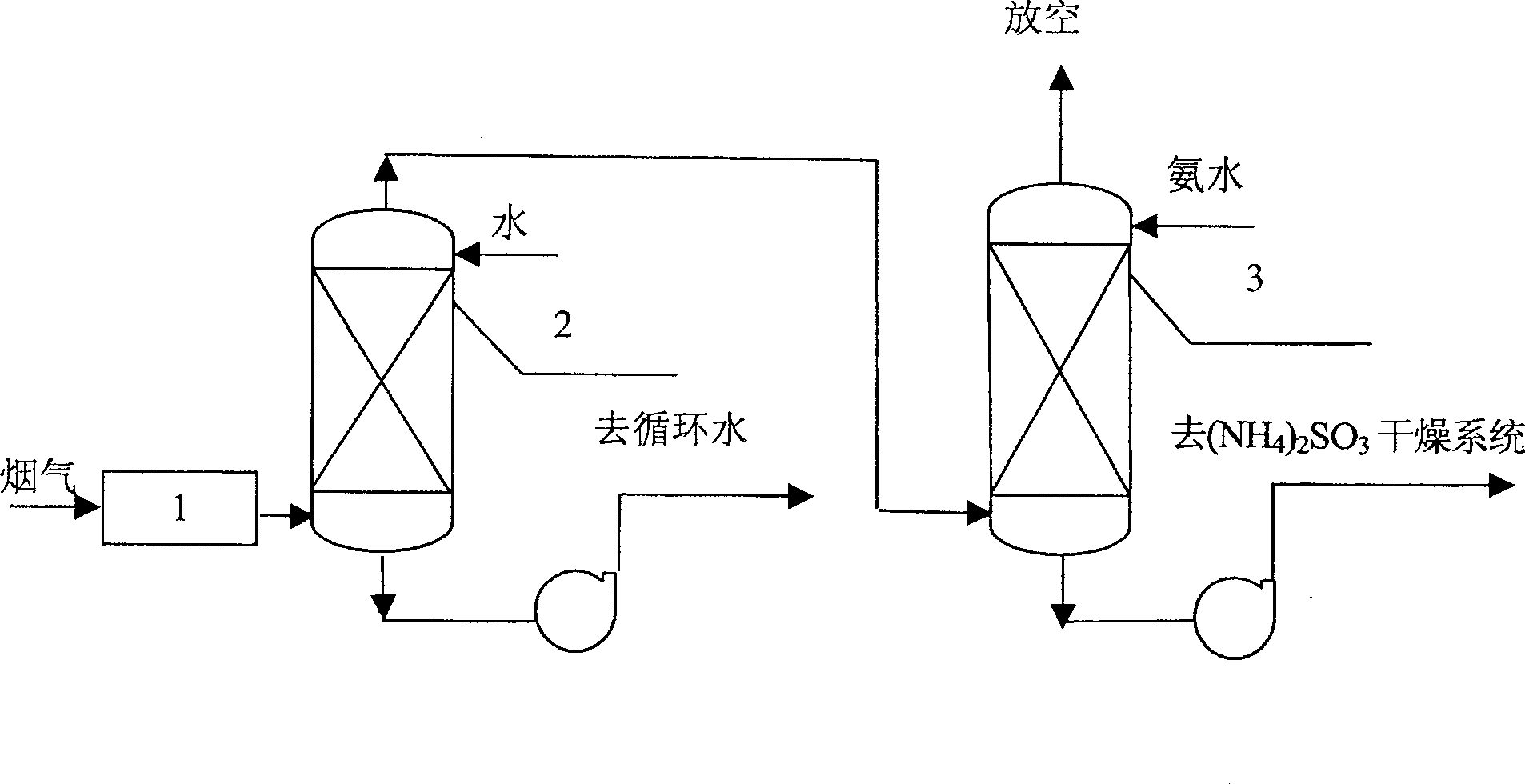

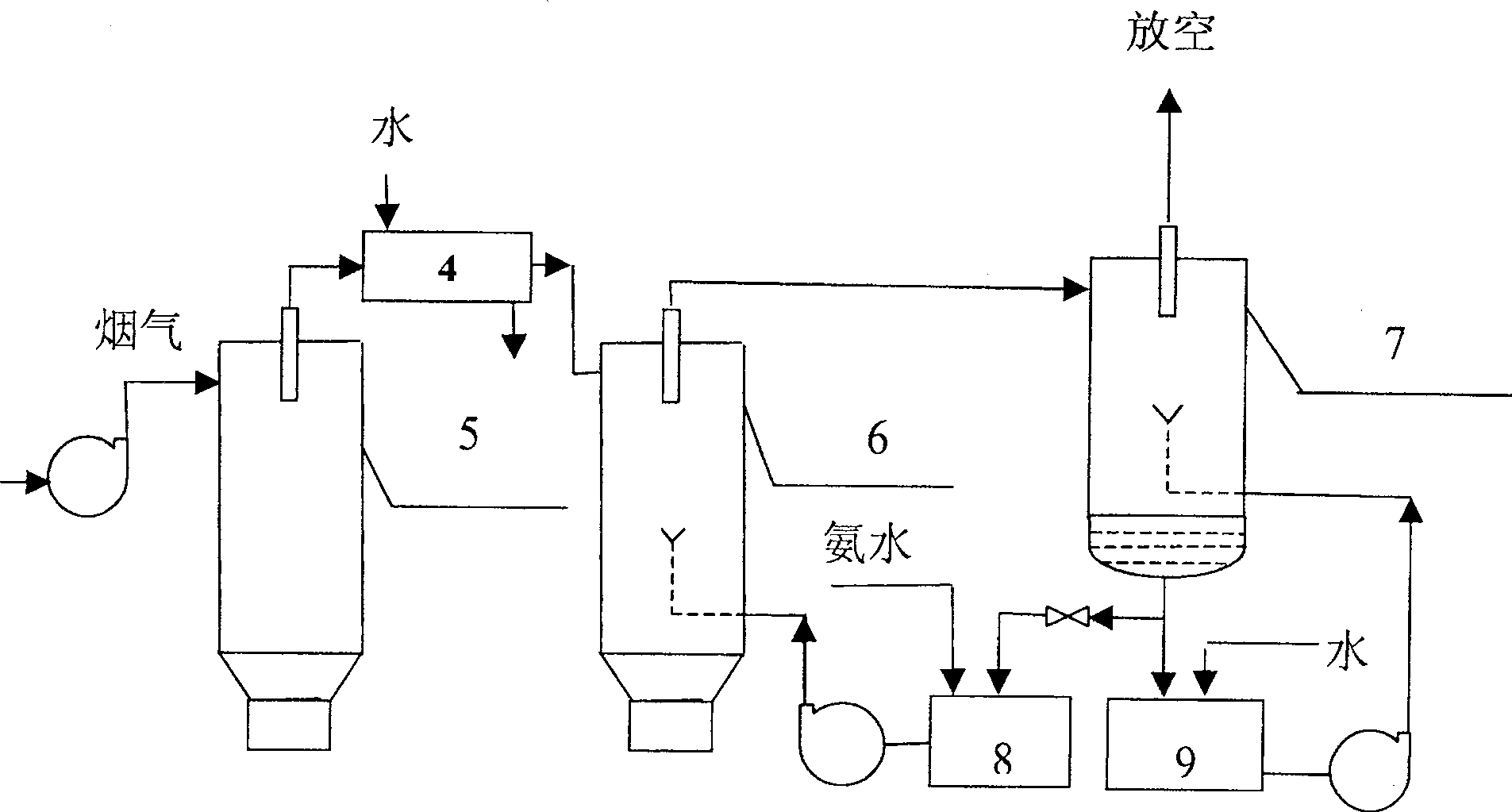

Process for ammonia method desulfurization of fume and by-producing ammonium sulfite

ActiveCN1970447APromote absorptionReduce desulfurization efficiencyDispersed particle separationAmmonium sulfitesVolumetric Mass DensitySpray tower

The invention discloses a flue gas desulfurizing method through ammonia process and generating method of by-product ammonium sulfite, which comprises the following steps: making flue gas into cyclone separator and heat exchanger to dedust and cool; atomizing ammonia and (NH4)2SO3 solution in the drying tower; contacting with flue gas to desulfurize; drying; separating; contacting flue gas with (NH4)2SO3 solution in the spray tower; removing residual SO2 and NH3 to lower density; saving ammonia; obtaining by-product (NH4)2SO3.

Owner:PETROCHINA CO LTD

A desulfurizing process

InactiveCN101532073ASolve the dilemma of poor long-term desulfurization effectImprove desulfurization efficiencyMelting tankCast iron

The invention relates to a desulfurization process, pertaining to the field of steel-smelting desulfurization technology. The technical problems the invention object to resolve is to provide a new desulfurizing agent to overcome the defect of bad desulfurization effects of the prior process. The inventive desulfurizing process includes: in the furnace tapping process, adding 55-65% of desulfurizing agent in the iron melt groove, after the tapping of the iron melt, in the desulfuration platform, mixing in the iron melt tank and adding 35-45% of the desulfurization agent. The inventive desulfurizing process can resolve the problem of ultrahigh sulfur content in the cast iron, wherein, the maximum desulfurization efficiency is 98%.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

