Ammonia desulphurization ultra-low discharging system and ammonia desulphurization ultra-low discharging process

An ammonia desulfurization and discharge system technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem of unsolved ammonia desulfurization, and the design emission indicators of ordinary empty tower spraying desulfurization systems cannot meet national requirements. , flue gas tailing products and other problems, to achieve the effect of improving oxidation efficiency, simple and clear structure, and conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

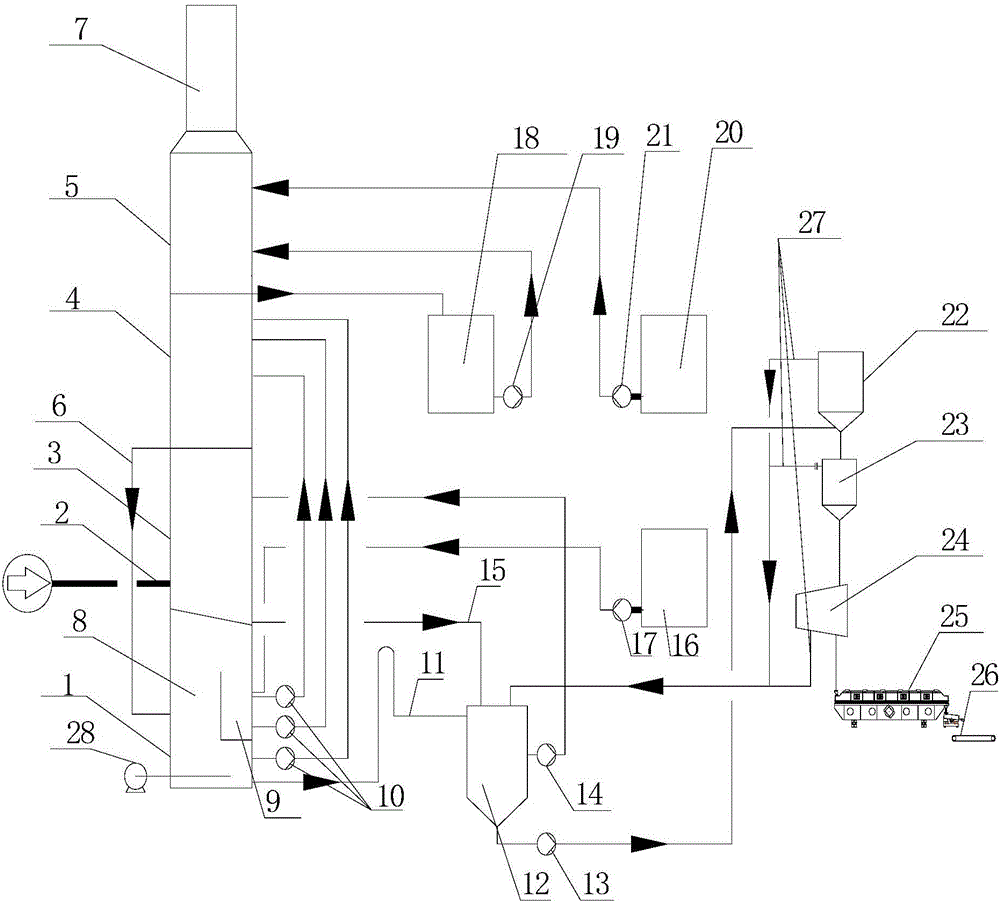

[0058] Such as figure 1 Shown is a schematic structural view of the ammonia desulfurization ultra-low emission system of the present invention. In the figure, 1 is a desulfurization tower, 2 is a flue inlet, 3 is a concentration cycle section, 4 is an absorption section, 5 is a purification water washing section, and 6 is a Return pipe, 7 is the chimney at the top of the tower, 8 is the oxidation section, 9 is the gas-liquid distributor, 10 is the primary circulation pump, 11 is the overflow pipe, 12 is the circulation crystallization tank, 13 is the crystallization pump, 14 is the secondary circulation Pump, 15 is the concentrate overflow pipeline, 16 is the ammonia water tank, 17 is the ammonia water pump, 18 is the circulating water tank, 19 is the circulating water pump, 20 is the process water tank, 21 is the process water pump, 22 is the first thickener, 23 is The second thickener, 24 is a centrifuge, 25 is a dryer, 26 is a packaging machine, 27 is an overflow liquid ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com