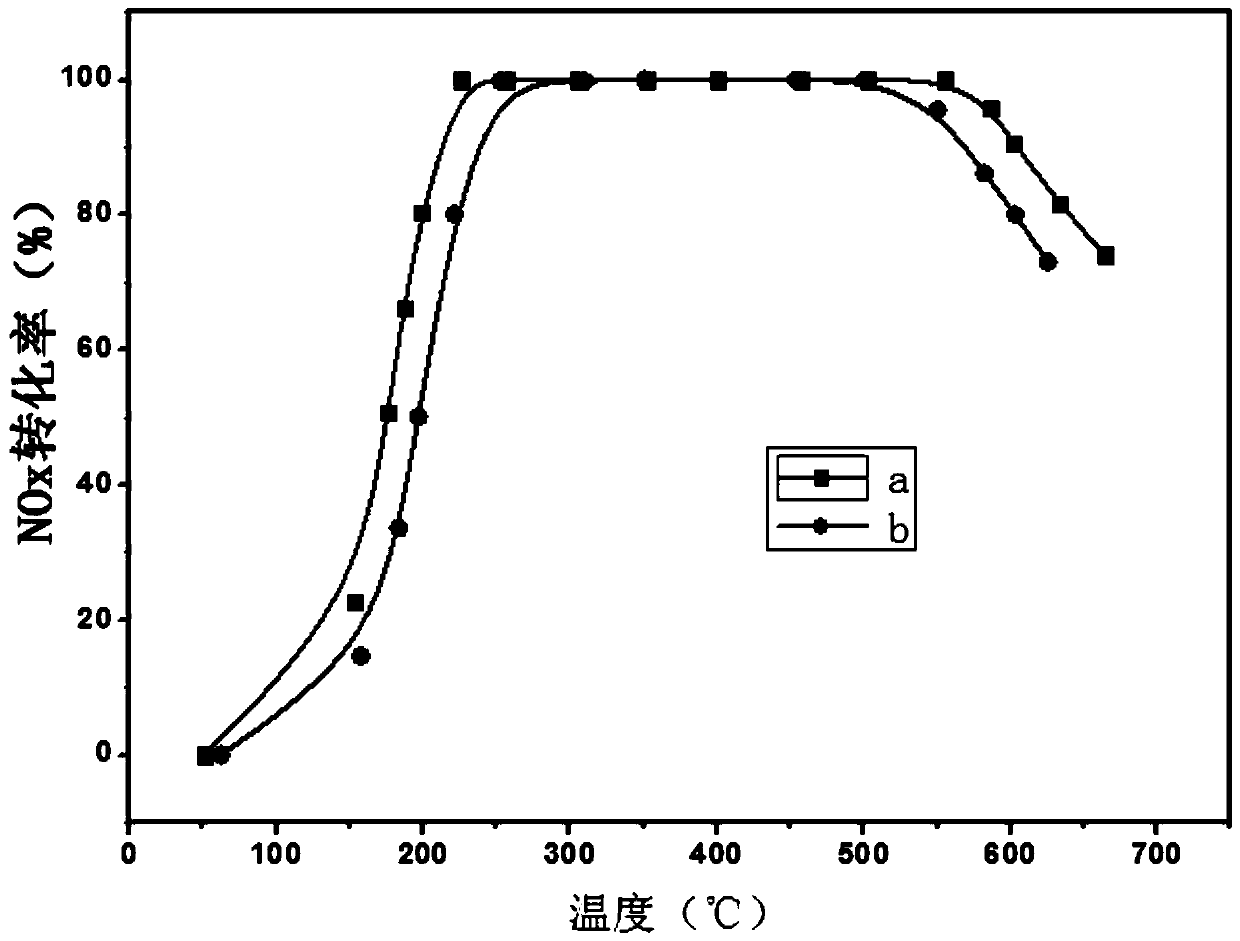

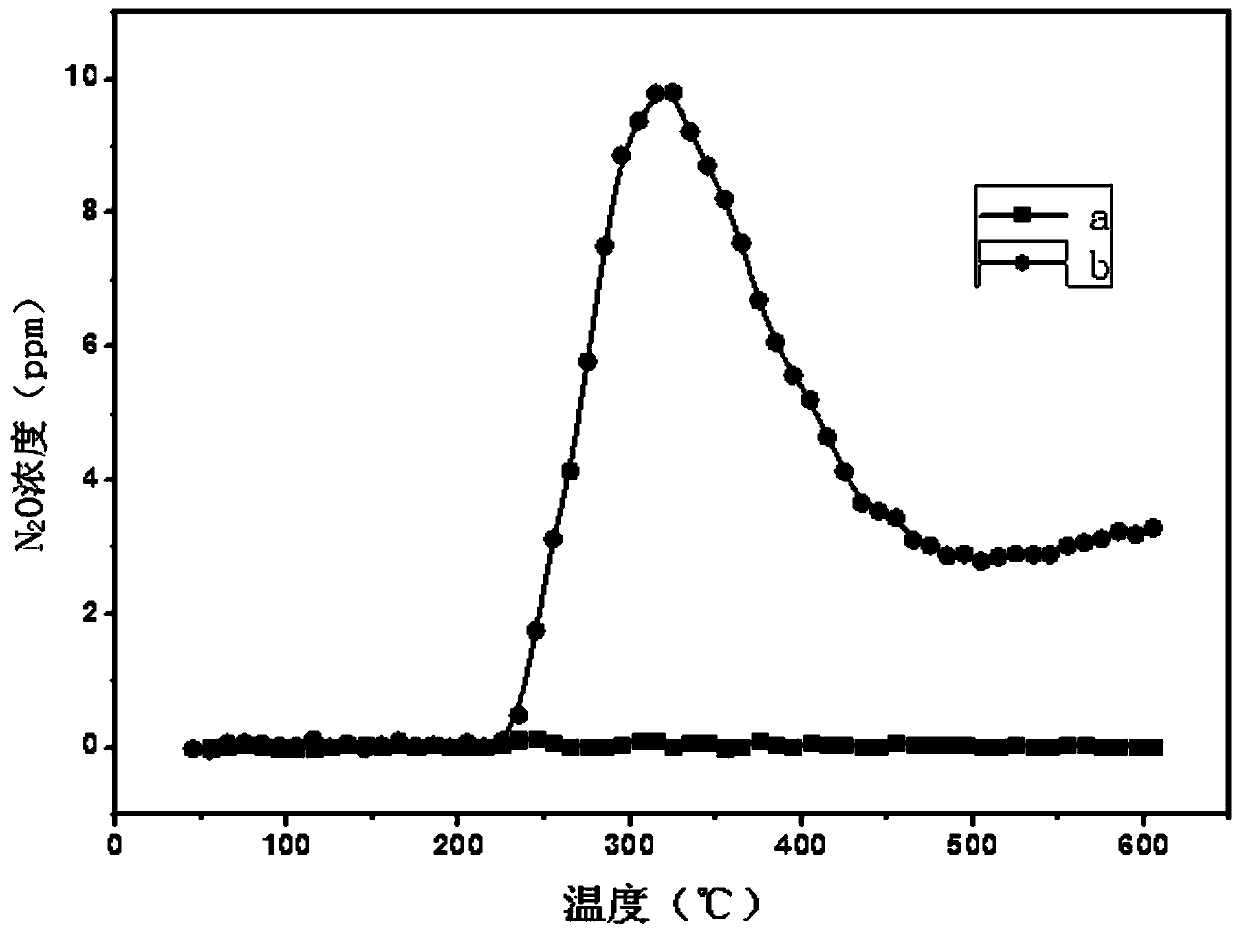

High-temperature-resistant high-activity Cu-based SCR catalyst and preparation method thereof

A SCR catalyst, high activity technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of reducing selectivity, etc., to improve selectivity, widen the catalytic activity window, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In some illustrative embodiments, a method for preparing a high-temperature-resistant high-activity Cu-based SCR catalyst includes the following steps

[0037] S1: Preparation of highly dispersed nano-Cu solution;

[0038] S101: Take the nano-Cu source, add it to deionized water, prepare a 0.5-10% solution, and stir for 10-60 minutes; the nano-Cu source is nano-Cu particles, and its precursor is copper nitrate, copper acetate, copper sulfate, copper chloride one or more of them.

[0039] S102: According to the ratio of copper source dispersant to Cu molar ratio of 0.1-9, add copper source dispersant and stir for 10-60min; copper source dispersant is one or more of sugars, alcohols or esters. Sugars are sucrose, maltose, fructose, dextran and the like. Alcohols include polyvinyl alcohol, polyethylene glycol, glycerol, and the like. Esters are ethyl acetate, butyl acetate and the like.

[0040] S103: According to the molar ratio of metal M to Cu being 0.1-2, add metal...

Embodiment 1

[0068] A method for preparing a high-temperature resistant and highly active Cu / Zr-SSZ-13 molecular sieve SCR catalyst, the specific implementation steps are as follows:

[0069] Preparation of Highly Dispersed Nano-Cu Solution

[0070] a. Weigh 15.0 g of nano-Cu solution, add 600.0 g of deionized water, and stir for 20 min.