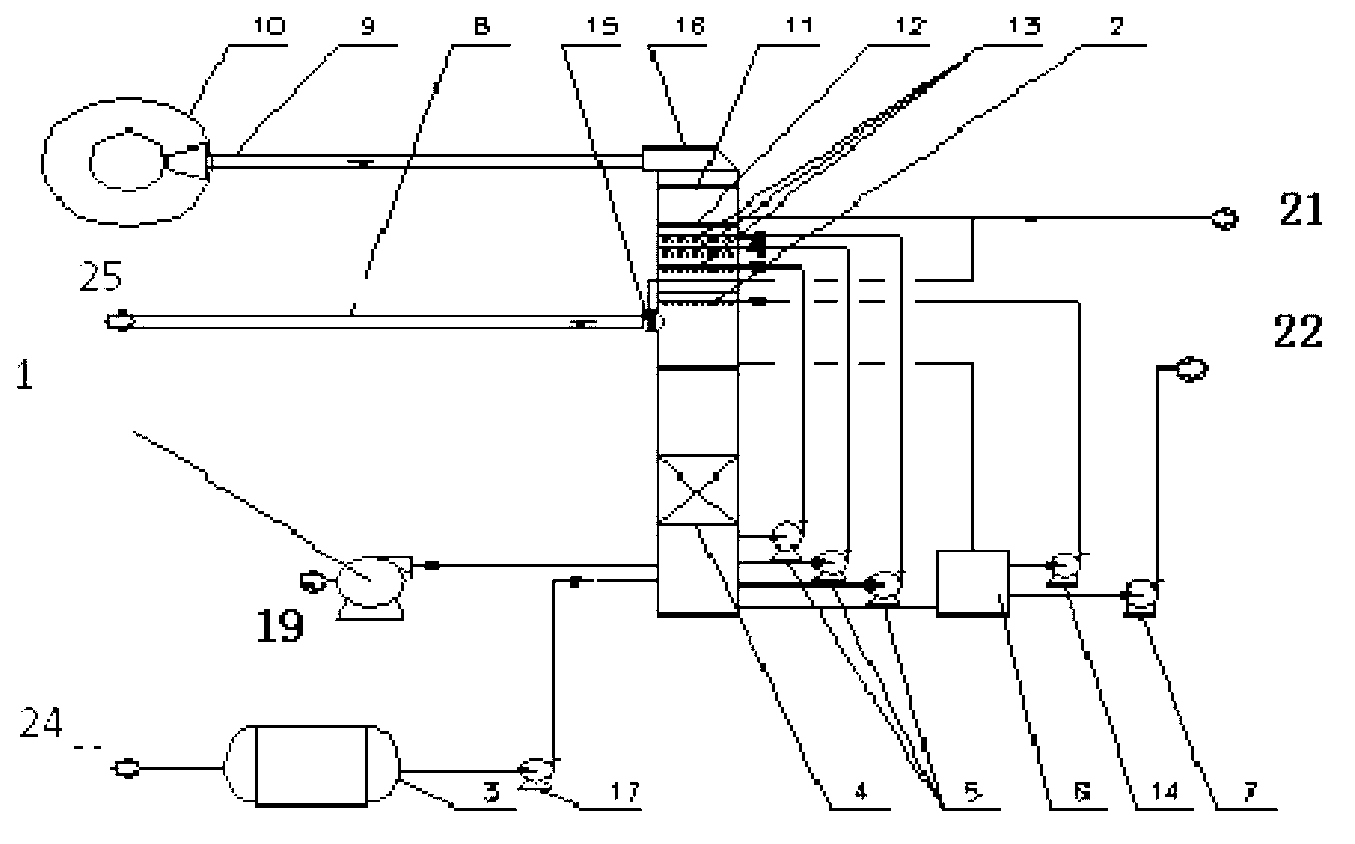

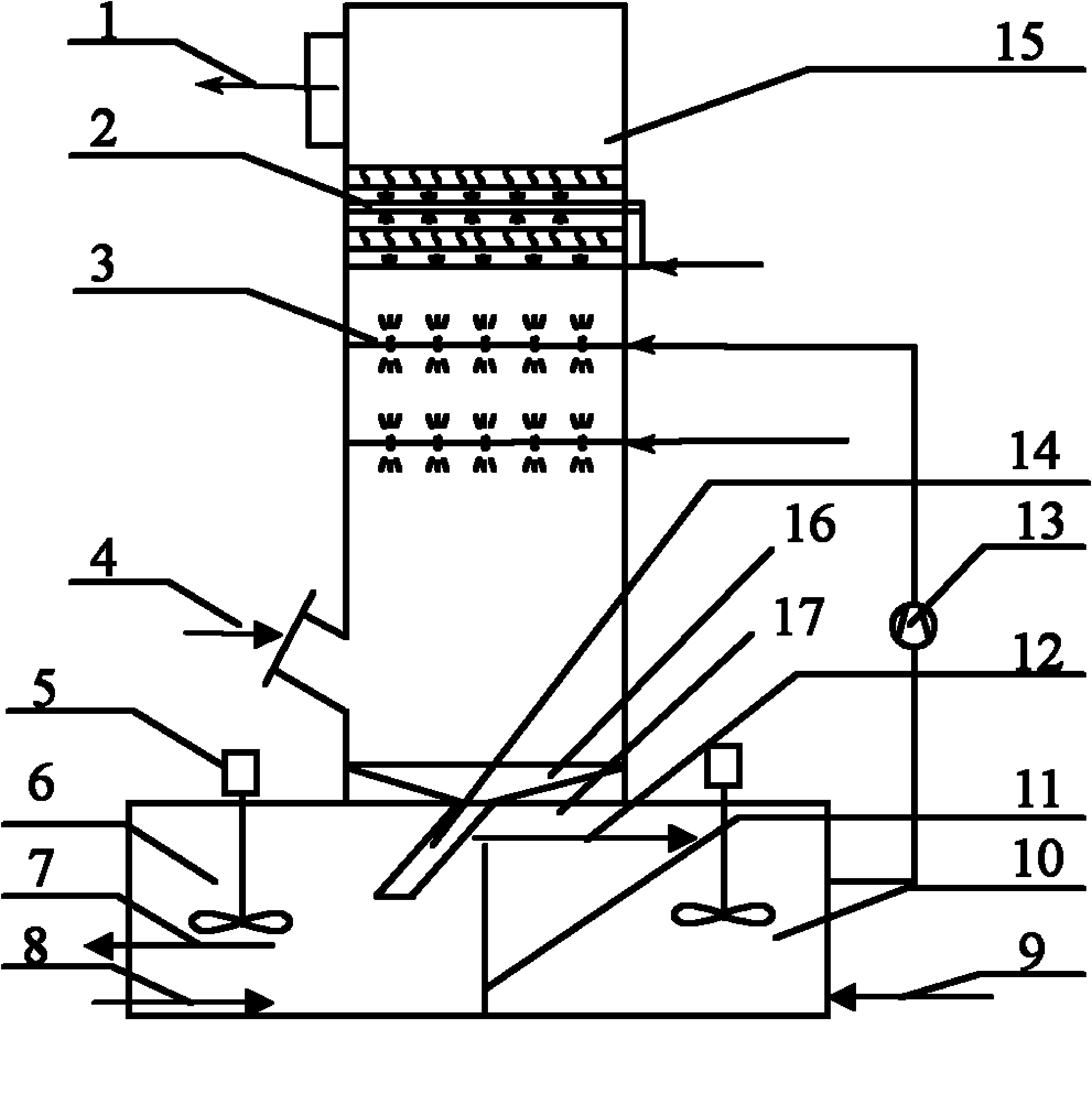

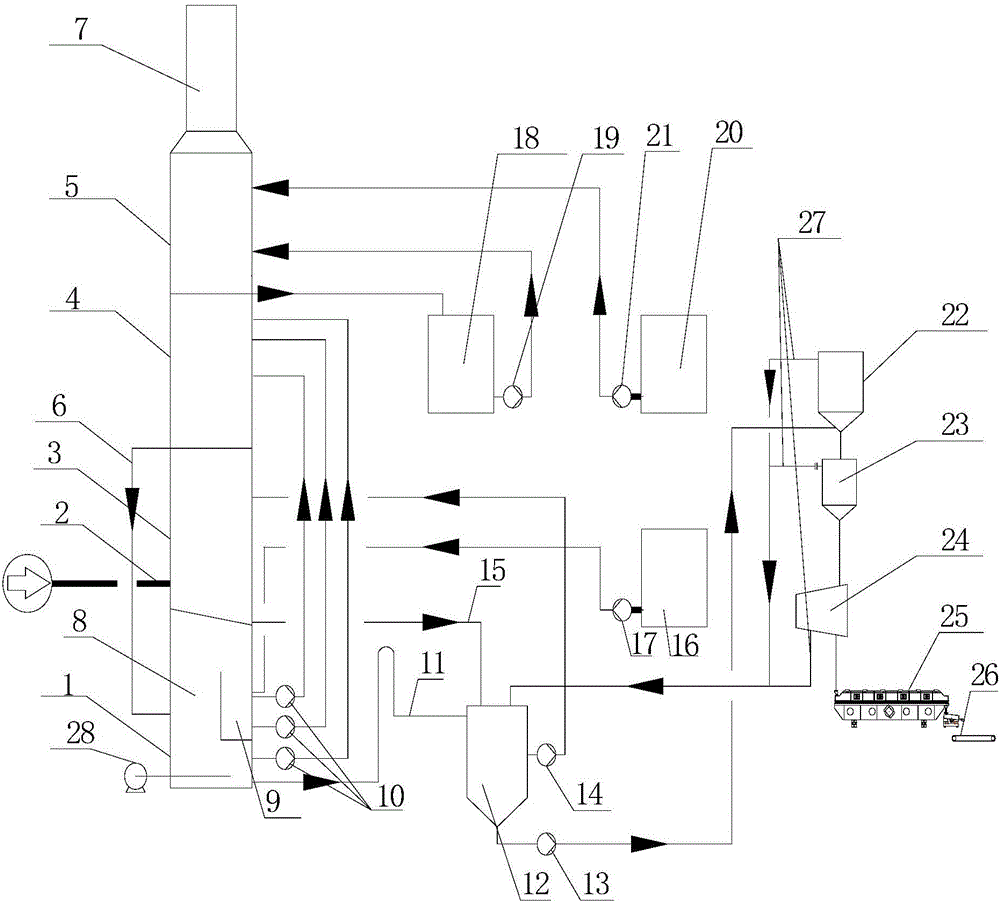

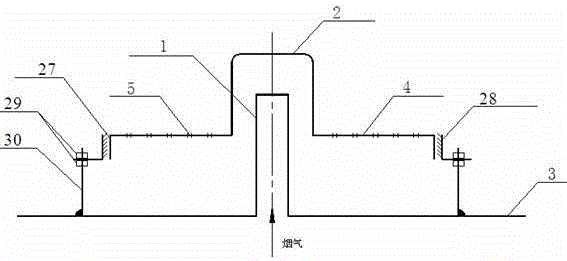

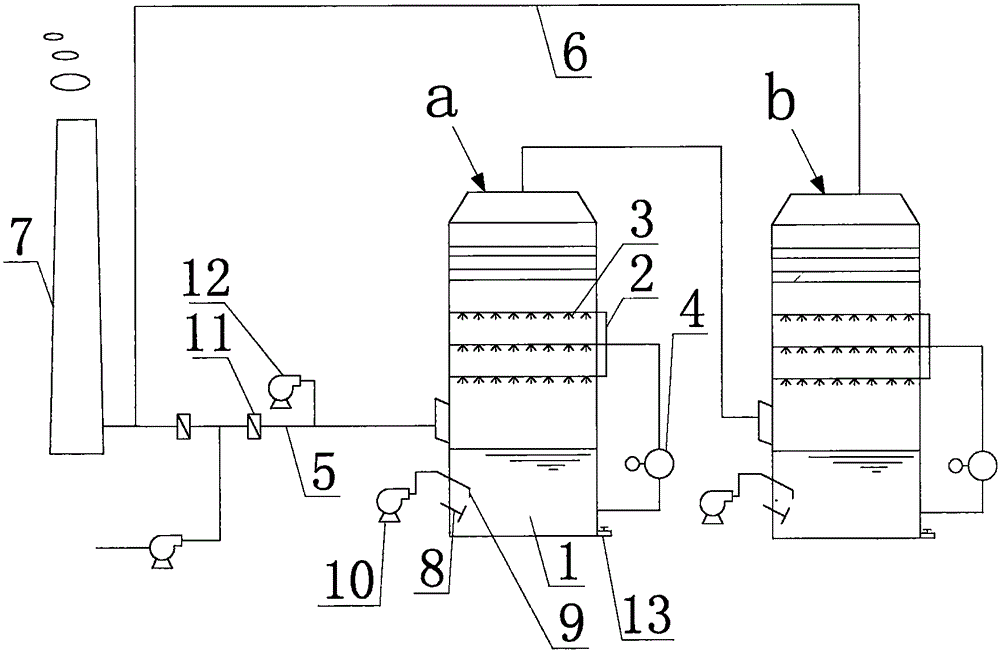

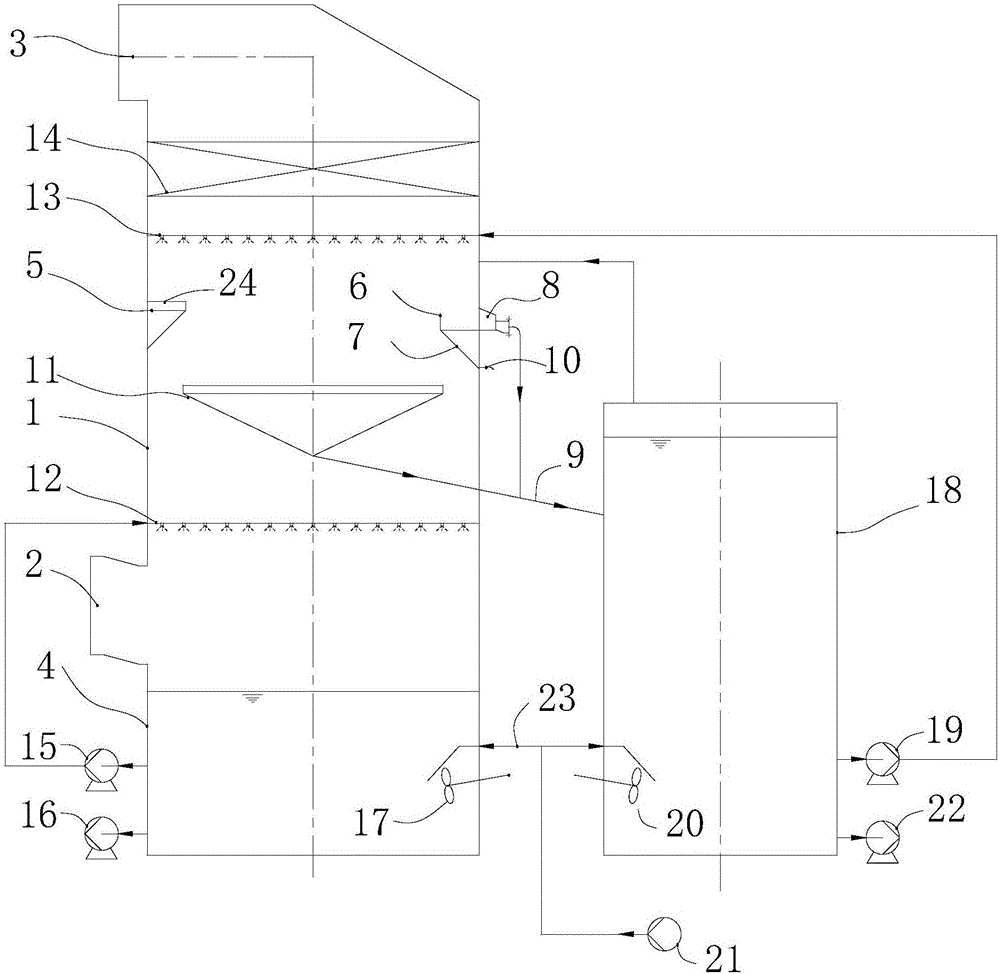

Ammonia desulphurization ultra-low discharging system and ammonia desulphurization ultra-low discharging process

