Venturi ring efficient mass transfer layer absorption tower

A Venturi and absorption tower technology, applied in the field of Venturi ring high-efficiency mass transfer layer and spray layer combined absorption tower, can solve the problem of low gas-liquid mass transfer efficiency, low intermediate air velocity, uneven gas distribution, etc. problem, to achieve the effect of prolonging the gas-liquid contact time, reducing the total power consumption, and reducing the cost of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

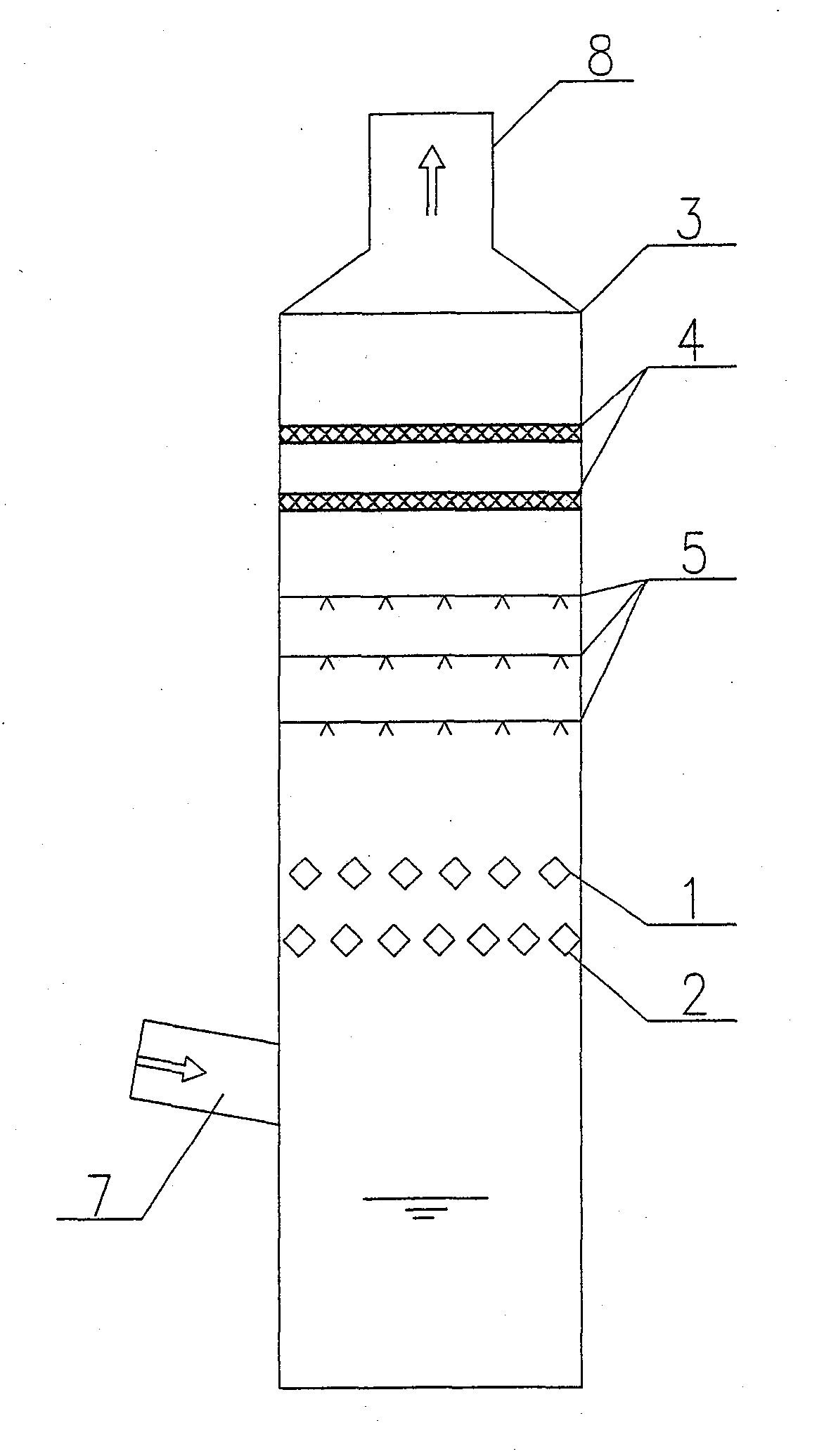

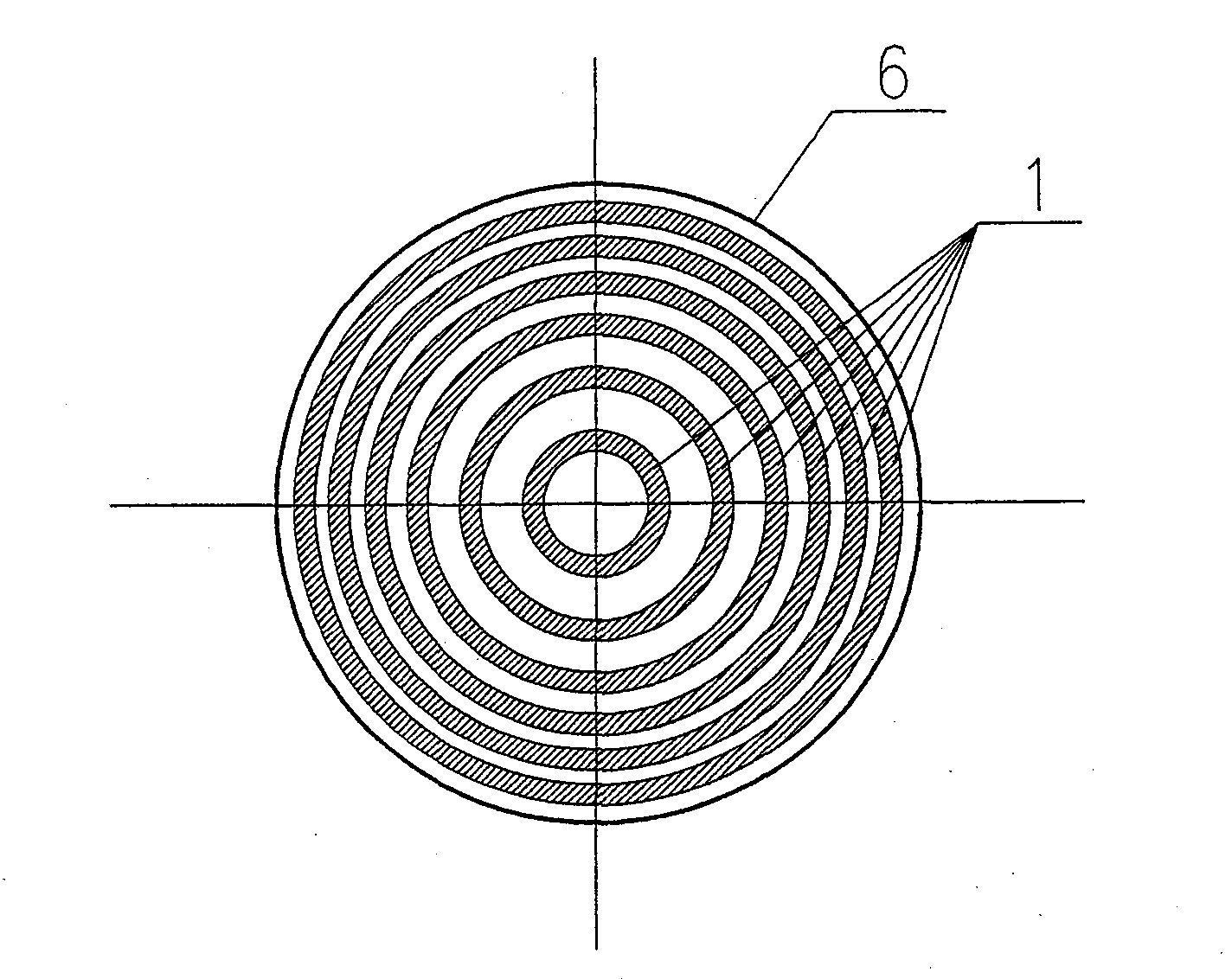

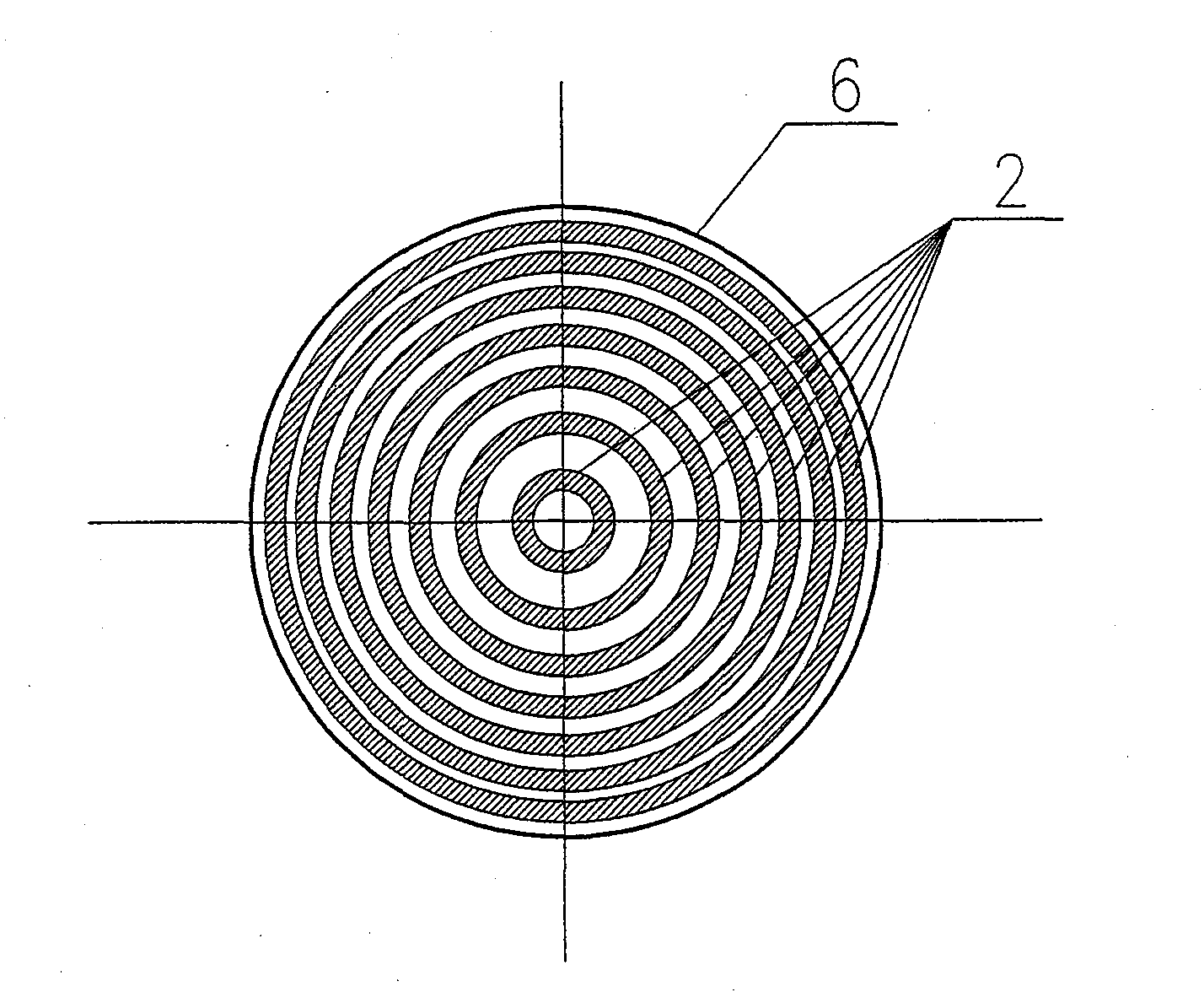

[0021] Limestone-gypsum wet flue gas desulfurization system adopts Venturi ring high-efficiency mass transfer layer absorption tower. A folded plate demister is installed above the spray layer, and the top of the absorption tower is the flue gas outlet. The Venturi rings of each high-efficiency mass transfer layer are arranged in concentric circles, the distance between the upper and lower layers is 1.5m, the opening rate of the lower Venturi ring high-efficiency mass transfer layer is 40%, and the opening rate of the upper Venturi ring high-efficiency mass transfer layer is 50%. After the flue gas enters the absorption tower from the flue gas inlet of the absorption tower, the air flow is uneven, showing the characteristics of low flow velocity in the middle of the tower and high smoke flow velocity close to the tower wall. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com