Wet catalyzed oxidation desulfuration method and device thereof

A technology of wet catalytic oxidation and desulfurization tower is applied in the field of coke oven gas desulfurization, which can solve the problems of enlargement, high cost of infrastructure construction, inconvenient repair and operation, etc., and achieve the effect of concise process flow and good power saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

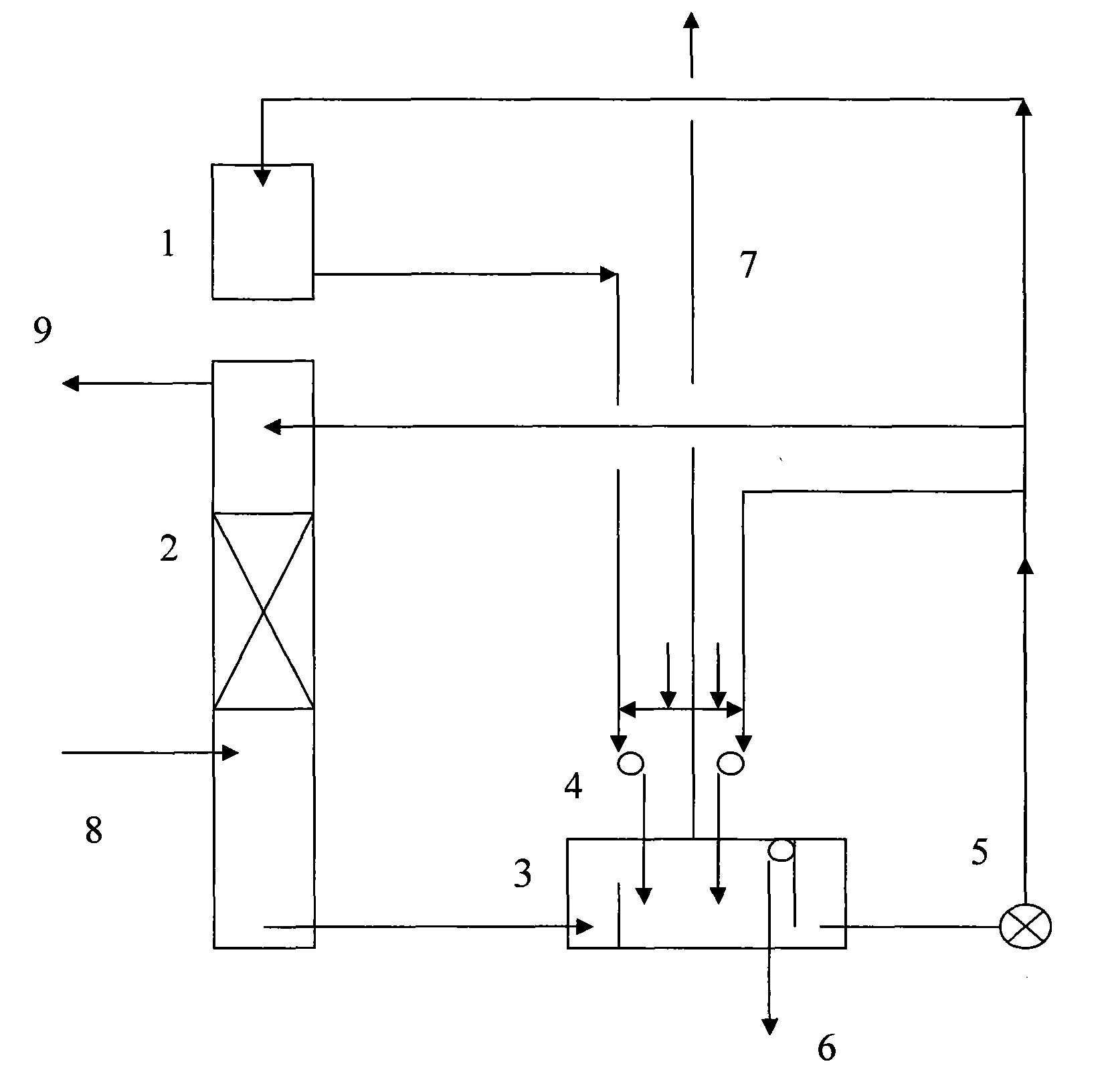

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

[0022] As shown in the accompanying drawing, it is the process flow of the wet catalytic oxidation desulfurization method of the present invention. The sulfur-containing gas 8 is in reverse contact with the desulfurization circulating liquid in the desulfurization tower 2, the gas 9 after removing hydrogen sulfide is discharged from the top of the tower, and the desulfurized rich liquid is discharged from the bottom of the tower for oxidation regeneration and recycling; the desulfurized rich liquid is regenerated in the solution circulation Liquid sealing, oxidation reaction, sulfur bubble separation and clear liquid circulation are completed in tank 3.

[0023] The regeneration of the desulfurized rich liquid includes continuous injection regeneration of circulating fluid after the pump and regeneration of the high-level solution tank 1 by potential energy injection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com