The invention discloses an ammonia desulphurization ultra-low discharging system and an ammonia desulphurization ultra-low discharging process, belonging to the field of environmental protection. The ammonia desulphurization ultra-low discharging system comprises a desulfurizing tower, an ammonia adding system, a circular crystallizing system, a purifying and washing system and a rear ammonium sulfate system, wherein the lower part of an oxidizing section of the desulfurizing tower is connected with the rear ammonium sulfate system through the circular crystallizing system; the upper part of the oxidizing section of the desulfurizing tower is connected with the ammonia adding system through a pipeline; the circular crystallizing system is connected with a concentrated circulating section of the desulfurizing tower through a pipeline; a purifying and washing section of the desulfurizing tower is connected with the purifying and washing system through a pipeline. The ultra-low discharging process provided by the invention belongs to a gas-liquid reaction and has the advantages of high reaction speed, complete reaction and high desulfurizing efficiency. The system disclosed by the invention meets the requirement on ultra-low discharge, is simple in structure, easy in realization and low in cost, and facilitates wide popularization and application.

Owner:张波

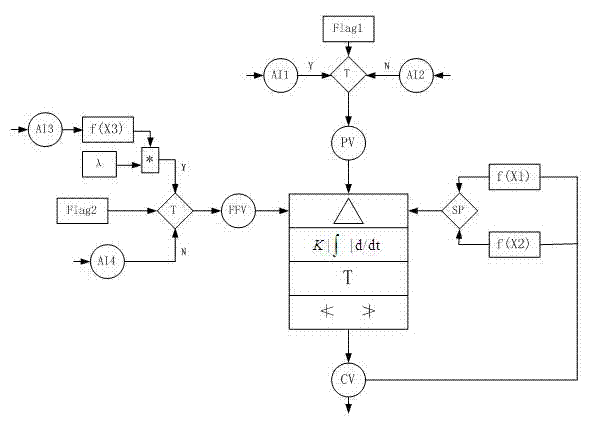

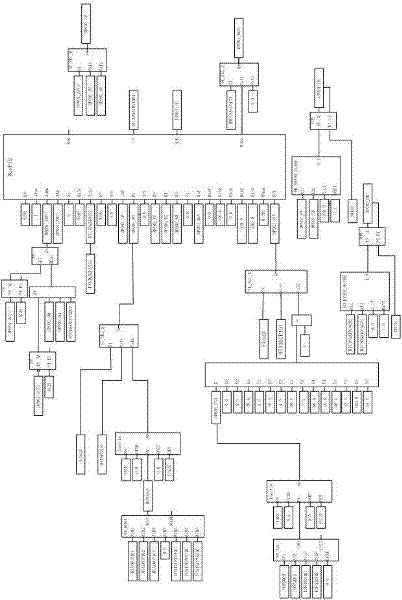

Automatic control steady-state undisturbed switching method for desulphurization booster fan

ActiveCN102508432AEnables bumpless switchingAchieve matchingAdaptive controlAutomatic controlEngineering

The invention discloses an automatic control steady-state undisturbed switching method for a desulphurization booster fan. According to the method, a controlled quantity is switched and selected flexibly, and a corresponding set value is tracked and set through an object transmission function; furthermore, the openness of a guide blade of a draught fan is used as a feedforward signal; the parameter optimization proportioning is realized by using a segmental polygonal function; and undisturbed adjustment of a static blade or a movable blade of the booster fan can be well realized by setting a proportion parameter. A unit runs securely and stably by rationally adjusting the controlled quantity and the feedforward signal of the booster fan. Under the secure running of a desulphurization system, the desulphurization efficiency of the unit can be guaranteed; desulphurization is automatically performed, so that the unit can generate power securely and stably; therefore, the labor intensity of an operator is reduced greatly, and the labor efficiency is improved. The method is high in practicability; the engineering is easy to implement; and the automatic control steady-state undisturbed switching method is wide in application prospect.

Owner:GUODIAN NANJING AUTOMATION

Composite desulfurizer for molten iron desulphurization or semisteel desulphurization and process method thereof

The invention discloses a composite desulfurizer for molten iron desulphurization or semisteel desulphurization and a process method thereof and belongs to the technical field of metallurgical production. According to the composite desulfurizer for molten iron desulphurization or semisteel desulphurization and the process method thereof, during desulphurization, the iron loss is little, efficiency is high, and the steelmaking steel grade smelting need can be met. The composite desulfurizer is a powder mixture at least comprising CaO, Mg, Na2O, CaC2, Al, Al2O3 and SiO2. The process method comprises the step that the composite desulfurizer of the components is injected to the lower-middle portion of molten iron needing to be desulphurized or the lower-middle portion of semisteel needing to be desulphurized along with nitrogen through a nitrogen conveying pipeline.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

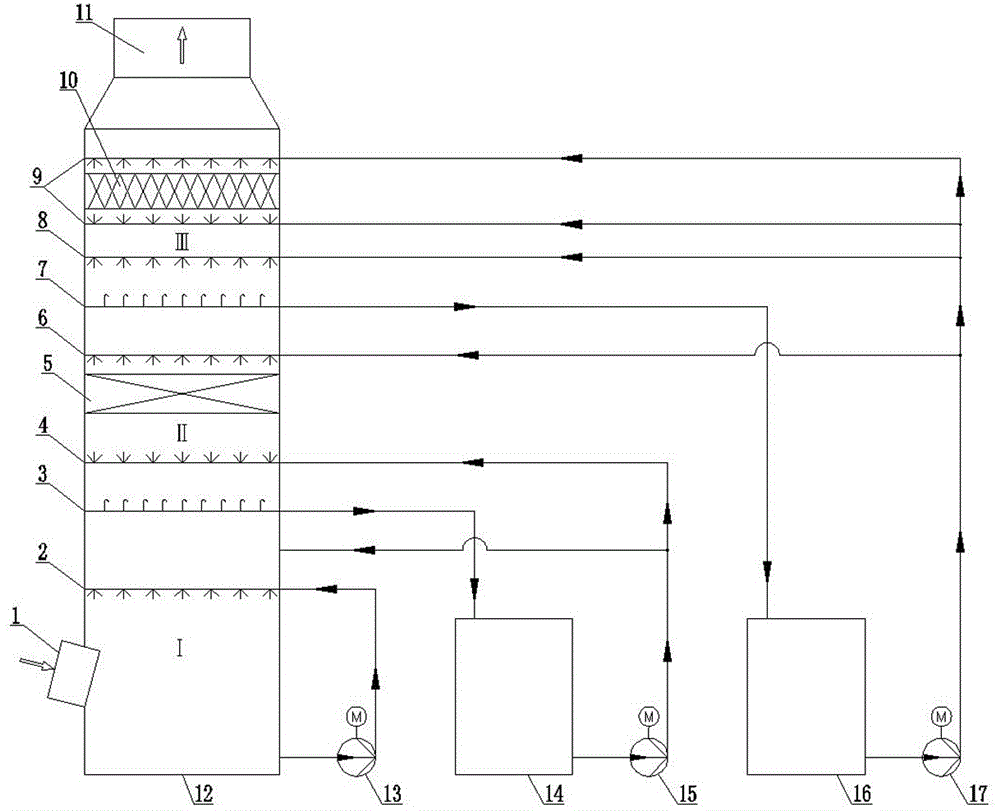

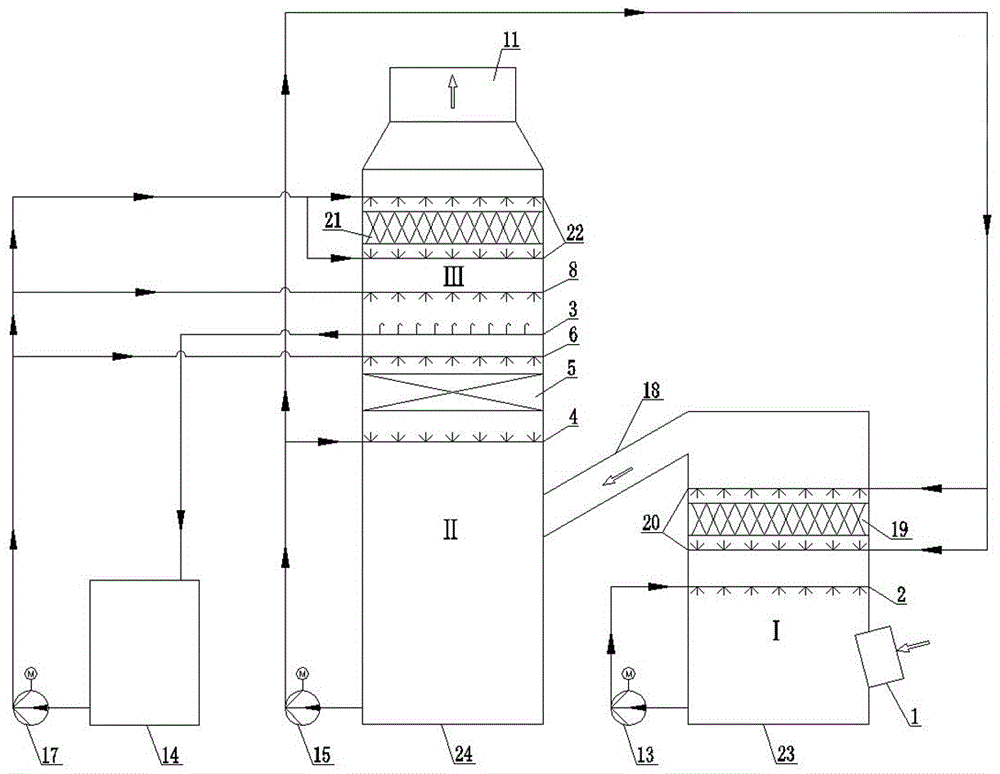

Three-cycle desulphurization method for wet type ammonia-process desulphurization and flue gas desulfurization tower or system

InactiveCN105727723AGuaranteed oxidationGuaranteed crystallizationGas treatmentUsing liquid separation agentFlue gasProcess engineering

The invention relates to the field of environmental protection and discloses a three-cycle desulphurization method for wet type ammonia-process desulphurization. The desulphurization method is implemented with a first slurry circulating loop, a second slurry circulating loop and a third slurry circulating loop, wherein in the first slurry circulating loop, slurry having mass concentration of 10%-20% and a pH value of 4.0-5.0 is used for carrying out cycle spraying treatment on flue gas, and the temperature of the flue gas treated by the slurry is 50-60 DEG C; in the second slurry circulating loop, slurry having mass concentration of 10%-15% and a pH value of 5.0-6.0 is used for carrying out cycle spraying treatment on the flue gas; and in the third slurry circulating loop, slurry having mass concentration of 3%-10% is used for carrying out cycle spraying treatment on the flue gas. The invention also discloses a flue gas desulfurization tower or system using the three-cycle desulphurization method. According to the three-cycle desulphurization method, the three independent circulating loops are divided according to the concentration of the slurry, the circulating loops separately control the slurry having different concentrations and pH values for treatment of the flue gas, and the contradiction of high desulphurization efficiency and high oxygenation efficiency of by-products is solved.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

Compound molten iron desulfurizer

The invention discloses a compound molten iron desulfurizer, which mainly comprises (by weight percent) active lime 60-75, calcium aluminate 5-8, inactivated 4-10, metallic aluminum 5-10, calcium fluoride 4-7, and balancing foreign matter. The desulfurizing agent has low cost and good sulfur removal effect.

