Spray tower for treating flue gas and gas gathering ring for the same

A flue gas treatment and spray tower technology, applied in the field of gas gathering rings, can solve the problem of insufficient flue gas absorption, achieve low pressure loss, improve desulfurization efficiency, and reduce flue gas escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with embodiment.

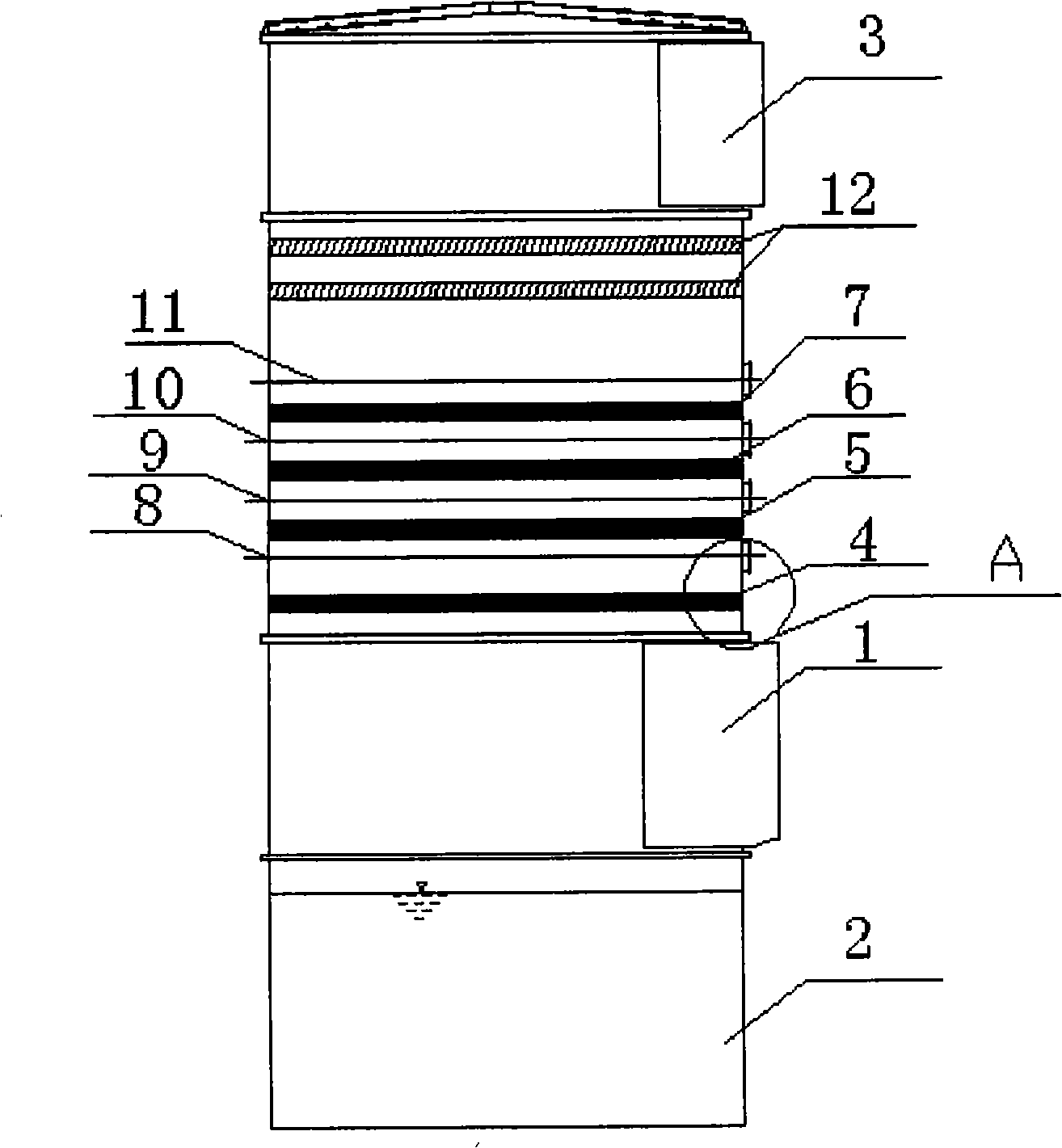

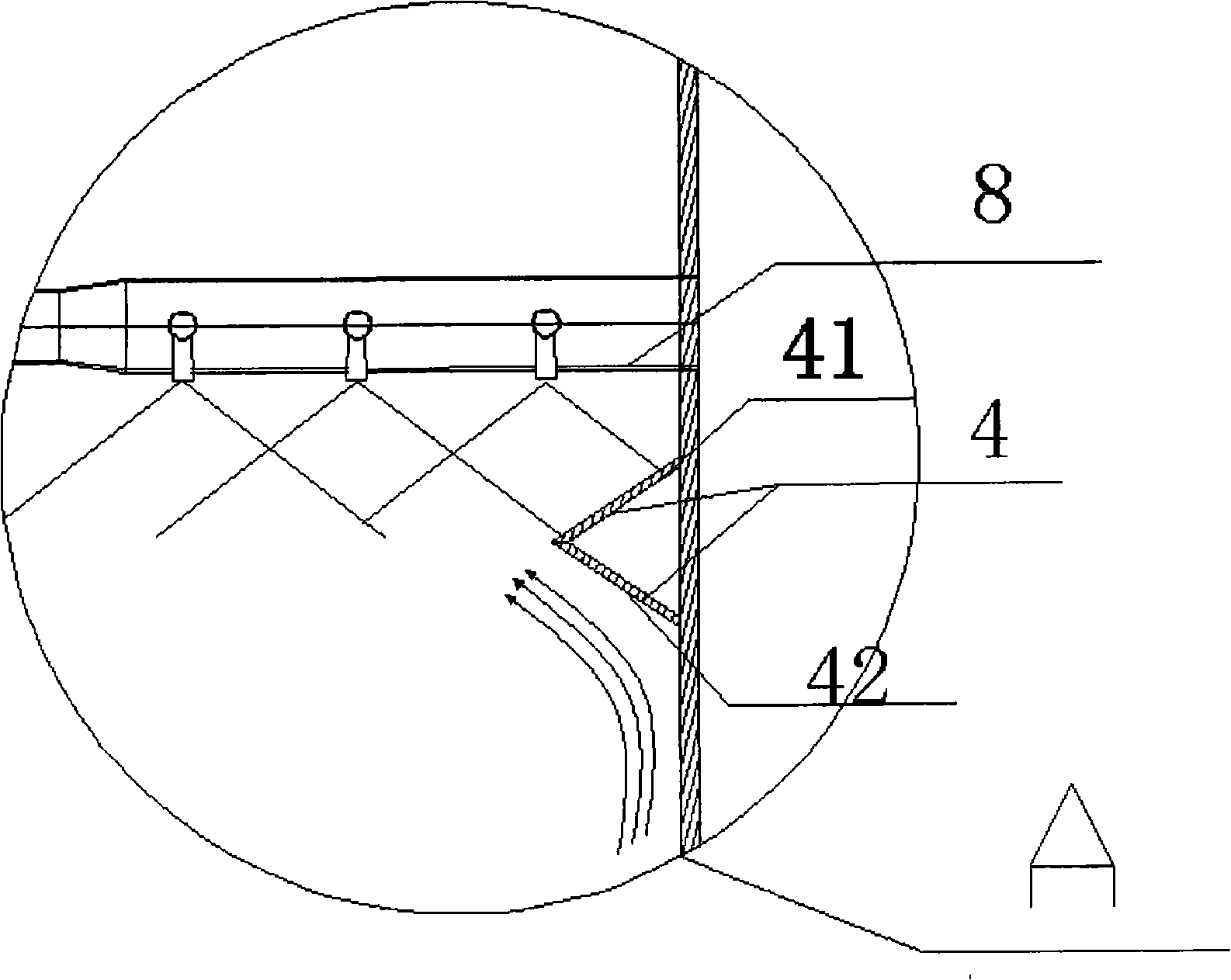

[0025] combine first figure 1 The operation of the spray tower adopting the preferred embodiment of the present invention will be described. During operation, the flue gas enters the spray tower through the entrance 1 of the spray tower, climbs up and passes through the first layer of gas gathering ring 4, the first layer of spray layer 8, the second layer of gas gathering ring 5, and the second layer of spraying Layer 9, the third gas-gathering ring 6, the third spray layer 10, the fourth gas-gathering ring 7, the fourth spray layer 11, the demister layer 12, and flow out from the outlet 3 of the spray tower. Those of ordinary skill in the art can understand that the number of spray layers and corresponding gas gathering rings can be changed arbitrarily according to different situations. There are cases of two, three or more than four layers. Shower arrangement. As mentioned above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com