Dry process-wet process combined new method for desulfurization, denitration, decarbonization and dedusting purification of coal-fired flue gas

A coal-fired flue gas and flue gas technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of low resistance, damage to the ecological environment, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

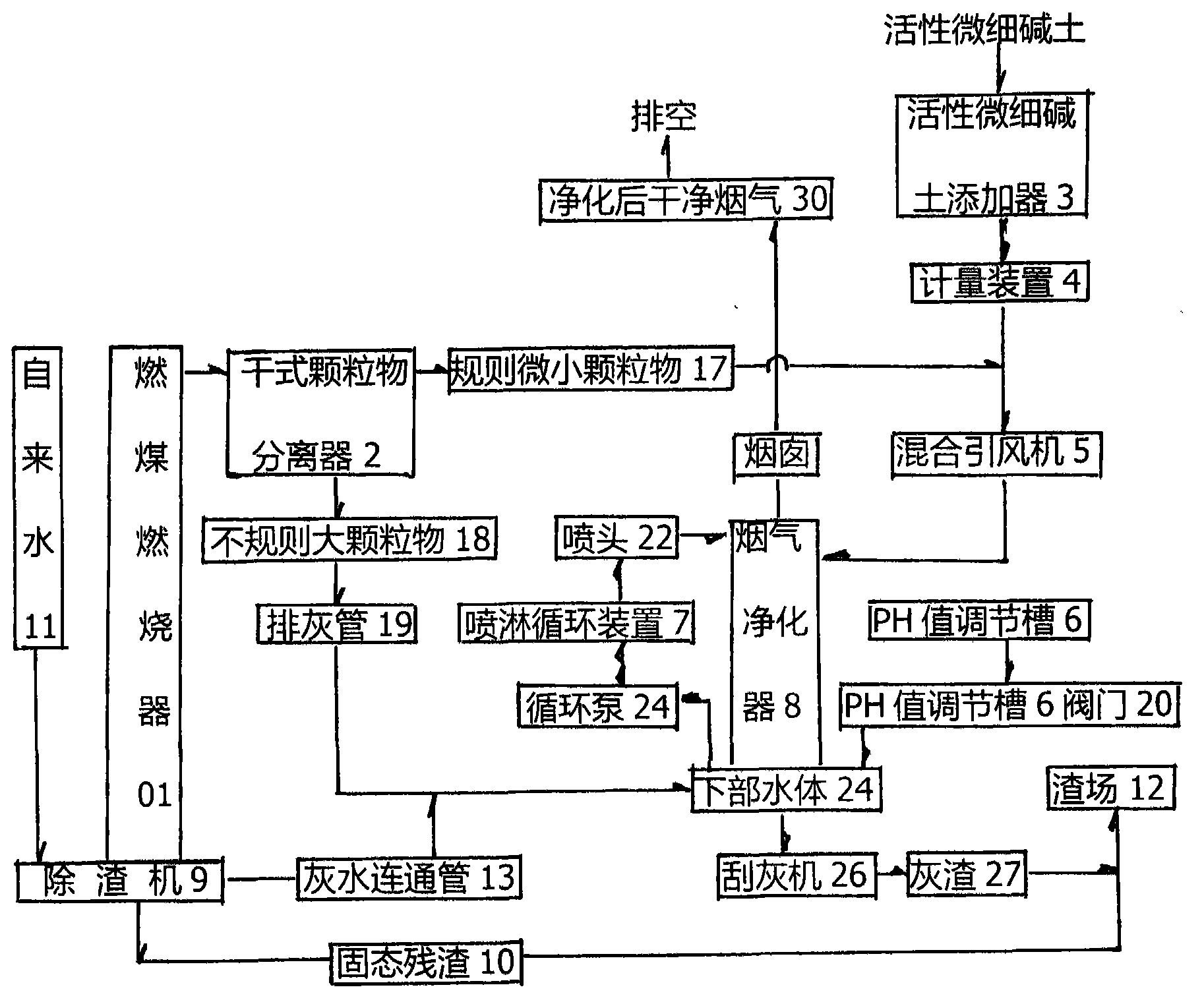

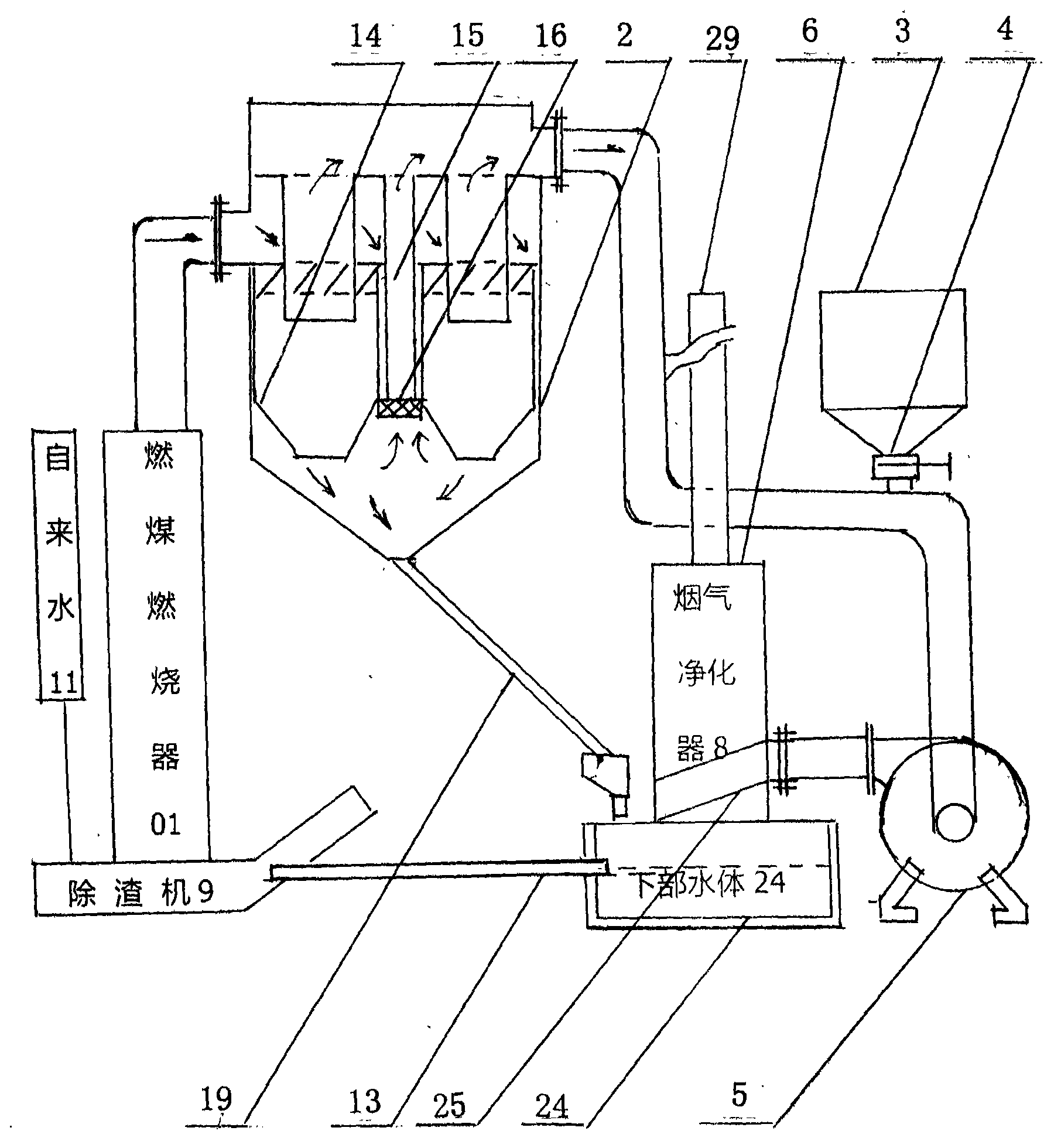

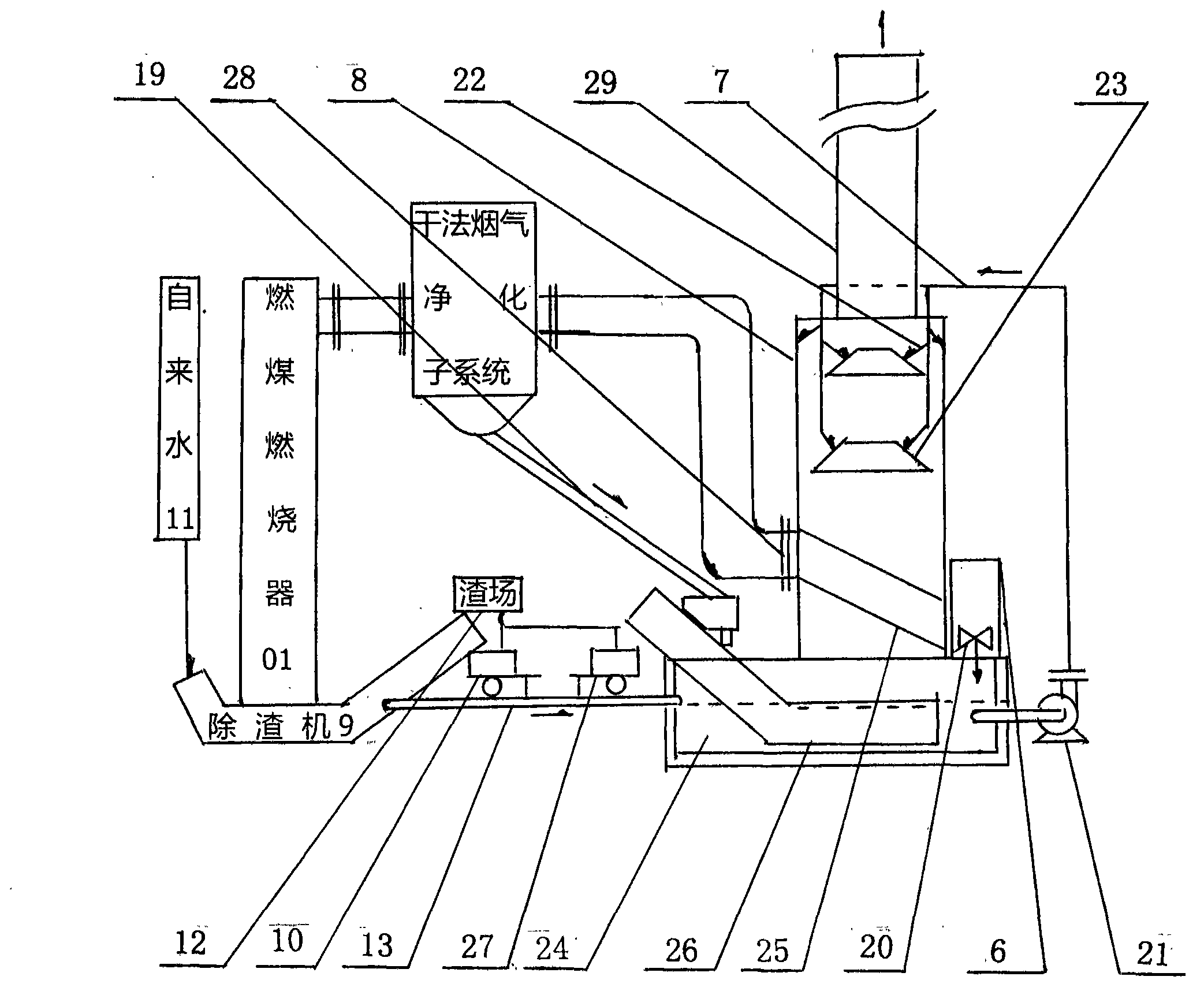

[0018] From figure 1 It can be seen from the figure that the flue gas containing dust, SO2 and other pollutants discharged from the coal-fired burner 1 first enters the dry particle separator 2, and the regular fine particles in the flue gas are separated in the dry particle separator 2. 17 and irregular large particles 18 are separated, and the regular fine particles 17 in the flue gas are passed through the metering device 4 by the active fine alkaline earth adder 3, and the added active fine alkaline earth enters the mixing induced draft fan 5 together with the flue gas. After the strong stirring by the induced draft fan 5 evenly completes the dry flue gas purification pretreatment, the flue gas enters the wet flue gas purifier 8 from the flue gas inlet 28 and then performs the wet flue gas purification treatment. The irregular large particles 18 separated by the dry particle separator 2 are discharged into the lower water body 24 of the wet flue gas purifier 8 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com