Owner:梁新亚

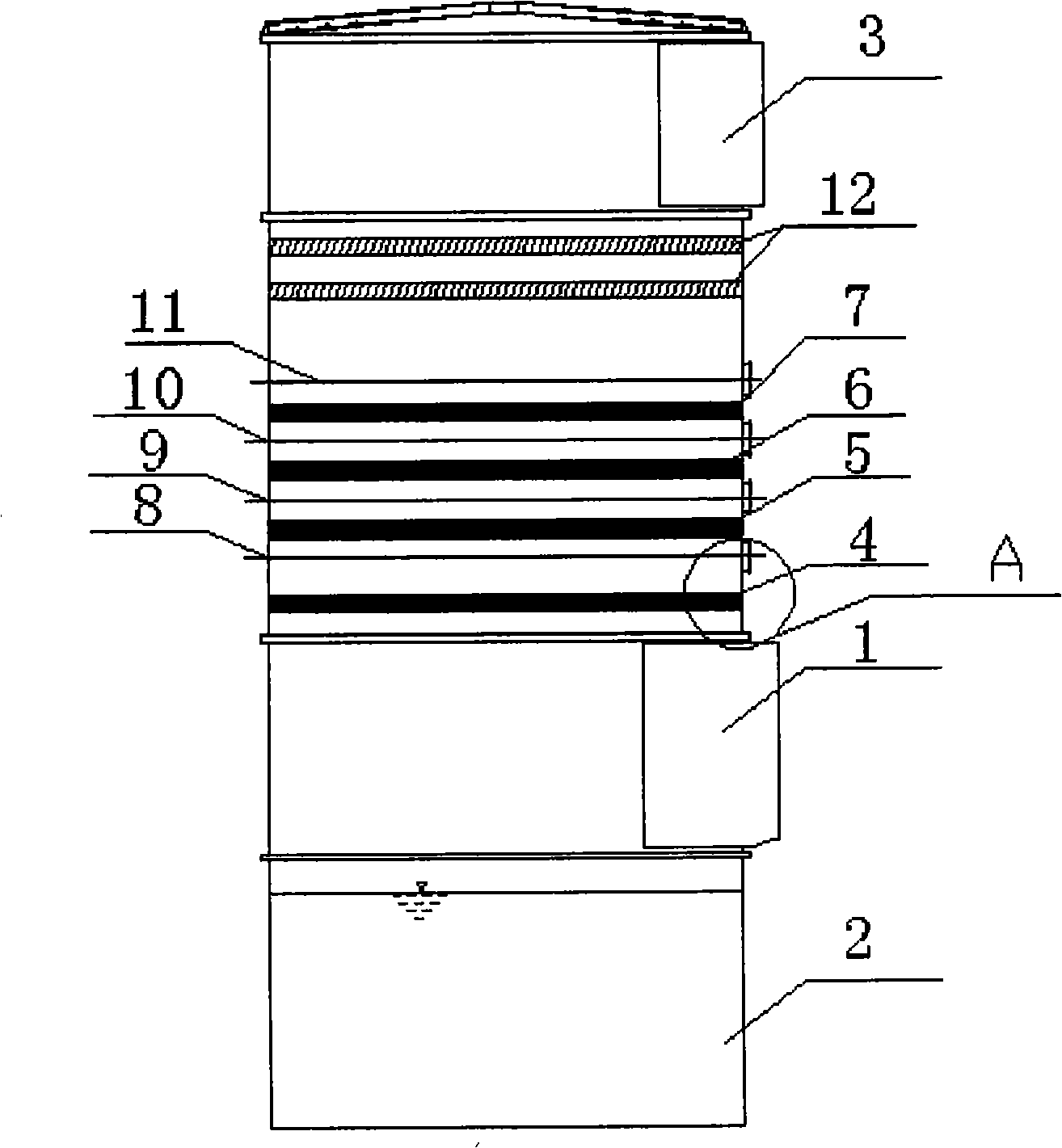

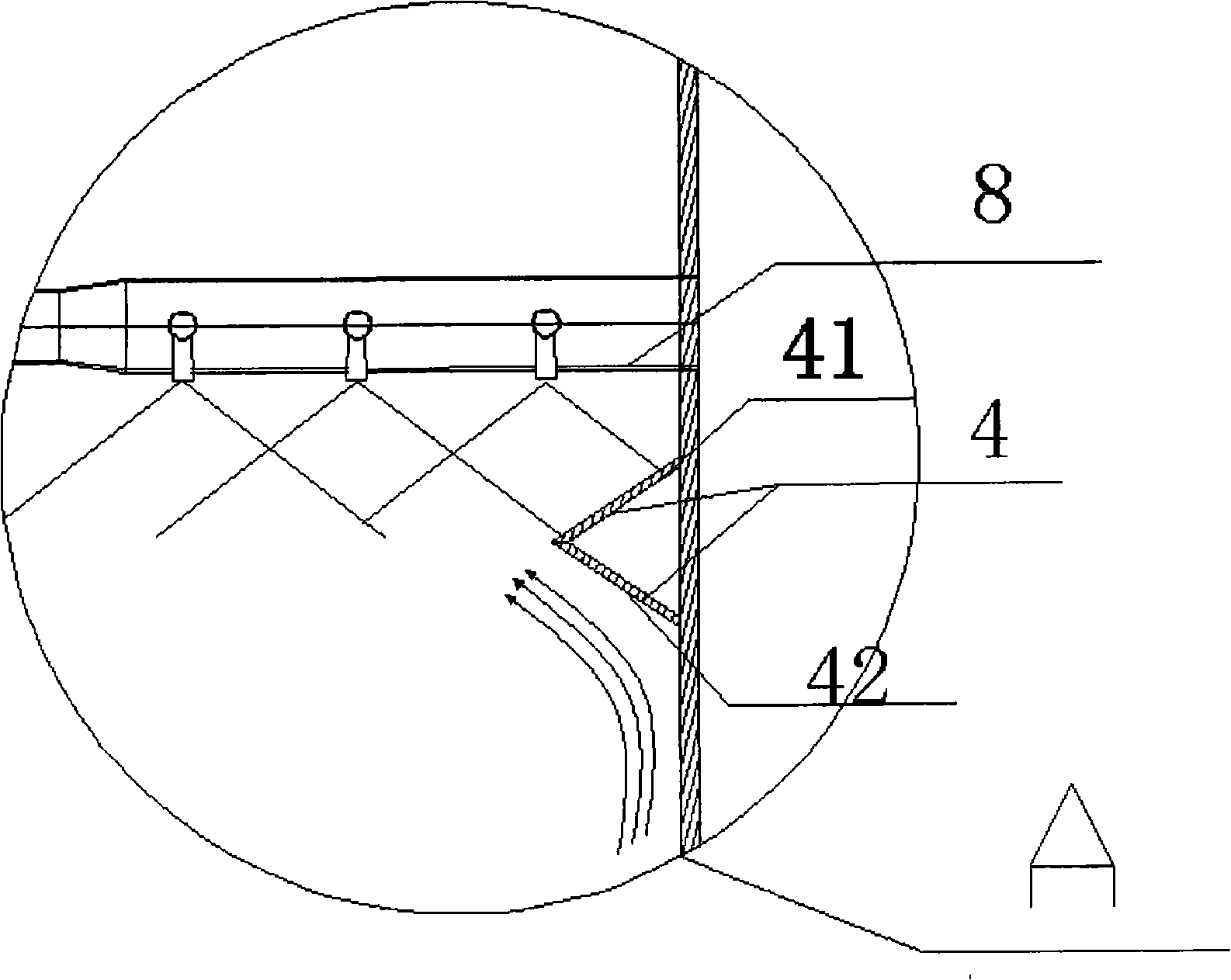

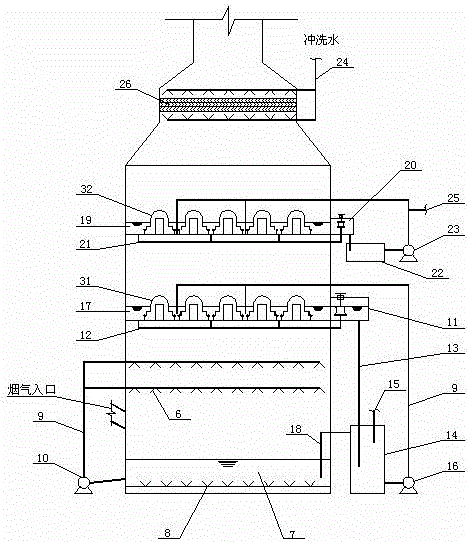

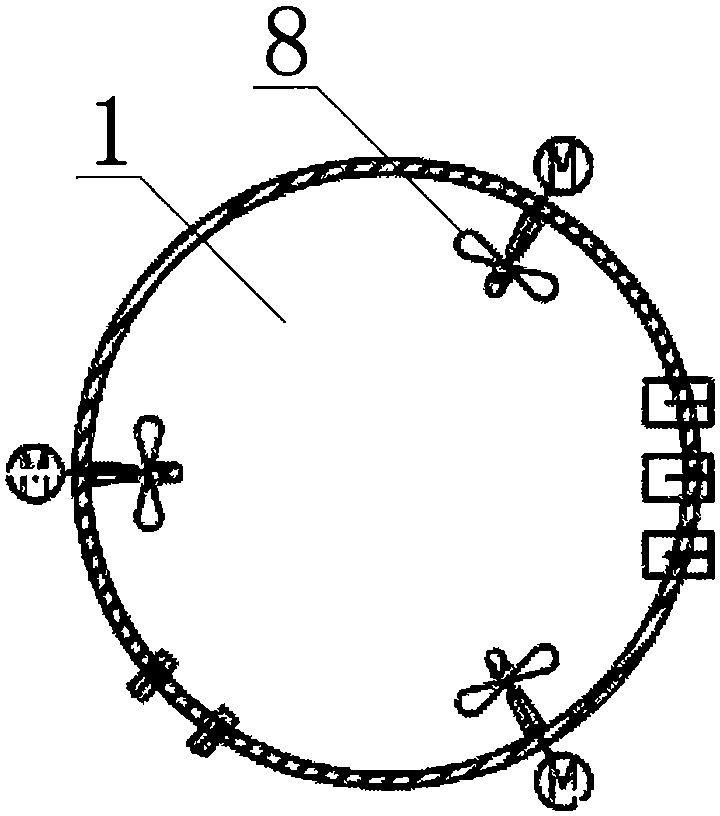

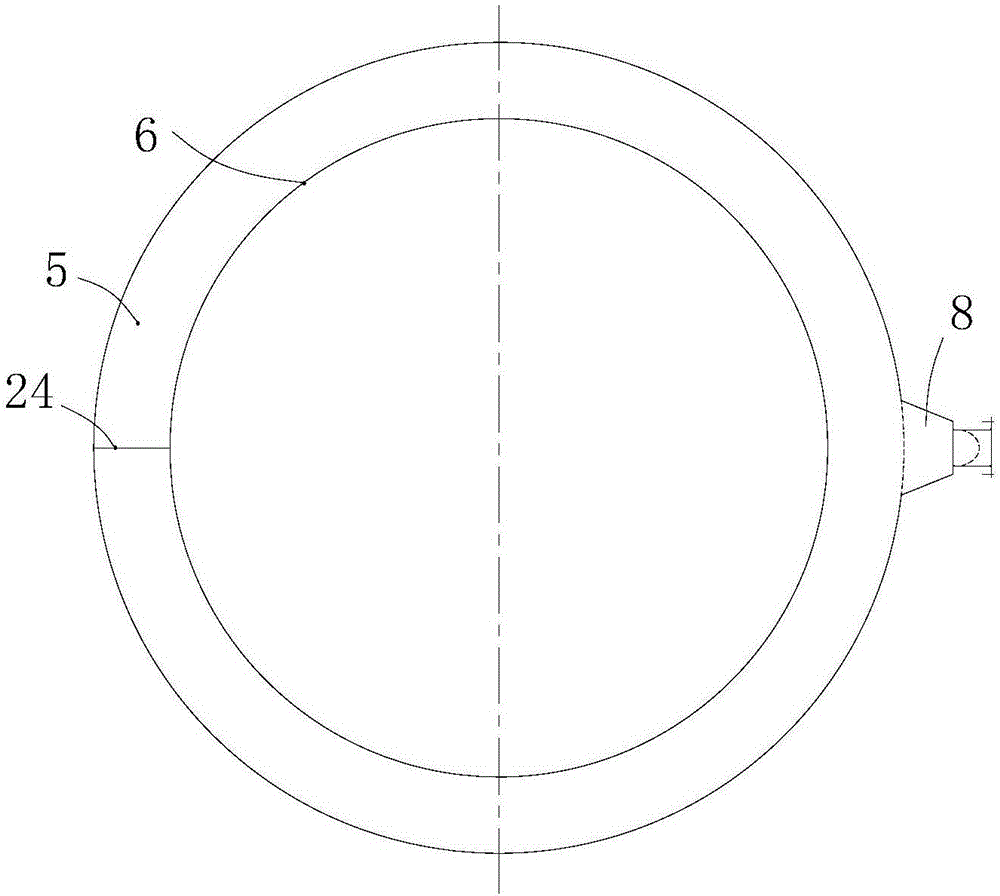

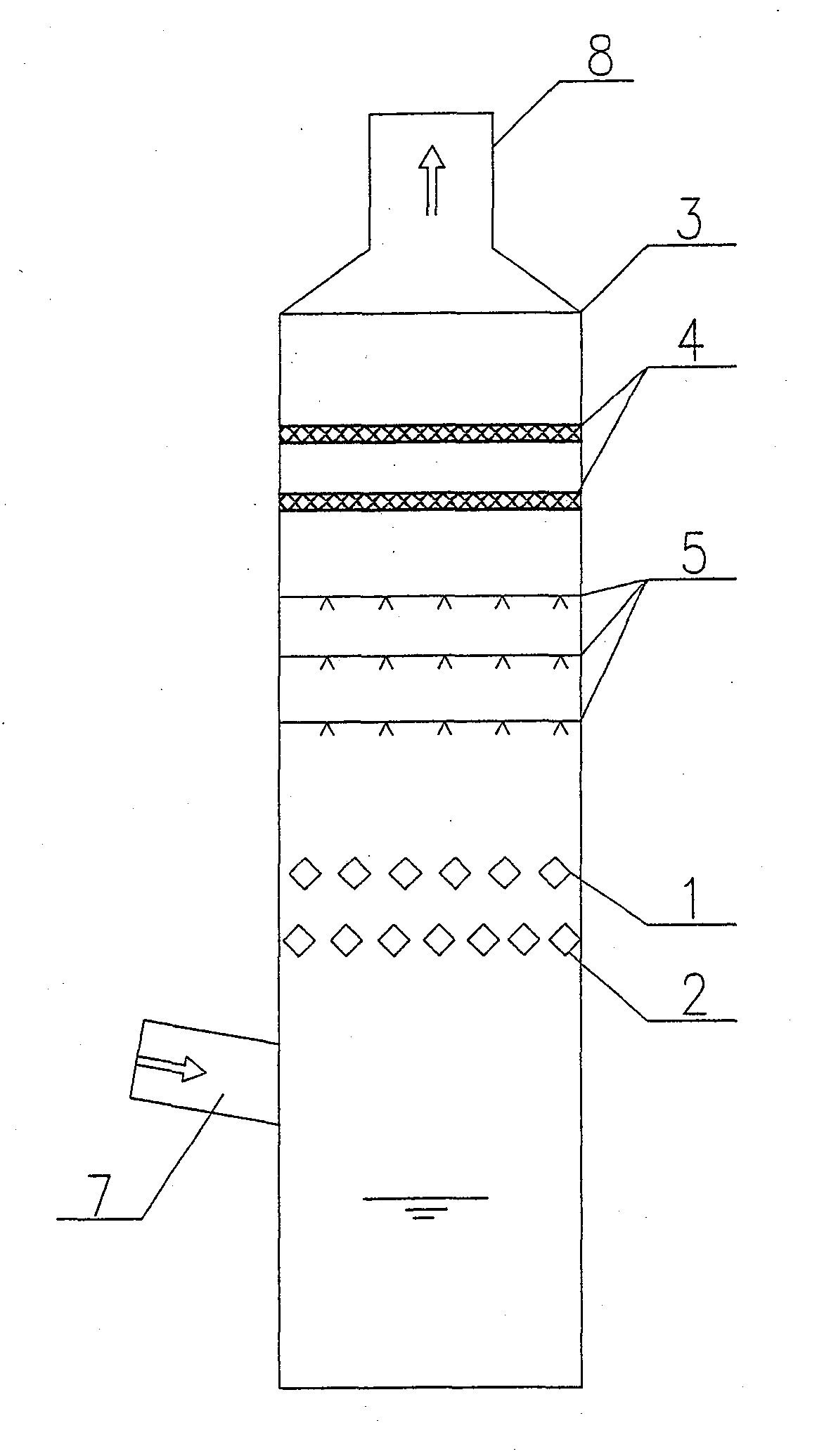

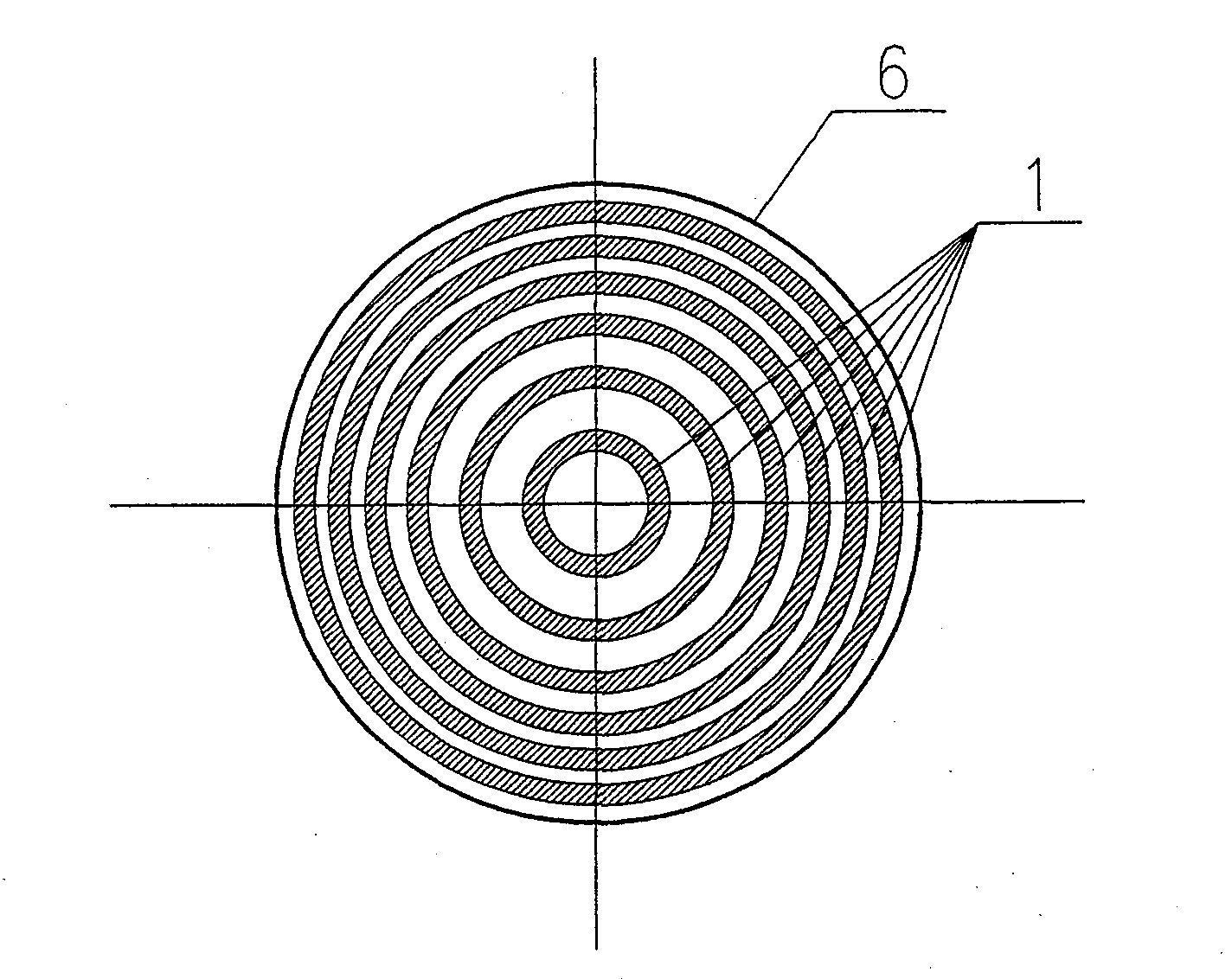

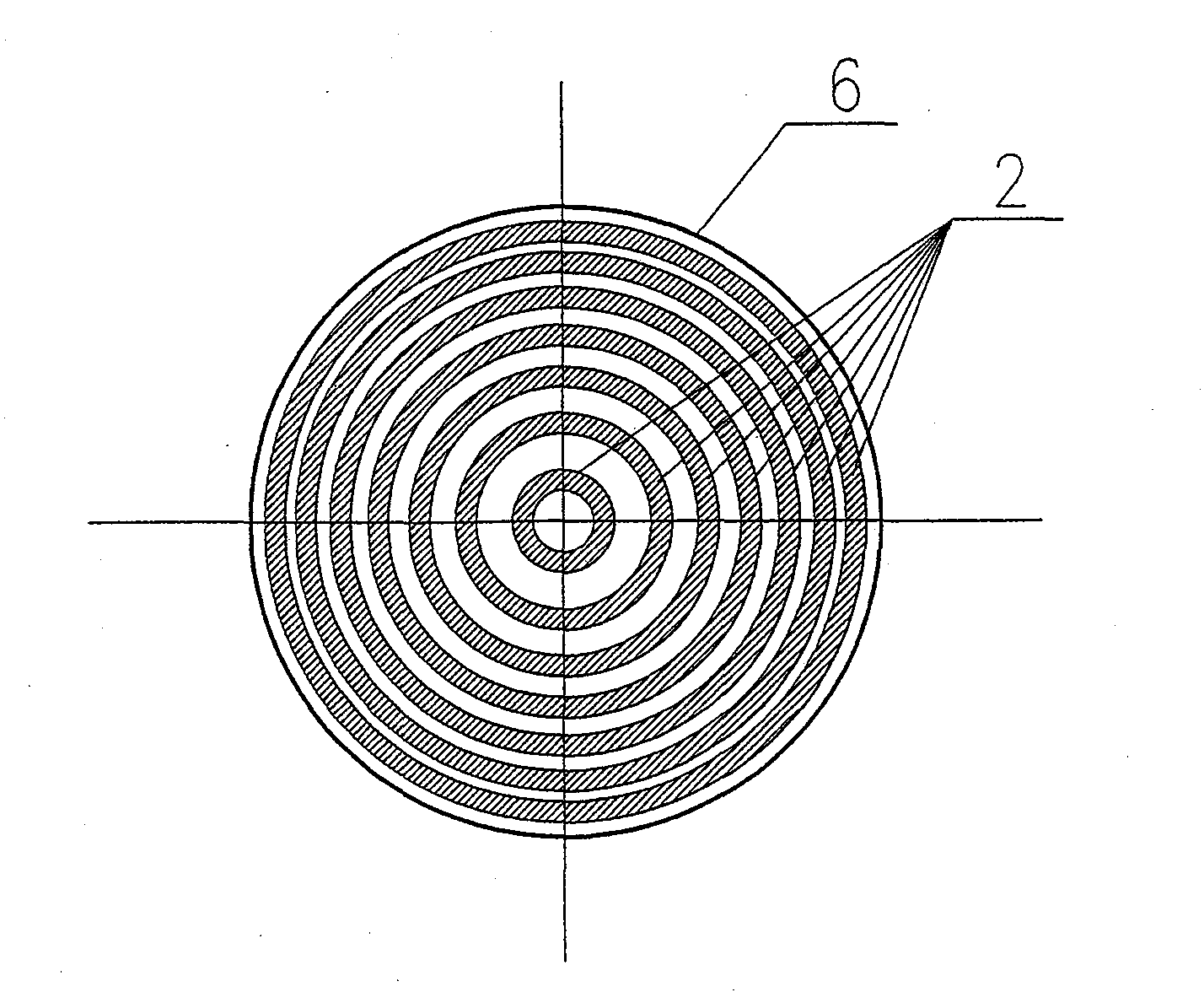

Spray tower for treating flue gas and gas gathering ring for the same

InactiveCN101274214AReduce escapeTake advantage ofGas treatmentDispersed particle separationFlue gasSpray tower

The technical proposal of the invention provides a gas collecting ring of a spraying tower used for flue gas disposal and the spraying tower comprising the gas collecting ring, aiming at solving the technical problem that the flue gas is convergent to a spraying dense area, thus leading the flue gas to exist in a guide tower. The gas collecting ring comprises a first plate, one end of which is connected on the side wall of the spraying tower, furthermore, the first plate extends upwards and obliquely from the side wall of the spraying tower to the center of the spraying tower. The gas collecting ring and the spraying tower have the technical effects that the flue gas is guided to the middle part of the tower through the gas collecting ring and sweeps through the spraying dense area, the escaping of the flue gas is reduced, and the desulphurization efficiency is improved.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

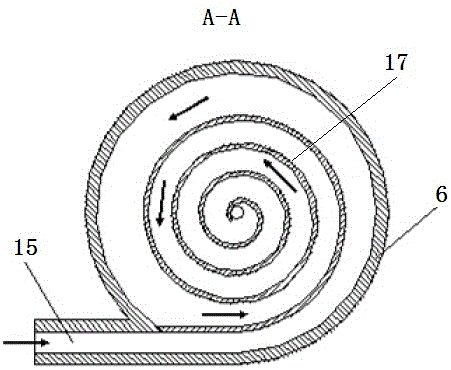

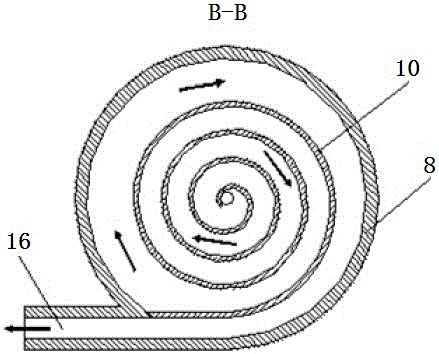

Coal-fired power plant smoke dehumidification system and technology

ActiveCN106642178AReduce cooling spray volumeReduce moisture contentDispersed particle separationCombustion technology mitigationDesiccantEngineering

The invention relates to a coal-fired power plant smoke dehumidification system and technology. At present, no system which can prevent white smoke and gypsum rain and restrain low-temperature corrosion of a chimney exists. The system comprises a low-temperature economizer, a low-temperature dust remover, a pressurizing fan, a desulfurizing tower and a smoke dehumidifier. The system is characterized by further