[0071] b. Add 30.0g sucrose and stir for 30min.

[0072] c. Add 4.29g of zirconium nitrate solution and stir for 20min.

[0073] d. Adjust the pH of the solution to 3.0 and stir for 30 minutes.

[0074] Preparation of Cu-molecular sieve in situ impregnation solution

[0075] a. Weigh 500g of SSZ-13 molecular sieve powder, slowly add it into the highly dispersed nano-Cu solution at a rate of 10g / min, keep stirring evenly, and stir for 90min until the molecular sieve is completely dispersed.

[0076] b. Add 0.8g acetylenic diol and stir for 60min.

[0077] c. Pass the prepared slurry into a sand mill, and grind for 40 minutes until the particle size D...

Embodiment 2

[0083] Embodiment 2: A kind of preparation method of Cu / Co-Beta molecular sieve SCR catalyst with high temperature resistance and high activity, the specific implementation steps are as follows:

[0084] Preparation of Highly Dispersed Nano-Cu Solution

[0085] a. Weigh 18.0 g of nano-Cu solution, add 600.0 g of deionized water, and stir for 10-60 min.

[0086] b. Add 30.0 g of sucrose and stir for 30 minutes.

[0087] c. Add 2.91g of cobalt nitrate solution and stir for 20min.

[0088] d. Adjust the pH of the solution to 3.0 and stir for 30 minutes.

[0089] Preparation of Cu-molecular sieve in situ impregnation solution

[0090] a. Weigh 600g of beta molecular sieve powder, slowly add it into the highly dispersed nano-Cu solution at a rate of 10g / min, keep stirring evenly, and stir for 90min until the molecular sieve is completely dispersed.

[0091] b. Add 0.8g acetylenic diol and stir for 30min.

[0092] c. Adjust the pH value of the solution to 5.8, the solid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com