Smoke purification and tail gas cleaning treatment device in acid making process

A treatment device and exhaust gas cleaning technology, applied in the directions of gas treatment, combined device, filtration loop, etc., can solve the problems of high cost of acid-making exhaust gas treatment, high energy consumption of exhaust gas treatment, and pollution of exhaust gas to the environment, and achieve harmless treatment. , the effect of reducing pollution and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

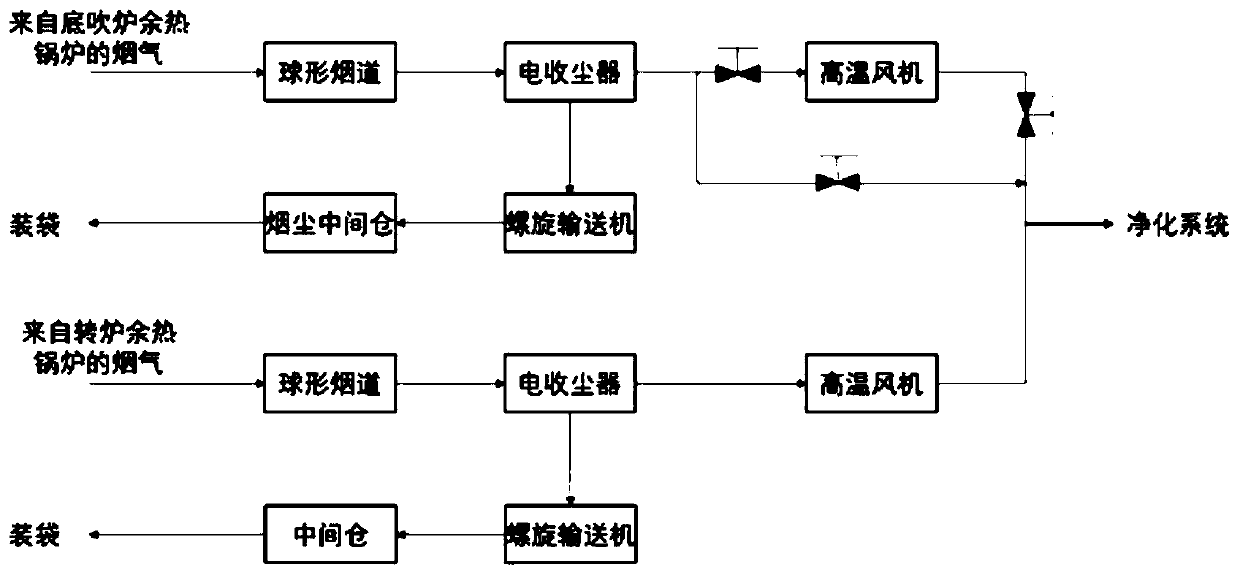

[0030] A flue gas removal of impurities and tail gas cleaning treatment device in the acid production process, a spherical flue is arranged at the rear end of the bottom blowing furnace, the spherical flue is connected to an electric dust collector, the electric dust collector is connected to a high-temperature fan, and the high-temperature fan is connected to a purification system; There is an electrostatic precipitator ash hopper at the bottom of the electrostatic precipitator, and the ash hopper of the electrostatic precipitator is connected to the screw conveyor, and the screw conveyor is connected to the smoke and dust intermediate warehouse; there is a valve A between the electric precipitator and the high-temperature fan, and between the high-temperature fan and the purification system. A valve B is set, and a valve C is set between the electrostatic precipitator and the purification system, which can realize the inclusion of about 25g / Nm in the flue gas from the smelting...