comprising a drying agent regenerator. A regenerator spiral plate annular channel and a regenerator air distributor are arranged in the drying agent regenerator. The regenerator spiral plate annular channel is installed in the regenerator air distributor. The smoke dehumidifier is provided with a dehumidifier spiral plate annular channel and a dehumidifier air distributor. The dehumidifier spiral plate annular channel is installed in the dehumidifier air distributor. A drying agent outlet in the smoke dehumidifier is connected with a drying agent inlet in the drying agent regenerator to form a circular dehumidification device. The system avoids formation of the white smoke and the gypsum rain, and greatly weakens corrosion to the chimney.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

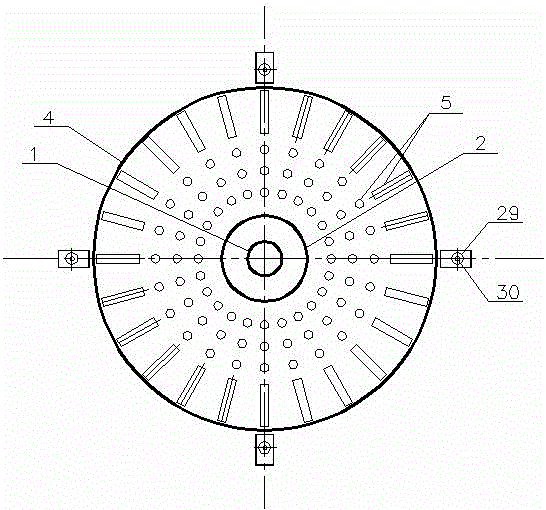

Ultra-low emission type desulfurization and dust removal rotational flow tray jet tower

ActiveCN106237824AImprove desulfurization efficiencyLow running costGas treatmentUsing liquid separation agentEngineeringLiquid storage tank

The invention relates to an ultra-low emission type desulfurization and dust removal rotational flow tray jet tower. The ultra-low emission type desulfurization and dust removal rotational flow tray jet tower comprises a desulfurization tower, wherein a sprinkling system is located on the lower portion of the desulfurization tower, a demister is located on the upper portion of the desulfurization tower, a size rotational flow tray mixer is arranged between the sprinkling system and the demister and located in a rotational flow tray mixer liquid storage tank, the size rotational flow tray mixer comprises a standpipe and a bubble cap, and the standpipe is covered with the bubble cap; multiple tray holes are formed in a tray of the size rotational flow tray mixer. The four desulfurization techniques including sprinkling, rotational flow, tray and bubbling are combined, the characteristics that the rotational flow tray can be used for uniform mixing and a bubbling technique absorbent is of a continuous phase and can achieve deep desulfurization are utilized, and deep desulfurization and deep dust removal are achieved. When the concentration of flue gas SO2 at an inlet of an absorption tower is below 10000 mg / Nm3, the requirement for ultra-low emission that the concentration of SO2 at an outlet is smaller than 35 mg / Nm3 can be met.

