Flue gas desulfurization and denitrification system device and method adopting ozone oxidation in cooperation with multi-stage spraying

A desulfurization and denitrification, system device technology, applied in the direction of chemical instruments and methods, combined devices, fertilization devices, etc., can solve the problem of easy blockage of the packing layer, gas resistance, etc., to optimize the flue gas flow field, reduce solid matter, and improve absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

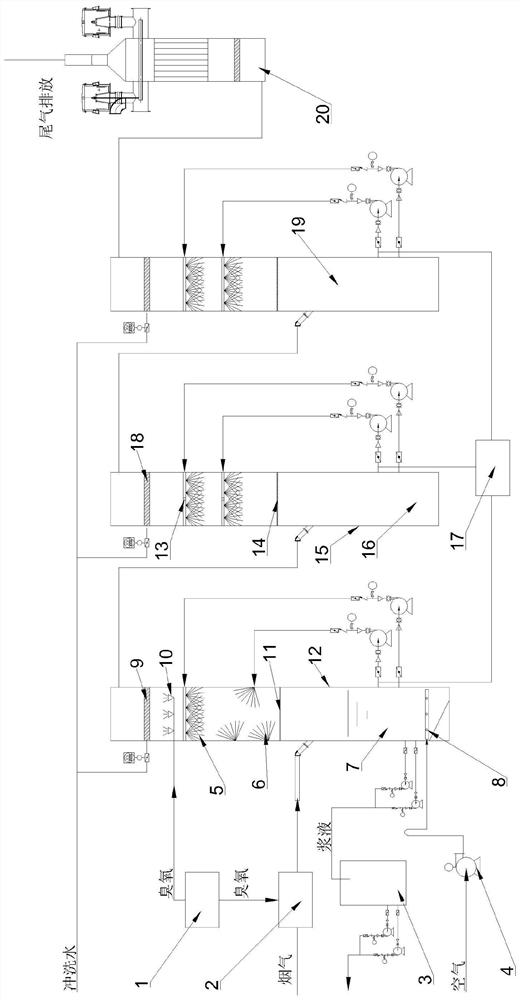

[0089] This embodiment provides a flue gas desulfurization and denitrification system device with ozone oxidation and multi-stage spraying, such as figure 1 As shown, a flue gas desulfurization and denitrification system device based on ozone oxidation and multi-stage spraying provided in the specific embodiment, wherein the flue gas desulfurization and denitrification system device includes first-stage spray absorption devices connected in sequence along the flue gas flow direction And the second-stage spray absorption device, two spiral spray modules 13 are arranged in the spray absorption device along the flue gas flow direction, the angle between the ozone inlet pipeline and the flue gas inlet pipeline is 45°, and the inclined spray module 6 The spraying direction is 60° upwards.

[0090] This embodiment also provides the desulfurization and denitrification method of the above-mentioned flue gas desulfurization and denitrification system device using ozone oxidation in con...

Embodiment 2

[0097] This embodiment provides a flue gas desulfurization and denitrification system device with ozone oxidation and multi-stage spraying, such as figure 1 As shown, a flue gas desulfurization and denitrification system device based on ozone oxidation and multi-stage spraying provided in the specific embodiment, wherein the flue gas desulfurization and denitrification system device includes first-stage spray absorption devices connected in sequence along the flue gas flow direction And the second-stage spray absorption device, two spiral spray modules 13 are arranged in the spray absorption device along the flue gas flow direction, the angle between the ozone inlet pipeline and the flue gas inlet pipeline is 90°, and the inclined spray module 6 The spraying direction is 30° upwards.

[0098] This embodiment also provides the desulfurization and denitrification method of the above-mentioned flue gas desulfurization and denitrification system device using ozone oxidation in con...

Embodiment 3

[0105] This embodiment provides a flue gas desulfurization and denitrification system device with ozone oxidation and multi-stage spraying, based on the flue gas desulfurization and denitrification system device with ozone oxidation and multi-stage spraying provided in the specific embodiment, wherein the flue gas desulfurization The denitrification system device includes a first-stage spray absorption device, a second-stage spray absorption device and a third-stage spray absorption device connected in sequence along the flue gas flow direction. A spiral spray module 13 is arranged in the spray absorption device, and the ozone The included angle between the intake pipeline and the flue gas intake pipeline is 135°, and the spraying direction of the inclined spray module 6 is 45° upward.

[0106] This embodiment also provides the desulfurization and denitrification method of the above-mentioned flue gas desulfurization and denitrification system device using ozone oxidation in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com