Embodiment 2

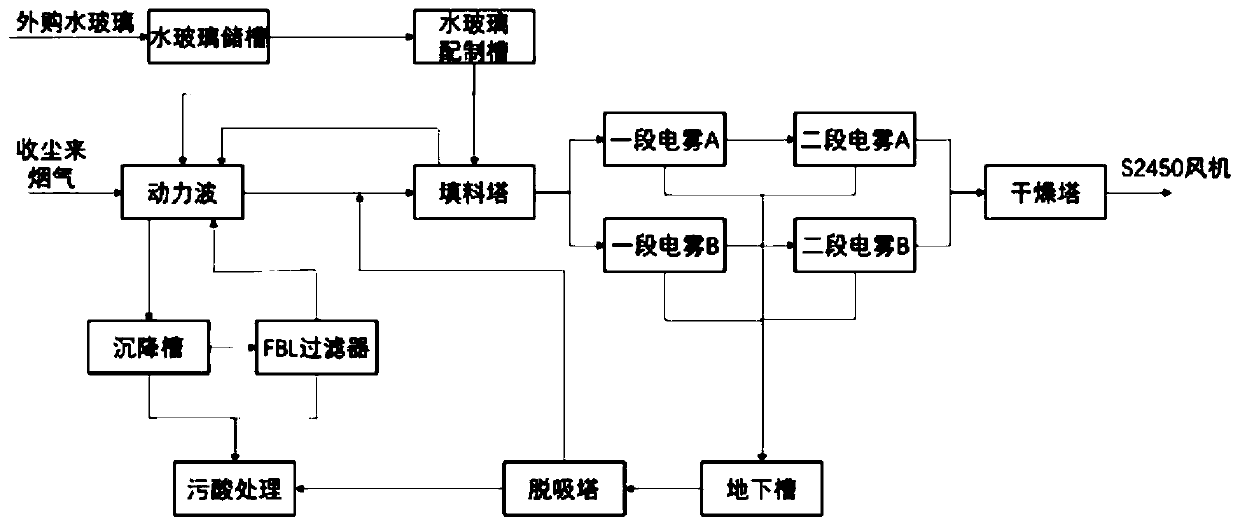

[0032] On the basis of Example 1, the flue gas from the purification system is transported to the power wave, the power wave is connected to the packed tower, and the packed tower is connected to the drying tower through the electrospray section; the power wave is provided with a bypass connected to the settling tank, and the settling tank is connected to the FBL filter. The FBL filter is equipped with a return pipeline connected to the power wave, the FBL filter and the settling tank are connected to the sewage acid treatment device; the electric fog section is connected to the underground tank; the underground tank is connected to the desulfurization tower, and the desulfurization tower is connected to the sewage acid treatment device, and the desulfurization tower is equipped with a loop Connecting the packed tower can realize that the flue gas from the electric dust collector enters the sulfuric acid system for power wave washing to remove a large amount of impurities in the...

Embodiment 3

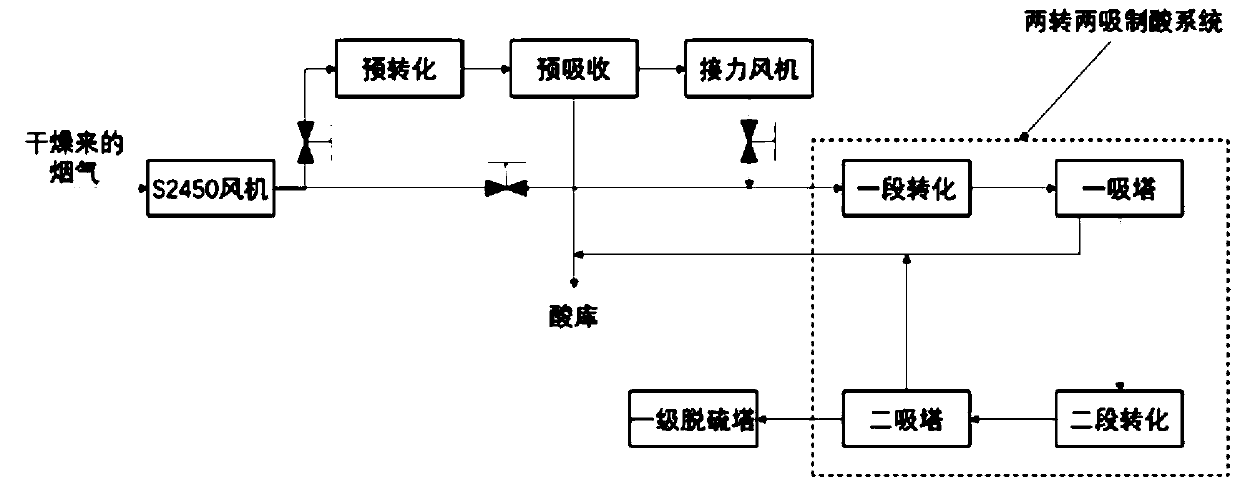

[0034] On the basis of Example 2, the drying tower is connected to the first-level conversion section through the fan, the first-level conversion section is connected to the first-level absorption tower, the first-level absorption tower is connected to the second-level conversion section, and the second-level conversion section is connected to the second-level absorption tower. The suction tower is connected to the first-level desulfurization tower; the first-level suction tower and the second-level suction tower are provided with a split pipe to connect to the acid storage; a pre-reformation device is installed between the fan and the first-stage conversion section, and the pre-reformation device is connected to the pre-absorption device, and the absorption device is connected to the Relay fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com