Owner:济南金孚瑞热能设备制造有限公司

Calcium base desulfurater primary and secondary content and impurity element simultaneous determination method

ActiveCN101598673AThe area of acid rain is developing rapidlyDetermination of contentPreparing sample for investigationAnalysis by thermal excitationSlurryDigestion

The invention relates to a calcium base desulfurater primary and secondary content and impurity elements simultaneous determination method, including the following steps: a calcium base desulfurater analysis sample is quantitatively weighed by a 180-200 mesh analysis sieve, a multi-step microwave digestion method is adopted for carrying out high temperature high pressure mixed acid microwave digestion on the quantitative calcium base desulfurater analysis sample, wherein the mixed acid is 2ml concentrated hydrochloric acid and 4-6ml concentrated nitric acid and the microwave digestion includes three steps, the sample after digestion is transferred for constant volume to prepare analysis solution, namely 2% dilute nitric acid is used for transferring the solution in the digestion inner pipe into a 25-50ml volumetric flask for constant volume to scale; and full spectrum direct-reading plasma emission spectrometer is used for accurately determining contents of multiple elements in the analysis solution. The invention not only can fast and accurately determine primary and secondary content and content of multiple elements in the calcium base desulfurater but also is applicable to determination of multiple elements in grout during desulfuration.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Compound molten iron desulfurizer

The invention discloses a compound molten iron desulfurizer, which mainly comprises (by weight percent) active lime 60-75, calcium aluminate 5-8, inactivated 4-10, metallic aluminum 5-10, calcium fluoride 4-7, and balancing foreign matter. The desulfurizing agent has low cost and good sulfur removal effect.

