Microwave-assisted catalytic oxidation method for biochemical tail water of brewing wastewater by various metals

A microwave-assisted, catalytic oxidation technology, applied in chemical instruments and methods, water/sewage treatment, food industry wastewater treatment, etc., can solve the problems of high operating cost and single effect, and achieve enhanced treatment efficiency, improved thermal stability and Dispersion and the effect of improving microwave utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Advanced treatment method of wastewater from a brewery in Sichuan

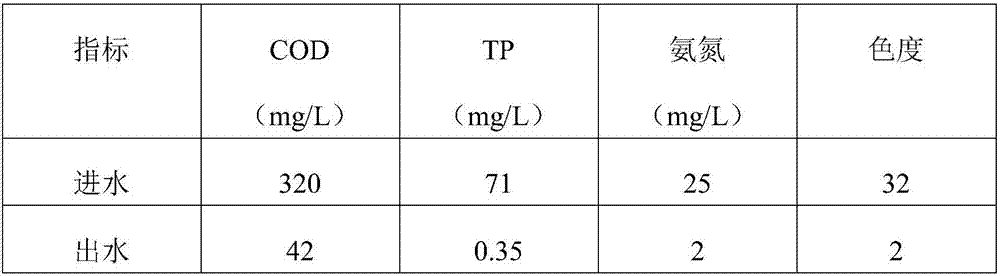

[0025] The processing capacity of the embodiment of the present invention is by 1300m 3 / d design, the effluent COD, total phosphorus, ammonia nitrogen, and chromaticity of the wastewater after biochemical treatment did not meet the standards, and the effluent after the final treatment met the discharge standards of the brewing industry. The specific influent and effluent water quality are shown in Table 1.

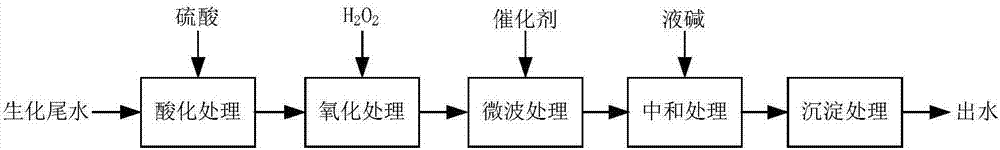

[0026] Specific process: First, use sulfuric acid to acidify the biochemical tail water of a brewery wastewater treatment station in Sichuan, control the pH value of the wastewater to 3.0, and oxidize the effluent after 15 minutes of acidification, and the oxidant is H 2 o 2 , dosing ratio according to H 2 o 2 The ratio of COD to biochemical tail water is 0.05:1. After reacting for 10 minutes, it enters the microwave reactor for treatment. Adds ceramsite loaded with iron, manganese and nickel m...

Embodiment 2

[0030] Wastewater treatment method of a brewery in Guizhou

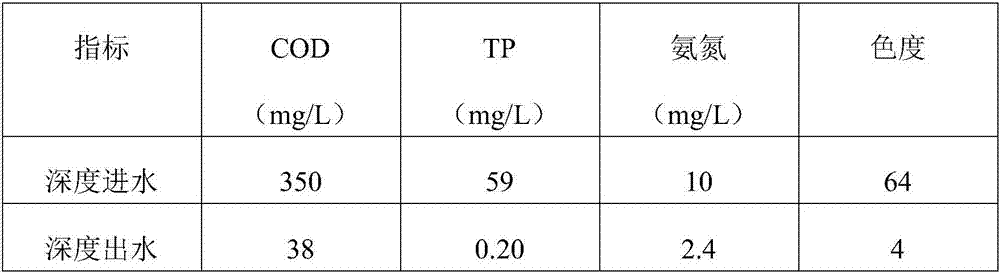

[0031] The processing capacity of the embodiment of the present invention is by 510m 3 / d design, the COD and total phosphorus of the biochemical tail water are high, and the chroma exceeds the standard, and the final treated effluent meets the discharge standard of the brewing industry. The specific influent water quality is shown in Table 2.

[0032] First, use sulfuric acid to acidify the biochemical tail water of brewing wastewater, control the pH value of the wastewater to 4.0, and oxidize the effluent after 10 minutes of acidification, and the oxidant is H 2 o 2 , dosing ratio according to H 2 o 2 The ratio of COD to biochemical tail water is 0.02:1. After reacting for 5 minutes, enter the microwave reactor for treatment. Add ceramsite loaded with iron, manganese and nickel metal oxides as a catalyst. The mass of iron oxide on the catalyst is 0.5% of the mass of ceramsite. , the mass of manganese oxide is ...

Embodiment 3

[0036] Advanced treatment method of wastewater from a brewery in Jiangsu

[0037] The processing capacity of the embodiment of the present invention is by 850m 3 / d design, the effluent COD, total phosphorus, ammonia nitrogen and chroma after the treatment of the sewage plant are not up to the standard, and the final treated effluent meets the discharge standard of the brewing industry. The specific influent and effluent water quality are shown in Table 3.

[0038] Specific process: First, use sulfuric acid to acidify the biochemical tail water of brewing wastewater, control the pH value of the wastewater to 3.5, and oxidize the effluent after 12 minutes of acidification, and the oxidant is H 2 o 2 , dosing ratio according to H 2 o 2 The ratio of COD to biochemical tail water is 0.04:1. After reacting for 10 minutes, it enters the microwave reactor for treatment. Adds ceramsite loaded with iron, manganese and nickel metal oxides as a catalyst. The mass of iron oxide on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com