Owner:梁新亚

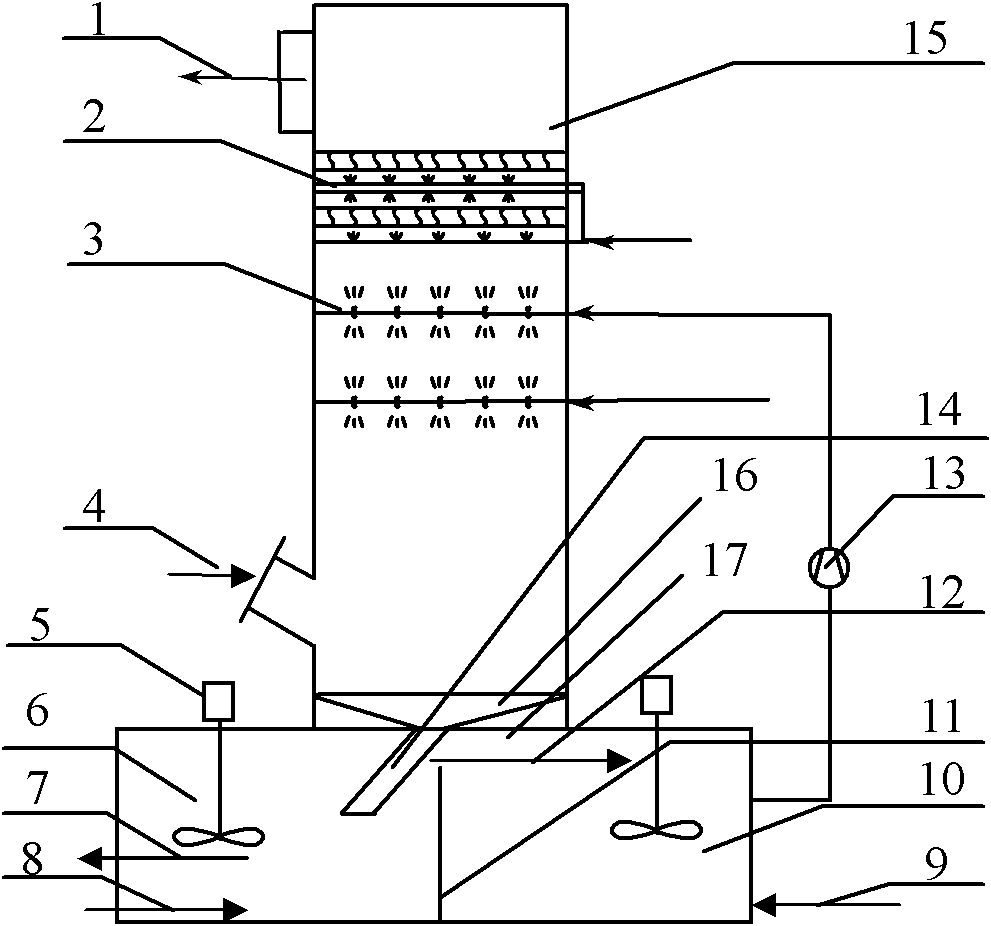

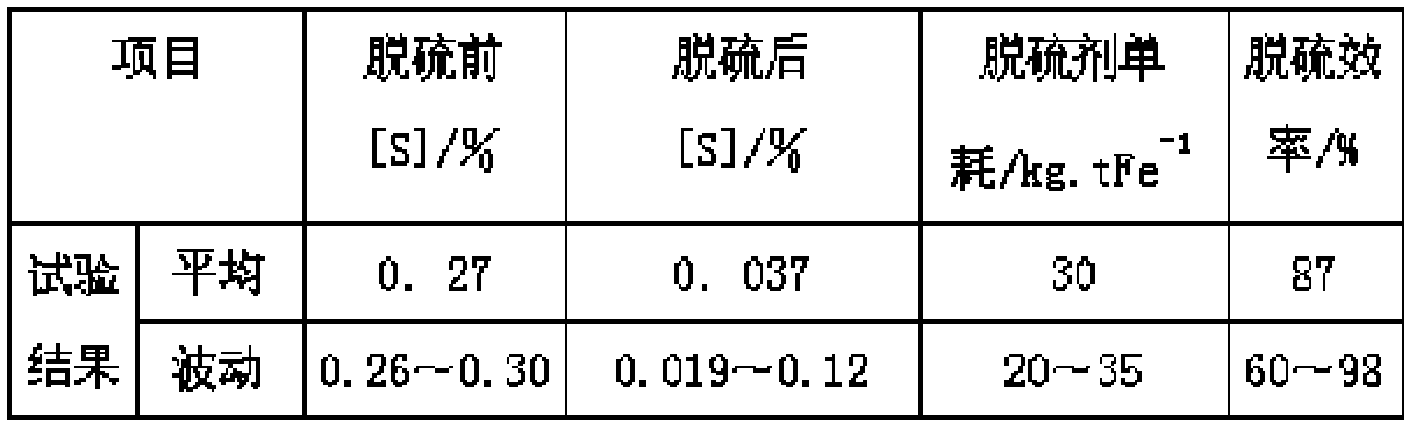

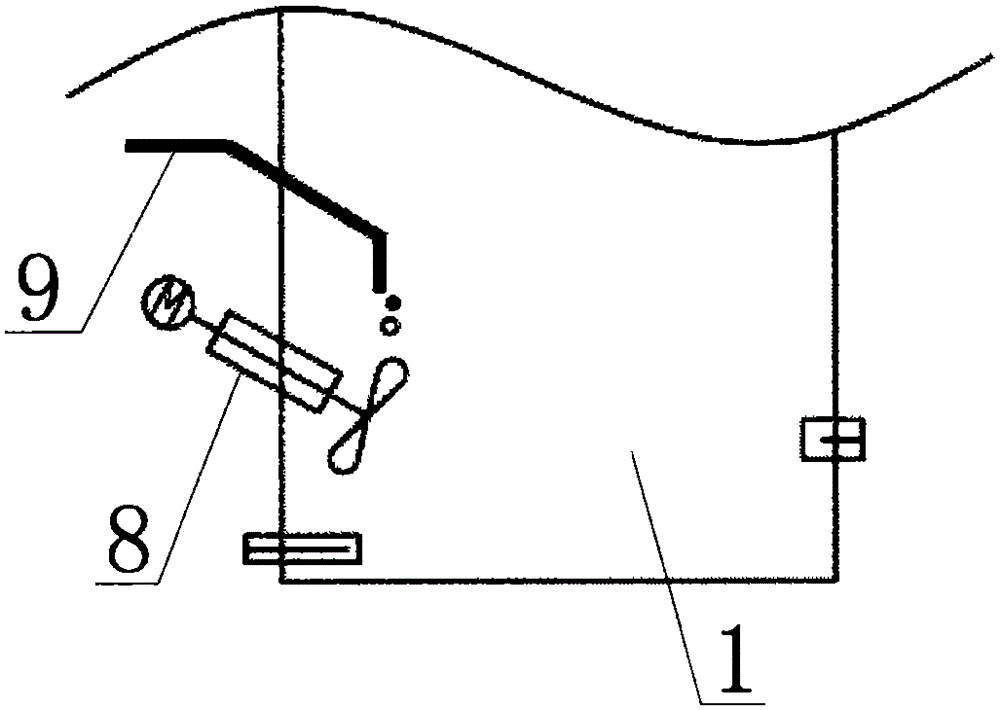

Half-dry type flue gas desulfurization device and method

InactiveCN105964071AAvoid enteringReduce workloadGas treatmentDispersed particle filtrationSocial benefitsCold air

A semi-dry flue gas desulfurization device and method, belonging to the technical field of flue gas desulfurization equipment and methods. The technical solution is: a desulfurization tower ash discharge valve is added at the bottom of the desulfurization tower. During the desulfurization process, the desulfurization tower ash discharge valve at the bottom of the desulfurization tower flue chamber is closed to prevent cold air from entering the desulfurization tower. The working load of the booster fan, and ensure the stability of humidity and flue gas temperature in the desulfurization tower, so the ambient temperature and flue gas temperature have no effect on desulfurization. Due to the stable humidity and flue gas temperature in the tower, it avoids the sticking of the tower and the clogging of the dust bag during spraying, and the desulfurization cost is low and the desulfurization efficiency is high. At the same time, the ash in the circulating ash bin of the present invention enters the Venturi chamber through the circulating ash conveying pipe. When the flue gas flow rate at the entrance of the desulfurization tower is large, part of the flue gas is sealed in the lower part of the Venturi chamber 3 by the ash discharge valve of the circulating ash bin. To support the returning ash, prevent falling, avoid environmental pollution, reduce production costs, and have significant economic and social benefits.

Owner:HEBEI IRON AND STEEL

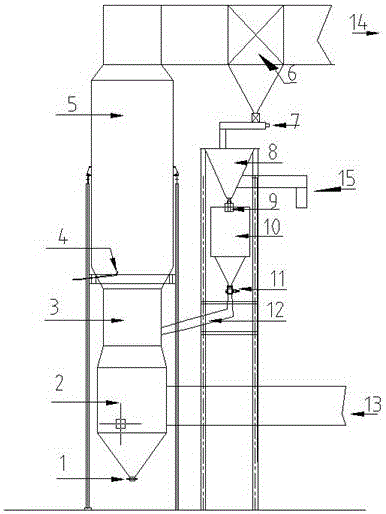

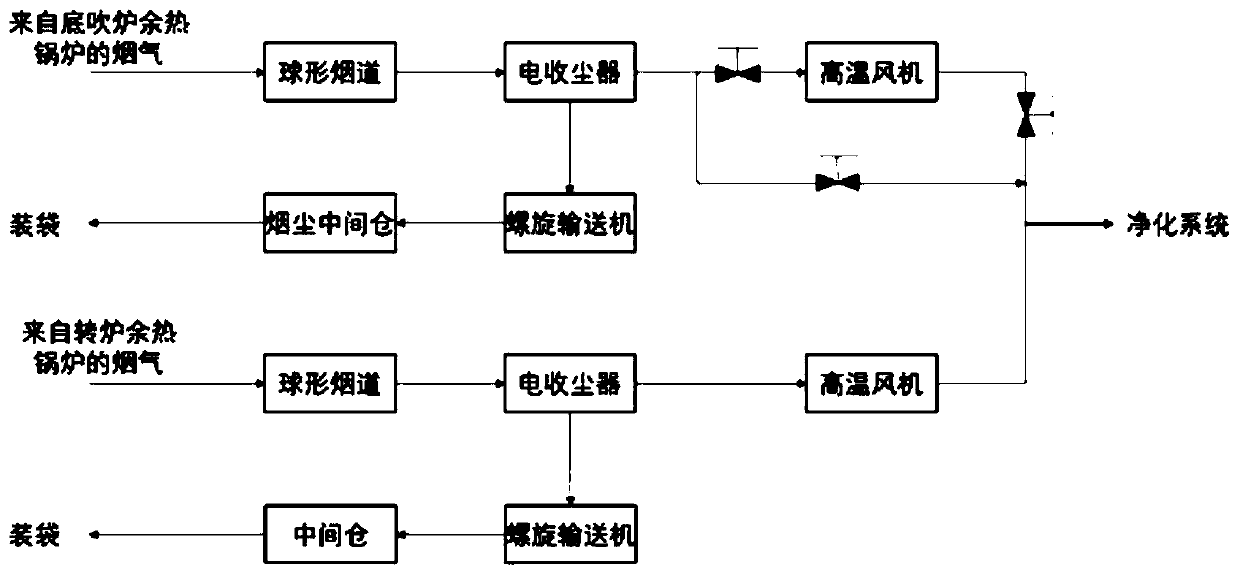

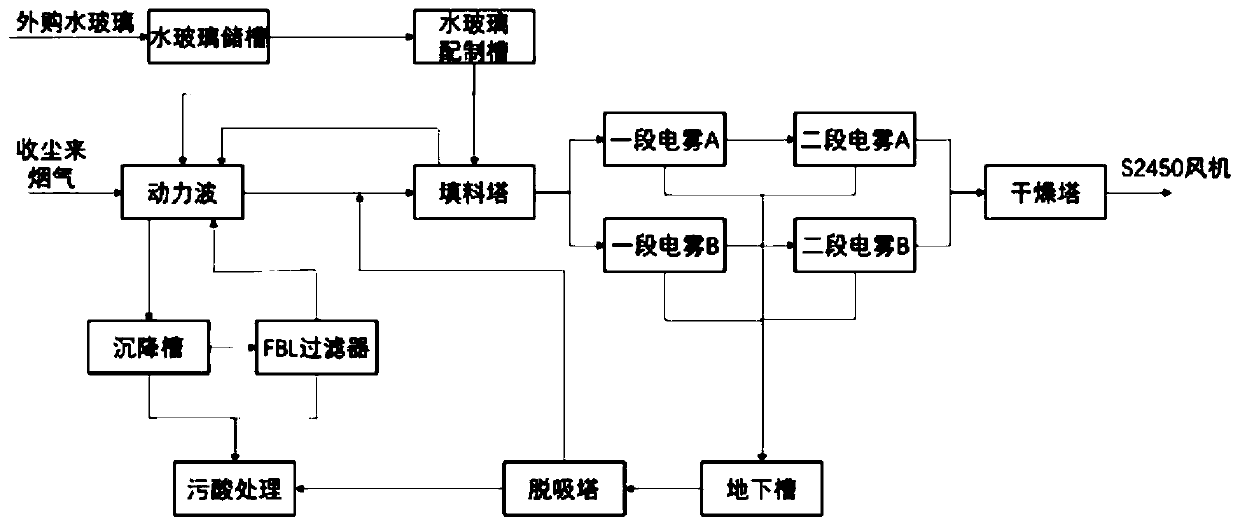

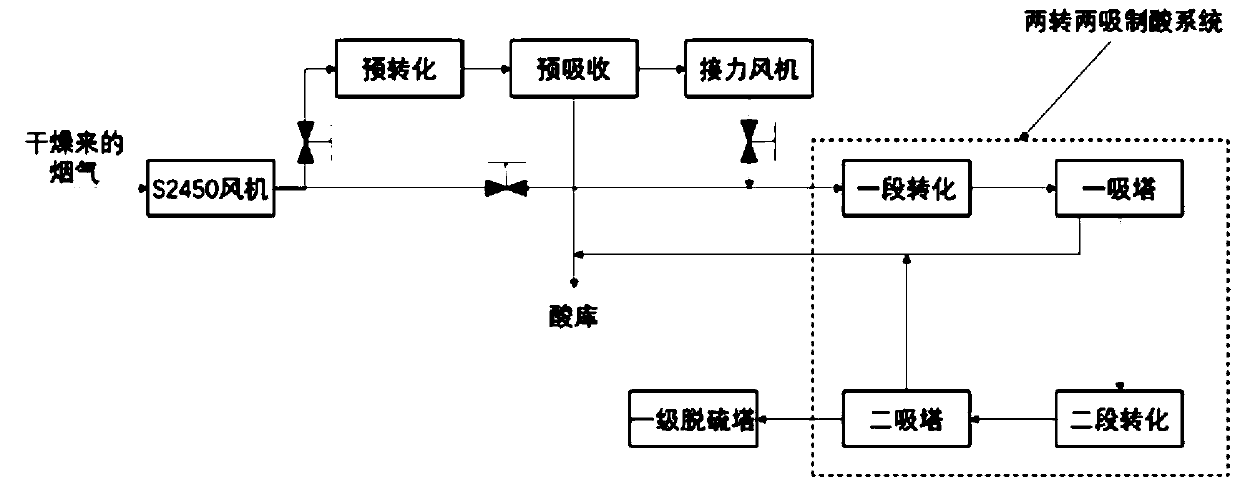

Smoke purification and tail gas cleaning treatment device in acid making process

InactiveCN110354622AReduce dust accumulationReduce the strength of cleaning actionCombination devicesGas treatmentElectricityHigh energy

The invention relates to a smoke purification and tail gas cleaning treatment device in an acid making process. A spherical flue is arranged at the rear end of a bottom blowing furnace and connected with an electrical precipitator; the electrical precipitator is connected with a high temperature fan; the high temperature fan is connected with a purification system; smoke of the decontamination system is conveyed to a dynamic wave; the dynamic wave is connected with a packing tower; the packing tower is connected with a drying tower through an electric mist section; the drying tower is connected with a primary conversion section through a fan; the primary conversion section is connected with a primary absorption tower; the primary absorption tower is connected with a secondary conversion section; the secondary conversion section is connected with a secondary absorption tower; and the secondary absorption tower is connected with a primary desulfurizing tower. The device solves the problems of high acid making tail gas treatment cost, environmental pollution due to tail gas, higher energy consumption for the tail gas treatment, high energy consumption and environmental pollution.

Owner:YIMEN COPPER CO LTD

A method for desulfurization of sodium sulfide wastewater

ActiveCN104817211BDosage is effectiveEffective control of dosageMultistage water/sewage treatmentLiquid wasteSewage treatment

The invention discloses a method for desulfurizing sodium sulfide wastewater, belonging to the fields of electronic electroplating wastewater treatment and comprehensive reutilization. The method comprises the following steps: (A) regulating the pH value of sodium-sulfide-containing waste liquor to 6.0-9.0; (B) introducing the sodium-sulfide-containing waste liquor subjected to pH value regulation in the step (A) into an aeration reaction tank, starting an aerator while adding 0.1-10 wt% of catalyst, and reacting for 0.5-2 hours; (C) naturally flowing the mixed solution obtained in the step (B) into a precipitation tank, and standing to precipitate for 1-2 hours; and (D) sending the supernate in the step (C) into the next sewage treatment unit as effluent water, taking out the residual precipitate in the precipitation tank, packing, and transporting. The catalyst is a metal and oxide thereof or a mixture of multiple metals and oxides thereof. The method has the advantages of high oxidization efficiency, thorough desulfurization, simple technique and the like, and can effectively remove sodium sulfide in wastewater.

Owner:NANJING UNIV +1

System for removing high-concentration sulfur dioxide in flue gas by means of cascading twin-tower wet method

InactiveCN105032161AIncrease power consumptionReduce desulfurization efficiencyDispersed particle separationHigh concentrationFlue gas

A system for removing high-concentration sulfur dioxide in flue gas by means of a cascading twin-tower wet method comprises purification towers and a smoke exhaust tower. A solution pool, spraying assemblies and a condenser are arranged inside the purification towers. Each spraying assembly comprises a spraying pipe. Anticorrosion nozzles are arranged on each spraying pipe. A gas inlet and a gas outlet are formed in the purification towers. The purification towers comprise the front tower and the rear tower. The gas outlet of the front tower and the gas inlet of the rear tower are connected through a pipeline to form a twin-tower purification set. The smoke exhaust tower is connected with a second ventilation pipeline. The cascading twin-tower method spraying method is adopted, and the sulfur removal efficiency of a single purification tower can be decreased; due to the fact that the number of the purification towers is increased, the sulfur removal efficiency of the whole purification set can still be ensured even though the sulfur removal efficiency of the single purification tower is decreased.

Owner:湖南高华环保股份有限公司

Two-stage circulation partition desulfurizing tower

InactiveCN106731591AReduce desulfurization efficiencyImprove desulfurization efficiencyDispersed particle separationSlurryTower

The invention discloses a two-stage circulation partition desulfurizing tower which comprises a tower body, wherein a first-stage circulation slurry spray system is arranged at the lower part of the tower body; a second-stage circulation slurry spray system is arranged at the upper part of the tower body and comprises a second-stage spray layer; a ring groove bottom plate is arranged in the tower body below the second-stage spray layer; the projection of the ring groove bottom plate on the horizontal plane is of an annular shape; the outer edge of the ring groove bottom plate is fixed on the inner wall of the tower body; a vertically upward ring groove side plate is fixed on the inner edge of the ring groove bottom plate; the ring groove side plate, the ring groove bottom plate and the tower body inner wall form a ring groove; and a liquid discharge box for discharging the spray liquid in the ring groove is also fixed on the tower body. The two-stage circulation partition desulfurizing tower disclosed by the invention has the following advantages: a 'waterfall' slurry area is avoided, the operation energy consumption is effectively reduced, and the first-stage and second-stage circulation slurry spray systems are completely separated, so that the second-stage circulation slurry spray system with a high pH value has relatively high desulfurizing efficiency, and the first-stage circulation slurry spray system with a low pH value improves the absorbent utilization rate and byproduct quality.

Owner:浙江菲达环保科技股份有限公司

Fine desulfurizing agent and preparation method thereof

ActiveCN102078749BEasy to spreadImprove desulfurization efficiencyDispersed particle separationCombustible gas purificationActive componentZinc

A raw material for fine desulfurizing agent comprises the following raw materials: 55 to 70 part of basic zinc carbonate, 15 to 30 part of copper carbonate, 8 to 13 part of alumina cement and 1 to 4 part of binder. The raw materials of the fine desulfurizing agent contain basic zinc carbonate and copper carbonate, larger pore paths can be generated in the accumulation process as the copper carbonate molecules have larger volume; and unreacted sulfide can be diffused into crystal lattices of active components more easily, therefore, the fine desulfurizing agent has higher desulfurizing precision and higher sulfur capacity.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Calcium base desulfurater primary and secondary content and impurity element simultaneous determination method

ActiveCN101598673BThe area of acid rain is developing rapidlyAbundant resourcesPreparing sample for investigationAnalysis by thermal excitationSlurryDigestion

The invention relates to a calcium base desulfurater primary and secondary content and impurity elements simultaneous determination method, including the following steps: a calcium base desulfurater analysis sample is quantitatively weighed by a 180-200 mesh analysis sieve, a multi-step microwave digestion method is adopted for carrying out high temperature high pressure mixed acid microwave digestion on the quantitative calcium base desulfurater analysis sample, wherein the mixed acid is 2ml concentrated hydrochloric acid and 4-6ml concentrated nitric acid and the microwave digestion includes three steps, the sample after digestion is transferred for constant volume to prepare analysis solution, namely 2% dilute nitric acid is used for transferring the solution in the digestion inner pipe into a 25-50ml volumetric flask for constant volume to scale; and full spectrum direct-reading plasma emission spectrometer is used for accurately determining contents of multiple elements in the analysis solution. The invention not only can fast and accurately determine primary and secondary content and content of multiple elements in the calcium base desulfurater but also is applicable to determination of multiple elements in grout during desulfuration.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Wet catalyzed oxidation desulfuration method and device thereof

InactiveCN101596405AEmission reductionRealize the secondary oxidation reactionChemical industryDispersed particle separationCatalytic oxidationCirculating pump

The invention discloses a wet catalyzed oxidation desulfuration method and a device thereof. The method comprises the following steps: the sulfurous gas is reversely contacted with the desulfurized recycling liquid in a thionizer, the gas is discharged from the top of the thionizer after being removed hydrogen sulfide, the desulfurized rich solution is discharged from the bottom of the thionizer for oxidization regeneration and recycling; liquid sealing, oxidation reaction, sulphur bubble separation and clear solution cycling are carried out on the desulfurized rich solution in a solution cycling and regenerating groove. The special device comprises the thionizer and the solution cycling and regenerating groove which is provided with a device for finishing liquid sealing, oxidation reaction, and sulphur bubble separation. In the invention, a solution circulating pump is used for realizing the operating power of the whole system in the thionizer, and has the advantages of energy saving, environment protecting, being efficient and integrated, simple process flow and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Venturi ring efficient mass transfer layer absorption tower

InactiveCN101579601BEvenly distributedImprove desulfurization efficiencyDispersed particle separationContact timeFlue gas

The invention discloses a Venturi efficient mass transfer layer absorption tower which sets a Venturi efficient mass transfer layer in an empty spray tower. By utilizing Venturi effect, the Venturi efficient mass transfer layer absorption tower can improve the efficiency of gas-liquid mass transfer, ensure uniform gas distribution, increase gas-liquid contact time and area, and reduce liquid-gas ratio and power consumption. The absorption tower is simple in structure, lower in resistance and easy in manufacture and maintenance, and can be widely used in the flue gas desulphurization, dust extraction and chemical fields.

Owner:山西晋丰节能环保工程设计有限公司 +1

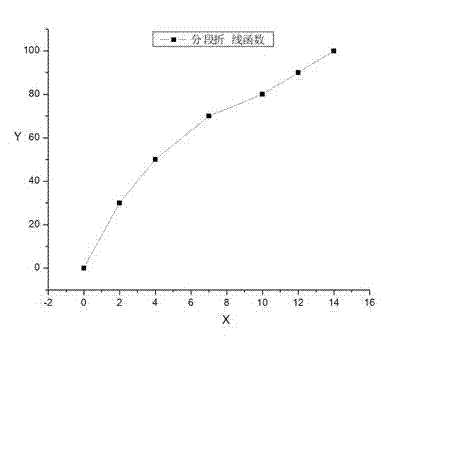

Composite injecting molten iron desulphurizing agent and desulphurizing technology thereof

The invention discloses a composite injecting molten iron desulphurizing agent and a desulphurizing technology thereof. The desulphurizing agent is prepared from passivated magnesium, lime and limestone with the mass ratio being 1 to (2-8) to (1-4); the diameter of passivated magnesium particles is 0.1-0.6 mm; the granularity of the lime is 200-300 meshes; and the granularity of the limestone is 300-400 meshes. The desulphurizing technology comprises the following steps of blowing the passivated magnesium, lime and limestone in molten iron as the desulphurizing agent for molten iron desulphurizing, wherein the mass ratio of the passivated magnesium, the lime and the limestone is 1 to (2-8) to (1-4), the diameter of the passivated magnesium particles and a spraying gun insertion depth satisfy the following relational expression: d=Y[6.75*10<-6>h(1+0.625h)<1 / 2>]<2 / 3>, Y is a prepositive coefficient, h is the spraying gun insertion depth, and d is the diameter of the passivated magnesiumparticles. For the composite injecting molten iron desulphurizing agent and the desulphurizing technology, by adopting an entirely new desulphurizing agent combination and optimizing the technologicalparameters including a desulphurizing agent proportion, the desulphurizing agent granularity and the spraying gun insertion depth, the desulphurizing rate and the utilization rate of the desulphurizing agent are greatly increased, and the desulphurizing cost is lowered.

Owner:武汉钢铁有限公司

Process for ammonia method desulfurization of fume and by-producing ammonium sulfite

ActiveCN100486676CPromote absorptionReduce desulfurization efficiencyDispersed particle separationAmmonium sulfitesVolumetric Mass DensitySpray tower

The invention discloses a flue gas desulfurizing method through ammonia process and generating method of by-product ammonium sulfite, which comprises the following steps: making flue gas into cyclone separator and heat exchanger to dedust and cool; atomizing ammonia and (NH4)2SO3 solution in the drying tower; contacting with flue gas to desulfurize; drying; separating; contacting flue gas with (NH4)2SO3 solution in the spray tower; removing residual SO2 and NH3 to lower density; saving ammonia; obtaining by-product (NH4)2SO3.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com